Whether it’s synthetic or natural products, understanding the distinctions between rubber materials and plastic is crucial for various industrial purposes and even advanced warfare.

Dive into this article to explore the fascinating world of plastic and rubber and learn how these materials shape our lives in countless ways.

What is Rubber?

Rubber is a natural product, mainly harvested from latex obtained from the rubber tree. Rubber is produced by the addition of small molecules called monomers. These molecules tie together with other monomers to form chains that hold onto larger atoms.

it is an elastic material characterized by its high elasticity, durability, and resistance to water and specific chemicals. It can be categorized into two main types: natural rubber and synthetic rubber.

- Natural Rubber: Derived from the latex sap of rubber trees, this type of rubber is an organic material. It is primarily made up of isoprene polymers and has been used for centuries for various applications.

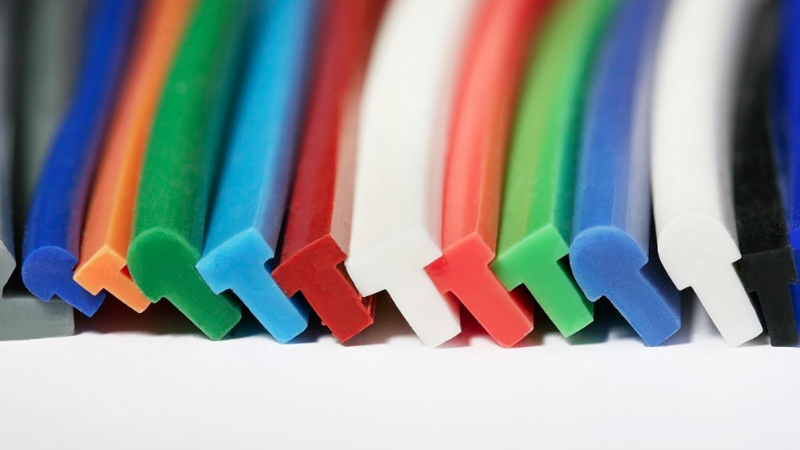

- Synthetic Rubber: Manufactured from petrochemicals like styrene-butadiene, ethylene propylene diene monomer, and nitrile, synthetic rubber is created through various chemical reactions. It often mimics the properties of natural rubber but can also have characteristics tailored to specific industrial needs.

The inherent properties of rubber materials——like elasticity, durability, and resistance—make it a highly versatile material. It is used in everything from vehicle tires to waterproof seals and industrial machinery components.

What is Plastic?

Plastic is a broad category of synthetic or semi-synthetic materials made from various organic compounds. These materials are created through the polymerization of monomers, usually derived from crude oil or natural gas.

The chemical reactions in this process result in long chains of polymers that give plastic its characteristic properties. It can be categorized into two main types: Thermoplastics and thermosetting plastics.

- Thermoplastics: These plastics become pliable when heated and return to a solid form upon cooling. Common examples include polyethylene and polypropylene.

- Thermosetting Plastics: Once these plastics are molded and cooled, they can’t be re-melted or re-molded. Examples include Bakelite and Melamine.

In terms of its chemical structure, plastics are generally composed of organic compounds and are characterized by their high malleability, allowing them to be formed into various shapes and sizes.

While rubber is mainly used for its elasticity and is often limited to specific uses like vehicle tires, plastic materials are used for many applications, ranging from packaging and kitchenware to construction and industrial purposes.

Inquire About Our Silicone and Plastic Products!

Composition: Rubber vs. Plastic

The composition of plastic and rubber varies widely based on their respective origins and manufacturing processes.

Rubber

- Natural Rubber: Derived from latex sap harvested from rubber trees, natural rubber is a natural material made primarily of organic compounds. It consists mainly of polymers of the organic compound isoprene, along with water and other organic compounds.

