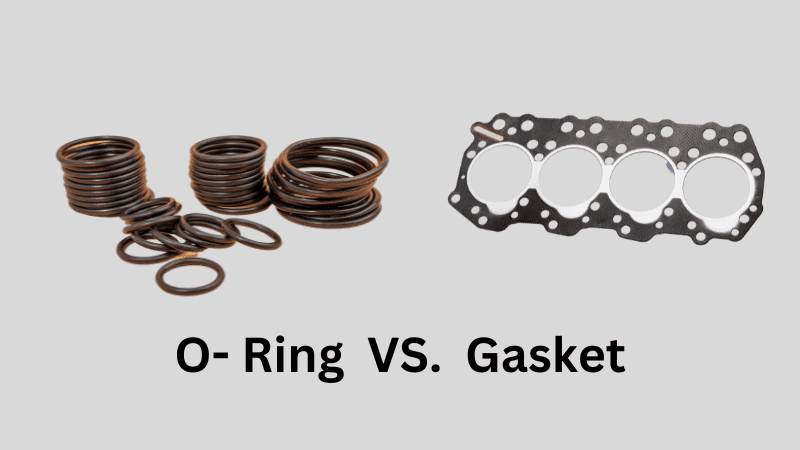

O-rings and gaskets are sealing products that can prevent fluid or gas leaks. Both gaskets and O-rings are made using flexible materials, but gaskets can also be made out of other rigid polymers and metals. These two usually sit between 2 or more parts. You can use both of them in motors, machines, and various fixtures and plumbing. On the surface, it seems like they are the same. But you can’t interchange these two.

What is an O-ring?

An O-ring is a type of gasket you can use as a mechanical seal. Although it can come in different sizes, thicknesses, or dimensions, the O-ring only has one shape – a donut shape. It’s a circular elastomer piece with a hollow center that you can also refer to as a packing joint.

The purpose of o-rings is to prevent fluid or gas leakage and to create a sealed surface where 2 or more parts meet. It usually sits in a groove where another part will join. When the parts join together, it puts pressure on the O-ring in the grooved part. Sometimes referred to as a packing joint or toric joint, the only design distinctions for these circular, hollow-centered, mechanical seals are size, thickness, and dimension. The sealing happens because the pressure on the o-ring makes it mold itself in the surrounding space.

O-rings are available in different elastomer materials like silicone rubber, nitrile rubber(NBR), and fluoropolymers. To choose the right material, you have to consider the application. This will also help define the elastomer’s hardness, thickness, size, and other qualities. The bottom line is that it should perform well under the right operational and environmental situations.

Despite the pressure, the elastomer material of the o-ring allows it to maintain the integrity of its shape. It can withstand pressure of up to 5,000 psi (pounds per square inch). It retains its shape even if there’s an additional vibration from the mechanical device. This makes the O-ring a very effective sealing product to keep liquids, air, and gas from escaping.

O-rings are used in joints and connections between pipes, hoses, and fittings in hydraulic systems to prevent fluid leakage. Rotating shafts O-rings are used as rotary shaft seals to prevent the leakage of lubricants or contaminants in rotating components like gearboxes and axles. O-rings typically fit into a groove at the interface where two rounded surfaces are joined together. The seals can also be used in high-pressure applications, and static or dynamic applications, such as jet engines and automobile engines.

Among the typical applications of o-ring are aerospace and automotive. This includes the following:

- Food containers and processing equipment

- Fuel systems

- HVAC systems (Heating, Ventilation, and Air Conditioning)

- Hydraulics

- Medical and pharmaceutical equipment or devices

- Oil seals for engines and devices

- Pipe joints

Send Your Inquiry Now!

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

What is a Gasket?

A gasket is a flat piece of material that sits between two flat surfaces and serves as a mechanical seal designed to provide a liquid-tight seal. But instead of having a looped circular shape, it’s usually a flat material. The main shape of gaskets is usually circular, too. But it can come in different shapes like rectangles, squares, ovals, triangles, or any other shape to fit complex mating surfaces.

Unlike o-rings, gaskets only use elastomer as their material – allowing it to retain its shape despite being up under pressure. Gaskets use elastomers, but they also use various materials like corks, foam, metals, complex polymers, etc.

The choice of shape, size, and material will mostly depend on the purpose of the gasket. If you plan to make it sit between the engine block and cylinder head of an automotive engine, you’re better off using a metal gasket.

While gaskets can use hard materials, it’s still essential that it has compression functionality. This means it has to be pliable enough to conform to the complex mating surfaces where it sits.

When using hard materials, the gasket must fit the design specifications. That’s how it can fit between two surfaces to create a liquid-tight seal. This prevents gas or liquid from leaking and contaminating other parts of the mechanical system.

The typical sealing applications of gaskets include the following:

- Aerospace industry

- Automotive and other modes of transportation

- Electrical motors and devices

- Electronics

- Food and beverage applications

- Handheld communication devices

- Medical devices and equipment

- Paper and pulp

- Power generators and transformers

- Telecommunication devices

Send Your Inquiry Now!

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

Main Differences between an O-ring and a Gasket

A lot of sealing products are usually interchangeable. However, O-rings and gaskets aren’t one of them. Although both are mechanical seals, there are specific differences that you should focus on.

These differences will help you identify which of the two is ideal for your application.

- Despite these similarities, there are fundamental differences between the two. Most obviously, the two sealing devices vary significantly in appearance. O-rings have a looped and circular shape. Gaskets are flat seals that sit between two mating surfaces. While all o-rings are gaskets, not all gaskets are o-rings.

- O-rings only use flexible materials because they require flexibility in their application. Gaskets can use elastomers and other materials like complex polymer, metal, cork, foam, etc.

- O-ring can only be circular. Gaskets can take on other shapes – depending on their application. The material that gaskets use can be pliable enough to allow customization into various mating surfaces – no matter how complex.

2 Considerations before Choosing between Gaskets and O-rings

If you want to know which mechanical seal to use, there are 2 essential things you need to consider.

The first is the shape of the seal needed. If the mechanical device’s mating surface has a groove, then o-rings will work best. But if the seal will sit on a flat surface, a gasket is best for the application. If the mating surface also requires a specific shape, that will tell you if you should go for o-rings and gaskets.

The second consideration is the pressure and temperature that the mechanical seal will deal with. Both gaskets and o-rings can work well in a wide range of temperatures. However, gaskets can withstand higher temperatures, while o-rings are the best choice for extreme-pressure applications.

Send Your Inquiry Now!

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

Conclusion

Gaskets and O-rings are both ideal mechanical seals. Knowing how the material will hold up in certain temperatures or under severe pressure is vital to prevent product failure. You must know the application first to decide which of the two you can use. For whatever purpose, Hongju Silicone can help you produce the proper rubber mechanical seal that fits your design and requirements.

Get Top-Of-The-Line O-rings And Gaskets From Hongju

Hongju Silicone has years of experience in molded silicone rubber products. Being one of the best suppliers and manufacturers of O-rings products in China, you can request complex designs, and we can meet those requirements for you.