Have you ever wondered what the exact function of a gasket is? Seemingly, they keep your machines running smoothly by playing a role in sealing and preventing leaks. In this guide, we will explain all aspects of gaskets, from their types to uses and the reason behind their importance.

Ready to explore the science behind their functionality and learn how to choose the right gasket for your needs?

What is a Rubber Gasket?

A rubber gasket is a kind of mechanical seal that fills the gaps between two surfaces to prevent leaks. Rubber gaskets are made from flexible materials like natural or synthetic rubber such as silicone. Their primary application is in machinery where a strong seal and flexibility are required.

The main role of rubber gaskets is to prevent the flow of liquids and gases out of the system and the entry of pollutants into the system. Thus, they have become integral components of a variety of industries, including automotive, aerospace, and HVAC.

Difference Between Gaskets and Seals

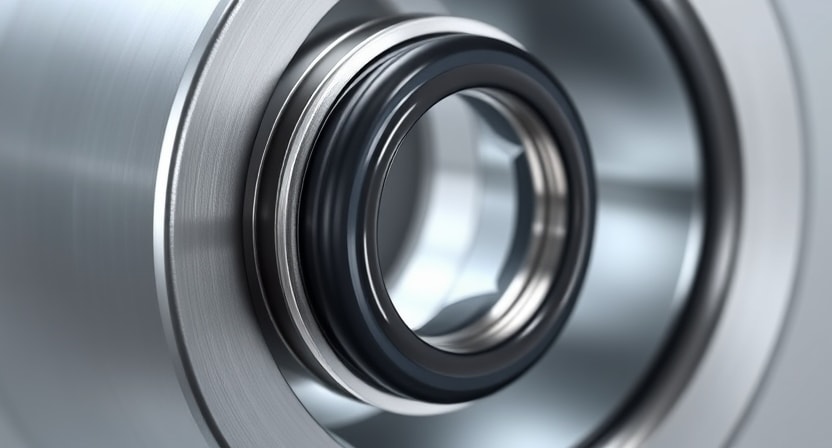

Both gaskets and seals are designed to prevent leaks, and while the terms are often used interchangeably, their applications differ greatly. Gaskets are designed to seal off surfaces that remain stationary or motionless during their function. Often, custom gaskets are made from thermoplastic elastomers to be used in static applications or fixed connections

On the other hand, seals were designed to provide efficient sealing for dynamic applications where at least one part is in motion. They are used in systems with moving parts to prevent any fluid or gas leak such as rotating shafts or hydraulic cylinders.

Types of Rubber Gaskets

There are plenty of rubber gasket materials, each tailored to meet the criteria of specific applications. Here’s an overview of the most commonly used types of rubber gasket materials and their unique characteristics.

Natural Rubber (NR)

Natural rubber gaskets are known for their high flexibility and wear resistance. They provide reliable sealing in low-temperature settings and general-purpose applications. Natural rubber gaskets are widely employed in non-critical sealing applications, such as water or low-pressure systems, due to their low cost and high adaptability.

Silicone Rubber

Silicone rubber gaskets are valued for their excellent temperature resistance, flexibility, and adherence to FDA guidelines. These qualities make them appropriate for application in food processing and medical equipment. Silicone gaskets are resilient over a wide temperature range, making them ideal for high-temperature applications as well.

