Tire manufacturing is a complex process. Each tire manufacturer follows unique and proven procedures, from raw materials selection to quality management. Tire companies are looking at other sources of rubber to solve the scarcity of natural rubber. In this blog, we will discuss natural rubber qualities, the causes for its scarcity, and novel alternatives with their advantages.

Let’s Begin!

Natural Rubber in the Tire Industry

Natural rubber is self-reinforcing by nature, with great mechanical strength and mild flexibility. It does, however, have viscosity constraints and other downsides. It must undergo processes like vulcanization and adding Carbon Black fillers to prepare it for use in tire industry manufacturing.

What is Natural Rubber?

Natural rubber is made up of long, loosely connected polymer chains of isoprene. When the links are pulled apart, they reunite, resulting in the elasticity of rubber. Natural rubber, as opposed to synthetic rubbers, is made from the latex sap of rubber trees (although other plants also produce latex, rubber trees produce the most latex, accounting for 99% of natural rubber).

Why Natural Rubber is Preferred for Tire Manufacturing?

Natural rubber is an important raw material in tires and many other products: 73% of global natural rubber usage is utilized in tire production, accounting for 20 to 40% of tire weight (depending on the segment).

Its amazing properties make it unique and also a significant choice for tire industry manufacturing. Rubber has undoubtedly proven to be the best choice, for example, for tire strength along with vehicle load support and tire resistance. Some of the best properties are as follows:

- High Tensile Strength: The tensile strength of natural rubber is very high. It can withstand considerable stress and strain due to its strength without breaking or deforming.

- Good Adhesion: It adheres easily to other materials, making it ideal for use in tire manufacturing, where different components must be bonded together.

- Exceptional Abrasion and Tear Resistance: Natural rubber is resistant to cutting, tearing, wear, fatigue, and abrasion, making it perfect for use in tire treads and other friction and abrasion-prone components.

- Flexibility: Natural Rubber is known to be the most flexible type of rubber, making it ideal for use in tire sidewalls. Moreover, it is used in other components as well, especially the ones that need bending and flexing.

- Water Resistance: Natural rubber is resistant to water and certain chemicals, making it perfect for use in tire production, where moisture and other substances are frequently exposed.

- Moderate Chemical Resistance: Natural Rubber offers a modest chemical resistance. This makes it useful in many useful applications.

- Durability: Natural Rubber provides long life to the tires and resistance to tear and wear. Therefore, it makes it an excellent choice for tire treads along with other components that are bound to encounter friction and abrasion.

- Abrasion Resistance: Natural rubber provides high resistance to abrasion. It helps in the long life of the tire and improves its overall road performance.

Send your inquiry for prompt quotations!

Applications of Natural Rubber

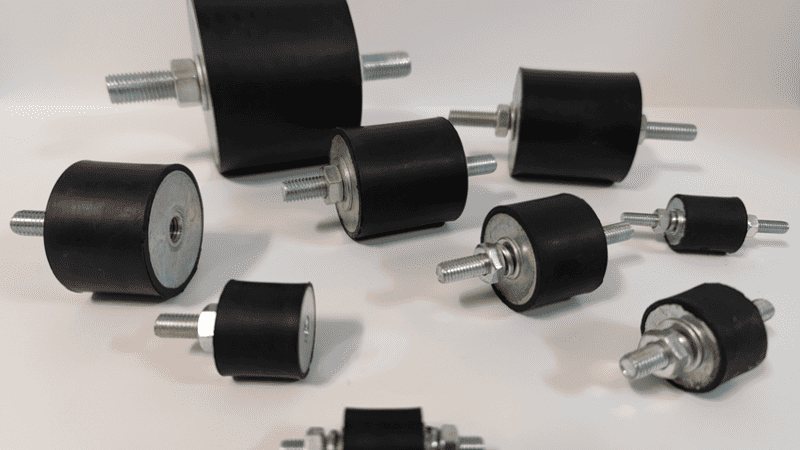

Natural rubber is used in applications that require high wear and heat resistance. You can also find technical applications of it. If you dig deeper, you will find it in anti-vibration mounts, rubber bands, springs, drive couplings, bearings, and adhesives. It is due to its strength and compressibility.

Around 50% of natural rubber is dedicated to the production of high-performance tires for tires for sports cars, long-route buses, and airplanes due to its exceptional strength and heat resistance. Truck tires have more natural rubber, and car tires have more synthetic rubber. Trucks carry heavy loads and travel intensively, so the tires are subject to wear and tear. Natural rubber’s abrasion properties are superior to synthetic rubber, so more natural rubber is used for trucks. Other applications like hoses, vehicle parts, foam mattresses, and battery boxes are also made from it.

