Both polypropylene and polycarbonate are versatile thermoplastics, but their properties, applications, and manufacturing processes are very different. This article will focus entirely on two plastic materials: polycarbonate and polypropylene plastics. We will discuss their various plastic material properties and applications, uses, costs, and safety. Let’s get right into it!

What Is PC Plastic?

PC plastic, commonly known as polycarbonate plastic, falls into the category of thermoplastic polymer. Polycarbonates are composed of linear carbonated polyesters with divalent phenolic groups linked by carbonate groups.

Manufacturers use a small amount of phosgene and bisphenol A to derive PC plastics and products in production plants. In addition, PC is easy to decompose and change color at high temperatures in injection molding, and injection molding requires a customized PC screw. So in fact, the processing cost of PC products is higher.

Moreover, PC plastic has a transparent nature. It is also pretty easy to mold and shape once heated. Although extremely strong and impact-resistant, polycarbonate plastic possesses inherent design flexibility. It quickly solidifies as it cools down. Demonstrating formidable strength, commendable chemical resistance, and high heat resistance, polypropylene proves suitable for an array of applications for high durability and impact resistance.

Unique Properties of PC Plastic:

- It has high impact resistance and strength.

- It offers exceptional heat resistance for high-temperature applications.

- The material also has high optical clarity and transparency, making it easy to see.

- PC plastic is also highly stable and robust.

Common Uses of PC Plastic:

PC is commonly used for plastic lenses in automotive components, electronic components, eyewear, exterior lighting fixtures, greenhouses, medical devices, and protective gear due to its unrivaled impact resistance, heat resistance, high transparency, and optical clarity.

- Medical: The medical industry readily uses PC plastic to produce blood filters, syringes, and other medical equipment.

- Electronics: The consumer electronics industry also uses PC plastics for their durability and impact resistance. Standard PC plastic products include screens, phone cases, and optical lenses.

- Automotive: This industry also uses PC plastic for various automotive components, including interior trim parts, instrument panels, headlamp lenses, face shields, etc.

- Safety: PC plastic is also highly suitable for safety equipment manufacturing. This includes the use of PC plastic in the production of safety goggles, helmets, safety gear, etc.

- Construction: This industry uses PC plastics for several purposes. For instance, construction companies use it as a roofing material or for glazing systems.

Inquire About Our Silicone and Plastic Products!

What Is PP Plastic?

PP plastic, commonly known as polypropylene plastic, is another type of thermoplastic polymer. Manufacturers use propylene monomers to derive Propylene monomers in production units. The material is known to have excellent durability and is lightweight, a rare combination in many plastic materials.

Moreover, like PC plastic, Polypropylene material is also mold-friendly, allowing manufacturers to mold it into any shape when heated. Furthermore, it is also known for good chemical resistance, making it suitable for applications with excellent chemical exposure.

Unique Properties of PP Plastic

No question that polypropylene is a great plastic material. Here are some properties of PP plastic:

- Propylene monomer has high flexibility. This allows it to retain properties upon extension without any bends or breaks.

- It is also highly chemical resistant, allowing it to resist harsh chemical environments easily.

- Propylene monomer also has good heat resistance. As a result, it is often used in applications with high temperatures.

- It has excellent durability and good fatigue resistance making it an ideal material for applications that need a reliable plastic material.

Common Uses of PP Plastic

Due to its low cost, chemical resistance, and ease of processing, it is widely used in applications.

- Packaging materials industry: food containers, bags, and wraps

- Automotive sector: bumpers, dashboard parts, battery cases

- Medical sector: syringes, test tubes, and other medical devices

- Textile industry: carpets, ropes, and other woven products

- Furniture: chairs, tables, and outdoor furniture sets.

Inquire About Our Silicone and Plastic Products!

PC Vs. PP: Physical Properties

Now that we have been through PC plastic vs. PP plastic basics, let’s dig deeper into the two materials’ physical properties.

Comparison of Melting Point

While some physical properties are similar, PP and PC plastic have drastically different melting points. For instance, PP plastic melts at approximately 160 degrees Celsius. On the other hand, PC plastic melts at an approximate temperature of 300 degrees Celsius.

As a result, we can conclude that PC plastic has better heat resistance when the two are compared head-to-head making it more suited for high-temperature applications.

