In this comprehensive guide, we will explore the unique properties of fluorosilicone O-rings, their applications, and why they are the preferred choice for many industries.

Whether you’re a seasoned manufacturer or a newcomer in the industry, this guide will provide you with a deeper understanding of these essential components.

What is a Fluorosilicone O-ring?

In the realm of manufacturing and industrial applications, O-rings are one of the most commonly used sealing solutions. But among the diverse materials available, one stands out due to low temperature performance and its unique properties—fluorosilicone(FVMQ).

Definition

A fluorosilicone O-ring is a loop of elastomer with a round cross-section, used in mechanical systems to seal off spaces between two surfaces. The “O” in the O-ring refers to its circular shape, while “fluorosilicone” indicates the type of material used in its production.

Fluorosilicone is not chemically compatible with brake fluids, hydrazine, or ketones and therefore should not be exposed. Fluorosilicone is ideal for static sealing applications but is not recommended for dynamic sealing operations.

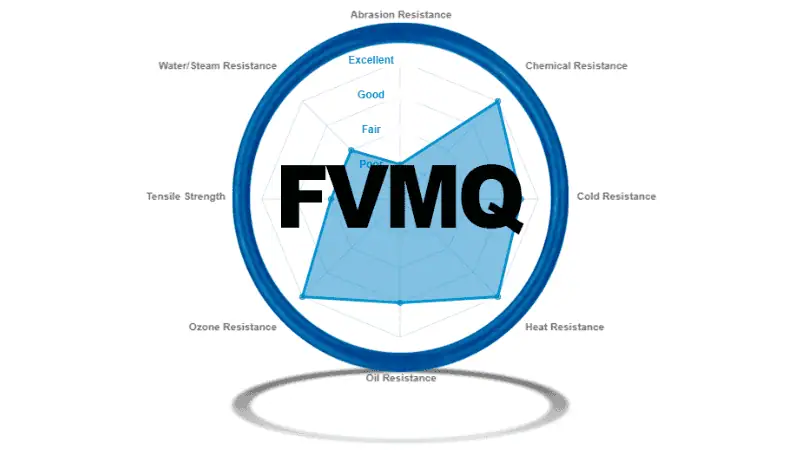

Fluorosilicone rubber contains trifluoropropyl groups next to the methyl groups. The mechanical and physical properties are very similar to silicone rubber.

However, fluorosilicone offers improved fuel and mineral oil resistance but poor hot air resistance when compared with silicone rubber. Fluorosilicone is a unique material that combines the benefits of silicone and fluorocarbon, resulting in a product that has exceptional temperature, great jet fuel resistance, and chemical resistance.

Key Characteristics

Fluorosilicone o-rings have several key characteristics that make them highly desirable for various applications. Here are some important points to consider:

- Resistance: fluorosilicone(FVMQ ) o-rings also feature excellent flexibility, compression durability, aging and sunlight resistance, and an overall wide range of basic chemical resistance. This makes them suitable for use in industries where exposure to such substances is common.

- Temperature Stability: With their ability to withstand high temperatures, fluorosilicone o-rings are ideal for applications that involve extreme heat conditions. They can maintain their integrity and sealing capabilities even when exposed to elevated temperatures.

- Durability: Fluorosilicone o-rings are known for their long-lasting performance. They can withstand frequent use without losing their sealing effectiveness or experiencing premature wear.

- Trifluoropropyl Content: The inclusion of trifluoropropyl groups in the material enhances the chemical resistance of fluorosilicone o-rings. This further expands their suitability for applications involving aggressive substances.

- Versatility: These o-rings offer versatility due to their unique composition. By combining the properties of silicone rubber and fluorocarbon elastomers, they provide an excellent balance between flexibility and durability.

Inquire About Our Silicone and Plastic Products!

How are Fluorosilicone O-Rings Made?

Fluorosilicone O-rings are created through a meticulous process that ensures their durability and efficacy.

The Material Selection and Mixing

The first step in making fluorosilicone O-rings involves the selection and preparation of the fluorosilicone rubber material. This material is carefully chosen based on its quality and the specific requirements of the O-ring to be made.

The material is then mixed with other additives to enhance its properties, such as its resistance to heat and chemicals.

Molding

The next phase is the molding process. The molding process for fluorosilicone O-rings can vary depending on the specific requirements of the product.