Due to its sticky characteristics, natural rubber is normally found in rubber cement and soil stabilization materials used around new roadways.

Raw rubber is also known to be used in adhesives and shoe soles, not necessarily, but occasionally. Furthermore, around 10% of latex harvested from trees is simply reduced to 60% rubber solution to produce products such as latex gloves or to utilize as a coating.

Factors Contributing to Natural Rubber Scarcity

Due to climate change and chronic illness among the world’s rubber trees, the car industry is facing a natural rubber supplies shortage. Many scientists believe natural rubber will no longer be employed in specialized industries in the coming years. Here are some of the other factors causing Natural rubber Scarcity:

1. Environmental Challenges

Tires are crucial parts of cars because they support the vehicle’s weight and movement while offering enough traction, safety, comfort, durability, steering precision, and fuel efficiency. However, greenhouse gas and other pollutant emissions, combined with the use of nonrenewable resources during tire manufacturing and use, have exacerbated global warming and caused environmental degradation.

These issues are harmful to the ecological balance of the environment. According to studies, the entire automobile industry is responsible for around 40% of global pollution, with tire manufacture and use accounting for 20%-30% of this total.

Tire companies worldwide have implemented various measures to reduce the industry’s impact on the natural environment. These measures aim to achieve the ultimate goal of carbon neutrality, which primarily includes reducing raw material consumption, decreasing tire weights, and increasing the use of natural and renewable resources.

2. Geopolitical and Trade Dynamics

Natural rubber scarcity is a complicated issue involving many aspects, including geopolitical and trade dynamics. Labor shortages and shipping line concerns caused by the epidemic have contributed to a natural rubber supply shortage in many Southeast Asian countries where natural rubber is produced.

A global rubber cartel has resulted in unpredictable prices and impoverished producers. Natural rubber production has declined due to the increased volatility of global rubber prices and a lengthy period of low prices.

Several characteristics of natural resource markets make them especially vulnerable to various forms of market power. Natural resources are frequently concentrated in a few countries, which raises the possibility of collusion and inhibits the establishment of totally competitive marketplaces.

The world economy relies on Asia for 90% of its rubber supply, and the United States alone bought $140 million in natural rubber from Southeast Asian countries in March 2021. Finally, geopolitical and trade dynamics are important contributors to the natural rubber shortage, and resolving these aspects is critical to ensuring a sustainable supply of only natural rubber.

3. Economic Ramifications

Natural rubber plantation science has a direct impact on economics since corporations like Michelin, the rubber giant, need to maintain supply and convert to 100 percent natural rubber by 2050.

As a result, the economic consequences of natural rubber shortage are severe, as rubber is employed in over 40,000 commercial items, including personal protective equipment like gloves and mask ear loops. Natural rubber shortages may cause a slowdown in worldwide rubber demand, which is expected to decrease to 2.8% in 2023 after a rapid recovery between 2021 and 2022.

Send your inquiry for prompt quotations!

Common Synthetic Materials Used in Tire Production

In addition, NR is commonly used in combination with synthetic rubbers such as styrene–butadiene rubber (SBR), butyl rubber (IIR), and chloroprene rubber in the tire industry, and this requires the addition of reinforcing agents, including CB and silica. Here are some common synthetic materials used in tire production:

1. Styrene-butadiene Rubber (SBR)

This is one of the two primary synthetic rubber polymers used in the production of tires. It is a styrene/butadiene copolymer that is used in conjunction with natural rubber. The physical and chemical characteristics of SBR have a significant impact on the performance of individual tire components and, consequently, the overall tire performance, including aspects like rolling resistance, wear, and traction.

2. Nitrile Rubber (NBR)

This is an acrylonitrile/butadiene copolymer of synthetic elastomer. It’s utilized to make fuel hoses, gaskets, and seals, as well as in the tire business. NBR is resistant to oil, fuel, and other chemicals, making it an excellent choice for tire applications.

3. Chloroprene Rubber(CR)

This is a synthetic rubber polymer that resembles neoprene. It is resistant to grease, heat, and ozone, making it ideal for use in tires. Tire sidewalls and other components are made from CR.

4. Ethylene-Propylene-Diene Monomer (EPDM)

This is a heat, ozone, and weather-resistant synthetic elastomer polymer. EPDM is used to make tire sidewalls, inner liners, and other components.

Exploring Alternative Materials for Tires

Tire manufacturers are investigating alternate tire materials to make them more environmentally friendly and sustainable. Alternative materials being researched include:

1. Dandelion Rubber (DR)

Dandelion rubber is a renewable resource that can be used in place of synthetic rubber. It is made from the roots of the Russian dandelion plant and is being researched as a potential replacement for regular rubber by tire producers. The Russian dandelion is a hardy plant capable of thriving in different climates and soil types, making it a viable alternative to typical rubber trees grown in certain locations.