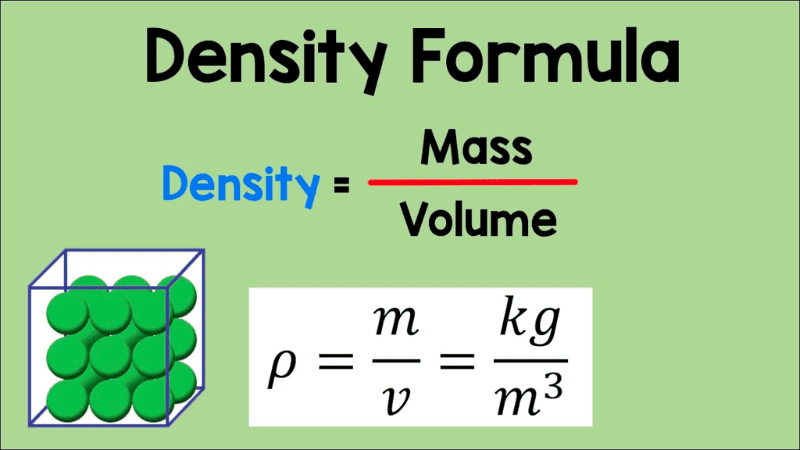

Comparison of Density

With regards to density, PP plastic is both more flexible and lighter compared to PC plastic. This means PC has a high density compared to PP plastic. If we look at the numbers, then PC plastic has a density of 1.20 g/cm3.

Contrarily, PP plastic’s density stays lower at 0.90 g/cm3. As a result, when choosing between the two for applications, one must keep the respective densities in mind.

Comparison of Tensile Strength

Even though both PP and Polycarbonate materials have good tensile strength, one wins over the other. In this case, PC plastic stands out with its higher tensile strength. Comparing the two materials, it is found that the wear resistance of PP is worse than that of PC. As a result, this material tends to withstand higher pulling forces and stretch without breaking apart.

Talking about numbers, the tensile strength of PP plastic stands at around 35 MPa. On the other hand, PC plastic has a tensile strength of around 55 MPa. Therefore, PC plastic suits applications that require plastics with better durability.

Inquire About Our Silicone and Plastic Products!

PC vs. PP: Chemical properties

Now that we have covered the main physical properties of polypropylene vs. polycarbonate let’s look at how both differ chemically.

Comparison of Resistance to Chemicals

When it comes to chemical resistance, PC plastic wins over PP plastic. It is more resistant to chemicals like alkalis, acids, and solvents. On the other hand, PP plastic does not last as long as PC plastic when exposed to these chemicals.

Comparison of UV Resistance

UV resistance is another common chemical property of PP and PC plastics. However, PC plastic has excellent UV resistance again, making it ideal for outdoor applications. Contrarily, while PP plastic can also withstand UV rays, it isn’t the best at it. As a result, prolonged exposure to sunlight can damage the material.

Comparison of Flammability

Flammability is one area where polycarbonate vs. polypropylene plastics differ drastically. PP plastic has high flammability meaning it can quickly spread flames and ignite once exposed to heat.

On the other hand, PC plastic has self-extinguishing characteristics. This means the material stops burning after removing the fire source. Hence, this makes PC plastic a safer option for applications where temperatures are high and exposure to fire is possible.

Environmental Impact of PC and PP Plastic

Plastics generally have a terrible impact on the environment. However, the intensity of the impact varies from plastic to plastic. For instance, bioplastics or recycled plastics have a significantly lower environmental impact than PP and PC plastics. But for now, let’s see how these two impact our environment.

Comparison of Biodegradability

Regarding biodegradability, both PC and PP materials are harmful to the environment. However, PP plastic does have partial biodegradability, which means it can break down under certain conditions.

On the other hand, PC plastic can take hundreds of years to decompose, which means it has deficient levels of biodegradability. As a result, while both plastic materials are harmful to the environment, PP plastic causes less damage compared to PC plastic.

Comparison of Recyclability

Given the climate change crisis, recyclable plastics have become more common than ever before. Here again, we see that PC plastic tends to be more difficult to recycle than PP plastic. This is because of the higher melting point of PC plastic.

As a result, recycling PC plastic requires more energy, whereas PP plastic does not require as much. It is relatively easier to recycle it and turn it into packaging materials and other plastic parts for toys and electronics.

Comparison of Impact on The Environment

Both PP plastic and PC plastic contribute to environmental pollution. However, the overall impact on plastic pollution for each material varies. For example, given PC plastic’s higher durability and strength, it does not require frequent replacement.

