We have compiled a list of the top 10 medical-grade silicone manufacturers in China. These are manufacturers who can provide medical-grade silicone products that meet international quality standards at sensible prices.

An Overview of the Medical-Grade Silicone Industry

Before we examine the different manufacturers and suppliers of medical-grade silicone products, it’s important to understand what this material and industry are all about.

What is Medical-Grade Silicone?

Medical-grade silicone is silicone rubber that has been approved for medical and pharmaceutical applications. It’s also classified as class VI silicone. This type of silicone must meet higher manufacturing and purity standards to ensure they are as safe for medical applications.

How is Medical-Grade Silicone Made?

All types of silicone start as quartz, an abundant substance that’s mainly made up of silicone dioxide. The quartz is taken through several processes that convert it into elemental silicon and finally into raw silicone.

The raw silicone can be in the form of liquid silicone rubber or high-consistency rubber. This material cures during the manufacture of the final silicone product which can be done through processes such as liquid silicone rubber injection molding and compression molding.

Medical and food-grade silicone are usually platinum-cured while silicone for industrial applications tends to be peroxide-cured.

Why Is Medical-Grade Silicone Popular?

Medical device manufacturers prefer medical-grade silicone because:

- It is biocompatible.

- It is considered non-toxic.

- Silicone is more durable than other elastomers.

- Medical silicone is hypoallergenic.

- The material is inert, i.e. it doesn’t chemically react with other substances.

- Silicone has excellent temperature resistance.

Common Applications of Medical Grade Silicone

- Inhalation masks and balloons for hospitals

- External covers for electronics used in medical and pharmaceutical environments

- Medical tubings e.g., IVs, catheters, and shunts

- Prostheses

- Parts of medical equipment e.g. MRI machines

Factors to Consider When Choosing a Medical Grade Silicone Manufacturer

To ensure you’re working with the right manufacturer, ensure that they meet at least the following conditions.

1. Third-Party/International Certifications

It’s not enough for a manufacturer to claim that their products and processes meet international standards, you need proof from a third party. Ensure the manufacturer has verifiable certificates that their processes and materials meet the standards of bodies like the ISO, FDA, and LFGB.

2. Manufacturer or Seller

A company might sell medical-grade silicone products but they may not manufacture them. This poses a few challenges such as tracing the origins of materials and an inability to get custom products from the company.

3. Quality Testing

Does the manufacturer test every product or are samples selected for testing? For some products, it may not be necessary or feasible to test every single product. However, some products may need to undergo certain tests. Ensure your manufacturer of choice will stick to your testing guidelines.

4. Experience and Expertise

Manufacturing medical-grade silicone products can be challenging since a poorly controlled process can lead to defective products. This is why you need a manufacturer that works with a team of experienced experts who understand the process well.

5. Manufacturing Facility

Some medical products must be manufactured in clean rooms. Ensure your manufacturer’s facilities can meet the conditions needed to properly manufacture your product.

Top 10 Medical Grade Silicone Manufacturers and Suppliers in China

| Position | Company Name | Year Established | Location (City) | No. of Employees |

|---|---|---|---|---|

| 1 | Hongju Silicone Co., LTD | 1999 | Dongguan | 51 – 100 |

| 2 | Hangzhou Trifanz Medical Device Co., LTD | 2019 | Hangzhou | 11 – 50 |

| 3 | Ningbo Luke Medical Devices Co., LTD. | 2011 | Yuyao City | 101 – 200 |

| 4 | Xiamen Neway Rubber and Plastic Products Co., LTD | 2002 | Xiamen | 51 – 100 |

| 5 | Saferlife Products Co., LTD | 2010 | Guangzhou | 51 – 100 |

| 6 | Milesun Rubber Co., LTD | 2002 | Guangzhou | 201 – 500 |

| 7 | Hochuen Medical Co., LTD | 2015 | Shenzhen | 201 – 500 |

| 8 | Yeeshine Technology Co., LTD | 2003 | Dongguan | 201 – 300 |

| 9 | Nanchang YiLi Medical Instrument Co., LTD | 2012 | Nanchang | 101 – 200 |

| 10 | McReat (Guangzhou) Bio-Tech Co., LTD | 2015 | Guangzhou | 201 – 300 |

This table offers a summary of the top 10 medical-grade silicone manufacturers in China. The companies on this list are judged on their expertise, technical experience, and ability to provide customers with high-quality medical silicone products.

