The performance, application properties, and price of each material, however, differ. In this article, we will have a brief discussion about these two materials, their uses in the medical device industries, and their similarities and differences in assisting healthcare professionals in making the right decision:

What Is Silicone?

The complete silicone polymer molecule is composed of repeating units of molecular units that are joined together to form long chains of the polymer. The chains are composed of monomers (repeated chemical units) that alternate between silicon and oxygen atoms. A silicone polymer chain is formed from these molecules, with hydrocarbons and other chemical groups branching off them.

What Is Latex?

Natural latex suspensions are thick and milky-white in color. Latex rubber gloves are popular forms of this material. The finished material of latex is highly flexible and able to withstand bending, elongation, and pulsating forces.

The producers of medical devices and products have significantly increased the usage of latex in their production. These include stethoscopes, diaphragms, endotracheal tubes, adhesive taps, blood pressure cuffs, rubberized bedsheets, artificial latex, and anesthesia and oxygen masks. However, an increased use of latex has significantly increased allergic reactions in humans.

The Nature Of Composition: Differentiating Silicone From Latex

Despite their similarities, silicone rubber and latex are different in their compositions: silicone rubber is based on silicon dioxide, while latex is based on resin. Both materials can be distinguished in a very simple way! By stretching it, you can tell that latex is generally more elastic and has a stronger pulling force. Furthermore, silicone latex differs in many ways, as we will explain below:

The Nature Of Composition Of Silicone

Silicone is an inorganic thermosetting polymer most often mixed with a base polymer and a catalyst to create a liquid formulation. A chemical reaction occurs upon mixing, causing it to cure due to an exothermic reaction.

Three subcategories of silicone exist:

- Liquid silicone rubber (LSR)

- Heat-cured rubber (HCR)

- Room temperature vulcanization (RTV)

At room temperature, RTV-2 is a mixture of a pre-polymer and a catalyst that cures when exposed to room temperature, as opposed to RTV-1, which is cured when exposed to air. Different methods can be used to process other silicone classes.

In most cases, RTV-1 is dispensable in tubes for immediate use and air curing. It is necessary to mix the two liquid components of RTV-2 just prior to use.

The most common techniques for processing silicone are

- Open mold casting

- Compression molding

- Injection molding

In terms of physical and mechanical properties, silicones come in a variety of options. Depending on the hardness, they range from Shore A 10 to Shore A 90. The silicone material is highly resistant to high temperatures, UV rays, ozone, and cut and tear but is resistant to abrasion, tensile strength, and breakage.

The Nature Of Composition Of Latex

The two main types of latex are natural and synthetic latex.

- Natural Latex

Hevea brasiliensis is the scientific term for the rubber tree that produces natural latex. Natural latex rubber is produced by slicing the bark of this tree and exuding its milky, white fluid. Dunlop or Talalay are two specific methods used to turn fluid into rubber material. The material produced by either process will be highly elongating, tear-resistant, and moisture-resistant. There is a possibility that some individuals find natural latex rubber allergic to their bodies.

- Synthetic Latex

Styrene-butadiene (SBR) polymer chains are used to synthesize synthetic latex, also known as emulsion polymers or engineered latex. There is no allergic reaction associated with synthetic latex. The most common technologies for processing natural and synthetic latex include

- Rubber injection molding

- Calendering, extrusion

- Immersion dipping

- Compression molding

Applications And Benefits Of Silicone In Medical Devices

In the medical field, silicone rubber can be used in a variety of applications, whereas latex rubber can be used only in certain situations. Many medical consumables utilize silicone rubber, such as silicone breathing masks, silicone infusion tubes, and orthodontic braces. In addition, silicone is used for the manufacture of artificial prostheses such as endonasal splints, cardiac pacemakers, cardiac stents, and more, primarily because of its superior safety as compared to latex. Human skin can potentially react to latex when it comes in contact with it.

There are some other applications of silicone in medical devices:

- High-temperature cookware, such as utensils and bowls

- Silicone catheters, hoses, implants

- Molds

- Industrial sealing and bonding

- Seals, gaskets, and caulk

Applications And Benefits Of Latex In Medical Devices

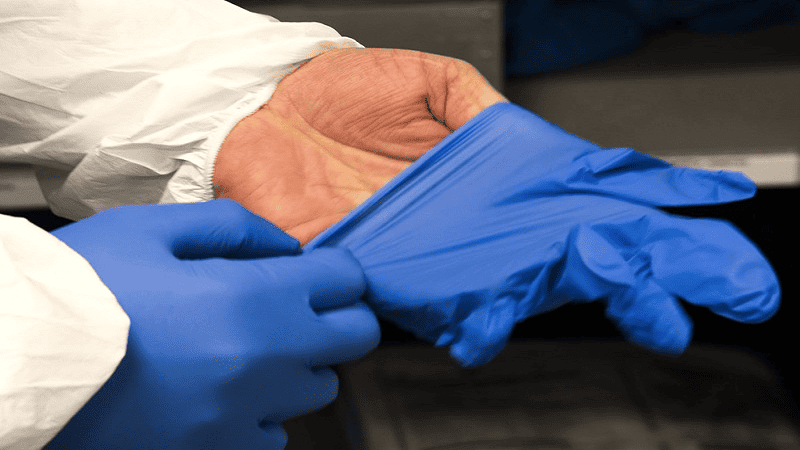

Silicone and latex both find use in medical products when it comes to medical applications. However, their medical applications differ significantly. Doctors typically wear latex disposable gloves during injections or surgeries. They have excellent barrier properties and anti-slip properties, as well as an extremely high level of elasticity, which makes them ideal for most individuals. In addition to being comfortable and easy to use, their ergonomic design enhances doctors’ ability to diagnose more efficiently.

