Silicone rubber gaskets are important for stopping leaks and contamination in different industries. They work well for glass jars and machinery. Silicone rubber is a versatile gasket material and the best material for preventing leaks. Choose silicone rubber gaskets for good performance and reliability.

No matter the challenge at hand, trust in the power of silicone seals to keep things sealed tightly.

Types and Grades of Silicone Gasket Sheet Materials

Due to their excellent sealing properties, silicone rubber gaskets are widely used in various industries. These gaskets are available in different types and grades.

Below we outline important information regarding selecting gasket materials to help industry professionals determine which material best suits their application.

Different formulations available for specific requirements

Silicone rubber gasket sheets have different types for specific needs like high-temperature resistance, or chemical resistance properties, or electrical insulation. There are silicone rubber gasket materials designed for your application. For instance:

- High-temperature silicone rubber gasket materials can handle very hot temperatures of up to 600°F (315°C). They are used in car engines, industrial ovens, and aerospace parts.

- Chemical-resistant silicone rubber gasket materials resist damage from oils, solvents, acids, and harsh chemicals. They are used in labs, chemical plants, and pharmaceutical industries.

- Silicone gaskets stop electricity from flowing between surfaces. They are used in electronic devices and electrical enclosures.

High-quality Gasket Materials With Varying Hardness Levels

Silicone rubber gasket sheets are made with different hardness levels, which are measured using the Shore durometer scale. Depending on the application requirements, you can choose from a temperature range of soft or firm silicone grades:

- Soft silicone gaskets have a low durometer rating (e.g., 30A) and offer excellent flexibility and compression capabilities. They provide effective sealing even on irregular or uneven surfaces.

- Firm silicone gaskets with a higher durometer rating (e.g., 70A) resist extrusion better under high pressure. They are often used in heavy machinery seals or applications needing more stability.

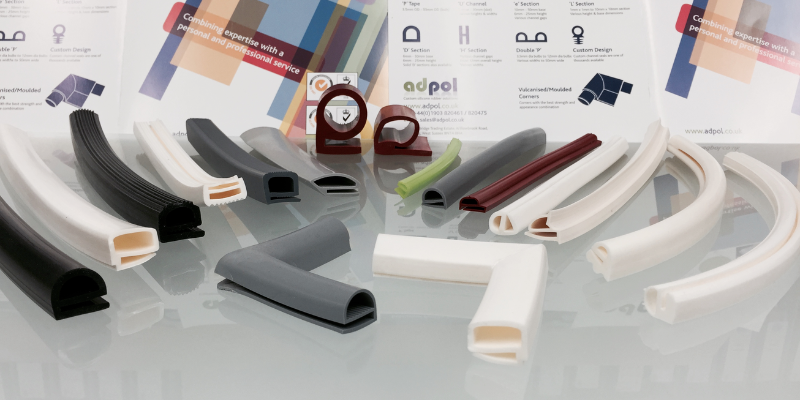

Customizable Options

Silicone rubber gasket materials come in different colors, thicknesses, and sizes for different needs. Colors help identify specific purposes or industries. Different thicknesses let you pick the right sheet for compression and sealing.

Silicone gaskets come in various sizes, from small rings to big sheets that can be cut to fit any shape. They are used in many industries for sealing purposes.

Exploring Molded Silicone Gaskets: Features and Benefits

Molded silicone gaskets offer a range of features and benefits that make them an excellent choice for various applications. From their customizable nature to their exceptional resistance to chemicals and weathering, these gaskets provide reliable performance in demanding environments. Let’s delve into the key advantages of using molded silicone gaskets.

Customizable gaskets molded to precise specifications

One of the most significant advantages of molded silicone gaskets is their ability to be customized according to precise specifications.

Manufacturers can make gaskets in different shapes, sizes, and thicknesses to fit specific needs. This customization prevents leaks and keeps unwanted substances out.

Can be designed with complex shapes and intricate details

Unlike other materials, silicone rubber offers remarkable flexibility. Molded silicone gaskets can be crafted with complex shapes and intricate details that are crucial in many industries.

Precision molding of gaskets ensures a tight seal in tough conditions, whether for automotive parts or medical devices.