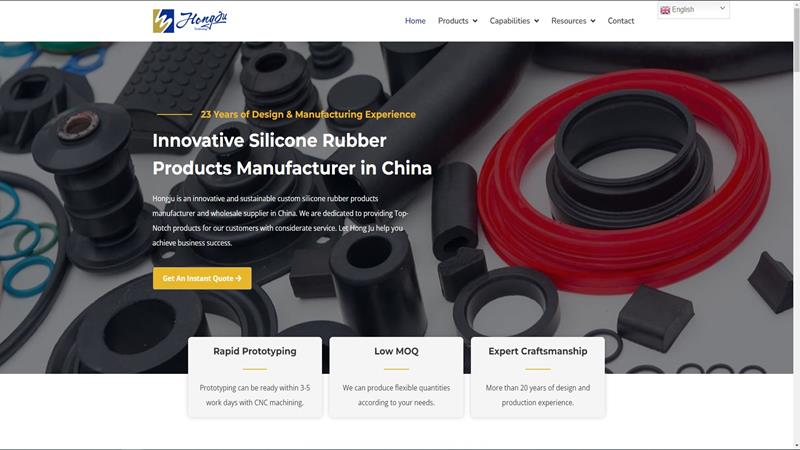

1. Hongju Silicone Co., LTD.

Company Overview

Hongju silicone is a company with more than 23 years of manufacturing experience. The company has distinguished itself in the area of silicone rubber manufacturing by producing high-quality parts that have attained both CE and FDA approval.

ODM and OEM manufacturing services are an important part of Hongju silicone’s operations. They have produced products for clients operating in the European and American markets.

The company provides excellent support to all clients through its English-speaking support team and uses eco-friendly materials for its products.

Pros

- The company has experience manufacturing FDA and CE-approved products.o

- They have experience manufacturing products for the medical industry.

- The company is ISO 9001 certified.

- Excellent support from start to finish.

Cons

- Not all the company’s products are for the medical industry.

Inquire About Our Silicone and Plastic Products!

2. HangZhou Trifanz Medical Device Co., LTD.

Company Overview

Located in the Yuyang Bio-Industrial Park, Hangzhou Trifanz Medical Device Co., Ltd is a company that specializes in the development and production of catheters for medical applications.

This company was founded in 2019, but it has a research and development team that brings almost 20 years of industry experience with them. They manufacture medical silicone products including endotracheal tubes, breathing circuits, and laryngeal mask airways.

The company adheres to strict quality standards and has passed CE inspection. They are ISO 13485 certified and can offer ODM or OEM services if desired.

Pros

- The company’s main focus is the production of medical devices.

- The company is ISO 13485 certified.

- Trifanz has a highly skilled workforce.

- They have partnered with international bodies such as the American Anesthesia Association.

Cons

- Trifanz doesn’t specialize in custom medical-grade silicone products.

- The company is still young.

3. Ningbo Luke Medical Devices Co., LTD.

Company Overview

Ningbo Luke Medical Devices was established in 2011 and it specializes in the development and production of medical devices for high-tech companies.

The company has many years of experience developing and making medical devices with a special focus on consumable devices made using silicone and plastic. Ningbo Luke’s products are manufactured in class 100,000 clean rooms.

The company manufactures silicone products using liquid silicone injection molding and extrusion molding. They have attained ISO 13485 certification.

Pros

- Ningbo Luke is experienced in manufacturing medical devices.

- The company has ISO13485 certification

- The company has multiple manufacturing processes available.

Cons

- Products that need clean rooms above class 100,000 can’t be manufactured.

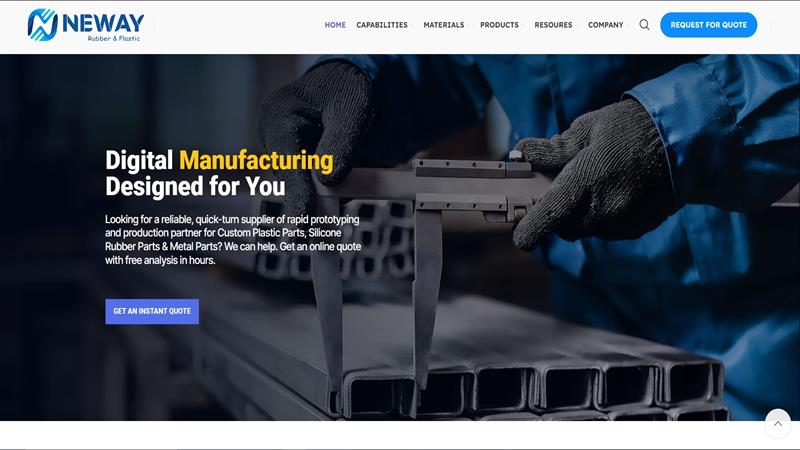

4. Xiamen Neway Rubber and Plastic Products Co., LTD.

Company Overview

Xiamen Neway manufactures custom silicone parts for both medical and food applications. Their products include a wide range of silicone kitchenware and plastic parts. The company also has an in-house team that designs and builds molds for rubber and plastic injection molding.

This company was established in 2002 and since then has risen to become a leading manufacturer that has produced products for the American and European markets.

For medical silicone parts, customers can have products made using several processes including injection molding, compression molding, die cutting, and transfer molding. The company’s raw materials have been tested for compliance by multiple bodies.

Pros

- The company has a lot of experience in manufacturing silicone rubber products.

- Xiamen Neway can make products using multiple processes.

- The company’s processes and materials have been vetted and certified.

Cons

- The company is invested in different fields apart from medical silicone product manufacturing.

- Some customers may need help with the many available materials and process options.

