This comprehensive overview provides insights into what silicone gaskets are, their advantages, manufacturing process, applications, and how to choose the right one for your needs. Whether you are a seasoned industry professional or new to the world of silicone gaskets, this article is designed to offer valuable insights and empower you to make informed decisions in your gasket selection process. Dive in to explore the compelling world of silicone gaskets.

What are Silicone Gaskets?

Silicone gaskets, also known as seals, are flexible components designed to fill the space between two mating surfaces, preventing leaks and maintaining pressure while excluding contaminants. They are typically cut from sheets of silicone rubber, high-performance, elastomeric materials characterized by impressive heat, chemical resistance, and elasticity.

In the past, asbestos was a common component of gasket materials and was widely utilized by manufacturers. However, over time, the detrimental health and environmental effects of asbestos became increasingly apparent, making it unsustainable as a material choice for gaskets. This led to the search for a safer and more durable alternative, culminating in the advent of silicone rubber gaskets.

The credit for the invention of silicone gaskets goes to Dr. William Dow Corning, who introduced them to the world in 1953. These powerful mechanical seals proved to be more robust and resilient than their asbestos counterparts, boasting superior temperature and chemical resistance properties and enhanced durability. This silicone switch offered an effective and sustainable solution to the challenges previously associated with asbestos gaskets.

Advantages of Silicone Gaskets

Silicone rubber gaskets offer a range of benefits and advantages that make them an ideal choice for various applications. Let’s explore the key benefits of silicone gaskets in detail.

Exceptional Heat Resistance

One of the standout features of silicone gaskets is their ability to withstand high temperatures. This makes them perfect for applications where extreme heat is involved, such as automotive engines, industrial machinery, and aerospace equipment. Silicone gaskets can tolerate a wide operating temperature range from -60°C to 230°C (-76°F to 446°F), ensuring optimal performance even in challenging environments.

Excellent Electrical Insulation Properties

Silicone rubber gaskets possess outstanding electrical insulation properties, making them a reliable choice for electronic devices. They effectively prevent the flow of electric current, reducing the risk of short circuits and electrical malfunctions. With silicone rubber materials gaskets providing a barrier against moisture and dust, electronic components are safeguarded from potential damage.

Low Toxicity Levels

Safety is paramount. Silicone rubber gaskets excel in this aspect as they have low toxicity levels. When exposed to heat or chemicals, they do not release harmful substances that could pose health risks or compromise the integrity of surrounding components. This makes silicone gaskets a preferred option in industries where safety is crucial.

Flexibility for Easy Installation and Removal

The flexibility offered by silicone rubber gaskets simplifies installation and removal processes without causing damage to mating surfaces. Their pliable nature allows for easy fitting into intricate shapes and contours, ensuring a secure seal between two surfaces. Whether it’s sealing pipes or enclosures, silicone gaskets provide convenience during assembly or maintenance tasks.

Long Service Life

Another notable advantage of silicone rubber gaskets is their long service life. Due to their resilience against extreme temperatures and resistance to degradation from exposure to chemicals, silicone gaskets can withstand harsh conditions over extended periods. This durability reduces the need for frequent replacements, resulting in cost savings and improved operational efficiency.

Send Your Inquiry Now!

