However, their potential health risks have led to a significant focus on phthalate-free materials, especially in the production of O-rings and gaskets. In this comprehensive guide, we delve into the world of phthalate-free O-rings and gaskets, exploring the reasons behind the shift and the available material alternatives. This article serves as an indispensable tool for manufacturers seeking to align their operations with safer, environmentally friendly practices while ensuring high product quality.

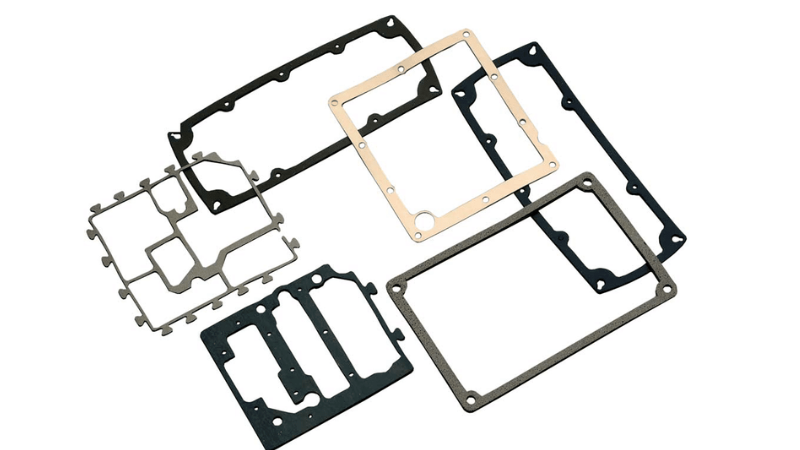

Understanding O-rings and Gaskets

In the world of manufacturing and industry, two components stand out due to their ubiquitous nature and the vital role they play in countless applications – O-rings and gaskets.

What are O-rings?

O-rings are round seals used to prevent leaks in various applications. These rings play a crucial role in maintaining the integrity of systems by creating a tight seal between two components. They are typically made from rubber or elastomers, which offer flexibility and durability.

What are Gaskets?

Gaskets are mechanical seals that fill gaps between two surfaces to prevent leakage. They play a crucial role in ensuring the integrity of various systems, such as pipelines, engines, and machinery. By creating a tight seal, gaskets prevent the escape or entry of fluids, gases, or other substances.

Gaskets can be made from a variety of materials depending on the specific application requirements. Common materials used for gasket production include rubber, metal, and composite materials. Each material offers unique properties that make it suitable for different environments and conditions.

Send Your Inquiry Now!

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

What are O-rings and Gaskets Made of?

O-rings and gaskets are essential components used in various industries to create a tight seal between two mating bodies or surfaces. Let’s delve into the different materials used in manufacturing O-rings and gaskets and how their composition affects the presence of phthalates.

O-rings Materials:

O-rings can be made from a variety of materials, each offering distinct properties suitable for specific applications. Here are some commonly used ring materials options:

- Nitrile Rubber: Nitrile rubber O-rings, also known as Buna-N or NBR, exhibit excellent resistance to oil, fuel, and other petroleum-based fluids. They are widely used in automotive and aerospace industries where exposure to fuels is common.

- Silicone: Silicone O-rings possess exceptional temperature resistance, making them ideal for high-temperature applications such as food processing equipment or medical devices where sterilization is required.

- Fluorocarbon Elastomers: Commonly referred to as Viton®, fluorocarbon elastomer O-rings offer superior chemical resistance against a broad range of harsh substances including acids, solvents, and fuels. These O-rings find extensive use in chemical processing plants and oil refineries.

Gasket Materials:

Gaskets come in various forms depending on the application requirements. The following materials are frequently utilized:

- Rubber: Rubber gaskets provide excellent flexibility and resilience, enabling them to conform to irregular surfaces effectively. They are commonly found in plumbing systems or machinery where a watertight seal is necessary.

- Cork: Cork gaskets offer remarkable compressibility along with good resistance against oils and solvents. Their ability to dampen vibrations makes them suitable for automotive applications, such as sealing oil pans or valve covers.

- Fiberglass: Gaskets made from fiberglass sheets are known for their high-temperature resistance and excellent electrical insulation properties. They are commonly used in electrical enclosures or HVAC systems.

- Graphite Sheets: Graphite gaskets possess exceptional thermal conductivity and can withstand extreme temperatures. They find extensive use in high-pressure applications like steam systems or exhaust flanges.

Understanding chemical compatibility and the material composition of O-rings and gaskets is essential. By selecting materials that are free of these chemicals, industries can ensure the safety and reliability of their products while meeting regulatory requirements.

Send Your Inquiry Now!

