You can establish yourself as an authority and stand out from the competition by offering custom exhaust gaskets. But how do you provide custom solutions and attract more customers? This article discusses the type of exhaust gaskets available and how you can customize them for your business.

What Are Exhaust Gaskets?

Exhaust gaskets are mechanical seals made from high-heat-resistant materials. It could be manufactured from embossed steel, silicone rubber, graphite, or ceramic composites.

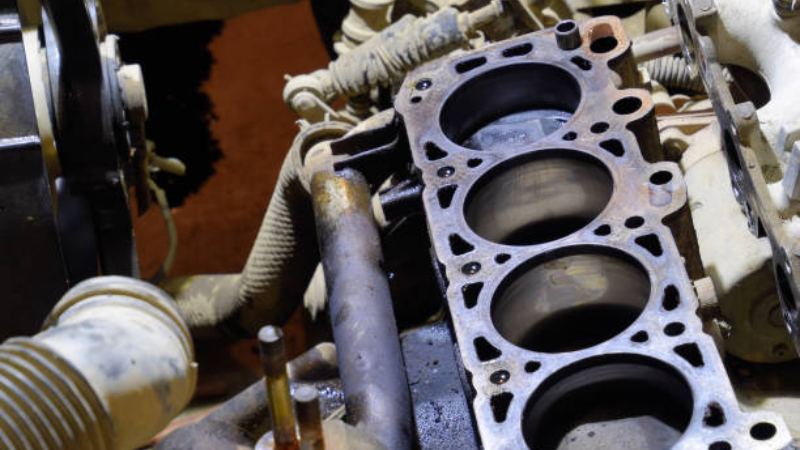

Sometimes, the gasket may be made from a combination of these materials. The exhaust gasket is essential to a vehicle’s engine because it seals the manifold and cylinder head.

What Do Exhaust Gaskets Do?

An exhaust gasket connects the exhaust manifold and cylinder head. This seal ensures the manifold redirects collected waste gases through the hole in the exhaust pipe. The manifold also pulls in new air simultaneously, filling the vacuum created by the exiting gas.

Furthermore, an exhaust gasket is critical to the function of a vehicle. It stops leaks and prevents temperature spikes from improving a vehicle’s performance. The exhaust gasket also protects the catalytic converter.

The Different Types of Exhaust Gaskets

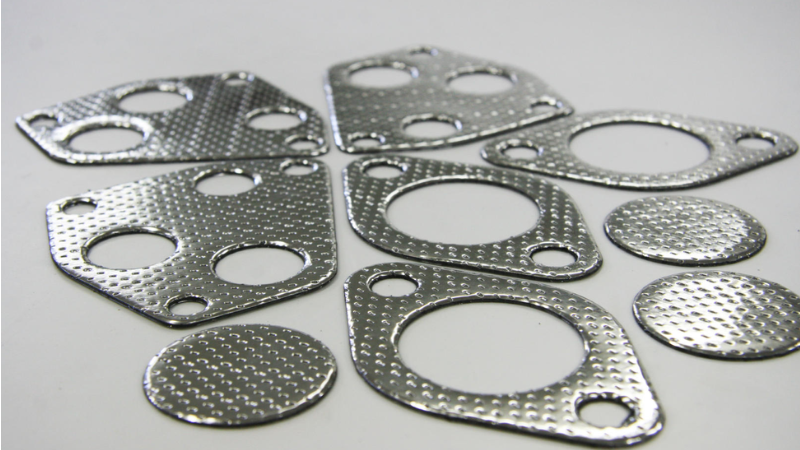

All exhaust gaskets have the same function. They prevent leaks and ensure gases move from the engine through the exhaust system. There are three types of exhaust gaskets; the most significant difference is the gasket’s location. The kinds of exhaust gaskets include;

Exhaust Manifold Gaskets

The exhaust manifold gasket is a seal located between the exhaust manifold and the engine head. This type of gasket can withstand extreme temperatures from gases and pressure from the cylinder.

The exhaust manifold gasket is usually made from two materials. The manifold side is often made from a metal like steel, while the engine head side is made from fiber. Consequently, there is less friction between the manifold and the gasket’s metal part.

