What Is Ozone-Resistant?

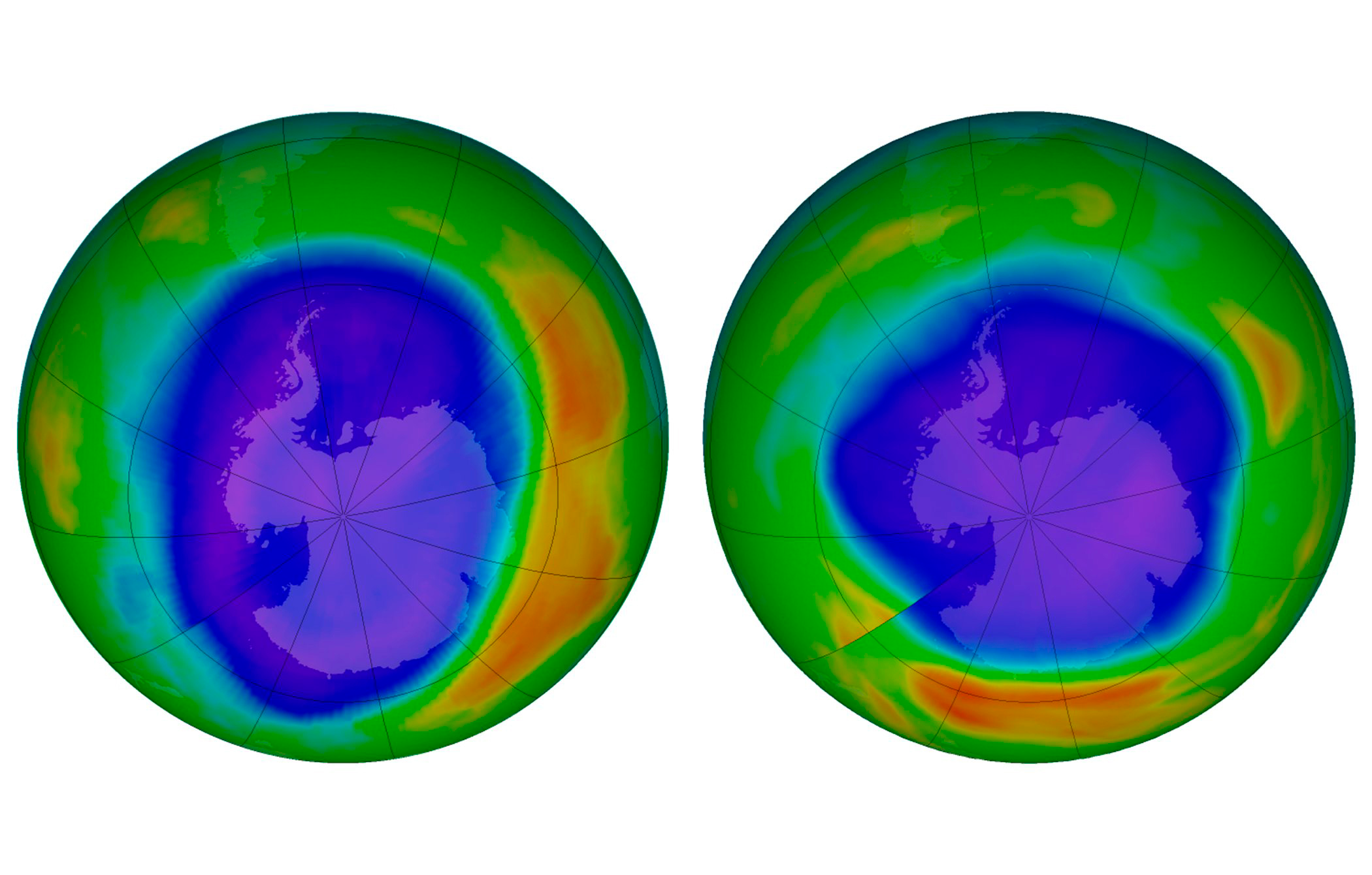

Ozone resistance is the ability of a material to withstand exposure to ozone without breaking down or becoming damaged. Ozone is a highly reactive gas in the Earth’s atmosphere and is created when ultraviolet (UV) light reacts with oxygen. It is highly reactive and can cause damage to specific materials, notably rubber, over time.

