This guide delves deep into the world of LIM, exploring its intricacies, benefits, applications, and so much more.

Whether you’re a seasoned manufacturer, an aspiring engineer, or just curious about cutting-edge production techniques, this comprehensive exploration promises insights that could redefine how you perceive modern manufacturing.

Whether you’re creating medical components, automotive parts, or electronics, LIM helps you get reliable results every time. In this guide, you’ll learn how it works, why it’s better than traditional methods, and how it can benefit your next project.

What is Liquid Injection Molding?

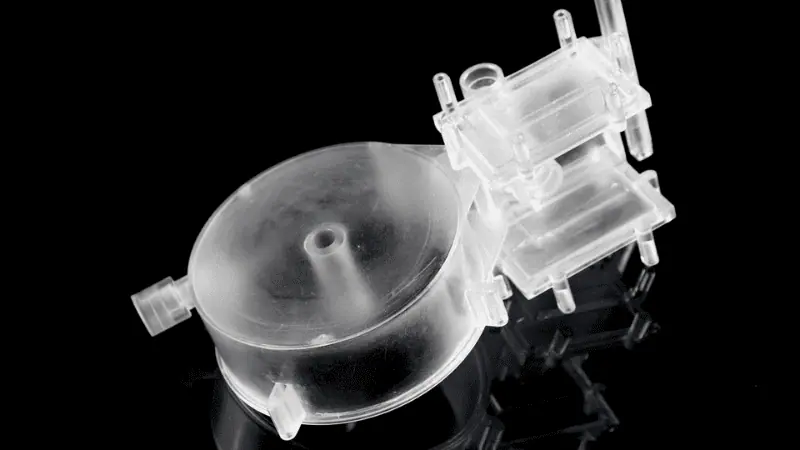

Liquid Injection Molding (LIM) is a specialized method in the molding process, primarily used for producing parts from liquid silicone rubber (LSR) and similar high-consistency elastomers.

Unlike traditional molding methods, which rely on a solid, granulated form of material, LIM utilizes a liquid form, paving the way for unique benefits and capabilities.

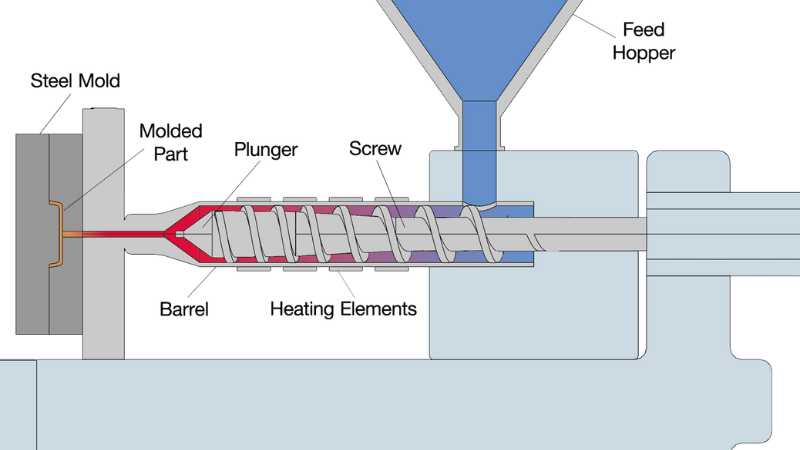

The Basic Mechanism

At its core, LIM involves injecting a two-part liquid silicone compound into a heated mold. The compound then cures within the mold, taking the desired shape of the end product. Once cured, the part is ejected from the mold, ready for post-processing or assembly.

Why LIM?

The primary allure of LIM lies in its precision and efficiency. Given that the starting material is in a liquid state, it easily fills even the most intricate mold designs, ensuring detailed and accurate parts.

Furthermore, the use of liquid materials often results in reduced waste, faster cure times, and a more streamlined production process.

As industries continue to demand parts that are both complex in design and consistent in quality control, LIM stands out as a preferred choice for manufacturers globally.

What are the Advantages of LIM over Traditional Methods?