Exhaust Flange Gasket

The exhaust flange gasket seals between the header pipe and catalytic converter. This type of gasket improves gas flow through the exhaust system. An exhaust flange gasket is made from steel and is resistant to high temperatures like the manifold gasket.

Header Gasket

Header gaskets seal gaps, allowing exhaust gases to flow through holes in the tailpipe without leaking. This type of gasket is often used between holes in the cylinder’s exhaust pipe, collector pipe, and manifold. Header gaskets are made from high-fiber materials containing steel fillers to withstand pressure and heat.

How to Make Custom Exhaust Gaskets for Your Business?

Many businesses produce exhaust gaskets, but you must stand out from the competition for increased sales and customer retention. Customization is a way to stand out and attract more customers. The process of making exceptional custom gaskets include;

Highlighting your business’s uniqueness

Many businesses sell custom gaskets, but what makes yours unique? It is best to highlight what products you offer that your competitor doesn’t. You can also incorporate what your customers love about your business.

For instance, if your returning customers do so because of your high-quality gaskets or personal service, add a personal touch to show your customers that you care about them.

Considering your customers’ needs

A custom exhaust gasket is a seal between two mating surfaces. When customizing the gasket, it is best to consider your customer’s needs. Since silicone rubber has several colors, you can customize gaskets in your customers’ chosen colors.

Generally, considering your customers’ needs ensures you create custom exhaust gaskets they will appreciate and use. You can also look into your customers’ feature requests based on past activity data and use them when producing custom gaskets.

Incorporating personalizations

Personalizing a custom exhaust gasket makes it unique and relevant to a specific user. For example, you can inscribe a customer’s initials, logo, or design during manufacturing. Packaging, temporary and permanent personalization are three ways to personalize exhaust gaskets.

Packaging is the simplest way to personalize custom exhaust gaskets. You can package your customer’s orders uniquely for an improved customer experience. In addition, you may use temporary personalization like stickers and labels. This type of personalization is especially suitable for mass-produced goods.

Permanent customizations may include engraving or printing. You can also produce the exhaust gaskets in custom colors. However, permanent personalizations may take a longer turnaround time, and mass production might not be easy.

Promoting customization services

After deciding on what and how to customize your exhaust gaskets, promoting your product is the next step. You can promote your customized gaskets on your Facebook and other relevant social media channels. In addition, you can post personalized content and run ads to increase reach and customer engagement.

Another way to promote the effectiveness of your customized gasket is to create blog posts or videos explaining the customization process and how they suit each customer. Showcasing your products and services establishes you as an expert in your field and builds customer trust and loyalty.

Advantages of Making Custom Exhaust Gaskets for Your Business

Customizing exhaust gaskets for your business offers numerous benefits, including;

- Increased customer satisfaction

As a business, creating custom exhaust gaskets makes it exclusive and with a personal touch. Customers may choose their designs, and the end product has sentimental value. They also feel like they are important to you and your business. Consequently, our customers will be more connected to your company and satisfied with their products.

- Building customer loyalty

Allowing your customers to choose customized exhaust gaskets establishes a connection between them and your business. This increases customer loyalty, retention, and referrals.

- Increased sales

Returning customers are a part of your business, contributing to your revenue. In addition, customers are willing to accept and pay more for a custom exhaust gasket as long as it has a personal touch. Also, because of the customizations, your customers may be willing to wait a little longer to receive their products.

- Better tools for customer insights and improved services

Businesses thrive on data and insights. It is best to monitor and measure your site statistics to understand what your customers watch and what they request. Your customers’ engagement and site statistics can help you restrategize and develop products based on their preferences.

Disadvantages of Making Custom Exhaust Gaskets for Your Business

Although making custom exhaust gaskets for your business offers numerous benefits, it also has downsides. These disadvantages include the following;

- Tricky implementation

Product customizations are significant, but implementing them en masse is not easy. You have to wait for your customers to accept their customizations before production. Therefore, you can’t stock up on exhaust gaskets ahead of time.

- Increased customer expectations

Offering your customers custom exhaust gaskets increases product prices and delivery timelines. Your return policy may also not be as flexible as usual. Consequently, your customers may have high expectations or be turned off from the customization process.