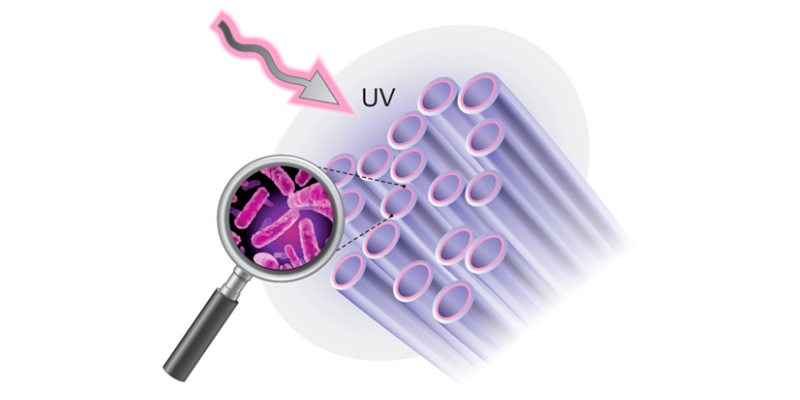

Excellent resistance to chemicals, UV radiation, and weathering

Silicone rubber is very resistant to chemicals, UV radiation, and harsh weather. This makes silicone gaskets great for outdoor use or industries with corrosive substances. They last a long time without getting damaged.

Provide superior compression set properties for long-term performance

A compression set is a material’s ability to bounce back after being squeezed. Silicone rubber is great at this and is better than other materials like regular rubber or plastic. Silicone gaskets made with silicone rubber keep their shape even when squeezed for a long time, so they seal things well.

Adding fiberglass to silicone and natural rubber just makes the gaskets even better. The fiberglass makes them stronger and more stable. This means they can handle more pressure and stay in shape even in tough situations.

Understanding FDA (Food Grade) Silicone Gaskets and Seals

Silicone rubber materials are popular in industries like food processing and packaging because they follow FDA food safety regulations. Let’s look at why FDA silicone gaskets are a good choice for these applications.

- Compliant with strict food safety regulations

Strict regulations are important. FDA silicone gasket materials meet FDA standards and are ideal for food processing, packaging, food processing machinery, and storage.

- Suitable for use in food processing, packaging, and storage

FDA silicone gaskets are useful in the food industry. They can be used to seal equipment or keep food and containers separate. These gaskets work well in different temperatures.

- Non-toxic, odorless, and resistant to microbial growth

FDA silicone gasket materials meet regulations and don’t introduce harmful substances to food. They are safe, odorless, and won’t affect the taste or quality of food. They also resist microbial growth to prevent contamination.

- Safe for direct contact with food products

FDA silicone gaskets are safe to use with food. They can be used in areas where equipment or packaging touches food. Manufacturers can use these gaskets without worrying about chemicals or contamination.

The Different Types of Silicone Rubber Gaskets

Silicone rubber is a versatile gasket material that is used as a silicone sponge, silicone foam, and silicone sheet. There are numerous varieties of silicone rubber gaskets. Given the high versatility general-purpose gasket material, you can get them in rolls or sheets of various thickness levels. Moreover, there are seven different types of silicone rubber gaskets:

- Gaskets Made of Solid Silicone

Solid silicone gaskets are pretty tight, as the name suggests. As a result, they offer incredible sealing capabilities. You can say they are more tightly packed than a sponge gasket.

As a result, choose a solid silicone gasket if you require a seal rating of IP67 or above. However, one thing to remember is that they are tough to compress.

- Sponge Silicone Gaskets

Sponge silicone rubber gaskets offer sponge-like features. They offer more padding and cushioning compared to a solid silicone gasket. Moreover, they either come with closed cells or open cells.

Open-cell silicone gaskets have pockets that allow chemicals, air, and water to pass. However, this is only when the gasket is not compressed.

On the other hand, closed cell silicone gasket also has pockets. However, nitrogen gas is not filling these pockets. As a result, no chemical, air, or water particles can pass through them. This stays true even at low compression.

Lastly, sponge gaskets can also withstand temperatures as high as 500 degrees Fahrenheit.

- Foam Silicone Gaskets

Foam silicone gaskets come in four levels: extra-firm, firm, medium, and soft. All different levels offer an extra level of compression. Moreover, like sponge silicone, foam silicone can be a closed cell, open cell, or a combination of both. As for temperature resistance, foam silicon gaskets can withstand heat as high as 400 degrees Fahrenheit.

