What Is a Rubber Keypad

A rubber keypad is an input device usually made with silicone rubber. Each key is shaped with a small dome or structure. The flexible silicone keys with webbing complete the circuit when pressed. The elasticity of silicone material bounces the key back after release.

The flexibility of silicone material allows it to withstand millions of actuations without losing shape. It resists UV, moisture, dust, chemicals, and a wide range of temperatures. That’s why keypads designed with silicone are ideal for consumer and industrial products.

Rubber Keypad vs. Membrane Switch

Rubber keypads and membrane switches are both electric input devices. Rubber keypads work with molded silicone domes. Membrane switches use flat layers of plastic film with printed circuits.

For a tactile keypad silicone is the best choice. Silicone keypad can be designed in different shapes, colors, and sizes. Membrane switches are thinner and can be sealed more easily.

Key Design Considerations

To design a silicone rubber keypad, first understand the product requirements and available space. We assess the following parameters to design a reliable keypad. Each spec influences others. The right balance between the design elements of the silicone keypad makes it practical and comfortable.

Button Shapes and Layout

When designing keypad buttons and layout two factors are most important: pressure range and button spacing. The table shows the most common button structures and their pressure ranges.

| Button Shape | Cone | Double Cone | Bell | Double Bell |

| Range of Pressure (Grams) | 30-250 | 50-250 | 80–200, 10–200 (non-click) | 30-200 |

The bell-shaped buttons give a consistent moderate smooth response at moderate force. That’s why they are best suited for medical devices. The frequent use of these buttons does not strain the user.

Cone or double cone structures tolerate higher actuation forces. They are suitable for industrial control panels. They provide excellent durability in demanding environments.

Button layout is as important as the shape. A spacious layouts with spacing of 3-5 mm between keys reduce errors in medical devices. For industrial use denser layouts with 2-4mm spacing work better. For consumer electronics, 1.5-3 mm spacing between keys balances user comfort.

Actuation force and Tactile Response

Actuation force is the pressure needed to press a key. It should be carefully selected to balance comfort and accuracy.

| Actuation Force | Allowable Variation (± grams) | Users Tactile Feedback |

| 50 g | 15 – 20 | Excellent |

| 70 | 20 – 25 | Excellent |

| 90 g | 20 – 30 | Excellent |

| 120 g | 25 – 35 | Excellent |

| 150 g | 25 – 35 | Good |

| 170 g | 35 – 50 | Good |

| 200 g | 50 | Fair |

The 70 -120 g range is considered a sweet spot for users. It balances speed and accuracy. In lighter switches this range prevents accidental presses. In heavy switches it reduces fatigue.

When the actuation force exceeds 200 g the keys become stiff. This range is useful for silicone rubber keypads exposed to vibration or accidental touches. A 200 g actuation force reduces comfort and increases fatigue in everyday use devices.

Travel Distance

Travel distance is the distance a key travels from its resting position to the point where it meets the electrical contacts. Travel distance affects the key tactile feel, size, and keypad life.

0.8 to 1.5 mm is the standard range. Shorter travel reduces the tactile feel and the keypad feels more like a touch sensor. Long distance increases tactile sensation.

Consider the target application of the keypad to decide the travel distance. For instance, in medical keypads short travel gives faster input. In automotive controls longer travel gives positive user feedback.

Material Properties of Silicone Rubber

Physical Properties of Silicone Rubber:

Silicone rubber is a versatile synthetic polymer. The high tensile strength and tear resistance of silicone rubber allow it to endure repeated pressing without wear. This extends the keypad’s lifespan.

The following table compares carbon conductor silicone (used for conductive contacts) with silicone insulator (used for the main keypad body):

| Typical Physical Property | Carbon Conductor | Silicone Insulator |

| Specific Gravity @ 72°C | 1.18 | 1.17 |

| Durometer Hardness (Shore A) | 65 ± 5 | 30–80 ± 5 |

| Tensile Strength (kg/cm²) | >50 | >70 |

| Elongation (%) | >100 | >250 |

| Tear Strength (kg/cm²) | >9 | >12 |

| Linear Shrinkage (%) | 3 – 5 | 3 – 4.5 |

| Volume Resistivity (Ohm·cm) | >5 | 1 × 10¹⁵ |

| Compression Set (%) | 15 – 25 | 10 – 20 |

| Abrasion Resistance | Moderate | High |

| Transparency/Colorability | Opaque, limited color | Wide range, supports backlighting |

| Permeability (Gas/Water Vapor) | Moderate | Low |

| Flame Retardancy (UL94) | V-1 | V-0 / V-1 (depending on grade) |

With these material strengths silicone rubber keypads perform well in different environments. You can fine-tune hardness, elongation, and coatings. You can build anything from soft-touch consumer keys to rugged industrial controls.