Liquid Injection Molding (LIM) offers several advantages over traditional manufacturing methods, making it a popular choice for producing high-quality parts. Let’s explore some key benefits of LIM:

1. Excellent Part Quality with Minimal Waste Material

One of the significant advantages of LIM is its ability to provide excellent part quality while minimizing waste material. Unlike traditional methods that may result in excess flash or scrap, LIM ensures precise and clean part production.

This reduces the need for additional finishing processes, saving both time and resources. With LIM, manufacturers can achieve intricate designs and complex geometries without compromising on quality.

2. Faster Production Cycles

Compared to conventional methods, liquid injection molding enables faster production cycles. The process involves injecting liquid silicone rubber (LSR) or other thermosetting materials into a mold cavity under high pressure.

This rapid injection allows for quick curing and shorter cycle times. As a result, manufacturers can produce larger quantities of parts in less time, increasing overall productivity.

3. Consistent Part Dimensions and High Precision

LIM excels at maintaining consistent part dimensions and achieving high precision throughout the production process. The liquid silicone rubber flows evenly into every detail of the mold, ensuring uniformity across multiple parts.

This level of accuracy is crucial in industries such as medical devices or automotive components, where precision is paramount. With LIM, manufacturers can meet tight tolerances consistently, reducing the likelihood of part rejection or rework.

4. Better Automation and Enhanced Design Flexibility

Due to design limitations, liquid injection molding machines can automate tasks that compression molders cannot compete with.

As a result, cycle times are cut down, consumers save money, and fewer workers are required due to the higher speed of our automation. Liquid injection molding also offers enhanced design flexibility compared to traditional methods like compression molding or transfer molding.

How does the Liquid Injection Molding Process work?

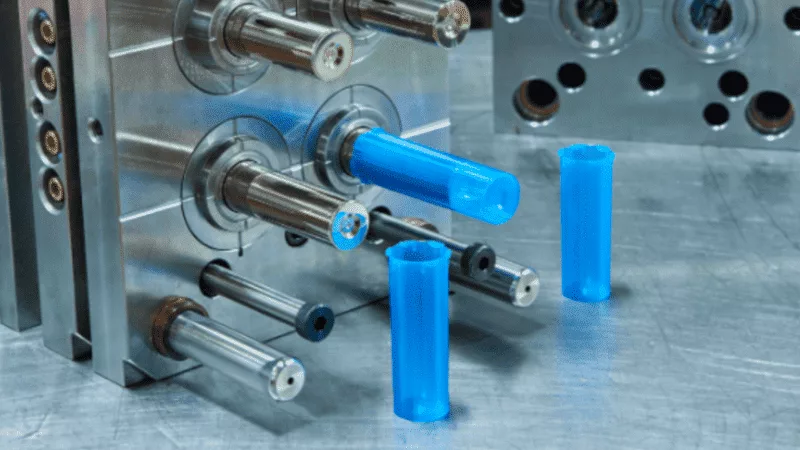

A standard liquid injection molding machine relies on a metered pumping device and an injection unit with a dynamic or static mixer attached. Liquid injection molding (LIM) is a highly efficient manufacturing process used to create various products from liquid silicone rubber.

Let’s delve into the details of how this innovative molding process works.

Preparing the liquid silicone rubber material

The first step of the LIM process involves preparing the liquid silicone rubber (LSR) material. LSR is a two-part platinum-cured elastomer that consists of a base and a curing agent. These components are mixed together in precise ratios to achieve the desired physical properties and curing time.

Once the LSR material is thoroughly mixed, it is loaded into an injection unit for further mixing, reaction processing.

Injecting the material into a closed mold under high pressure

With the LSR material prepared, it is time for injection. The mold used in liquid injection molding typically consists of two halves that fit together perfectly to form a closed cavity. This mold design ensures accuracy and precision during production.

The LSR material is injected into the closed mold under high pressure using an injection unit. The high-pressure environment helps fill every intricate detail of the sealed mold, ensuring uniformity and consistency in the final product.

Curing and part removal

After injecting the LSR material, it undergoes a curing process within the closed mold. Curing can occur through various methods, such as heat or chemical reactions, depending on the specific requirements of the product being manufactured.