Ozone-resistant materials can withstand prolonged exposure to ozone without breaking down or becoming damaged. These materials often play a vital role in outdoor applications where they may be exposed to high ozone levels. The best examples include weather stripping, hoses, seals, and gaskets.

Moreover, the automotive, chemical processing and aerospace industries readily use these materials. It helps them counter the threat of ozone exposure and chemical resistance in various applications.

Is Rubber Immune To Ozone?

To understand this, we need to answer the following two questions:

Does Ozone React With Rubber?

Rubber is not immune to ozone. Ozone can react with rubber, causing it to become brittle or crack over time. Ever heard of ozone cracking or ozone deterioration? Yes, these processes happen due to ozone’s reaction to rubber.

Moreover, the susceptibility of rubber to ozone deterioration depends on the type of rubber and the conditions.

For instance, some types of rubber, such as butadiene rubber (BR), chloroprene rubber (CR), and ethylene propylene diene monomer rubber (EPDM), have more excellent resistance to ozone deterioration than others.

Does Ozone Generator Damage Rubber?

An ozone generator produces ozone. It uses a highly reactive form of oxygen by breaking down oxygen molecules (O2) into individual atoms. Moreover, these atoms can then react with other molecules to form ozone (O3).

Additionally, Ozone generators play a vital role in air purification and other applications. However, exposure to high ozone concentrations can damage rubber and other materials. Hence, we recommend using caution when using an ozone generator.

As a result, if you have to use an ozone generator in the presence of rubber, take preventive measures. These will reduce the damage to the surrounding rubber products.

Send Your Inquiry Now!

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

What Type Of Rubber Is Ozone Resistant?

Several types of rubber are resistant to ozone. These include butadiene rubber (BR), chloroprene rubber (CR), and ethylene propylene diene monomer rubber (EPDM).

Chloroprene Rubber (CR)

This is a synthetic rubber made from chloroprene, a monomer produced by the polymerization of chlorobutadiene. Moreover, it has excellent ozone and weather resistance, making it a good choice for outdoor applications.

On top of it, CR also has oil, water, and chemical resistance, making it a versatile material for use in a wide range of applications.

Ethylene Propylene Diene Monomer Rubber (EPDM)

This synthetic rubber is made from ethylene, propylene, and a small diene monomer. Credit to the elements, it shows excellent ozone and weather resistance.

Moreover, it also shows excellent heat resistance, UV light, and other types of weathering. Hence the material has the potential for a variety of outdoor applications. Additionally, EPDM is often used in automotive applications, such as weatherstripping, seals, and hoses.

The Benefits Of Ozone-Resistant Rubber

Here are some benefits of using ozone-resistant rubber:

- Excellent resistance to ozone: Ozone-resistant rubber withstands exposure to ozone pretty well. As a result, the material has exceptional qualities to counter ozone cracking or deterioration. This helps in keeping outdoor rubber products intact for long-term use. Additionally, it helps avoid mechanical failure by resisting ozone.

- Weather resistance: Rubbers that offer ozone resistance also show other outdoor performing qualities. Weathering resistance is one of the top ones where the material resists moisture and UV light and has high-temperature resistance. This further widens the spectrum for ozone-resistant rubber in terms of applications.

- Chemical resistance: Not all but some types of ozone-resistant rubber show incredible resistance to oils, certain chemicals, and water. These include chloroprene rubber (CR) and ethylene propylene diene monomer rubber (EPDM).

- Elasticity: Many types of ozone-resistant rubber have good elasticity. As a result, they have great potential for use in seals and other components that require this property.

- Abrasion resistance: Some ozone-resistant rubber, such as butadiene rubber (BR), has good abrasion resistance combined. Thus, they are suitable for active or intense wear and tear applications.

Send Your Inquiry Now!

