Having this much choice can trigger headaches when choosing the right type of plastic for the products. Are you in the same boat? Well! Don’t worry; we will comprehensively discuss the 7 types of plastics. It will help you make effective decisions and choose the best plastic for your products. Here we begin!

1. Polyethylene Terephthalate (PET)

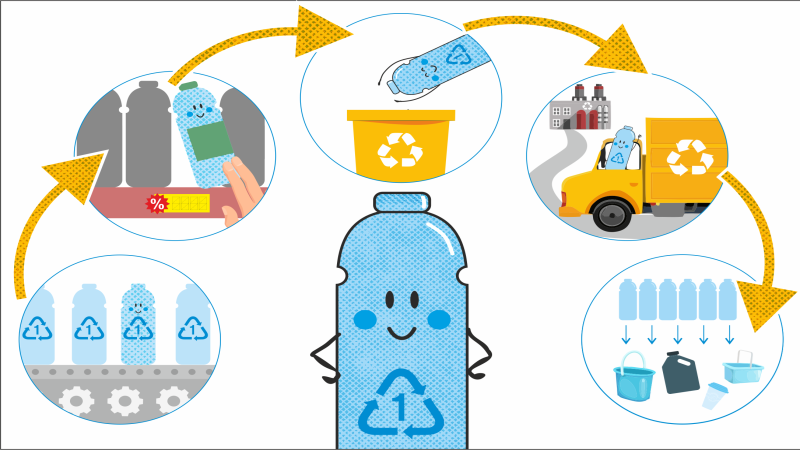

Polyethylene terephthalate (PET) is a universal polymer. It is one of the most commonly used plastics subjected to recycling. This plastic resin is a member of the polyester family and consists of numerous qualities.

Its strength, clarity, and exceptional chemical resistance make it the most desired choice. Polyethylene terephthalate is immensely convertible and found in anything from drink packaging purposes to disposable cups and egg cartons to plastic bottles and cold beverage cups.

Properties of PET

There are several properties of polyethylene terephthalate, and the core of them are:

- Thermal Stability: It acquires amazing thermal stability resulting in the perfect shaping and processing of the product during manufacturing.

- High Strength and Durability: Polyethylene terephthalate acquires impressive strength making it suitable for processes that require higher integrity. In addition, it also possesses higher impact resistance qualities.

- Cost-effectiveness: PET plastics are in high demand due to their cost-effectiveness and adaptability. PET container applications are common in food containers.

- Lightweight Material: It is a lightweight plastic, which makes it highly suitable for portability and reducing transportation costs.

- Recyclable Material: The recyclable nature makes polyethylene terephthalate the most sustainable plastic option compared to others.

2. Polyvinyl Chloride (PVC)

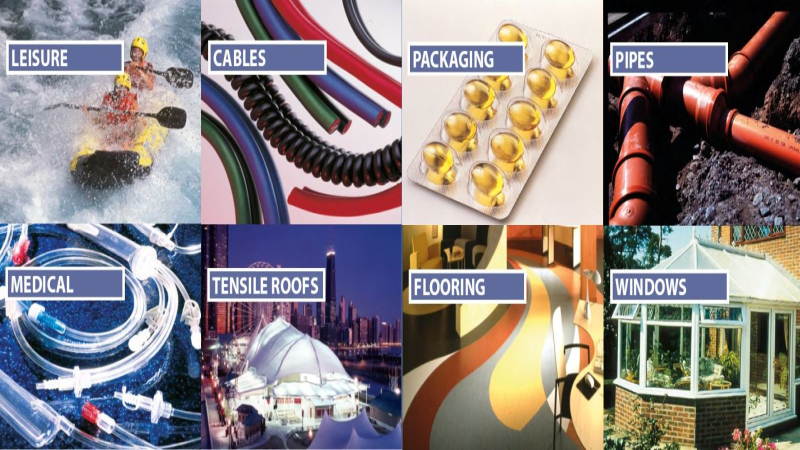

Polyvinyl chloride(PVC) is highly appraised for its extraordinary flexibility and versatility. This is a versatile type of plastic among other types of plastic materials. It is widely used in health care, construction, and many other industries.

PVC is a highly valued type of plastic for its remarkable strength and rigidity. In addition, it has superior resistance against abrasion, making it the material of choice for applications such as flooring, pipes, and building materials.

Properties of PVC

Polyvinyl Chloride PVC attains a captivating range of properties, thus becoming the most commonly used plastic material. Let’s take a look at its properties highlighted below:

- Higher Resistance: It is highly durable, resistant to abrasion, and long-lasting. The high demand for PVC pipes and flooring in construction work is due to its wear and tear properties and higher Resilience.