- Synthetic Rubber: Made from petrochemicals like crude oil, synthetic rubber is crafted through various chemical reactions. Types like SBR (Styrene Butadiene Rubber), CR (Chloroprene Rubber), and Nitrile Rubber(Nitrile Butadiene Rubber) are commonly used.

Plastic

- Thermoplastics: These are made from plastic polymers such as polyethylene, polypropylene, or polyvinyl chloride (PVC). These polymers are usually derived from petrochemicals.

- Thermosetting Plastics: Composed of polymers cross-linked together in a three-dimensional network, thermosetting plastics are designed to maintain their shape even under high temperatures. Examples include Bakelite and Melamine.

The main differences in composition between rubber and plastic stem from their origin—rubber can be natural or synthetic, while plastics are typically synthetic or semi-synthetic. This fundamental distinction in composition leads to varied mechanical properties like strength, elasticity, resilience, and thermal stability, making each material suitable for specific industrial purposes.

Inquire About Our Silicone and Plastic Products!

Plastic vs. Rubber: Key Differences

Understanding the key differences between plastic and rubber can help in making an informed decision for various applications. Here are some of the most significant contrasts:

| Attribute | Rubber | Plastic |

|---|---|---|

| Origin | Can be natural (from rubber trees) or synthetic (from crude oil) | Mostly synthetic, derived from natural gas or crude oil |

| Elasticity | Highly elastic, able to return to its original shape after stretching | Generally less elastic; some specialized plastics can be flexible but not truly elastic |

| Heat Resistance | Varies; natural rubber is generally not heat-resistant, but certain synthetic rubbers can be | Generally more heat-resistant, especially thermosetting plastics |

| Durability | Highly durable and resistant to wear, especially synthetic types | Varies widely; some plastics are highly durable, while others are not |

| Environmental Impact | Biodegradable if natural; synthetic types are less so | Typically non-biodegradable; recycling is possible but not always efficient |

| Applications | Vehicle tires, footwear, industrial seals | Containers, electronics, furniture |

| Cost | Generally more expensive due to the manufacturing or extraction process | Usually ch |

These main differences help to explain why rubber is often preferred for applications requiring high elasticity and durability, such as vehicle tires, while plastic is commonly used for its versatility in forming various shapes and its general affordability.

Typical Applications: Rubber vs. Plastic

Rubber and plastic materials have distinct applications due to their unique properties. Let’s explore the typical uses for each material:

Rubber

- Footwear: Utilized in the soles of shoes for its anti-slip properties.

- Vehicle Tires: One of the most widespread uses due to its excellent grip and durability.

- Medical Equipment: Latex gloves and various types of tubing.

- Advanced Warfare: In some cases, it is used for creating heavy-duty, blast-resistant materials.

- Industrial Seals and Gaskets: Used in machinery to prevent leaks and for shock absorption.

Plastic

- Furniture: From chairs to tables, plastic offers a lightweight, durable option.

- Automotive: Dashboard, internal fittings, and some external parts are often made from plastic.

- Electronics: Utilized in everything from casing to internal components. Plastic’s excellent electrical insulation properties help ensure safety and reliable performance in electrical systems.

- Industrial Purposes: Used in the manufacturing of PVC pipes, fittings, and even large structural elements.

- Plastic Containers and Packaging: Due to its ability to take on various shapes, plastic is ideal for food storage, bottles, and general packaging such as plastic films, and plastic food containers.

Understanding the typical applications of each material can help in choosing the right one for your specific needs. Whether it’s the high durability and elasticity of rubber or the versatility and cost-effectiveness of plastic, each material has its own set of advantages and limitations.

Inquire About Our Silicone and Plastic Products!

Sustainability: Environmental Impact

When it comes to sustainability and environmental impact, both rubber and plastic have unique challenges and opportunities.

Rubber

- Recycling: While rubber can be recycled, the process can be energy-intensive.

- Biodegradability: Natural rubber is biodegradable, which gives it an edge in terms of environmental friendliness.

