Rubber injection molders and suppliers in China are a mixed bag. Experience is no longer a consistent gauge of expertise, and even an excellent manufacturer will have their limitations, which you must consider.

Luckily, we have compiled this list of China’s top 10 rubber injection molding companies and suppliers for you. The companies on this list have been carefully selected based on different factors to help you choose a manufacturing company you can count on in 2024.

An Overview of the Rubber Injection Molding Industry

Rubber injection molding is a manufacturing process where uncured rubber is injected at high pressure into a mold. The heat from the pressure sets off the curing process, also called vulcanization, and the rubber material takes the shape of the mold in the injection molding machine.

Similar to a plastic mold, the rubber mold used in this process can be used to produce parts that have complicated geometries and designs. With a good mold design, the level of precision can be very high.

Rubber injection molding is used for a wide range of materials including:

- Natural rubber

- Nitrile rubber

- Silicone rubber

- Fluorosilicone rubber

- Neoprene, etc.

There are different forms of injection molding including organic rubber injection and liquid silicone rubber injection molding. The main products manufactured using this process include bumpers, bushings, diaphragms, grommets, isolators, o-rings, seals, and plugs.

The versatility of rubber injection molding has made it the go-to production method for the world’s largest manufacturers in various industries including the automotive industry, food and beverage, medical, etc.

Factors to Consider When Choosing Rubber Injection Molding Companies

When you have many manufacturers and suppliers to consider, it can be difficult to tell them apart. This can be easier if you know the key factors to consider when assessing different injection molding companies.

Product Experience

Although experience with a specific production process is important, sometimes you want manufacturers that offer even more. In this case, you may want a manufacturer who has experience making rubber products similar to yours.

When rubber and plastic injection molding companies have never manufactured a certain type of product, they may struggle to meet your standards. This can be a problem when dealing with complex designs, tight tolerances, or niche materials.

Available Production Capacity

If you need one million parts, you need a manufacturer who can handle an order that large. A manufacturer’s capacity is determined by factors such as:

- Number of injection molding machines available to them

- Types of injection molding machines (automatic or semi-automatic)

- Number of employees

- Availability of materials, etc.

If a manufacturer is lacking in one or more areas, filling your order may take longer.

Quality Control Procedures

Manufacturing is expensive and time-sensitive. You do not want to invest your money and time in thousands of defective products.

Look into the quality control procedures used by any manufacturer you’re considering. The manufacturer’s procedures need to test the qualities that define the success or failure of your product.

Minimum Order Quantity (MOQ)

Some manufacturers have a minimum order quantity. This can be necessitated by the scale of their operations.

When you need a small number of rubber products, confirm that they are above the manufacturer’s MOQ threshold. Some manufacturers may not accept orders smaller than the MOQ or charge a premium for their services.

Pricing Structure

Does the manufacturer charge by the hour or per product? It’s important to establish this so you don’t find yourself with a manufacturing bill that eats into your profit margin.

Top 10 Rubber Injection Molding Companies in China

| Position | Company Name | Year Established | Location (City) | No. of Employees |

|---|---|---|---|---|

| 1 | Hongju Silicone Co. Ltd | 1999 | Dongguan | 51 - 100 |

| 2 | Qingdao Wielian Plastic & Rubber Co. Ltd | 2008 | Qingdao | 51 - 100 |

| 3 | Gofai Rubber Co. Ltd | 2013 | Qingdao | 101 - 200 |

| 4 | Tebate Co. Ltd | 2018 | Dongguan | 10 - 50 |

| 5 | RiLong Co. Ltd | 1990 | Shenzhen | 300 |

| 6 | Ningbo Yombo Rubber & Plastic Products Co. Ltd | 2011 | Yuyao | 101 - 150 |

| 7 | Xiamen Better Silicon Rubber Co. Ltd | 2018 | Xiamen | <50 |

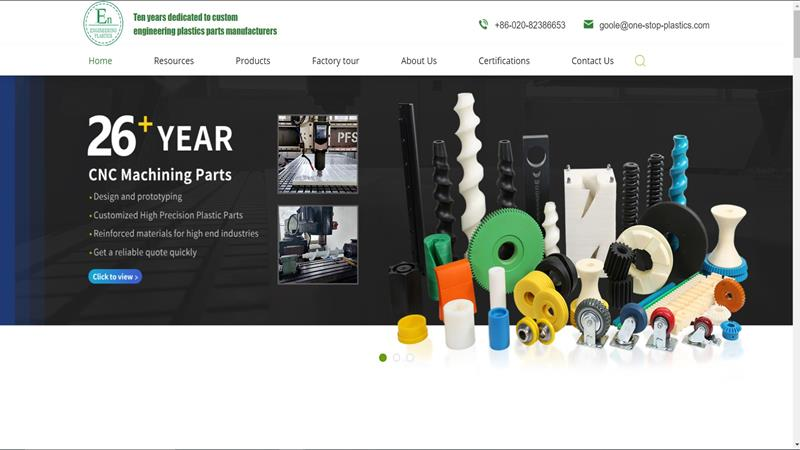

| 8 | Guangdong Engineering Plastic Industry Co. Ltd | 1988 | Guangzhou | 70 - 120 |

| 9 | Zhongshan Melon Plastic Tech Co. Ltd | 2007 | Zhongshan | 51 - 100 |

| 10 | Xiamen Kingtom Rubber Plastic Co. Ltd | 1996 | Xiamen | 200 - 300 |

The table provides a summary of 10 rubber injection molding companies in China. These companies have set themselves apart by the quality of their rubber injection molded products, expertise, and commitment to delivering a good experience for their customers.