However, compression molding and injection molding are two commonly used methods in the industry.

- Compression Molding: In compression molding, the fluorosilicone material is placed into an open, heated mold cavity. The mold is then closed, and pressure is applied, causing the material to fill the mold cavity and take on its shape. This process is often used for larger or more complex O-rings that might be difficult to produce with other methods.

- Injection Molding: Injection molding, on the other hand, involves heating the fluorosilicone material until it is molten and then injecting it into a closed mold under high pressure. This method is typically faster and more efficient than compression molding, making it a good choice for high-volume production runs.

The molding process is key in determining the shape, size, and properties of the final product. It requires high precision and attention to detail to produce high-quality Fluorosilicone O-rings.

Inspection and Quality Control

Once the O-ring has been molded and cured, it goes through a stringent inspection process. Each O-ring is checked to ensure it meets the precise specifications and quality standards.

This can involve visual inspection, as well as the use of measurement tools to check dimensions, other mechanical, and physical properties.

Applications of Fluorosilicone O-rings

Due to their strong resistance and their exceptional characteristics, Fluorosilicone o-rings have low abrasion resistance and are preferred for use in static environments.

They find extensive applications in a wide array of industries. Here are a few notable uses:

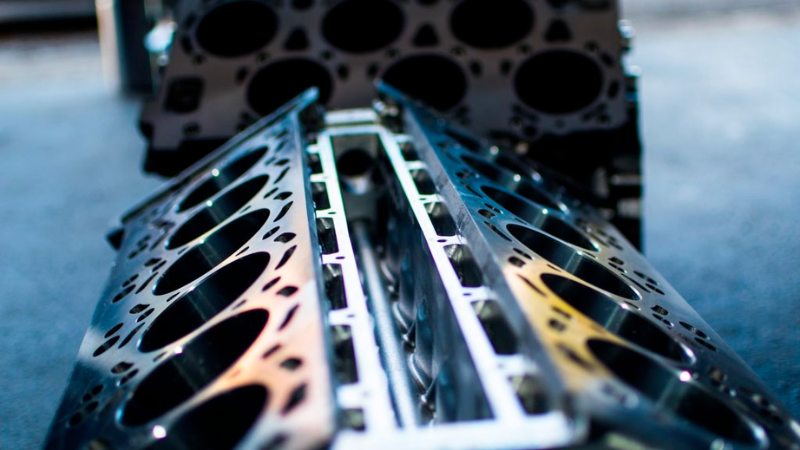

- Automotive Industry: These O-rings are highly valued in the automotive sector for their excellent resistance to various fuels, oils, and coolants. They are typically used in fuel systems, transmission systems, and engine components.

- Aerospace and Aviation: Fluorosilicone O-rings’ outstanding temperature range and chemical resistance make them ideal for use in aircraft fuel systems, hydraulic systems, and engine components.

- Electronics: In electronic devices, these O-rings are used for their ability to resist environmental factors like ozone, UV light, and varying weather conditions. They are essential for ensuring the longevity and reliability of electronic equipment.

- Oil and Gas Industry: With excellent resistance to a wide range of oils and chemicals, Fluorosilicone O-rings are used in many applications in the oil and gas industry, including drilling equipment, pumps, and valves.

- Medical Devices: Due to their biocompatibility and resistance to sterilization processes, these O-rings are used in various medical devices like pumps, respirators, and analytical instruments.

Inquire About Our Silicone and Plastic Products!

Key Factors for Selecting Fluorosilicone O-Rings

There are several key factors that need to be considered. These factors will ensure optimal performance and longevity in your application. Let’s dive into the important considerations:

Temperature Range Compatibility

One of the first things you should assess is the temperature range compatibility of the fluorosilicone o-rings. These o-rings are known for their superior resistance to extreme temperatures, with a wide temperature range of both high and low.

The actual temperature range of a compound in an end-use application is highly dependent on the part type, hardware configuration, applied forces, chemical media, pressure, thermal cycling effects, and other factors.

Ensure that the chosen o-rings can withstand the specific temperature conditions they will be exposed to.

Chemical Resistance Evaluation

Another crucial factor is evaluating the chemical resistance of fluorosilicone o-rings against specific fluids or substances.