5. Saferlife Products Co., LTD.

Company Overview

Saferlife Products was launched in 2010. It mainly supplies disposable medical products. Their products are used in sports therapy and healthcare. The company has a factory that currently has more than 1000 square meters of floor space.

Saferlife Products is ISO 13485 certified. Their tapes have been approved for use by the FDA and CE. The company offers a variety of medical silicone products including breath resuscitators, waterproof dressing, and earplugs.

Pros

- The company is ISO 13485 certified.

- The company is focused on the manufacture of products for medical applications.

- Saferlife has multiple products that have been vetted by the FDA.

Cons

- Saferlife Products has a limited range of medical silicone products.

- There is no indication that the company manufactures custom silicone products.

6. Guangzhou Milesun Rubber & Plastic Technology Co., LTD.

Company Overview

Milesun Rubber & Plastic Technology is part of the Milesun Group of companies that was established in 2002. The company now produces and supplies a range of silicone parts and products and has factories covering 15000 square meters.

The company’s products are used in various industries in addition to the medical industry. The company has attained ISO 9001 certification and its products can meet different standards including FDA and CE.

Its silicone products include kitchenware and watch bands.

Pros

- The company has many years of experience.

- Milesun rubber & plastic is ISO certified.

- Their products can meet FDA and CE standards.

Cons

- Medical silicone product manufacture is a small part of the company’s operations.

- The company’s primary focus doesn’t seem to be the medical industry.

7. Hochuen Medical Co., LTD.

Company Overview

Despite having been founded in 2015, Hochuen Medical has risen quickly and now dwarfs other companies in the field of medical device manufacturing.

This company has become one of the main manufacturers for clients seeking In Vitro Diagnostics devices and other medical products. This is helped by the fact that the company has three factories, including two in China.

The company leadership is composed of medical experts and they even have class 10000 cleanrooms for manufacturing.

Pros

- The company’s leadership is made up of experts in various medical fields.

- Hochuen Medical is ISO 13485 certified.

- They have offices in China, the USA, and Singapore.

- Multiple manufacturing methods are available for liquid silicone rubber.

Cons

- Customers may not get a personalized service from a company with such a large scope and footprint.

- No product page on the website.

8. Yeeshine Technology Co., LTD.

Company Overview

Yeeshine Technology launched in 2003 and has been offering a range of services including injection molding and CNC prototyping.

The company has 20 individuals in its engineering and technical team. It has 87 injection molding machines and 30 people in its quality management team.

The company has manufactured different silicone products in the past using compression and injection molding processes. Some of its products are intended for medical applications.

Pros

- Parts can be made using either injection molding or compression molding.

- The company has a large staff.

- Quality control is a key consideration for the company.

- The company has many years of experience.

Cons

- The manufacture of medical silicone products is a small part of what the company does.

- Limited information is available on the company’s experience manufacturing medical devices using medical-grade silicone.

9. Nanchang YiLi Medical Instrument Co., LTD.

Company Overview

YiLi Medical has been around since 2012 with its first factory starting operations in 2013. Just one year later, the company got both ISO and CE certification.

Today, the company manufactures multiple products using medical-grade silicone including catheters, laryngeal mask airways, endotracheal tubes, and urine bags. The company also offers ODM and OEM manufacturing services.

The company’s products are manufactured in class 100000 clean rooms and 100% of their manufactured products are tested. Free samples are available for certain products.

Pros

- This company is focused on the manufacture of medical devices.

- Many of the company’s products have attained FDA and CE approval abroad.

- The company’s products have been used in many countries including the UK, Germany, and Saudi Arabia.

Cons

- The company doesn’t have clean rooms above class 100000.

- OEM/ODM products don’t seem to be at the center of the company’s operations.

10. MCREAT (Guangzhou) Bio-Tech Co., LTD.

Company Overview

MCREAT (Guangzhou) Bio-Tech was established in 2015. The company has a plant area covering 5,300 square meters and 2,200 square meters of its production workshop is a class 100,000 clean room.

This company has ISO 13485 certification and manufactures medical-grade silicone products including laryngeal masks, catheters, gastric tubes, and breathing circuits.

Pros

- The company’s main focus is the manufacture of medical products.

- The company has a catalog of silicone products.

- Some of the company’s products have attained FDA and CE approval.

Cons

- OEM services are available but may not be the focus of their operations.

- Clean rooms above level 100,000 are not currently available for manufacturing.

Conclusion

Medical-grade silicone is one of the most useful materials today. It has turned out to be an ideal replacement for products such as latex which can affect some patients negatively.

When you need a product made using medical-grade silicone, you need manufacturers who can deliver on this promise. This list of medical silicone manufacturers and suppliers in China offers many good options you can reach out to today.

Why Pick Hongju For Your Medical Grade Silicone Needs?

Hongju Silicone is a company with years of industry experience and a respected name when it comes to the manufacture of silicone rubber products. They are ISO-certified and have made products that have been approved by agencies such as the FDA and CE. When you have questions about medical-grade silicone manufacturing there will be an expert at Hongju Silicone ready to provide an answer.