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

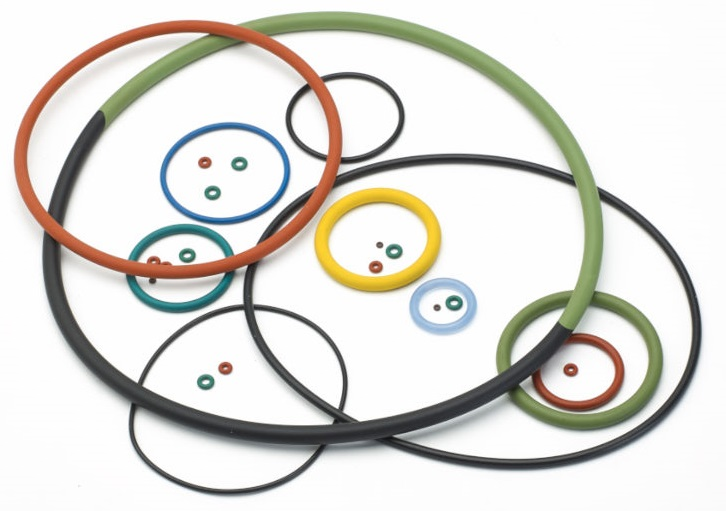

Types of Silicone Gaskets

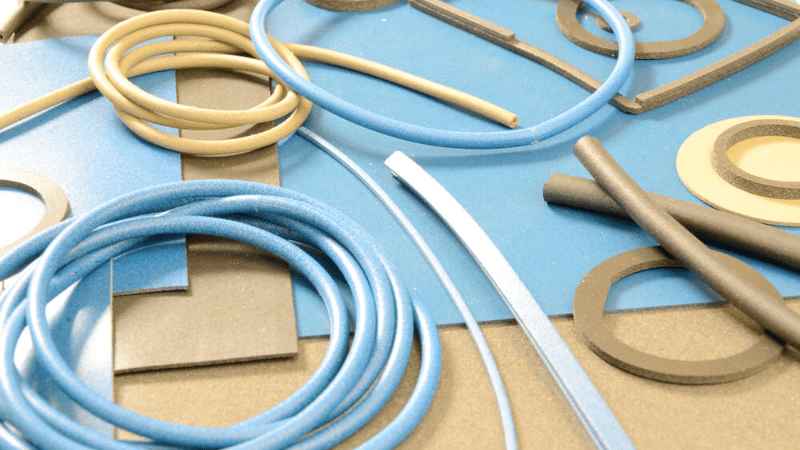

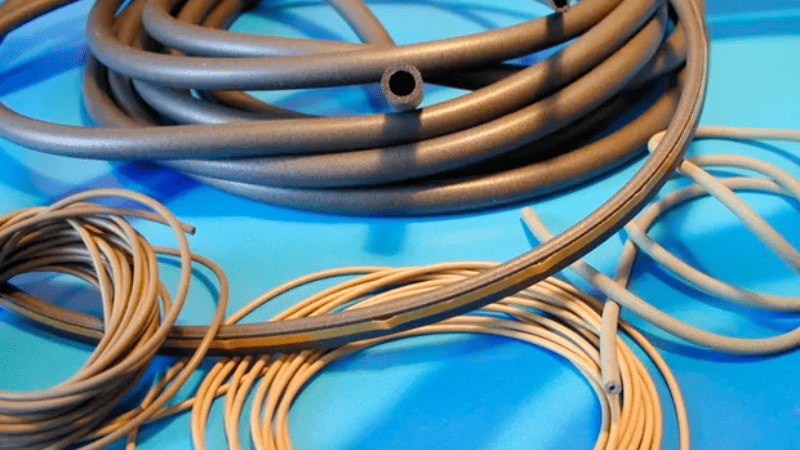

You can get a silicone rubber gasket in different forms/types. Due to their versatility, silicone gaskets can come in rolls or sheets of various thicknesses. So, here are the different types and forms available:

- Fluorosilicone Gaskets: Fluorosilicone gaskets combine the benefits of silicone with enhanced chemical resistance. They are primarily used in aerospace and automotive applications, where they are exposed to harsh chemicals and extreme temperature variations.

- Food-Grade Silicone Gaskets: These gaskets are specifically designed for food and beverage industry applications. They are made from FDA-approved silicone that can resist degradation from cleaning agents, heat, and repeated use.

- Conductive Silicone Gaskets: Used widely in electronics, these gaskets have conductive properties that protect sensitive components from electromagnetic and radio frequency interference.

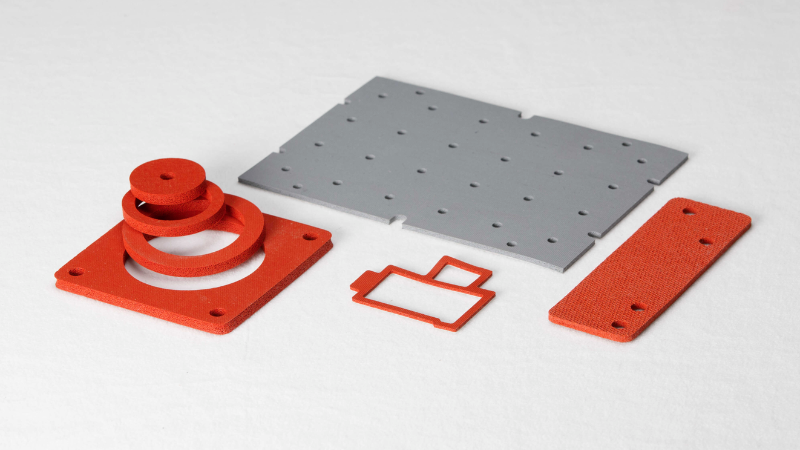

- Molded Silicone Gaskets: Molded silicone gaskets are manufactured using a molding process, which allows for the creation of intricate shapes and designs. They are ideal for applications that require custom, complex geometries.

- Die-Cut Silicone Gaskets: Die-cut silicone gaskets are produced using a die-cutting process. This method allows for precise, repeatable cuts, making it perfect for applications that demand accuracy and consistency.

- Foam Silicone Gaskets: These gaskets are made from silicone foam, a lightweight material that provides excellent compression set resistance and sealing properties. They are typically used in sealing, cushioning, and insulation applications.

- Sponge Silicone Gaskets: Sponge silicone gaskets are softer and more compressible than their solid counterparts. They offer excellent resistance to extreme temperatures and are used in applications where a tight seal is required.

- Solid Silicone Gaskets: Solid silicone gaskets provide the highest level of strength and durability among silicone gaskets. They are used in various industries, including automotive, electronics, and medical devices, for their robust sealing capabilities.

Where Can You Use Silicone Gaskets?