Seals made of FVMQ provide benefits such as Excellent flexibility and compression set resistance, High-level aging, weather, and UV resistance Resistance to animal and vegetable oils, fuels, oxidizing chemicals, and aromatic and chlorinated solvents.

Different sealing applications may involve exposure to various chemicals, fuels, or solvents. It is essential to choose o-rings that can withstand these substances without deteriorating or losing their sealing properties.

Compression Set Values Assessment

To determine long-term seal integrity under pressure cycles, assessing compression resistance and set values is vital.

This evaluation helps identify how well the fluorosilicone o-ring retains its original shape after being compressed and released repeatedly. Opt for o-rings with low compression set values for better performance over time.

Durometer Hardness and Dimensional Requirements

Matching durometer hardness and dimensional requirements with your application’s needs is critical for a successful seal.

The durometer hardness determines the flexibility and resilience of the o-ring material, while dimensional requirements ensure a proper fit within your equipment or system.

The Benefits of Using Fluorosilicone Seals Over Conventional Rubber O-Rings

Fluorosilicone seals, also known as fluorosilicone o-rings, offer several advantages over conventional rubber o-rings. Let’s explore the key benefits that make them an increasingly popular material choice for various applications:

- Superior Resistance to High Temperatures: Fluorosilicone seals excel in high-temperature environments where conventional rubber o-rings may fail. Their silicone rubber composition enables them to withstand extreme heat without losing their sealing effectiveness.

- Excellent Fuel and Oil Resistance: These seals exhibit exceptional resistance to fuel and oil, making them well-suited for automotive applications. They can endure prolonged exposure to gasoline, diesel, and other petroleum-based fluids without deteriorating or compromising their performance.

- Enhanced Chemical Compatibility: Fluorosilicone seals offer enhanced chemical compatibility in harsh environments. They can resist degradation when exposed to a wide range of chemicals, including solvents, acids, and bases.

- Low Compression Set Properties: One of the key advantages of fluorosilicone seals is their low compression set properties. This means they can maintain their original shape and sealing effectiveness over extended periods of use. As a result, they provide reliable long-term sealing performance.

Inquire About Our Silicone and Plastic Products!

How to Ensure You’re Getting a Good Deal When Purchasing Fluorosilicone O-Rings?

When purchasing fluorosilicone o-rings, it’s important to ensure you’re getting a good deal. Here are some key points to consider:

Reputable Suppliers with Proven Track Records

- Look for suppliers with a proven track record in providing high-quality fluorosilicone o-rings.

- Choose reputable suppliers who have established themselves in the industry and have positive customer reviews.

- Opt for suppliers who are known for their reliability, consistency, and excellent customer service.

Compare Prices and Quality Across Different Manufacturers

- Take the time to compare prices and quality across different manufacturers to ensure competitive pricing.

- Consider factors such as material quality, durability, and performance when comparing options.

- Don’t just focus on the price; prioritize value for money by assessing both cost and quality.

Verify Certifications and Compliance with Industry Standards

- Ensure that the fluorosilicone o-rings you purchase meet industry standards by verifying certifications.

- Look for products that comply with relevant regulations and standards, such as ISO certifications.

- Certification ensures that the o-rings have been tested and meet specific requirements for reliable performance.

Request Samples or Conduct Tests Before Committing to Bulk Purchases

- Before making bulk purchases of fluorosilicone o-rings, request samples from potential suppliers.

- Test the samples thoroughly to assess their quality, compatibility with your application, and overall performance.

- This step allows you to verify that the product meets your requirements before investing in larger quantities.

By following these guidelines when purchasing fluorosilicone o-rings, you can ensure that you get a good deal without compromising on quality or reliability.

Inquire About Our Silicone and Plastic Products!

Conclusion

Fluorosilicone O-rings stand as an unparalleled solution in numerous industries due to their excellent temperature stability, excellent chemical resistance, and durability.

With applications spanning from aerospace applications to medical devices, these O-rings offer reliability and performance in the harshest of environments.

Buy Fluorosilicone O-rings from Hongju

At Hongju Silicone, we offer top-tier Fluorosilicone O-rings designed to cater to your specific needs. As an industry leader in manufacturing silicone products, our promise is to provide solutions that bring unmatched quality, durability, and performance.

Make the smart choice today with Hongju Silicone to improve your business.