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

Industrial Applications Of Ozone Resistant Rubber

Unsurprisingly, ozone-resistant rubber has made a mark in many industries. The most prominent examples include:

- The Automotive Industry: uses ozone-resistant rubber in various applications, including weatherstripping, seals, and hoses. For instance, weatherstripping made from ozone-resistant rubber effectively seals doors and windows to eliminate drafts and leaks. Also, seals from this type of rubber prevent leaks in pipes and other equipment. Additionally, hoses made from ozone-resistant rubber transport fluids and gases throughout the vehicle thanks to low gas permeability.

- The Aerospace Industry: also makes use of ozone-resistant rubber. Especially when rubber products come in contact with high ozone levels due to atmospheric pressure. Moreover, it plays a vital role in the form of seals and gaskets to stop leaks in fuel and hydraulic systems and in hoses to transport fluids and gases.

- The Chemical Processing Industry: relies on ozone-resistant rubber to protect against the effects of ozone and other chemicals. It uses seals, gaskets to prevent leaks in pipes and tanks, and hoses to transport chemicals.

- The Construction Industry: employs ozone-resistant rubber in various applications, including weatherstripping, seals, and hoses. For example, it seals doors and windows to prevent drafts and leaks. Moreover, it also uses seals to stop leaks in pipes and other equipment. Additionally, hoses made from ozone-resistant rubber transport water and other fluids on construction sites.

- The Food And Beverage Industry: also utilizes ozone-resistant rubber, particularly when the rubber comes in contact with high ozone levels.

Common Ozone Resistant Rubber Products And Their Uses

Ozone Resistant Rubbers have several applications in a variety of industries. Some of the most common ones include:

- Weatherstripping: rubber products such as weatherstripping to seal doors and windows use ozone-resistant rubbers to prevent leaks and drafts. Its resistance to ozone and other weathering makes it durable for outdoor use.

- Hoses: Ozone-resistant rubber is often used in stockings to transport fluids or gases due to incredible fluid resistance. Its chemical resistance and ozone-resistant properties make it a good choice for outdoor applications where the hoses may be subjected to atmospheric conditions and need fluid resistance.

- Gaskets: gasket and seal joints also use ozone-resistant rubber to prevent leaks. Its resistance to ozone and other chemicals makes it suitable for various industries, including automotive, aerospace, and chemical processing.

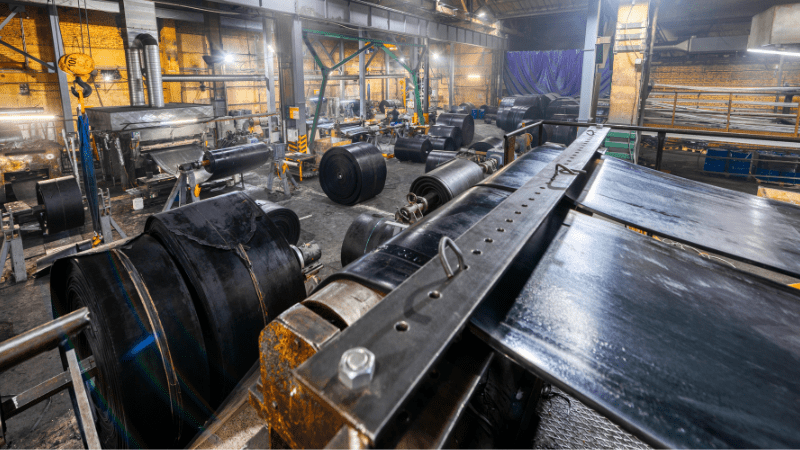

- Belts: Ozone-resistant rubber is used in belts, such as conveyor belts, to transport materials within a factory or other industrial setting. Its resistance to ozone and other atmospheric conditions makes it a durable choice for outdoor applications, thanks to its mechanical properties.

These are just a few examples of the many applications of ozone-resistant rubber. By now, you must know that the versatility of ozone-resistant materials makes them a highly suitable option for various applications in various industries.

Send Your Inquiry Now!

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

Are There Any Disadvantages To Using Ozone-Resistant Rubber Products?

There are a few potential disadvantages to consider when using ozone-resistant rubber products. These include:

- Increased cost: Ozone-resistant rubber products may cost more than other types of rubber due to the specialized materials and production processes required.

- Limited availability: Some types of ozone-resistant rubber may not be widely available or only be produced by a few manufacturers, making it harder to obtain these products.