Therefore, tailoring the experience and managing your customer expectations is best. For example, you may have to offer custom exhaust gaskets to your customers as a premium service to justify the pricing and production timeline.

Things You Need to Make Custom Exhaust Gaskets

The primary things you need to make custom gaskets are an appropriate material and a molding process.

Material

The gasket can be made from several materials, including cardboard, neoprene, silicone, cork, cast iron, and nitrile rubber. The properties of each material translate to the gasket, impacting its efficiency and functionality. The most popular gasket materials include;

- Cork

Cork is a lightweight, stable, and waterproof material. In addition, its high oil, wear, and temperature resistance make it a popular gasket material. Cork has an upper-temperature limit of 275 degrees Fahrenheit, which is lower than other gasket materials. In addition, being a natural material, cork is vulnerable to fungi, mold, and fungi attacks.

- Cork and rubber

Because of its natural limitations, cork is reinforced with rubber to produce a better-performing gasket. This material combines the cork’s compressibility and rubber’s flexibility and resilience. Cork and rubber gaskets have high weather, acid, and chemical resistance.

- Silicone

Foam, sponge, and solid silicone are excellent gasket materials. The difference between these types of silicone rubber is their cell structure. Nevertheless, they all possess properties of silicone, including high thermal stability, flexibility, and resilience.

In addition, silicone gaskets are inert, waterproof, and stable at high and low temperatures.

- Natural rubber

Natural rubber is an excellent elastomer for rubber gaskets. It has excellent resistance to UV light, making it suitable for outdoor use.

In addition, this gasket material is stable even in applications that use mild acids, alkalis, and inorganic salts. The downside to this gasket material is that it is unsuitable for applications requiring oils and solvents.

- Urethane

Urethane is a popular exhaust gasket material. This material is waterproof and elastic. It is suitable for volatile weather conditions and retains its properties even in fluctuating temperatures. Furthermore, urethane gaskets are flexible and can conform to any shape.

- Neoprene

Neoprene is a flexible, waterproof material with excellent UV and ozone resistance. In addition, the material has good tear strength and is resilient.

However, this material may not withstand petroleum-based fuels. Other properties of neoprene gaskets are their corrosion resistance and chemical stability over a wide temperature range.

- Compressed non-asbestos

Asbestos is strong, fibrous, and has high chemical and heat resistance. Unfortunately, this material is harmful to human health. Hence, compressed non-asbestos. Compressed non-asbestos is an alternative to asbestos.

This material is resilient and has excellent heat, oil, and gas resistance. The material is also waterproof and remains stable in steam applications.

Molding process

There are different processes for manufacturing custom exhaust gaskets. Each method has its benefits and downsides. Some of the most common gasket manufacturing methods include;

- Die-cutting

Die-cutting is the fastest gasket manufacturing method. This method involves passing the rubber material through a rotary die. As the die rotates and contacts the material, it cuts out the desired gasket. This method cuts out gaskets en masse in a short period.

- Compression molding

Compression molding is ideal for more flexible gasket materials. This process creates the gasket shape on a heated mold. It is a low-volume production process suitable for creating less intricate gaskets.

After placing the gasket material into the heated mold, it is compressed to form the exhaust gasket. After curing, the mold is opened to release the final custom gasket.

- Injection molding

Injection molding is also fast, producing a high volume of gaskets. This process involves melting the gasket material and putting it in the injection molding machine. The machine then injects the molten material into the open mold.

After cooling and curing, the gaskets are removed. Injection molding is not only fast, but it is also accurate. The produced gaskets have little to no flash. Consequently, this method is especially ideal for high-precision gasket production.

Conclusion

Custom exhaust gaskets help you stand out from the competition. You can customize your exhaust gaskets for your business, addressing customer needs and improving sales.

You can run personalized content and ads and use cookies and data to determine your customers’ interests. This information can then help you improve and tailor your customer experience.

Contact Hongju for Customized Rubber Products!

Hongju is a rubber products manufacturer with capabilities for creating custom exhaust gaskets. Regardless of your product specifications, we are ready to create high-quality, tailor-made products that exceed your expectations.

Our customer support is always ready to help you understand how our services are used and how our all-inclusive solutions can benefit you. Reach out to us today!