- Die Cut Silicone Gaskets

Die-cut silicone rubber gaskets are relatively easier to make. Manufacturers can produce thousands in just one hour. As a result, they are a highly typical type of gasket that comes at economical prices. Moreover, you can find them in different thicknesses and sizes.

- Conductive Silicone Gaskets

Conductive silicone gaskets are created by combining conductive particles with high-quality silicone. They have popular applications in electrical equipment. Usually, the conductive materials used are carbon, nickel, or silver-plated nickel.

- FDA Silicone Gaskets

FDA-approved silicone rubber gaskets are food-grade gaskets. As a result, these gaskets are fungus-resistant, tasteless, and odorless. Moreover, they have powerful resisting capabilities against high and low temperatures.

- Fluorosilicone Rubber Gaskets

Fluorosilicone rubber(fluorinated silicone rubber) gaskets are ideal for petroleum or oil-based chemicals. They have not only high resistance to extreme temperatures but also resist petroleum-based chemicals, including oils and fuels.

Applications of Silicone Rubber Gaskets in Various Industries

Silicone rubber gaskets are used in many industries for sealing things. They are important for sealing automotive, medical, and electrical equipment. Let’s look at some examples of how silicone rubber gaskets are used in different industries.

Automotive Manufacturing: Engine Sealing

In the automotive industry, silicone rubber gaskets play a crucial role in engine sealing. These gaskets provide a reliable barrier between engine components, ensuring that no fluids or gases escape while maintaining optimum performance.

Whether it’s preventing oil leaks or maintaining coolant flow, silicone rubber gaskets are known for their durability and resistance to high temperatures and harsh chemicals commonly found in engines.

HVAC Systems: Air-Tight Seals

Silicone rubber gaskets are essential components in heating, ventilation, and air conditioning (HVAC) systems. They ensure air-tight seals within the ductwork, vents, and other HVAC equipment. By effectively sealing joints and connections, these gaskets prevent air leakage and improve energy efficiency. They help maintain consistent temperature control by minimizing heat exchange between different zones within HVAC systems.

Medical Equipment: Sterility Maintenance

The medical industry uses silicone rubber gaskets to keep equipment sterile. These gaskets stop bacteria and fluids from getting in. Silicone rubber is a good choice for medical use because it doesn’t react with bodily fluids or interfere with sensitive procedures.

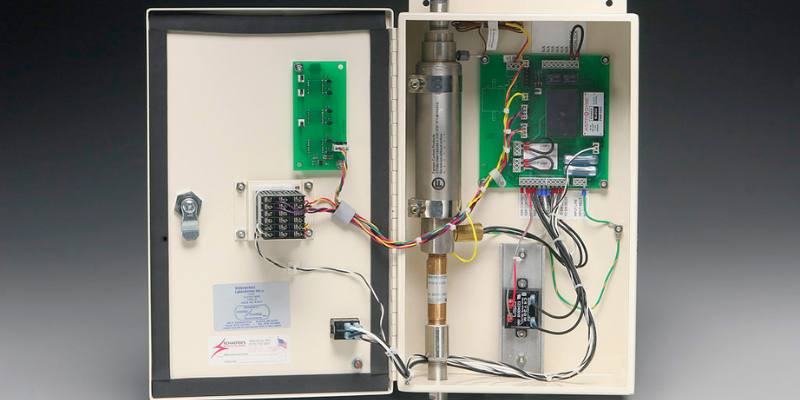

Electrical Enclosures: Reliable Sealing Solutions

Silicone rubber gaskets seal electrical enclosures to protect sensitive components from moisture, dust, and vibrations. They create a tight seal around doors or panels, preventing damage to the electronics inside. These gaskets are also resistant to extreme temperatures and UV radiation, making them ideal for electrical applications.

Conclusion

In conclusion, silicone rubber gaskets offer a versatile and reliable sealing solution suitable for a wide range of applications. Their customizable features make them an ideal fit for specific requirements, while their long-lasting nature reduces the need for maintenance or replacement. They offer a high degree of flexibility and durability that make them a go-to solution for many applications.

Get Top-Of-The-Line Products From Hongju

If you need reliable silicone and gasket manufacturing solutions, choose our company – Hongju Silicone. We offer a wide range of silicone rubber gasket materials, including custom options.

Our team of experts follows Google’s E-A-T(expertise, authoritativeness, and trustworthiness) concept and provides excellent customer service. If you need standard or custom gaskets, we’ve got you covered.