During this stage, cross-linking takes place within the LSR material, transforming it from its liquid state to a solid elastomer with excellent mechanical properties.

The process is designed for repeatability, ensuring each molded product is consistent with the last. Advanced machines even offer real-time monitoring and feedback systems, ensuring optimal conditions are maintained throughout the process.

Extensive Technique of Liquid Injection Molding

Liquid Injection Molding (LIM) is not just a straightforward process; there are various techniques within LIM that cater to different product requirements, production scales, and design intricacies.

Delving into the more extensive techniques within LIM can offer deeper insights into its flexibility and adaptability. Here’s an overview:

Micro LIM

Used for producing extremely small and intricate parts, Micro LIM requires specialized equipment and molds to ensure the fidelity and accuracy of the final product. These might be used in medical devices or microelectronics.

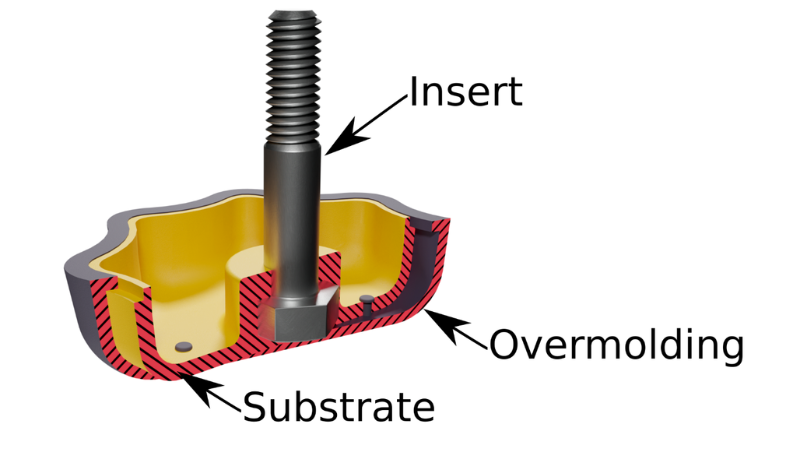

Overmolding

This technique involves molding silicone rubber over a preformed part, usually made of a different material. It’s used to create composite products that benefit from the properties of both materials, like a tool with a hard plastic core and a soft silicone grip.

Cold Runner Systems

To minimize material wastage and enhance the efficiency of the molding process, cold runner systems are employed. They facilitate the direct injection of LSR into the mold cavities without a spillover, ensuring that there’s minimal waste.

Insert LIM

Metal, plastic, or other material inserts can be placed into the mold, and LSR is molded around them. This is popular for products that need to combine the flexibility of silicone with the strength or functionality of another material, such as surgical instruments.

Understanding the breadth of techniques available in LIM showcases the versatility of this method. Depending on the product’s requirements, manufacturers can choose and even combine techniques to achieve the desired outcome efficiently.

What Materials can be used in Liquid Injection Molding?

Liquid Injection Molding (LIM) is a unique process primarily centered around the molding of high-viscosity liquids.

While the process can theoretically accommodate various materials, the most commonly used material is Liquid Silicone Rubber (LSR). This section explores the primary material used in LIM and its key characteristics.

Liquid Silicone Rubber (LSR)

Liquid Silicone Rubber is the mainstay of the LIM process due to its distinctive properties:

- Versatility: LSR can be formulated to have a wide range of hardness, elasticity, and mechanical properties. It’s available in different grades, from soft and flexible to rigid.

- High-Temperature Resistance: LSR can withstand high temperatures, making it suitable for applications that experience thermal stress or need post-process sterilization.

- Chemical Resistance: LSR is resistant to many chemicals, oils, and solvents, ensuring the durability of the molded components in challenging environments.

- Biocompatibility: Certain medical-grade LSR formulations are biocompatible, meaning they’re safe for use in medical devices and implants that come into contact with the human body.

- Optical Clarity: Some LSR grades can be transparent, making them ideal for optical components.

Fluorosilicone Rubber (FSR)

While not as commonly used as LSR, Fluorosilicone Rubber is sometimes chosen for LIM due to its enhanced chemical resistance, particularly against fuels, oils, and solvents. It retains many of the beneficial properties of regular silicone rubber.