- Higher Strength: Polyvinyl Chloride reigns supreme for its rigidity and strength. A wide range of applications utilize it for its structural strength requirements.

- Dimensional Stability: It maintains its shape during various conditions and ensures consistent performance in applications like furniture parts, window frames, etc.

- Chemical and Water Resistance: It offers excellent resistance to water and a huge range of chemicals like alkalis, acids, and oils. PVC is a high-demand material for outdoor executions like building exteriors and roofing.

- Versatile and Lightweight Material: PVC is a lightweight material ideal for construction. With the addition of different fillers, it can process hard pipes, electric cables, durable hoses, and fire-retardant materials.

- Low Electrical Conductivity: It is a good insulator of electricity and suitable for many electrical applications like electrical conduit, wire insulation, etc.

- Slow Recycling: Its degradation rate is slow and full of hurdles, whereas its production involves the use of substances, raising potential health concerns.

Hongju Awaits Your Quote Request!

3. Polypropylene (PP)

Polypropylene (PP) is a genuine workhorse and a champion in the plastics industry. PP is a thermoplastic polymer formed from polymerizing propylene gas, a byproduct of petroleum processing. The chemical structure of PP consists of repeating units of carbon and hydrogen (C3H6)n.

Among the 7 types of plastics, polypropylene (PP) is a rigid plastic because of its high strength, lighter weight, and excellent adaptability.

Properties of Polypropylene

It finds broad usage across a vast array of applications due to its remarkable properties, as explained below:

- Strength and Flexibility: PP has incredible strength in comparison to other plastic materials. Thus, its flexible form is ideal for use in applications requiring sturdiness and power.

- Lightweight Nature: Due to its lightweight nature, its usage is crucial in applications for reducing weight. The strength and durability make it a perfect material for recycling bins and baby bottles.

- Chemical and Heat Resistance: PP shows excellent resistance to chemicals such as oils, acids, and bases used for food containers. It can also bear moderate temperatures without warping or melting.

- Moisture Resistance: It is a waterproof plastic by nature, hence absorbs minimal moisture. This property makes it an ideal material for manufacturing disposable sanitary pad liners.

- Recyclable Material: PP comes in the post-consumer plastics list for lessening plastic waste, with code number 5 of recycled plastic.

- Packaging Goods: Most plastic wraps for packing materials are made of PP. It has common material for food storage containers and food packaging materials.

4. Polystyrene (PS)

Polystyrene (PS) is the most common plastic among the 7 different types of plastic. It is in high demand for its cost-effectiveness, ease of use (a common example is plastic bags), and distinct properties. Besides that, it offers a range of characteristics that make it worthy of countless applications in contrast to other types of plastics.

Properties of Polystyrene

Below are the key properties of PS that make it a valuable material to use in different applications:

- Transparent Nature: This is the most versatile transparent plastic, ensuring clear visibility of the enfolded product.

- Slow Recycling Rate: It is among hazardous materials as it remains in the environment for a longer period due to its slow degradation rate. However, researchers are actively pursuing various avenues to improve PS recycling facilities.

- Cost-effective and Lightweight: It reigns high among the lightweight and very inexpensive resin. Due to these advantages, it is in high demand for the production of many lightweight and disposable products.

- Thermal and Chemical Resistance: PS holds a good resistance to particular bases, acids, and alcohols. However, due to its low melting point, it is not suitable for applications exposed to high heat.

5. Polycarbonate (PC)

Polycarbonate, also abbreviated as PC, is a broadly used thermoplastic polymer. It is a type of plastic most commonly used for its higher symbiosis of thermal stability, mechanical strength, and optical clarity.

PC is a rigid, transparent thermoplastic polymer that is easy to melt, shape, and solidify repeatedly. These unique features along with its exceptional properties made it a go-to material in various applications.

Properties of PC

It offers a unique blend of the following properties:

- High Strength: PC displays excellent strength, beating many other transparent plastics in impact resistance. PC holds significant stress without facing abrasion.

- Optical Clarity: It exhibits magnificent optical clarity, causing effusive light transmission. PC is ideal for the manufacturing of medical tubing and devices.

- Heat Resistance: It demonstrates high thermal stability and tolerates temperatures exceeding 266°F without melting. So, it’s perfect for use in applications where heat exposure is in demand.

- Recycling of PC: The recycling of polycarbonate is possible but after a series of steps including sorting, shredding, and washing. Various recycling programs help it to transform into new products such as plastic bags and grocery bags to decrease plastic waste.

6. Polyethylene (PE)

Polyethylene, also known as (PE), is the most widely used type of plastic worldwide known for packaging materials. It holds a prominent position within the types of plastics because it’s a very inexpensive resin. It’s further divided into two types: High-density polyethylene(HDPE) and low-density polyethylene (LDPE) plastic.