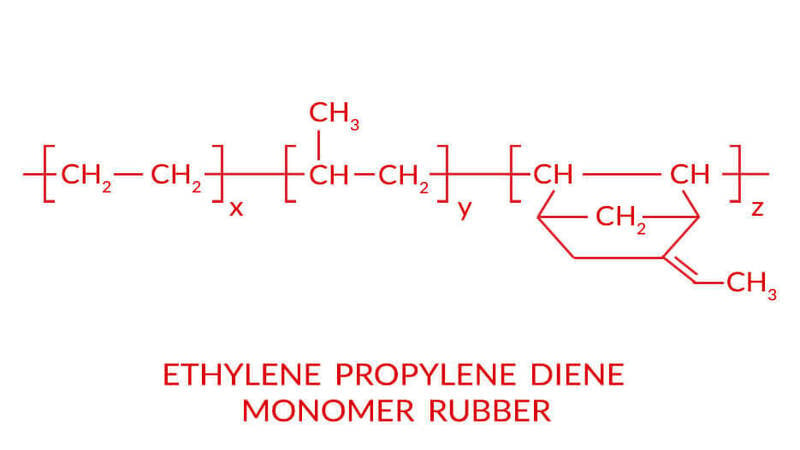

EPDM (Ethylene Propylene Diene Monomer)

EPDM rubber gaskets are extremely resistant to weathering, UV radiation, and ozone, making them the preferred choice for outdoor and automotive applications. Their exceptional durability and tolerance to environmental factors assure long-term functioning, especially in extreme settings. They’re commonly used to seal windows, doors, and other exterior components.

Nitrile Rubber (NBR)

NBR is made of acrylonitrile butadiene rubber, a material that provides excellent chemical resistance. Nitrile rubber gaskets are designed specifically to withstand oils, gasoline, and chemicals. These gaskets are commonly used in automobile systems, including gasoline tanks and engine components, as well as industrial machinery.

Neoprene Rubber

Neoprene gaskets are made up of chloroprene rubber and maintain an acceptable balance between adaptability, chemical resistance, and durability. They are widely utilized in HVAC systems, naval applications, and industrial machines due to their ability to resist a wide range of temperatures and environments. Neoprene‘s flexibility and resistance to degradation make it ideal for both indoor and outdoor use.

Viton® (FKM)

Viton gaskets are well-known for their extraordinary resistance to chemicals and high temperatures. They are used in vital industries like aerospace, chemical processing, and oil and gas. Viton gaskets’ ability to tolerate harsh environments ensures reliable performance in very demanding applications.

Common Gasket Types

Gaskets come in a variety of materials, each designed to meet specific sealing requirements across industries. Here’s an overview of the most common gasket types, the characteristics of their material properties, and their applications:

Paper Gaskets

Paper gaskets are the most cost-effective option, and they are commonly used to seal oil and water. They are lightweight and simple to manufacture, making them a popular alternative for less demanding applications. However, they are not ideal for high-temperature situations since their performance degrades under heat or pressure.

Varnished Paper Gaskets

Varnished paper gaskets are a step above standard paper gaskets. The paper gaskets become more durable and resistant to high temperatures after being varnished. They are frequently used in applications where normal paper gaskets would fail, such as sealing certain engine block components.

Cork Gaskets

These gaskets are made of cork material and are perfect for low-load applications with irregular surfaces. Cork gaskets are very resistant to oils and solvents, making them a great choice for certain cylinder head gaskets. However, they are not water-resistant, limiting their use in wet conditions.

Cork and Rubber Mixed Gaskets

Cork and rubber-mixed gaskets are made by combining cork and flexible materials such as nitrile or neoprene. This blend produces gaskets that are stronger and more flexible than pure cork gaskets. Their greater durability makes them appropriate for a broader range of applications.

Metal Material Gaskets

As the name suggests, these gaskets are made from metal. They are required in instances where nonmetallic materials fall short. They are commonly used in automotive engines and are specifically built to withstand high temperatures and pressures.

Copper-Coated Asbestos Gaskets

Copper-coated asbestos gaskets are designed to withstand intense heat conditions. While their heat resistance is unmatched, modern substitutes have replaced them due to the health risks linked with asbestos.

How Do Gaskets Work?

Gaskets are mechanical seals that cover the gap between two static surfaces, preventing liquids, gases, or pollutants from leaking through. Their effectiveness is based on their ability to form a tight, solid seal when compressed.