The following are the other applications of latex in medical applications:

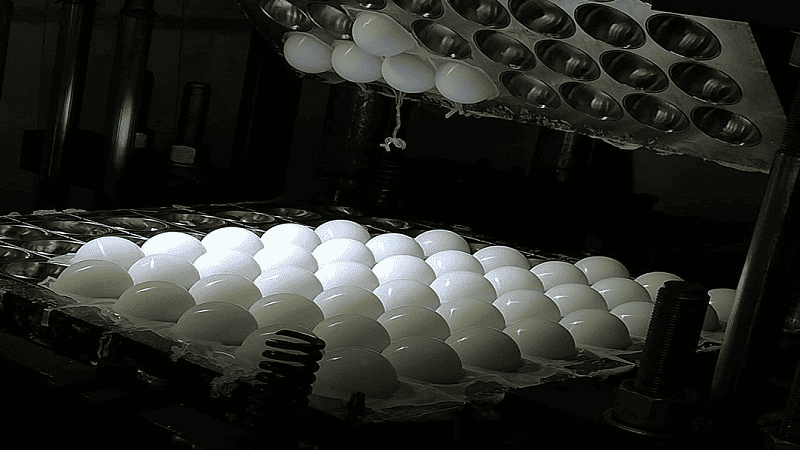

- Latex gloves, swim caps, balloons, boots

- Cosmetics

- Open-cell foam mattresses

- Catheters

- Rubber bands

- Adhesives

Compared to latex, silicone rubber is widely used in the production of medical supplies because of its durability. Many medical products use this element to enhance their durability and reliability of the medical treatment.

Comparative Analysis: Silicone Vs. Latex

Here is the comparative analysis of the physical and mechanical properties of silicone and latex (table):

| Property | Silicone | Latex |

|---|---|---|

| Chemical Structure | Polysiloxane | Natural rubber latex, or synthetic latex (e.g., styrene-butadiene) |

| Elasticity | High | Very High |

| Tensile Strength | Moderate to High | High |

| Tear Resistance | Moderate | High |

| Temperature Resistance | High (-50 to 200°C) | Moderate (-20 to 70°C) |

| UV Resistance | High | Poor |

| Chemical Resistance | Good to various chemicals | Moderate, varies by chemical |

| Biocompatibility | Generally High | Moderate to High (but may cause allergies) |

| Water Absorption | Low | Moderate |

| Oil Resistance | Moderate to High | Poor to Moderate |

| Transparency | Can be made transparent | Generally opaque |

| Gas Permeability | Moderate | Low |

| Aging Resistance | Excellent | Moderate (Can deteriorate with time and exposure to elements) |

| Cost | Generally more expensive | Less expensive |

| Odor | Odorless | May have a rubbery smell |

| Biodegradability | Poor | Better, especially for natural latex |

| Applications | Medical implants, tubing, gaskets, kitchenware, etc. | Gloves, balloons, medical devices, etc. |

The silicone and latex comparison table indicates the different properties of these two materials and their differences. Silicone shows higher thermal resistance as compared to latex. On the other hand, latex has more abrasion resistance. The comparative properties of silicone and latex can help medical professionals make the right decision about the material they choose according to their needs.

Safety Concerns And Environmental Impact: Comparing Silicone And Latex

Since natural latex is made from trees, which are renewable resources, it can be considered a sustainable material. Synthetic latex, on the other hand, is manufactured using petroleum, which is not sustainable. There is no way to recycle synthetic or natural latex, but natural latex is considered biodegradable. Bacteria can decompose it, but it takes approximately six months to four years for it to become wholly decomposed.

Unlike some thermoplastics, silicone cannot be recycled since it is a thermosetting polymer. Silicone decomposes into harmful chemicals at temperatures higher than its maximum operating temperature. Since silicone is manufactured using petroleum products that are not renewable or sustainable resources.

The Real Cost Of Silicone Versus Latex

The cost of silicone tends to be relatively high since it is considered a high-tech engineering material. There is a wide variation in silicone prices depending on the grade. As far as latex is concerned, natural latex is more expensive as compared to synthetic one. Since silicone is more suitable for various applications, silicone is typically more expensive when compared with latex.

Conclusion

From the above discussion, it is clear that latex and silicone are different from each other not only in composition but also in applications, materials, characteristics, and other factors. However, the choice between latex and silicone depends upon the usage and requirement of the situation. Silicone may be pricy as compared to latex, but the overall results of using silicon and the safety can compensate for the high price.

Get Top-Of-The-Line Products From Hongju

Hongju provides you with the perfect business solution with its innovative technology and services. Our silicone rubber parts are the perfect solution for your needs. It is the Hongju team’s mission to assist you in forming the ideal silicon product for your application by working together with you.