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

Risks of Phthalates in O-rings and Gasket Materials

Navigating the world of seals and gaskets, one often encounters a crucial component – phthalates. But what exactly are these substances and why should we be concerned?

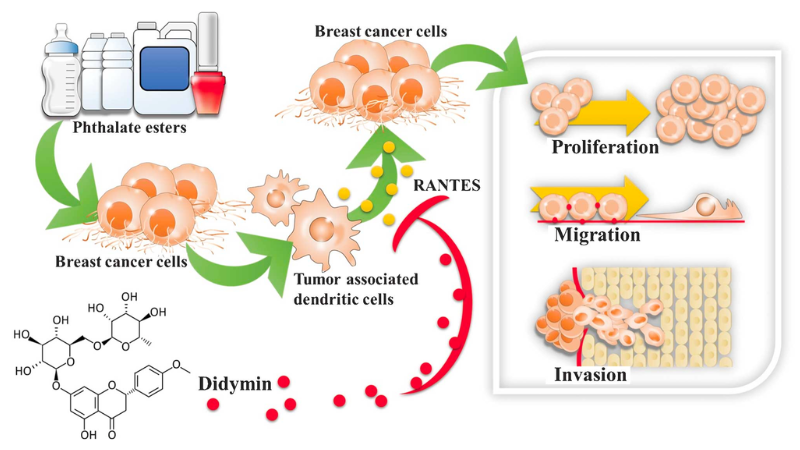

What are Phthalates?

Phthalates, or phthalate esters, are chemical compounds regularly added to plastics to boost their flexibility, transparency, durability, and longevity. They’re found in a myriad of everyday items ranging from food packaging to personal care products, toys, household items, and in certain cases, o-rings and gaskets.

The Health Concerns

Phthalates aren’t chemically bound to the plastics they’re added to, meaning they can seep out over time, especially when exposed to heat or fatty foods. It’s through this leaching process that humans are primarily exposed to phthalates, predominantly via ingestion and, to a lesser extent, inhalation or skin contact.

A growing body of research points towards possible health risks associated with phthalates. They’ve been linked to issues such as endocrine system disruption, reproductive problems, and developmental issues in children. Some studies even suggest a potential correlation between high phthalate levels and obesity, insulin resistance, and cardiovascular problems. It’s believed that phthalates disrupt the production of chemicals called neurotransmitters in the brain, which play a role in learning and behavior.

The Impact on Businesses and Industry

As the health risks linked to phthalates become more apparent, many manufacturers are opting for phthalate-free alternatives for their products, including o-rings and gaskets. This shift ensures safer products, especially in industries like food processing and pharmaceuticals, where exposure to leached substances could have significant health consequences.

Choosing phthalate-free materials for your o-rings and gaskets isn’t just responsible practice; it can also provide a competitive edge, demonstrating a commitment to health and safety.

Identifying Phthalate-Free Materials for O-Rings and Gaskets

Now that we’ve explored the potential hazards of phthalates, it’s essential to shift our focus toward alternatives. Today, more than ever, the demand for phthalate-free materials in the production of O-rings and gaskets is increasing. Manufacturers can use phthalate-free materials with excellent tensile strength, high performance, and oil resistance for your o rings and gaskets. They will meet customers’ sealing needs without creating problems for the end user.

Alternative Materials

When it comes to manufacturing phthalate-free O-rings and gaskets, various safe and effective materials can be used. These materials are safe, meet international standards, and work well in many industries.

Silicone

Silicone is a highly versatile material known for its exceptional heat resistance, flexibility, and durability. It’s phthalate-free and safe for use in various applications, including food processing, healthcare, and high-temperature environments. It’s also highly resistant to weathering and oxidation, making it suitable for outdoor use.

EPDM (Ethylene Propylene Diene Monomer Rubber)

Ethylene Propylene is a synthetic rubber material highly resistant to weather, ozone, and UV light. It’s also phthalate-free, making it a safe choice for O-rings and gaskets. EPDM’s excellent resistance to heat and a wide range of chemicals makes it an excellent choice for automotive, industrial, and outdoor applications.

Nitrile (Buna-N)

Nitrile, also known as Buna-N, is a synthetic rubber material that offers high temperatures and excellent resistance to oils, fuels, and many chemicals. It’s a phthalate-free material that offers a balance of good resistance to heat and excellent mechanical properties, making it a popular choice for oil and gas industries.

Fluorocarbon (Viton)

Fluorocarbon, commonly known by the brand name Viton, is a high-performance synthetic rubber material that offers excellent resistance to extreme temperatures, oils, and chemicals. It’s a safe, phthalate-free material widely used in the aerospace, automotive, and chemical industries.