- Performance limitations: While ozone-resistant rubber can generally withstand exposure to ozone and other atmospheric conditions, it may not perform as well as different types of rubber in specific applications. For instance, it may not have the same tensile strength or tear resistance level.

When deciding whether ozone-resistant rubber products are suitable for your application, weighing the potential disadvantages against the benefits of excellent resistance to ozone is essential. In some cases, the benefits may outweigh the potential drawbacks, while in other cases, a different type of rubber may be a better choice.

EPDM vs. CR vs. BR

EPDM (ethylene propylene diene monomer), CR (chloroprene rubber, also known as Neoprene), and BR (butadiene rubber) are all types of synthetic rubber commonly used in ozone-resistant products. Have a look at the comparison of the ozone resistance of these three types of rubber:

- EPDM: EPDM has excellent resistance to ozone and is commonly used in ozone-resistant products due to this characteristic. It withstands prolonged exposure to ozone without breaking down or becoming brittle.

- CR (Neoprene): CR has moderate ozone resistance but is not as resistant as EPDM. It may be suitable for some ozone-resistant applications but may not be the best choice for applications where the rubber will be exposed to very high ozone levels.

- BR: BR has a low level of ozone resistance and is not generally used in ozone-resistant products. Hence, we won’t recommend it as the best option for outdoor or other applications where the rubber comes in contact with high ozone levels. However, BR, when vulcanized, can be altered to show greater ozone resilience, so we count it.

Overall, EPDM has the most excellent resistance to ozone among the three, whereas BR takes the bottom position.

Send Your Inquiry Now!

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

How To Choose The Right Ozone-Resistant Rubber For Your Needs?

To choose the suitable ozone-resistant rubber for your needs, consider these five points:

1. Determine Your Specific Needs

Identify what properties and characteristics are essential for your application. For instance, do you need a rubber that resists ozone, UV radiation, or other atmospheric conditions? Do you need a rubber with a particular tensile strength or flexibility level? Understanding your specific needs will help you narrow down your options and select the suitable ozone-resistant rubber.

2. Evaluate The Environment

Consider the conditions in which the rubber will be used. Will it come in contact with high ozone levels or other atmospheric conditions? Will it be used outdoors or indoors? Understanding the environment will help you choose a rubber suitable for those conditions.

3. Research Available Options

Look into the different types of ozone-resistant rubber that are available and consider their properties and characteristics. Compare other brands and products to find the best fit for your needs.

4. Factor In Cost

Ozone-resistant rubber may cost more than other types of rubber due to the specialized materials and production processes involved. As a result, determine your budget and consider the cost of different options to find a rubber that meets your needs and fits your budget.

5. Seek Expert Advice

If you are uncertain about which ozone-resistant rubber is the best choice for your application, consider seeking the advice of a rubber specialist or expert. They can help you identify the best options based on your specific needs and requirements.

Send Your Inquiry Now!

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

How Can Ozone-Resistant Rubber Be Used To Improve Safety And Efficiency In Factories?

Ozone-resistant rubber can improve safety and efficiency in factories in various ways. It can reduce the risk of equipment failure by withstanding ozone and other atmospheric conditions.

As a result, this makes it a durable choice for outdoor components such as conveyor belts, hoses, seals, and gaskets. Moreover, these components have a low likelihood of cracking or becoming brittle due to ozone deterioration, which can prevent equipment failure and potential accidents.

Furthermore, ozone-resistant rubber can also create a safer working environment by preventing spills and leaks. This helps avoid potentially hazardous conditions for workers. For instance, hoses and seals made from ozone-resistant rubber are less likely to fail due to ozone damage. As a result, the chances of accidents and injuries are reduced significantly.

In addition, ozone-resistant rubber can improve efficiency in factories by reducing downtime and maintenance costs. For example, gaskets and weatherstripping made from ozone-resistant rubber are less likely to fail due to ozone damage, which can help reduce the frequency of repairs and maintenance.

Also, It can improve energy efficiency by preventing drafts and leaks in doors and windows. In summary, using ozone-resistant rubber can enhance safety and efficiency in factories by reducing the risk of equipment failure, providing a safer working environment, and reducing downtime and maintenance costs.