High-density Polyethylene(HDPE) has a linear molecular structure whereas low-density polyethylene has a tangled molecular structure and significant chain branching. High-density polyethylene (HDPE) is not so common but used in specific applications e.g., most frozen food bags and detergent bottles.

Whereas, low-density polyethylene LDPE provides ease in our everyday life in the form of hot and oily food bags, microwaveable pouches, and disposable diapers.

Properties of PE

Here’s a look at some key properties that make PE a versatile plastic:

- Hydrophobic Property: PE is a high-density polyethylene that shows amazing water resistance and the ability to prevent oxygen, water, and moisture intrusion. It is also used in manufacturing water bottles, squeezable bottles, milk jugs, infant formula packaging, and paper milk cartons.

- Chemical Resistance: It excels in its resistance to many chemicals, such as acids, bases, and alcohols. Thus, the manufacturers mostly use HDPE for container lids, hot food containers, and detergent bottles.

- Thermal and Optical Property: Some varieties of high-density Polyethylene ensure crystal-clear visibility, while some are opaque. PE boasts a low melting point, which helps with molding and shaping during manufacturing.

- Electric Insulation: PE is the winner as an electrical insulator and protects the users from harmful electric shocks. That’s why it is also an ideal choice in the automotive industry.

- Mechanical Resistance: In contrast to other plastics, PE exhibits lower tensile strength. However, its exceptional flexibility makes it ideal for manufacturing plastic bags and films.

- Recycling of PE: PE is among the most hazardous plastic materials as it takes centuries to decompose properly due to its slow recycling process. However, certain recycling programs help to reduce plastic waste and plastic pollution.

Hongju Awaits Your Quote Request!

7. Acrylonitrile-butadiene-styrene (ABS)

Acrylonitrile-butadiene-styrene, also known as ABS, is a broadly used thermoplastic polymer. It is a type of plastic well known for its excellent properties. It is a terpolymer consisting of three monomers – acrylonitrile, butadiene, and styrene. ABS attains an amazing blend of strength, versatility, and ease of processing.

Properties of ABS

Here are the key properties of ABS that have made it a popular choice in various industries:

- Chemical Resistance: ABS shows good resistance to different mild chemicals used for common applications like ketchup containers and shampoo bottles. However, it’s not suitable for highly concentrated chemicals.

- Mechanical Performance: It exhibits good impact resistance and is highly durable for applications in different industries. ABS displays impressive tensile strength and rigidity to withstand pressure and stress.

- Thermal Resistance: ABS also boasts a good balance between heat resistance and pressure. However, it has a relatively low melting point and cannot withstand extreme heat.

- Processability and Aesthetic Finishing: The material is ideal for prototyping and customized applications because of its excellent machinability. It contains a smooth and glossy surface, enhances visual appeal, and adds aesthetics to a broad range of products.

- Recycling of ABS: ABS is a widely recycled plastic used to make new products and minimize environmental impact and plastic waste. The resin identification code for ABS is 7.

Importance of Plastic in Promoting Recycling and Sustainability

The plastic industry introduced convenience to the world at the cost of environmental health as it can leach hazardous materials. Plastic has several benefits in terms of recycling and sustainability. Although plastic resins are not a green material, they can play a significant role in recycling and sustainability when managed effectively. Here are some reasons why:

- The recycling of plastics cuts down the need for fresh plastics and initiates less energy and fewer resources.

- Not all plastic types have slow decomposition most of them are reusable materials and thus decrease single-user waste.

- Plastics excel in lightweight nature and hence reduce fuel consumption during transportation. It can result in a lower greenhouse effect.

- Plastic packaging extends the shelf life of goods. Hence, the promotion of minimal spoilage and waste of goods.

- The recycling of plastic saves up space on land for other things instead of filling it with trash.

- Plastic recycling makes it possible to recover resources and use them to improve the circular economy.

- There are fewer effects on oceans and marine life with proper recycling and waste management practices.

Hongju Awaits Your Quote Request!

Conclusion

Having divided plastic resins into 7 types, the plastic industry is making hundreds of products from them. Each type has its unique properties that make it fit for a certain use. There are some ins and outs of each type but overall they are highly useful for various applications. making hard plastic products to soft and flexible products.

Despite the buzz of its effects on the environment, plastic is contributing towards sustainability. Using recyclable plastics and making the right choices about the types of plastics helps reduce the harmful impacts on the environment.

Purchase High-Quality Sustainable Plastic from Hongju Silicone

Looking to buy high-quality eco-friendly plastics? Hongju Silicone offers various types of plastics to meet your needs. Get in touch if you want to be part of a greener initiative with eco-friendly recyclable plastics. Reach out to us to learn about our different types of plastic products and skyrocket your business.