The plant’s roots produce a milky fluid that can be used to make rubber. During WWII, the Russian dandelion was used as a source of rubber. However, production of rubber from this plant ceased after the war. On the other hand, researchers have optimized the Russian dandelion for large-scale rubber production.

3. Guayule Rubber (GR)

Guayule Rubber is another renewable material being researched as a replacement for regular rubber. Guayule (Parthenium argentatum) is a native North American renewable, non-food crop, thriving with minimal water and without the need for pesticides. It offers a locally generated, eco-friendly supply of natural rubber. Bridgestone is developing as a source for natural rubber production from the guayule bush found in the United States Southwest.

The guayule procedure includes:

- Planting the guayule bush from seed.

- Watering minimally.

- Managing weeds for two years as the plants mature.

The plants are then chopped flush to the ground and baled into cubes weighing 750 to 800 pounds. This process is done twice over four years, after which the buried roots are tilled under, and a different crop is planted. In a 90-minute closed-loop process, the bales are ground at a biorefinery, yielding three commercially viable products. It includes hypoallergenic natural rubber, resin (used in coatings, inks, and adhesives), and bagasse (used for biofuels and bio-based chemicals).

3. Eucommia Ulmoides Gum (EUG)

Eucommia ulmoides gum is a natural rubber-like substance collected from the Eucommia ulmoides tree’s bark. It is being researched as a possible replacement for synthetic rubber. The Eucommia ulmoides tree is endemic to China and is well-known for its therapeutic benefits. The tree’s bark includes a chemical that can be processed into a rubber-like material. EUG is being studied as a possible alternative to synthetic rubber sourced from petroleum and is not a sustainable resource.

EUG has good rubber-plastic duality and has a wide range of applications in biomedicine, textiles, aerospace, and other sectors. Since EUG offers superior tribological properties, it is a viable alternative to natural rubber (NR) in aircraft tire applications.

Researchers created a thiazolidinedione-modified Eucommia ulmoides gum elastomer with increased elasticity and shape memory capabilities. The modified EUG might become a good tough elastomer with high strength, elongation, and toughness or a unique rubber by changing the TAD feed.

Send your inquiry for prompt quotations!

Benefits of Using New Materials in Tires

New materials in tires can bring several benefits, including cost savings and environmental sustainability. Here are some of the benefits of using new materials in tires:

1. Cost Savings

New materials can replace high-priced natural rubber. It can further lead to cost savings for tire manufacturers as they create more sustainable materials to build a tire.

2. Environmental Sustainability

Green tires made from new materials can help to relieve today’s mounting environmental challenges. Sustainable tires are created with environmentally friendly materials and low-emission manufacturing procedures.

They frequently use recycled or renewable materials, such as natural rubber, bio-oils, recycled tires, and recycled plastic bottles. This method promotes a circular economy by reducing reliance on nonrenewable resources.

3. Improved Fuel Efficiency

Sustainable tires have reduced rolling resistance, enabling fuel savings. This can minimize energy and fuel usage, as well as greenhouse gas emissions.

4. Reduced Emissions

When used, eco-friendly tires emit fewer hazardous emissions than standard tires. Soybean oil, for example, guarantees that the tire’s rubber compound remains malleable at varying temperatures while also helping to reduce the quantity of petroleum-based materials required for tire production.

To give a high level of grip, a high-quality silica made from rice husk waste residue, a byproduct of rice manufacturing, is also employed within the tire. In addition, polyester from recycled plastic bottles is converted into base chemicals for usage as technical-grade polyester in tire cords.

5. Extended Tire Life

Retread tires are less expensive and perform just as well as new tires, making them an efficient and cost-effective tire replacement option. By reusing recycled rubber and extending the life of important materials, retreading tires minimizes waste and provides environmental benefits.

Send your inquiry for prompt quotations!

Conclusion

Due to the low cost of labor required to grow and tap trees, rubber has been a relatively economical raw material for decades. However, the rubber industry does not seem to grow. To address the issue of natural rubber shortage, manufacturers must study new alternatives and work on other materials.

This blog has provided information on natural rubber alternatives and how these materials can help with tire industry manufacturing. So, be prepared to face the issue, and if you need new rubber materials and solutions for your next project, Hongju is all set to deliver as per your needs.

Why Choose Hongju for Rubber Products?

Hongju is a leading manufacturer and wholesale supplier of silicone rubber products. We specialize in the development and production of high-quality rubber products. Hongju adheres to the work ethics of quality, innovation, and customer satisfaction. We offer a wide range of rubber products using only environmentally friendly materials. If your industry is also ready to turn your company into a sustainable products supplier, Hongju has the materials you need.