Maintenance And Care Of Ozone-resistant Rubber Products

Proper maintenance and care can extend the lifespan of ozone-resistant rubber products and ensure their best performance. Here are some tips:

- Store the products properly: If you need to store ozone-resistant rubber products for an extended period, keep them in a cool, dry place away from direct sunlight and other sources of ozone. This prevents ozone deterioration and different types of weathering.

- Clean the products regularly: Regular cleaning removes dirt and debris that can cause wear and tear. Use a soft cloth or brush and a mild soap and water solution to clean the products, and rinse them thoroughly to remove soap residue. Avoid harsh chemicals or solvents that can damage the rubber.

- Inspect the products regularly: Regular inspection can help you identify potential issues early, which can prevent problems from worsening. Look for cracks, tears, or other signs of damage, and replace damaged parts as needed.

- Protect the products from extreme temperatures: Ozone-resistant rubber generally has excellent heat and cold resistance. However, extreme temperatures can still cause damage over time. If you need to store or use the products in extreme temperatures, take appropriate measures to protect them, especially if it’s a matter of low-temperature performance.

Following these maintenance and care tips can ensure the best performance and protection from your ozone-resistant rubber products.

Send Your Inquiry Now!

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

Rubbers That Have Poor Resistance To Ozone

Several types of rubber have poor resistance to ozone and may break down or become damaged when exposed to high ozone levels over time. Examples include:

- Natural rubber: Derived from the sap of rubber trees, natural rubber is generally not resistant to ozone and may break down or become damaged when exposed to high levels.

- Butadiene rubber (BR): Made from the monomer butadiene, BR has a low level of ozone resistance and is not generally used in ozone-resistant products.

- Nitrile rubber (NBR): Made from the monomer acrylonitrile, NBR has a moderate level of ozone resistance. However, conventional nitrile rubber is not as resistant as other types of synthetic rubber, such as EPDM rubber or CR.

- Styrene-butadiene rubber (SBR): Made from a blend of styrene and butadiene monomers, SBR has a moderate level of ozone resistance, but it is not as resistant as other types of synthetic rubber such as EPDM or CR.

Overall, natural rubber, butadiene rubber, nitrile rubber, and styrene-butadiene rubber are all types of rubber that have relatively poor ozone resistance compared to other kinds of rubber, such as EPDM rubber or CR. Moreover, natural rubber tends to perform the worst.

FAQS: Ozone-Resistant Rubber

Want a clearer understanding of ozone-resistant rubber? Well then, let’s have a look at some of the most frequently asked questions people ask about ozone-resistant rubbers:

What rubber is ozone-resistant?

Technically, any rubber that can withstand prolonged exposure to ozone without losing mechanical properties falls in this category. However, the most common names include EPDM rubber and CR. On the other hand, rubbers such as nitrile and natural rubber tend to show vulnerability to ozone exposure.

Is rubber immune to ozone?

There is no definite answer to this question because while some rubbers perform exceptionally well in countering ozone, they aren’t 100% immune. As a result, you can expect EPDM rubber to withstand ozone for prolonged periods. However, there will come a point when you have to replace this rubber, no matter how late it gets. Hence, 100% immunity to ozone doesn’t exist in any rubber, even if high resistance levels do.

Does ozone react with rubber?

Ozone is a highly reactive element in the atmosphere. As a result, it does react with rubber. However, it reacts more intensely with certain rubbers than others. Moreover, the rubber’s quality also determines the reaction’s intensity. For instance, EPDM rubber tends to withstand this reaction pretty well, and natural rubber does the opposite.

Send Your Inquiry Now!

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

Conclusion

To conclude, outdoor applications with ample exposure to sunlight and ozone require specialized rubbers. As discussed, EPDM rubber and CR are the best choices. However, given your conditions, you should still look for the most suitable option. For instance, in some cases, even moderately resistant ozone rubbers such as silicone rubber can do the job pretty well.

Want The Best Rubber Solutions For You Ozone Applications?

Hongju is at your disposal with a wide variety of ozone-resistant rubbers and products. You can customize the order as per your needs and wishes. We will send you a prototype before the final order if you want a prototype.