Silicone gaskets have an extensive range of applications due to their resilience, flexibility, and resistance to a multitude of harsh conditions. Here are a few key industries where silicone gaskets are highly utilized:

1. Aerospace and Automotive

Silicone gaskets are favored in the aerospace and automotive industries due to their excellent resistance to extreme temperature fluctuations and their ability to maintain their flexibility and strength over time. They’re commonly used in engines, exhaust systems, and various other automotive components.

2. Medical and Pharmaceutical

The high heat resistance and non-reactive nature of silicone make it an excellent choice for various medical applications, including sealing and insulating medical devices and equipment. They’re also used in pharmaceutical production due to their resistance to degradation from cleaning and sterilization processes.

3. Food and Beverage

Food-grade silicone gaskets are ideal for food and beverage processing applications. They’re resistant to degradation from cleaning agents and can tolerate the high temperatures associated with sterilization processes. They’re used extensively in processing equipment, storage containers, and dispensing devices.

4. Electronics

In the electronics industry, conductive silicone gaskets are used to shield sensitive components from electromagnetic and radio frequency interference. They also provide effective sealing against environmental elements.

5. Industrial Manufacturing

In various industrial applications, silicone gaskets are used for sealing, insulation, vibration damping, and protection against environmental conditions. Their ability to withstand harsh chemicals, extreme temperatures, and pressure makes them a top choice in this sector.

Send Your Inquiry Now!

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

The Potential Drawbacks of Using Silicone Gaskets

While silicone gaskets offer many advantages, it’s important to note that they might not be the ideal choice for every application. Here are some potential drawbacks that you should consider:

Limited Chemical Resistance

Silicone gaskets have a strong resistance to water, ozone, and UV light, but their chemical resistance is not universal. They can degrade when exposed to certain chemicals such as aromatic hydrocarbons, fuels, and mineral oils. Hence, they might not be the best option for applications involving these substances.

Lower Physical Strength

Compared to some other rubber materials, silicone isn’t as physically strong or tear-resistant. If the application involves substantial physical stress or high-pressure environments, silicone gaskets might not be the optimal choice.

Price

Silicone gaskets can be more expensive compared to gaskets made from other materials. The high cost of cut gaskets might be a deterrent for some applications, especially for large-scale projects where budget constraints are a significant factor.

While these factors may sound like disadvantages of versatile gasket material, they are only potential issues depending on the specific application. For many use cases, the benefits of silicone gaskets outweigh these potential drawbacks. It’s essential to consider your specific needs, requirements, and constraints when choosing a gasket material.

How to Select the Right Silicone Gasket for Your Needs?

There are several important factors to consider. Let’s delve into these considerations to help you make an informed decision.

Temperature Range Requirements

The first thing you need to assess is the specific temperature range requirements of your application. Silicone gaskets are known for their excellent thermal stability, making them suitable for both high and low-temperature environments. However, it is essential to select a silicone gasket that can withstand the temperatures your application will encounter. Consider factors such as continuous operating temperature, intermittent exposure, and extreme temperature fluctuations.

Compatibility with Chemicals and Substances

Another vital consideration when choosing a silicone gasket is its compatibility with chemicals or substances it will come into contact with during operation. Different types of silicone have varying resistance properties against oils, solvents, acids, and other aggressive substances. To ensure longevity and avoid premature failure, carefully evaluate the chemical environment your silicone rubber gasket materials will be exposed. Look for manufacturers’ specifications or consult experts if needed.

Required Hardness or Durometer

The hardness or durometer of a silicone gasket determines its ability to seal under pressure and conform to surface irregularities. The required hardness level depends on factors such as sealing pressure and surface conditions of the mating surfaces. Softer silicone gaskets provide better conformability but may not handle higher pressures effectively. On the other hand, harder gaskets offer improved durability but may struggle with uneven surfaces. Consider these aspects while selecting the appropriate hardness or durometer for your application.

Size, Shape, and Thickness

Size matters. Measure accurately and consider any size restrictions imposed by design constraints. Evaluate the shape of the gasket and how it aligns with the mating surfaces. Irregular shapes may require custom-made gaskets for optimal performance.

The thickness of the silicone gasket also plays a crucial role in achieving an effective seal. Thicker gaskets provide increased compression and sealing capabilities, but they may not be suitable for applications with limited space or low-pressure requirements. Conversely, thinner gaskets can accommodate tighter spaces but might compromise on sealing efficiency.

Send Your Inquiry Now!

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

Final Words

Silicone gaskets are truly an asset for industries that prioritize durability, versatility, and reliability. With an impressive range of applications across sectors and a rich array of types to cater to specific needs, they offer an optimal sealing solution that stands the test of time.

Although they come with potential drawbacks, the benefits they offer make them an excellent choice in numerous situations.

Buy High-Quality Silicone Gaskets from Hongju

Whether you are in search of conductive silicone gaskets for electrical applications, food-grade silicone gaskets for food processing industries, or any other type of silicone gasket, Hongju Silicone has got you covered.

With an unwavering commitment to quality and customer satisfaction, we provide top-notch silicone gaskets tailored to meet your specific needs.