As a result, it has a lower negative impact on the environment compared to PP plastic which is often used for packaging material and disposable products. Hence, there is a greater need for PP plastic replacement resulting in more plastic pollution over time.

Comparison of Production Costs

Given the physical and chemical properties differences, PP and PC plastics also have different costs. If we look at the production processes, such as injection molding, then PC plastic has a more complex production process than PP material.

Moreover, it also requires more energy. Hence, the overall cost of production for PC plastic is more than for Propylene monomers.

Comparison of Market Prices

The market price for each plastic depends on several factors, including market demand, supply, and production cost. Generally, PC plastic is more complex and costly to produce. As a result, PP plastic has a higher demand and storage due to its low cost and more straightforward production process.

Explanation of Factors That Affect the Cost

Here is a short list of factors that affect the cost of polypropylene vs. polycarbonate:

- Cost of raw materials

- Quality of the final product

- Transportation costs

- Energy costs

- The complexity of the production process

- Labor costs

- Other production expenses

Inquire About Our Silicone and Plastic Products!

Applications of PC and PP Plastic

Let’s see how PP and PC plastics differ when it comes to their real-world applications:

Comparison of Industries That Use PC and PP Plastic

PP and PC materials are used in various industries, including electronics, packaging, construction, automotive, etc. However, PP plastic is more suitable for applications that require higher flexibility. Hence, it is a widely used material in household items, food packaging materials, etc.

On the other hand, PC plastic takes advantage of its higher strength and durability, making it suitable for electronic components and automotive parts.

Examples of Products Made from PC and PP Plastic

- Food packaging: PP plastic is often used for food containers, as it is non-toxic, heat resistant, and has a high melting point that can withstand hot temperatures without degrading.

- Household items: PP plastic is commonly used for household items such as storage containers, bottle caps, and drinking straws. Contrarily, PC materials are used for water-plastic bottles and food containers.

- Automotive industry: PC and PP plastics are used in the automotive industry. PC materials are often used for headlights and PP plastic for bumpers and interior trim components. Actually, in automotive applications, PP is a low-cost alternative to ABS and AES, where cosmetic considerations are outweighed by cost or the need for maximum impact resilience.

- Electronic devices: PC plastic is commonly used for computer components, phone cases, and CDs/DVDs due to its durability and optical clarity.

- Medical equipment: PC plastic is used for medical equipment such as incubators and blood oxygenators due to its strength, transparency, and resistance to heat and chemicals.

Modern life cannot survive without plastic use. We need plastic products in our daily lives for almost every other thing. Hence, the products we use must be safe. However, despite this, some health risks are associated with polycarbonate polypropylene plastic materials.

Health Risks Associated with PC and PP Plastic

Health risks associated with PP plastic:

- These chemicals may have negative health effects, including disrupting hormones and increasing the risk of certain types of cancer.

- However, some studies have suggested that it may leach chemicals such as ethylene and propylene into food and drinks, particularly when exposed to high temperatures.

- Generally considered safe for use in food containers and packaging.

Health risks associated with PC plastic:

- Exposure to BPA has been linked to various health problems, including cancer, infertility, diabetes, and obesity

- Can leach BPA into food and beverages, especially when heated or exposed to acidic or fatty foods

- PC plastic also contains other chemicals, such as phthalates, which harm human health

- It has bisphenol-A (BPA), a hormone disruptor that can affect the brain and behavior.

Overall, the health risks associated with PP plastic are lower than those associated with PC plastic. Moreover, ensure you work with manufacturers who follow all regulations set by the FDA and European authorities regarding the quality of polycarbonate polypropylene plastics.

Inquire About Our Silicone and Plastic Products!

Conclusion

To conclude, polypropylene vs. polycarbonate has its benefits and drawbacks. While one has more strength and durability, the other offers a low-cost, flexible solution. Moreover, the desired properties and performance requirements of the end product can considerably impact the chosen material’s cost.

As a result, it all comes down to the application in question. You must determine your customer’s specific needs before ordering each plastic.

Get Premium PC and PP Plastic from Hongju

At Hongju, we have dedicated ourselves to providing customers with safe-to-use polycarbonate polypropylene plastics products worldwide. We have years of experience in the industry and can provide you with the best plastic material products at competitive prices.