High-Consistency Rubber (HCR)

Although typically used in traditional compression and transfer molding, some high-viscosity HCR formulations can be adapted for LIM. These materials are more like traditional rubber in consistency before curing.

Note: While LIM is mostly associated with LSR, technological advancements continue to push the boundaries of the materials that can be used in this process.

However, the unique characteristics of LSR, especially its flow properties and rapid curing times, make it the dominant choice for LIM.

What are the Limitations of the Process?

Liquid injection molding (LIM) is a highly versatile process that offers numerous advantages for producing complex and intricate parts. However, like any manufacturing method, it also has its limitations.

Understanding these limitations is crucial for making informed decisions when considering LIM as a production option.

Higher Initial Tooling Costs

One of the primary limitations of liquid injection molding is its higher initial tooling costs compared to other processes.

The complexity involved in designing and fabricating molds specifically tailored for LIM can result in increased expenses upfront. This factor may deter some manufacturers who are working with tight budgets or require short production runs.

Viscosity Constraints

The viscosity of liquid silicone rubber (LSR) used in LIM imposes certain limitations on the process. LSR typically exhibits higher viscosities than thermoplastics used in traditional injection molding.

As a result, the flow characteristics during injection can be restricted, especially when dealing with intricate geometries or thin-walled components. Manufacturers must carefully consider these constraints to ensure successful mold filling and part replication.

Mold Complexity

Liquid injection molding may not be suitable for all geometries due to mold complexity. While LIM excels at producing intricate designs with fine details, excessively complex shapes can pose challenges during both mold design and manufacturing stages.

The more intricate the geometry, the greater the risk of complications such as trapped air pockets or incomplete filling of cavities. Manufacturers should evaluate whether their desired part design aligns with the capabilities of LIM to avoid potential issues.

Despite these limitations, liquid injection molding remains an excellent choice for many applications that demand precision and high-quality parts.

Design Considerations for Liquid Injection Molding

When designing LSR products, it is important to take into consideration the design parameters related to liquid silicone injection molding. However, to maximize the benefits and minimize issues, it’s essential to understand some critical design considerations for LIM:

- Draft Angles: Always incorporate draft angles into your mold design. This facilitates easier removal of the part from the mold, minimizing potential damage and reducing wear on the mold.

- Wall Thickness: Maintain consistent wall thickness as much as possible to ensure even curing and minimize issues like warping. If variable thickness is necessary, aim for smooth transitions.

- Venting: LSR is a low-viscosity material, which means it can easily trap air. Ensure your mold design has adequate venting to allow trapped air and volatiles to escape.

- Gating: Consider the gate’s location and type carefully. Proper gating ensures a complete fill and minimizes potential defects like air traps or weld lines.

- Tolerances: While LSR can achieve tight tolerances, it’s crucial to understand its behavior, including potential shrinkage, to design the mold accurately.

- Texture and Finish: LSR can replicate the mold’s surface finish very accurately. If a specific texture or finish is desired on the final part, it must be integrated into the mold design.

- Part Integration: If the LSR part needs to be bonded with another component (like a plastic or metal piece), the design should facilitate this integration, considering factors like bonding agents or mechanical interlocks.

Generally speaking, design considerations for LIM are about the same as design considerations for plastic injection molding. However, there are a few points to note.

By addressing these considerations in the design phase, manufacturers can optimize the LIM process for efficiency, reduce defects, and ensure the final product meets or exceeds the desired specifications.

How Accurate are the Final Products?

Liquid injection molding (LIM) is renowned for its ability to produce final products with exceptional accuracy. This advanced manufacturing process utilizes metering units to precisely control the flow of liquid silicone rubber (LSR), resulting in high dimensional accuracy and repeatability.

One of the key advantages of LIM is its capability to achieve tight tolerances, meeting even the most demanding specifications. The metering units carefully regulate the quantity of LSR injected into the mold cavity, ensuring that each part is consistently produced within precise measurements.

This level of accuracy is particularly crucial in industries where precision is paramount, such as medical device manufacturing or aerospace engineering.