Neoprene (Chloroprene)

Neoprene is a synthetic rubber offering good chemical stability and flexibility over a wide temperature range. Its phthalate-free formulation makes it safe for use in various applications, including automotive, marine, and weather-resistant products.

Choosing the Right Material

The material you choose for your o-rings and gaskets will depend largely on your application. However, regardless of the material, it’s crucial to ensure it is free from phthalates. Requesting a material certification from your supplier can help confirm the material’s composition and its phthalate-free status.

By opting for phthalate-free materials, you can provide your customers with a safe and reliable product, while also taking a crucial step in maintaining health and safety standards in your industry.

Send Your Inquiry Now!

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

How to Know If an O-ring or Gasket Contains Phthalates?

Determining whether your O-rings or gaskets contain phthalates can be challenging. Nevertheless, it’s an essential step for ensuring a safer product and adherence to the growing regulations in various industries. Here’s how you can confirm the presence (or absence) of phthalates:

Request Material Certificates

The most straightforward method to confirm whether an O-ring or gasket contains phthalates is to request a Material Safety Data Sheet (MSDS) or a certificate of compliance from the supplier or manufacturer. These documents provide detailed information about the material’s composition and can confirm whether phthalates have been used in the product’s manufacturing process.

Conduct Lab Testing

If the documentation is unavailable or if there are doubts about the authenticity of the documents, the product can be sent for lab testing. Various analytical methods, such as Gas Chromatography-Mass Spectrometry(GC-MS) and Fourier Transform Infrared Spectroscopy (FTIR), can be used to identify the presence of phthalates accurately.

Check Regulations and Standards

In many countries, there are strict regulations that prohibit the use of phthalates in certain products. Therefore, if your product is compliant with these regulations, it’s likely that it does not contain phthalates. For example, any product that adheres to the EU’s REACH regulations or the US’s Consumer Product Safety Improvement Act (CPSIA) is free from certain types of phthalates.

Remember, being informed about the presence of phthalates is not just about regulatory compliance; it’s also about ensuring the safety of your customers and the environment. By actively seeking phthalate-free alternatives, you are taking an essential step toward creating a safer and healthier world.

Send Your Inquiry Now!

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

The Benefits of Using O-rings and Gaskets Made From Safe Materials

Choosing O-rings and gaskets made from safe, phthalate-free materials presents a wealth of benefits, not only for manufacturers but also for consumers and the environment. Here are some of the key advantages of opting for these safer materials:

Improved Safety for Both Users and the Environment

Phthalate-free o-rings and gaskets offer a significant advantage. These materials are free from harmful chemicals that can pose risks to both end-users and the environment. Phthalates, commonly used in many industrial applications, have been linked to various health issues, including hormone disruption and reproductive problems. By opting for o-rings and gaskets made from safe materials, manufacturers prioritize the well-being of their customers.

Using phthalate-free materials ensures that potential hazards are eliminated at their source. This proactive approach helps prevent any adverse effects on human health or the environment throughout the life cycle of products.

Compliance with Stringent Regulations

Another advantage of using phthalate-free o-rings and gaskets is compliance with stringent regulations. Governments worldwide have implemented strict guidelines concerning chemical usage in various industries. By utilizing these safe materials, manufacturers reduce legal risks associated with non-compliance. Failing to adhere to such regulations can lead to severe penalties, lawsuits, and damage to a company’s reputation.

Complying with these regulations not only safeguards against legal consequences but also demonstrates a commitment to responsible manufacturing practices.

Enhanced Brand Reputation

Opting for o-rings and gaskets made from safe materials also has a positive impact on the company and brand reputation. In today’s conscientious market, consumers are increasingly concerned about the quality and safety of the products they purchase. By choosing phthalate-free options, companies showcase their commitment to providing high-quality products that prioritize customer well-being.

A strong brand reputation built on trust fosters customer loyalty and attracts new customers. When consumers know that a brand prioritizes their safety and health, they are more likely to choose those products over competitors. By going the extra mile to ensure safe materials are used in designs and manufacturing processes, companies can differentiate themselves from others in the market.

Send Your Inquiry Now!

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

Conclusion

Choosing the right materials for O-rings and gaskets is crucial in today’s industries, where safety and compliance with international standards cannot be compromised. The widespread use of phthalate-free materials brings significant health and safety advantages without sacrificing performance and reliability.

Get Top-Of-The-Line Products From Hongju

At Hongju Silicone, we prioritize safety, quality, and compliance. We are dedicated to providing the industry with top-notch, phthalate-free O-rings and gaskets.

Our expertly engineered products are designed to meet your specific needs without compromising health and environmental considerations. Embrace a safer future with us—Choose Hongju for all your O-ring and gasket requirements.