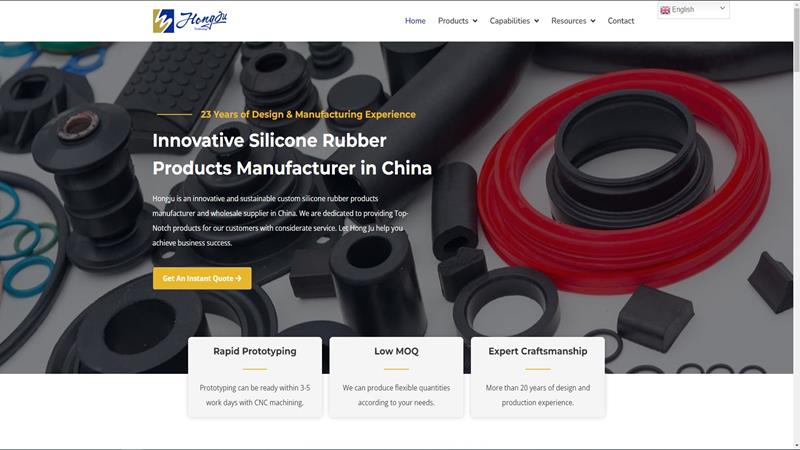

1. Hongju Silicone Co., Ltd.

Hongju Silicone is a leading company in the area of injection molding. The company uses innovative technology to manufacture rubber products including grommets, gaskets, O-rings, and consumer goods.

This company was founded in 1999 and works with an experienced team of engineers and designers. Customers can expect short lead times, production of complex part designs, and excellent customer service.

The company offers design guidelines on its websites for prospective customers. Its rapid prototyping services also make it easier to test different designs affordably before production starts.

Pros

- Round-the-clock customer support

- Support for different CAD formats

- The company is ISO 9001 certified

- Competitive production costs

- Excellent range of rubber materials

Cons

- The company has other interests apart from injection molding

- The current maximum injection molding volume is 13.3 cubic inches

Inquire Now for Fast Quotations!

2. Qingdao Weilian Plastic & Rubber Co., Ltd.

Qingdao Weilian was founded in 2008 and has quickly risen to be an important player in the rubber injection molding industry. The company’s catalog already boasts 100 different products that include rubber shock absorbers, silicone rubber seals, and even OEM products.

This company has an R&D department to help it develop and produce products using different materials. The aftersales service attends to the needs of a long list of clients from all over the world including Hong Kong, Japan, North America, and Europe.

Pros

- Familiarity with overseas markets and customers

- At least 5 quality inspectors hired by the company

- Investment in research and development helps the company innovate

Cons

- The company isn’t strictly focused on injection molding and also makes plastic products

- The company website is challenging to navigate

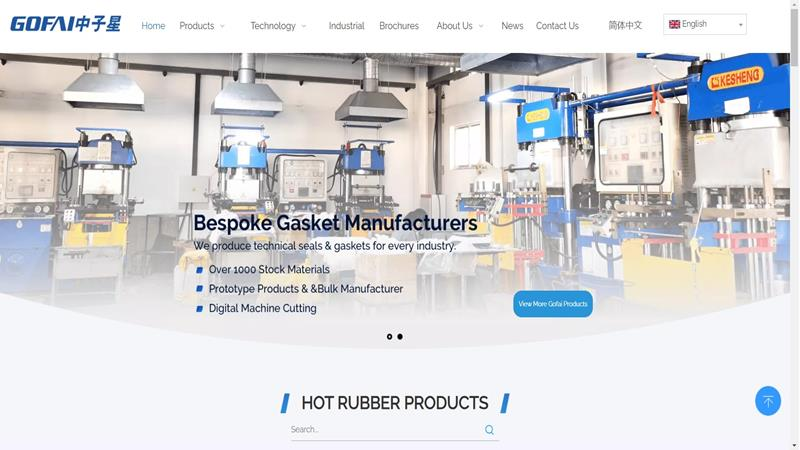

3. GOFAI Rubber Co., Ltd.

Gofai Rubber was only recently established in 2013. This, however, belies the expertise and experience of the team working there which goes back much further.

The company is headquartered in Qingdao City where it operates as both a designer and manufacturer of rubber injection molded products. Its main products now include seals, gaskets, bumper pads, boots, bellows, and soundproofing.

Pros

- High level of rubber-related engineering expertise

- Good approach to customer support

- A multi-step approach to product design, approval, and production improves customer satisfaction.

- English-speaking support staff

Cons

- Rubber injection molding competes with other interests and products within the company

- The company is relatively new to the scene

4. Tebate Co., Ltd.

Tebate is one of the youngest rubber and plastic injection molding companies and suppliers on this list. This company was only founded in 2018 and is located in Dongguan City.