Moreover, finished parts manufactured through liquid injection molding exhibit excellent surface finish and detail reproduction. The LSR material has inherent self-lubricating properties, enabling it to flow smoothly within complex mold geometries and intricate features.

As a result, the final products showcase a remarkable level of detail and intricacy, capturing even the finest design elements.

What are Some of the Most Common Applications of LIM Technology?

Liquid Injection Molding (LIM) is a versatile manufacturing process that finds applications in various industries. Let’s explore some of the most common uses of this technology.

Medical & Healthcare

- Catheters and Tubing: LIM is extensively used to produce flexible and biocompatible tubing and catheters for various medical applications.

- Respiratory Devices: Masks, valves, and other components, especially those needed in ventilators, benefit from the precision and biocompatibility offered by LIM.

- Surgical Instruments: The ability of LIM to create detailed and sterilizable components makes it ideal for certain surgical tools and devices.

- Implantable Devices: Due to its biocompatibility, LSR produced via LIM is used in specific implants and medical devices.

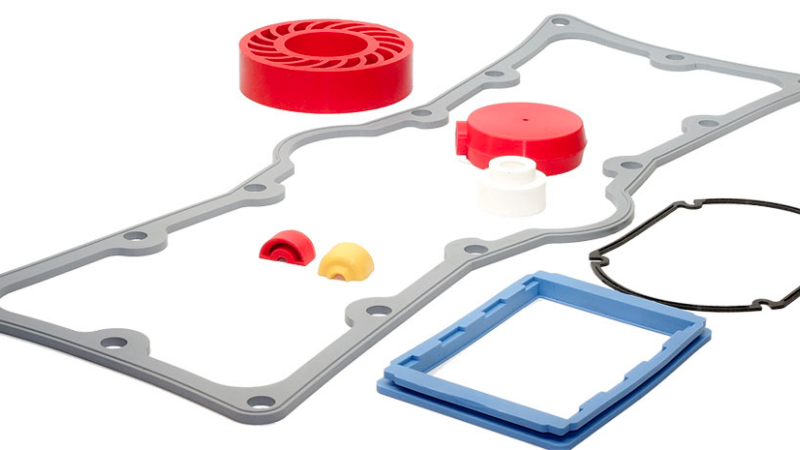

Automotive

- Seals and Gaskets: The durability and temperature resistance of LIM-produced parts make them suitable for various seals and gaskets in vehicles.

- LED Headlights: LIM technology is employed to produce parts of LED headlights due to its transparency and heat resistance.

- Sensor Components: Many sensors in modern vehicles use components produced through LIM for their precision and reliability.

Consumer Electronics

- Buttons and Keypads: LIM offers the ability to produce water-resistant and durable buttons and keypads for devices like remote controls, phones, and other gadgets.

- Protective Covers: LIM is used to create protective and shock-absorbing cases for electronics.

Industrial

- Sealing Elements: LIM is used to create seals for various machinery and equipment, ensuring longevity and resistance to wear and tear.

- Vibration Dampeners: Certain industrial equipment components made through LIM serve to reduce vibration and noise.

Aerospace

- Component Seals: LIM-produced seals are used in various aerospace applications due to their durability and resistance to extreme conditions.

Are there Any Health or Safety Concerns With Using LIM Technology?

Liquid injection molding (LIM) has gained significant popularity in various industries, especially in the production of medical devices. While liquid silicone rubber (LSR), the primary material used in LIM, is generally considered safe, there are certain health and safety concerns that manufacturers should be aware of to ensure a secure working environment.

One important aspect to consider is the proper handling of LSR during the manufacturing process. Although LSR itself poses minimal risks, it is crucial to follow specific precautions to prevent potential harm.

These precautions include wearing appropriate personal protective equipment (PPE), such as gloves and goggles, to avoid direct contact with uncured silicone. Ensuring proper ventilation in the workplace can help minimize exposure to any fumes or vapors emitted during the molding process.

Another consideration relates to additives or fillers that may be incorporated into certain LSR materials for specific applications. These additives can enhance properties like flame resistance or improve mechanical performance.

