Rubber Materials for The Aerospace Industry

First, let’s have a look at some of the different types of rubber materials you can use for aerospace products:

- Nitrile Rubber (NBR): Many aerospace oil and fuel system components use NBR. This is because nitrile has excellent oil and fuel resistance properties.

- EPDM: This rubber material performs exceptionally well against ozone, weathering, and heat. Thus, it easily withstands harsh conditions in aerospace applications.

- Silicone: the engine gaskets and seals used in airplanes often use silicone rubber. Why? Because silicone incredibly resists heat and has a low compression set.

- Neoprene: whether its heat, chemicals, or ozone, neoprene withstands them all. Moreover, the material has a high demand for electrical and weather applications thanks to its insulating properties.

- Polyurethane: This material offers excellent durability. Also, it can withstand abrasions, making it a suitable choice for hoses and cables.

Types of Aerospace Rubber Molding Methods

Different types of rubber molding processes help produce aerospace-custom molded rubber parts. These include:

Compression Molding

Compression molding requires a set amount of rubber. This rubber is then placed inside a heated mold. Moreover, the final shape derives from a combination of pressure alongside heat.

Transfer Molding

This method uses the pot and plunger mechanism. A set amount of uncured rubber goes into the pot, also known as the chamber. It is then transferred into a heated mold using a plunger. As a result, transfer molding helps create exact custom-molded parts.

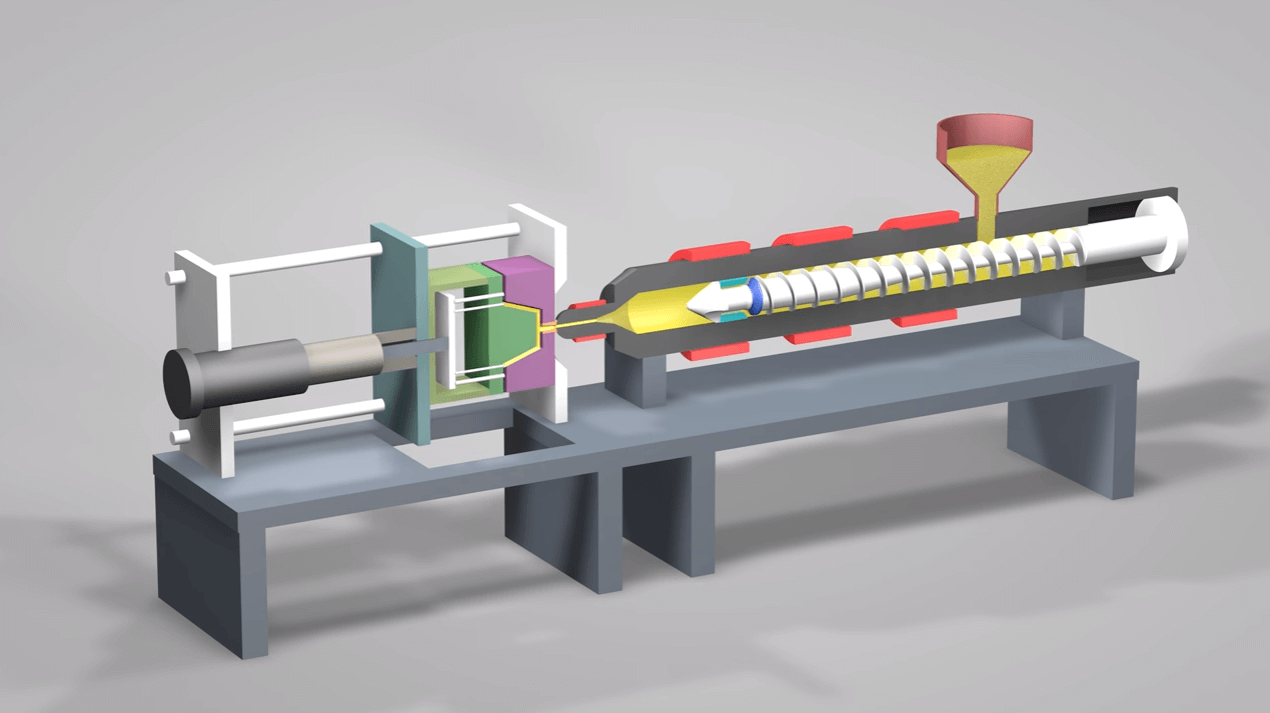

Injection Molding

In this molding process, the manufacturer takes uncured rubber and injects it into a heated mold. Moreover, they also apply pressure which helps shape the rubber into the desired form. This molding technique helps create small rubber components for aerospace applications.

The Benefit of Using Molded Rubber Products for Aerospace

The most prominent benefits of custom-molded rubber parts in the aerospace industry include:

- Flexible: custom molded rubber offers excellent elastic properties. Hence, they become a suitable option for dynamic applications.

- Durable: rubber tends to withstand challenging conditions in the aerospace industry. This has mostly to do with the durability of vulcanized custom-molded rubber components.

- Versatile: rubber components also offer incredible versatility. This includes altering their shape, size, color, and even material. Moreover, you can also place customized orders as per need.