Tebate manufactures various injection molded parts including medical instruments, parts for consumer goods, and automotive parts. The company works with a team of 8 engineers and operates 20 injection molding machines.

The company prides itself on the advanced technology it uses to achieve high precision in its products. It also offers additional services including overmolding and insert molding.

Pros

- Good production volume

- Excellent manufacturing precision

- Good level of expertise

Cons

- The company is very young

5. RiLong Mold Co., Ltd.

RiLong Mold started as a supplier of high-precision parts using plastic injection molding in 1990. In 2006, they started the process of including rubber products by setting up a base of operations in Dongguan.

Across all its operations, the company now employs 300 experienced staff. Their R&D team alone has more than 30 experts constantly improving their rubber and plastics machinery and processes.

RiLong Mold has a diverse product range today and it includes rubber molds, housings, membrane keypads, etc. The company has attained various certifications including ISO 9001 and ISO 14001.

Pros

- The company has worked with big-name clients including Honeywell and Epson.

- Weekly updates on orders and same-day response to questions.

- Experience working with American, Asian, and European customers.

- Many post-processing options are available, e.g., laser etching and spray painting.

Cons

- The company’s operations are not centered on rubber injection molding

6. Ningbo Yombo Rubber & Plastic Products Co., Ltd.

Ningbo Yombo is a leading manufacturer of rubber products. Its base of operations is in Yuyao City near both the Ningbo and Shanghai ports.

The company’s main products include rubber gaskets and O-rings. They work with a range of materials that include silicone and nitrile rubber to provide products with excellent temperature and oil resistance.

Pros

- The company has various quality testing equipment including an aging box.

- The company has a manageable range of products.

- May be a good fit for smaller customers

Cons

- No listed international certifications.

- The company hasn’t been around for very long.

7. Xiamen Better Silicon Rubber Co., Ltd.

Xiamen Better Silicon Rubber Company offers rubber injection molding services from Xiamen City. This company was recently established in 2018.

Better Silicon currently has four separate production operations. The liquid silicon rubber injection molding is done in a clean room. Among their product offerings are smartphone rubber components and medical devices.

The company also has its mold-making plant where it manufactures molding equipment for plastic and rubber injection molds. It works with medical and food-grade silicone materials.

Pros

- The company is a good match for clients looking for silicone products for medical equipment.

- The company is ISO certified.

- Molds can be made in-house

Cons

- The company has limited experience

- The company mainly works with two rubber materials

8. Guangdong Engineering Plastic Industry Company Co., Ltd.

Guangdong Engineering Plastic Industry Company has been around since 1988. The company’s operation currently covers approximately 10000 square meters. Rubber injection molding is just one in a long list of services this company offers which include CNC machining and plastic injection molding.

The company uses many different raw materials and they are all 100% virgin. The company manufactures many customer rubber products using silicone rubber.

Pros

- The company has many years of experience

- The scale of operation is large

- Has ISO certification

Cons

- The company’s main focus seems to be CNC machining.

9. Zhongshan Melon Plastic Tech Co., Ltd.

Zhongshan Melon Plastic Tech was started in 2007 in Zhongshan City. The company currently employs 90 staff including 10 technical experts. 40% of the employees have been with the company for more than 7 years.

Today, the company manufactures products using a wide range of rubber materials including EPDM, NR, and PU. Its main products include gaskets, O-rings, and parts for home appliances. The company also makes molds for liquid silicone rubber injection molding.

Pros

- A good source of rubber molds

- Works with many rubber materials

- Has loyal and experienced technicians

- Has a detailed quality assurance process

Cons

- The company is more focused on the European market

- Uses ASTM, not ISO standards to assess the quality of rubber materials

10. Xiamen Kingtom Rubber Plastic Co., Ltd.

Xiamen Kingtom Rubber Plastic Company is located in Xiamen City. It was founded in 1996 and has produced products for various industries including heavy machinery, automotive applications, electrical products, etc.

The company has an extensive list of certifications including ISO 9001 and ISO 14001. The company has a sales office in the US.

Pros

- The company has established an international presence, especially in the US

- Experience making an extensive list of rubber products

- The company has 25 staff in its R&D department

- Many years of experience

Cons

- The company has less experience producing products for certain industries.

Final Thoughts

Choosing a reliable rubber injection molding company or supplier in China is far from straightforward. A big-name manufacturer isn’t always better for your needs in this industry, but you may not get the capacity you want from a smaller manufacturer.

To make this process less strenuous, this guide highlights some of the best available rubber injection molding companies you can work with. The companies on this list don’t just deliver good products but understand how to cater to the needs of an international company.

Why Choose Hongju Silicone For Your Rubber Injection Molding Needs

Do you need rubber injection molding services but don’t know where to start? We have a solution for you. Hongju Silicone has been around since 1999. It is one of the most experienced rubber and plastic injection molding companies on this list and can deliver an unmatched level of service. When you need assistance injection molding you’ll have access to a long list of experts with many years of experience. Contact us today to get your rubber injection molding questions answered.