However, some additives may have health considerations during processing. Manufacturers must closely follow safety guidelines provided by material suppliers when working with these specialized formulations.

To ensure the utmost safety when utilizing LIM technology for medical device production, it is essential for manufacturers to adhere strictly to industry regulations and recommendations.

Regulatory bodies such as the Food and Drug Administration (FDA) provide guidelines specifically tailored for medical device manufacturing processes involving LIM.

What Happens to Your Mold When It Is Not Maintained Properly?

Mold maintenance plays a crucial role in the overall performance and longevity of your mold. Neglecting proper maintenance can have detrimental effects on both the quality of your parts and the efficiency of your production process. Let’s explore some of the consequences that can arise when molds are not maintained properly.

Increased Wear and Tear

Lack of regular mold maintenance can result in increased wear and tear, which directly impacts part quality. Over time, molds endure significant stress due to repeated use, high temperatures, and pressure.

Without proper care, this wear and tear can lead to various issues such as dimensional inaccuracies, flash formation, or even complete failure of the mold.

To mitigate these problems, it is essential to implement a comprehensive maintenance routine that includes cleaning, lubrication, and inspection.

Regular cleaning removes any debris or contaminants that may accumulate on the mold surface during production runs. Lubrication helps reduce friction between moving parts within the mold assembly. Inspection allows for early detection of any signs of damage or deterioration.

Mold Fouling or Buildup

One common problem resulting from poor mold maintenance is fouling or buildup on the mold surface. During production runs, residue from plastic materials can accumulate on the mold cavity walls or other critical areas.

This buildup not only affects part quality but also disrupts the smooth flow of molten material during injection.

Fouling can lead to various production issues such as incomplete filling of cavities, short shots, or even blockages in complex geometries. To prevent these problems, regular cleaning using appropriate solvents or cleaning agents is necessary.

Tips for Maintaining Your Liquid Injection Molded Products

Proper storage conditions are crucial to prevent material degradation and maintain the integrity of your liquid injection molded (LIM) products.

By following essential guidelines, you can ensure that your durable parts remain in optimal condition for an extended period.

1. Store in a Controlled Environment

To protect your liquid injection molded products from environmental factors that could compromise their quality, it is important to store them in a controlled environment. Maintain a stable temperature within the recommended range and control humidity levels to avoid moisture-related issues.

2. Clean Regularly and Appropriately

Regular cleaning is essential for maintaining the performance and longevity of your LIM products. Use appropriate cleaning methods based on the specific materials used in their manufacturing. Avoid abrasive cleaners or harsh chemicals that could damage or degrade the surface of the parts.

3. Monitor Environmental Factors

Monitoring environmental factors such as temperature and humidity can significantly aid in preserving liquid injection molded products. Fluctuations in these factors can affect the structural integrity of the parts over time.

Consider using sensors or monitoring devices to keep track of these variables and make necessary adjustments when needed.

4. Protect from Sunlight and UV Radiation

Exposure to sunlight and ultraviolet (UV) radiation can cause discoloration, brittleness, or other forms of degradation in LIM products. To prevent this, store your parts away from direct sunlight or use protective coatings that offer UV resistance.

By following these tips, you can ensure that your Liquid Injection Molded products remain functional and durable for the duration of their intended lifespan. Proper care and attention will not only save costs in replacements but also ensure reliable performance.

Conclusion

The world of manufacturing has witnessed many innovations, but few are as versatile and efficient as Liquid Injection Molding (LIM). From its precision in crafting intricate designs to the wide array of materials it accommodates, LIM stands as a testament to engineering prowess.

Whether you’re interested in the vast applications of LIM technology or simply trying to maintain the longevity of your molded products, it’s evident that LIM offers a wealth of benefits, both for producers and consumers alike.

Choose Hongju for Top-tier LIM Solutions!

Interested in leveraging the precision and efficiency of LIM for your projects? Dive deeper into this transformative manufacturing process with our expert team. At Hongju, we provide cutting-edge solutions tailored to your needs. Contact us today and bring your designs to life with unparalleled accuracy and quality!

Contact us today to streamline your manufacturing and bring your most demanding designs to life—with speed, accuracy, and consistency.