Environmental Resistance

Silicone rubber naturally resists moisture and dust. So it can be used outdoors and for medical devices. In addition, silicone resists water, UV light, ozone, and many chemicals. These properties keep keypads functional in harsh outdoor environments.

Heat and Chemical Resistance

Silicone rubber keypads can operate within –40°C to +150°C. without losing its unique qualities. That’s why silicone is used in electronics, medical devices, and industrial machinery.

It can also withstand exposure to many chemicals from cleaning agents to mild acids. Ideal for both sterilizable medical equipment and industrial machinery.

Manufacturing Overview

The silicone rubber keypad manufacturing has an impact on the performance and reliability of the device. The choice of molding process, contact method, and surface finishing shapes durability, tactile feedback, and overall product quality.

Compression Molding

The primary manufacturing process for producing silicone rubber keypads is compression molding. Silicone rubber material is placed into a mold and compressed under heat. It creates durable and precise parts.

Overmolding With Plastic

In some designs, silicone rubber has been used for overmolding with plastic. The silicone rubber is overmolded onto a rigid plastic frame. This process increases strength without hardening the soft-touch surface.

Contact Methods

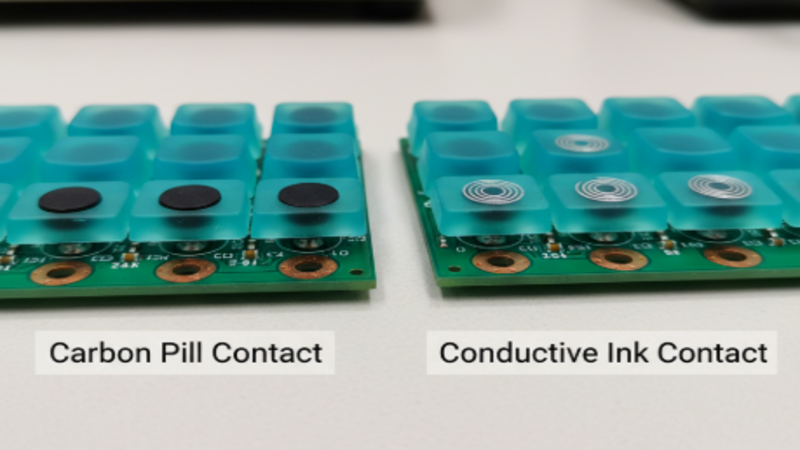

Silicone rubber keypad is interfaced physically with the PCB(Printed Circuit Board) usually with two common methods:

- Carbon pill: This is the most common contact method. It can be used for every size and shape of silicone rubber keypad. Conductive carbon pills are pressed into the base of the key. When the key is pressed it creates a reliable circuit contact.

- Conductive ink: It is used in lightweight and complex designs. The conductive ink is printed onto the key surface which completes the circuit when the PCB is touched.

Printing Methods

Printing explain the function of a key. Common printing methods include screen printing, pad printing, and laser etching. With screen printing, you can apply bright colors and symbols at a lower cost. Laser etching is used with backlit keypads. It enhances durability and precision.

General Specifications & Standards

Some key specifications should be evaluated carefully before designing a silicone keypad. These parameters influence the keypad feel and performance in real world conditions.:

- Keypad Travel (0.8–1.5 mm): It is the total distance a key moves before activation. It directly affects tactile feel and speed of input, so it must match user expectations.

- Actuation Force (60–300 g): The pressure required to press a key. The right force prevents user fatigue in consumer or medical devices. It also brings durability in industrial use.

- Lifecycle (up to 1,000,000 presses): It indicates the total presses before the keypad failure. This matters most because frequent replacements increase cost and reduce product trust.

- Operating & Storage Temperature (-40°C to +150°C / -50°C to +170°C): It indicates the safe conditions for use and storing the keypad. Keypads designed with proper temperature ranges make devices functional in cold outdoor and hot industrial settings.