When a gasket is pushed between two surfaces, it adapts to surface irregularities, leaving no openings through which any substances might escape. The science of gaskets focuses on compressive force and material elasticity. For optimal function, the gasket material must compress sufficiently to fill any spaces between the two mating surfaces while retaining structural integrity.

Rubber is often used to make gaskets, as rubber’s elasticity allows it to rebound, resulting in a stable seal even after multiple compression cycles.

For a gasket to function optimally, it needs to be fit properly. A badly fitted gasket or one composed of mismatched materials can cause leaks, system errors, and even catastrophic failures in important applications.

Factors Affecting Gasket Function

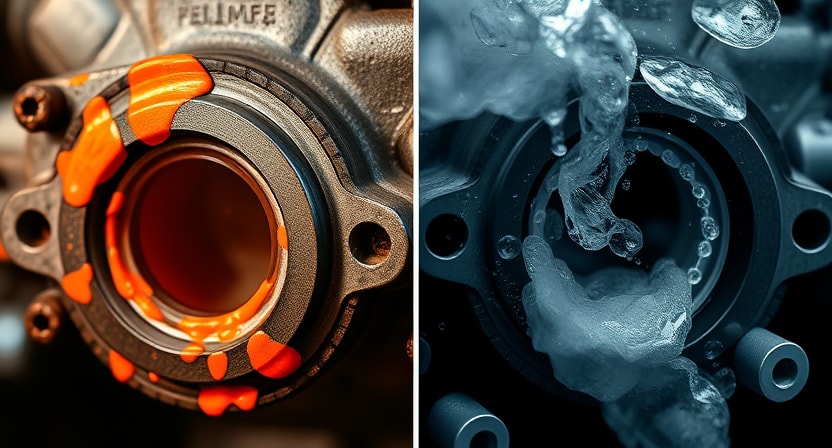

External factors such as pressure, temperature, and chemical exposure all influence gasket performance. High-pressure conditions require gaskets that can tolerate extreme compressive forces without losing shape.

Similarly, exposure to severe temperatures can cause certain materials to deteriorate or harden over time, resulting in seal failure. Chemical resistance is also important, especially in industries where gaskets are exposed to lubricants, fuels, and corrosive substances.

Key Applications of Rubber Gaskets

Rubber gaskets are used across almost all industries that rely on machinery. Here are some of their most common uses of gaskets industry-wise.

Automotive Industry

Rubber gaskets are vital for sealing engines, transmissions, and exhaust systems. They prevent fluid leaks, such as oil, coolant, and transmission fluid, resulting in better vehicle performance. Cylinder head gaskets, in particular, are engineered to withstand the high pressure and heat of an engine block.

Oil and Gas

Rubber gaskets are used in pipelines, valves, and storage tanks as they can endure high pressures and strong chemicals. Their reliable sealing and resistance to oils and fuels make them critical for preserving equipment integrity in the oil and gas industry.

Food and Beverage

FDA-approved rubber gaskets are used in food processing equipment for safe and sanitary operations. These gaskets form airtight seals in mixers, tanks, and pumps, avoiding contamination and ensuring compliance with food safety requirements.

Construction and Plumbing

Rubber gaskets are essential in construction for forming waterproof seals in pipes, windows, and HVAC systems. They prevent leaks and drafts, which improves energy efficiency and structural integrity in buildings.

Electronics

Rubber gaskets protect delicate electronic components from dust, water, and electrical interference. They are often used in covers for smartphones, tablets, and industrial control systems.

Medical and Pharmaceutical

Rubber gaskets made of biocompatible materials are used in medical devices and equipment, including ventilators and surgical instruments. They maintain a sterile, leak-free environment and are resistant to cleaning compounds and high-temperature sterilization.

Importance and Advantages of Rubber Gaskets

Rubber gaskets serve as vital components in many industries, providing operational integrity by preventing leaks, withstanding pressure, and conserving temperature stability. They form a tight seal between two surfaces, preventing fluids from escaping and pollutants from entering the system.

This ability to form a durable seal has made rubber gaskets a necessary component of reliable performance.