- Economical: rubber molded products are pretty cost-effective compared to alternate materials. Moreover, they also have a long shelf and service life. Hence, they reduce maintenance and replacement costs in the long run.

Molded Rubber Products Used In Aerospace

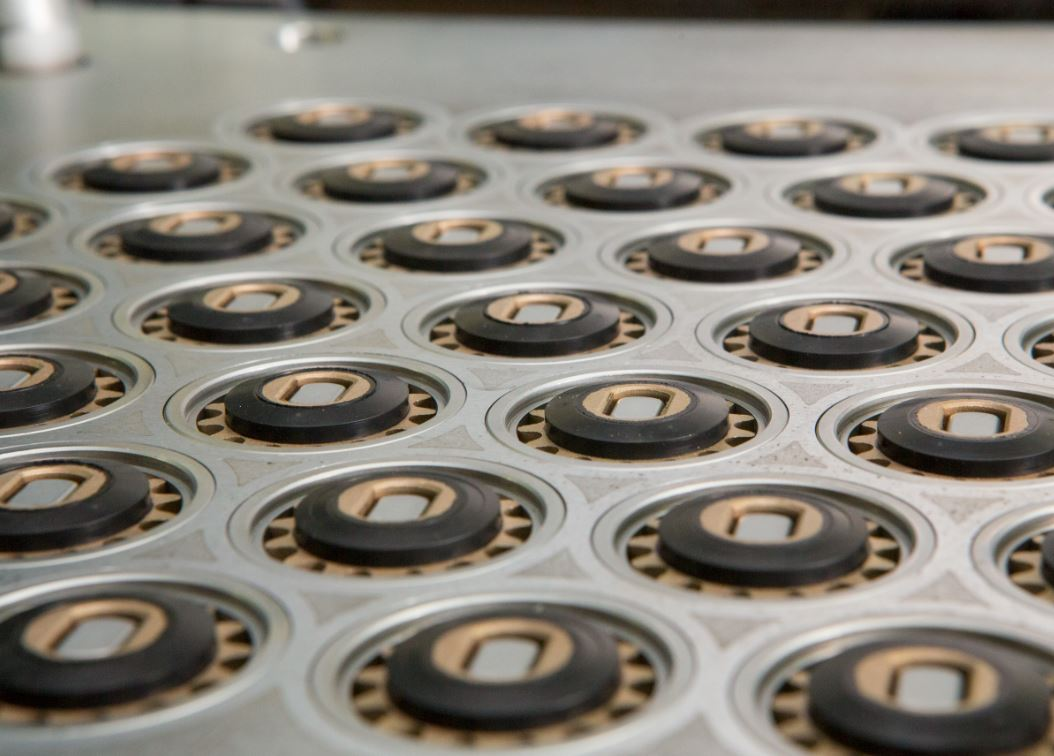

- Seals: help prevent leaks in aerospace fuel and hydraulic systems.

- Gaskets: help seal two surfaces tightly together, such as fuel tanks and joints.

- O-rings: used in oil systems and fuel systems for sealing purposes.

- Tubing: used for transfer purposes such as transferring fuel or oil from one component to another.

- Bushings/Mounts: used for isolating vibrations and reducing noise

- Diaphragms: helps control flow and pressure in fuel and oil systems.

How to Choose The Right Molded Rubber Part for Your Need?

The question for a million dollars. We all want to choose the right molded rubber parts for our needs. But how to do so? Well, several factors go into the decision-making process.

For starters, you must consider the intended use and the environmental conditions. You should also figure out the type of chemicals, high temperatures, and movement the products will come in contact with.

Moreover, you must also consider your budget. We never recommend that you compromise on the quality due to a lack of funding. Instead, you must always look for the most reliable products in the given amount. It takes some research, but you will get there.

Also, you must ensure that the supplier you work with has a solid reputation in the industry. This helps businesses, in the long run, develop partnerships based on trust.

FAQs: Aerospace Molded Rubber Parts

What types of rubber are used in aircraft?

Different types of rubber serve various purposes in private, commercial, and aerospace equipment. These include silicone, nitrile, neoprene, EPDM, etc. You can also customize these materials as per the need of the application.

What is the molding process of rubber?

Standard molding processes include compression molding, transfer molding, and injection molding. Each has its benefits and is used to produce various molded aerospace rubber products.

What rubber products are used in aerospace?

The most common rubber products used in aerospace include O-rings, hoses, gaskets, seals, tubes, etc.

How do you manufacture custom-molded rubber parts?

Rubber parts are manufactured in specially designed production plants. Most of the production for aerospace rubber products takes place in China, which has high competition in this industry.

Conclusion

To conclude, the aerospace industry has incredible demand for molded rubber products. If you are a rubber business working closely with the aerospace industry, you need a reliable supplier. We have already provided enough information, including the uses, types, and benefits of molded rubber parts for this industry.

Count On Hongju for Exceptional Molded Rubber Components for Aerospace

Do you want your customers to fly high with premium rubber-molded products? We have got you covered. At Hongju, we only use the best-in-class raw materials to ensure consistent product quality. Contact our sales team today!