- Dielectric Strength (>1min@500VRMS): It indicates a keypad’s resistance to an electrical field. The keypads with high dielectric strength do not conduct electricity or break down. This ability prevents current leakage and protects users and circuitry.

Dimensional Tolerances in Keypad Manufacturing

Dimensional tolerance is the acceptable variation in keypad size during production. It has a high impact on the user experience and product performance. For silicone keypads, ±0.1 mm is typical for critical dimensions. For non-critical areas ±0.3 mm is acceptable.

With the right dimensional tolerance the silicone keypads fit and function correctly when assembled. Proper tolerance makes the devices functional in harsh environments. It reduces adjustments which benefits the manufacturers. It lowers the cost of manufacturing.

In small medical devices strict tolerance is essential for the perfect alignment of the keys with the circuit. Any variation can cause a malfunction. For industrial equipment, slightly looser tolerances are acceptable because rugged designs can absorb minor variations without affecting usability.

Application Examples

Silicone rubber keypads serve in various industries due to their durability and versatility.

Automotive Keypads

In automobiles silicone keypads are used in dashboards and remote controls. Automotive keypads must be designed to withstand temperature swings and frequent use. A slightly higher actuation force prevents accidental presses during driving.

Medical Devices

Medical keypads should prioritize hygiene and precision. Silicone’s ability to resist cleaning chemicals and sterilization makes it ideal. The cone shaped keys provide reliable tactile feedback.

Industrial Control Panels

These keypads are exposed to dust, gloves, and harsh environments. Higher actuation forces and cylindrical keys help operators make accurate inputs without errors.

Consumer Electronics

In devices like calculators, remotes, and gaming controllers comfort matters most. Flat or soft keys with low actuation force work best for prolonged and easy use.

| Application | Recommended Force | Key Type |

| Automotive | 100 – 150g | Cone |

| Medical | 70 – 90g | Cone |

| Industrial | 150 – 250g | Cylindrical |

| Consumer electronics | 60 – 90g | Flat |

Cost & Customization Overview

Several factors influence the overall price of a rubber keypad. Material selection plays the biggest role. Premium silicone grades, conductive coatings, and backlighting compounds increase cost but also improve performance.

Tooling complexity adds another layer. Intricate shapes, laser-etched legends, or multi-color molding demand more resources. Protective coatings such as polyurethane or epoxy also affect pricing. However, these coatings extend keypad lifespan and prevent wear.

Despite higher initial costs most OEMs choose custom silicone rubber keypads because they offer flexibility that membrane switches cannot. Designers can control travel distance, actuation force, and texture. They can even integrate branding through color and shape.

Customization enhances usability. It also gives products a unique look that resonates with users.

Conclusion

When you design a silicone rubber keypad the right combination of design structure, actuation force, travel distance, and tolerance control provides long term performance. Silicone rubber has unmatched durability and environmental resistance. That’s why it has become the first choice for medical devices, industrial equipment and consumer electronics.

Design Keypads That Last – Get a Custom Solution Today

Looking for a partner to develop your next keypad solution? At Hingju Silicone, we combine advanced molding techniques with strict quality standards to deliver keypads that perform well in every application. Our team helps you choose the right specs so your product feels premium and lasts longer.

Contact us today to request a quote or get professional assistance for designing a custom silicone rubber keypad design.

FAQs

Q1. What advantages do silicone rubber keypads have over membrane switches?

Users are satisfied with the strong tactile feel. Silicone rubber keypads enhance tactile feel which brings user satisfaction. It gives designers the flexibility to shape and size. They are more durable in harsh environments.

Q2. How can I choose the right actuation force for my product?

The selection of the actuation force depends on the industry in which the keypad is used. 70-100g actuation force provides comfort and accuracy in most applications. The rugged industrial equipment suits higher forces (200g+).

Q3:What design options are available for custom rubber keypads?

You can choose button shapes, travel distance, tactile feel, surface coatings, and printing methods. You can contact the engineering team at Hongju to optimize these features for your exact application.

Q4:What factors affect the cost of custom silicone keypads?

The cost of a silicone keypad depends on tooling, material quality, coatings, and printing methods. Many OEMs choose custom designs because of the longer lifespan and better performance. It keeps customers happier. So it saves money in the long run.