- Resource Intensive: However, rubber tree requires significant land and water resources for cultivation.

- Chemical Treatment: Synthetic rubber often involves the use of chemicals that can be harmful to the environment.

Plastic

- Recycling: Plastics are generally easier to recycle than rubber, and some types are highly recyclable.

- Microplastics: The degradation of plastic products can lead to the formation of microplastics, which pose a significant environmental risk.

- Resource Origin: Most plastics are derived from crude oil or natural gas, both non-renewable resources.

- Non-Biodegradable: Most plastics are not biodegradable and can take hundreds of years to break down.

Understanding the sustainability factors can influence decisions on material choice, especially in industries and applications where environmental impact is a major concern.

Inquire About Our Silicone and Plastic Products!

How to Choose Between Rubber and Plastic for Your Project

When choosing between plastic and rubber for your project, there are several factors to consider. By evaluating the required properties, environmental impact, cost-effectiveness, and availability of both materials, you can make an informed decision that aligns with your specific application.

Required Properties

Consider the desired properties of your project when deciding between rubber and plastic. Rubber has elastic properties in varying degrees. Plastic, on the other hand, is not as elastic. If elasticity is crucial, rubber may be the better option. On the other hand, if rigidity is important, plastic might be more suitable.

Environmental Impact

Assessing the environmental impact is essential for projects with sustainability goals. Evaluate how both rubber and plastic materials align with your project’s objectives. Consider factors such as recyclability, biodegradability, and carbon footprint.

Cost-effectiveness and Availability

Determining the cost-effectiveness and availability of rubber or plastic options is vital in making a practical choice. Compare prices and availability for both materials based on your specific application requirements. Keep in mind that certain types of rubbers or plastics may have different costs or limited availability.

By considering these talking points – required properties, environmental impact, cost-effectiveness, and availability – you can effectively choose between rubber and plastic for your project without compromising on functionality or sustainability goals.

Exploring the History of Rubber and Plastics

Plastic and rubber have distinct manufacturing processes and considerations. The history of rubber and plastics is not only fascinating but also sheds light on their varying applications and impacts over time.

Rubber

- Ancient Uses: The use of rubber dates back to ancient civilizations. The Olmec civilization in present-day Mexico was using natural rubber as early as 1600 BCE for various applications including making balls for games.

- Vulcanization: The process of vulcanization was invented by Charles Goodyear in 1839. This revolutionized the rubber industry by making rubber more durable and elastic. Vulcanization is an irreversible chemical process that transforms the putty-like, dough-like, or chewing gum-like rubber into a product that has tensile, elongation, and memory similar to a rubber band.

- World War II: The war led to a surge in the demand for rubber, prompting the creation of synthetic rubber.

- Modern Uses: Today, rubber is widely used in various industries, from automotive to healthcare.

Plastics

- Post-War Era: After World War II, the use of plastics expanded exponentially into various consumer goods.

- Early Plastics: The first synthetic plastic, Bakelite, was developed in 1907 by Leo Baekeland. It was initially used as an electrical insulator.

- Mass Production: The development of new types of plastics and plastic polymers in the 1930s allowed for mass production and broader applications.

- Environmental Concerns: As the usage of plastics grew, so did awareness of their environmental impact, leading to current conversations around sustainability and biodegradable plastics.

Understanding the history of these materials not only provides context but can also guide future innovations and applications.

Inquire About Our Silicone and Plastic Products!

Conclusion

Plastic and rubber are two distinct materials that have revolutionized various industries, from automotive to healthcare. While both materials come from organic compounds, their chemical structures, properties, and applications differ significantly.

Get In-Depth Insights and Quality Materials with Hongju

Whether you need high-quality rubber for its elasticity or versatile plastic for its wide range of applications, Hongju has got you covered.

Reach out to us today to discuss your requirements, and let our experts guide you in making the most sustainable and effective choice for your project.