Aside from their crucial role in sealing, rubber gaskets provide various benefits that make them a popular choice in a variety of applications. Their outstanding sealing properties provide long-term protection against contaminants while their durability enables a longer service life, especially in harsh environments.

Rubber gaskets are intended to withstand extreme temperatures and chemical exposure, making them appropriate for demanding operational settings.

Furthermore, the customizability of rubber gaskets enables manufacturers to customize their size, shape, and material composition to specific requirements, improving their performance in specialized applications.

These characteristics, together with their cost-effectiveness, provide industries with reliable and economical sealing solutions that exceed many other materials.

Rubber gaskets remain an important component in assuring system reliability and operational efficiency across industries because of their intrinsic benefits, which include their capacity to prevent leaks, bear pressure, and dissipate heat.

Gasket Properties and Testing

Many factors impact the performance of a gasket, but its physical properties are the most important ones. In order to know the reliability of a gasket’s physical properties, you have to be able to test it. Here are some physical properties of gaskets and testing methods that ensure operational reliability.

Physical Properties of Gaskets

A gasket must have the correct balance of strength, flexibility, and thermal stability to survive a variety of environments. These qualities allow them to form reliable seals even in high-pressure or high-temperature settings.

Gasket Testing Methods

To ensure reliability, gaskets are subjected to rigorous testing procedures such as hot compression testing, tensile testing, and chemical resistance evaluations. These tests confirm that the gaskets meet the performance requirements for their intended applications.

How to Choose the Right Rubber Gasket for Your Needs

Selecting the right rubber gasket is essential for ensuring reliable performance in various applications. Here are some crucial factors to consider while choosing a rubber gasket.

Identify Your Application Requirements

Begin by determining the operating temperature, pressure, and potential chemical exposure of your application. These factors will help you determine the type of gasket required to satisfy the specific needs of your system.

Material Selection

Choose a rubber material that is compatible with the environmental conditions of your application. Silicone is appropriate for high-temperature situations, whereas nitrile rubber is excellent if you want a gasket resistant to oils and fuels.

Customization Options

The correct size and thickness of the gasket are crucial for achieving a secure seal. Choosing custom gaskets fitted to your system’s specs will improve both reliability and performance.

Certifications and Standards

Check that the gasket complies with all applicable industry standards, such as FDA for food-grade applications, RoHS for environmental compliance, and ISO for general quality assurance. Compliance ensures safety and efficiency.

Supplier Reliability

Work with a reliable supplier who maintains consistent quality and meets delivery deadlines. A trusted manufacturer ensures that your gaskets satisfy performance objectives and minimize potential downtime.

Frequently Asked Questions

Q. What are the signs of gasket failure?

Common indicators of gasket failure include visible leaks, corrosion around the seal, and physical damage to the gasket material. Addressing these warning indicators as soon as possible helps to avoid future damage and system inefficiencies.

Q. How can I prevent gasket failure?

Perform routine inspections to spot signs of wear and tear correct any misalignments or repair any visible damage.

Q. Why Choosing the Right Gasket Material Matters

The selection of the right gasket material is critical for its functionality. A good material increases longevity, improves performance, and reduces maintenance costs, resulting long long-term durable products.

Conclusion

Rubber gaskets are a dynamic addition to machine functionality. They serve as core components of every piece of equipment across a variety of industries. Now that you know all the critical details about rubber gaskets, it’s time to apply this knowledge to your operations.

By choosing the right gasket materials, ensuring proper installation, and performing regular maintenance, you can enhance the efficiency and reliability of your systems.

Ready to Improve Your Machine’s Operational Efficiency with Ideal Sealing Solutions?

As a trusted manufacturer with years of expertise in designing and delivering high-quality gaskets, Hongju Technology is committed to meeting your unique needs. Our products are built to perform in the most demanding conditions, ensuring superior reliability and cost-effectiveness.

Contact us to request a free consultation from our expert today!