Whether you need replacement rubber feet for your favorite speaker or want to add some stability to your kitchen drawers, there’s an assortment of sizes and styles available. So next time you notice those unassuming black circles on the bottom corners of your equipment, remember their importance in keeping things steady and secure.

What is a Rubber Feet?

Rubber feet are small pads made from rubber materials. These versatile accessories are designed to be attached to the bottom of objects or surfaces, serving multiple purposes. With their soft and flexible nature, rubber feet act as shock absorbers and provide traction for enhanced stability.

One of the primary functions of rubber feet is to absorb shocks and vibrations. Their primary purpose is to protect surfaces from scratches or scuffs that may occur from the object moving or being used. When objects such as electronic devices or furniture are placed on hard surfaces, they can create unwanted noise or damage due to constant impact. However, by attaching rubber feet to these objects, the impact is absorbed, reducing noise levels and preventing potential damage.

The Benefits of Using Rubber Feet

When it comes to incorporating rubber feet into a product design or using them to augment existing rubber products or equipment, the advantages are wide-ranging. Let’s break down the benefits to fully understand why these elements are so widely adopted across various industries.

Enhanced Stability and Safety

First and foremost, rubber feet are excellent in preventing slips and falls. By increasing friction between the object and the surface it rests on, rubber feet provide a much-needed grip, thereby enhancing stability and reducing the risk of accidents.

Surface Protection

Rubber feet act as a buffer between the object and the surface it is placed on. They protect the surface from scratches, scuffs, and other types of damage, preserving the aesthetic and structural integrity of both the product and the surface it interacts with.

Noise and Vibration Reduction

Thanks to the shock-absorbing qualities of rubber, these feet are effective at dampening the noise and vibration generated by the object’s operation. This ability makes rubber feet particularly beneficial for heavy machinery and appliances that generate significant amounts of noise and vibration.

Durability

Rubber is a material renowned for its durability and longevity. It can withstand high levels of wear and tear, making rubber feet a cost-effective solution for protecting products and surfaces over a long period of time.

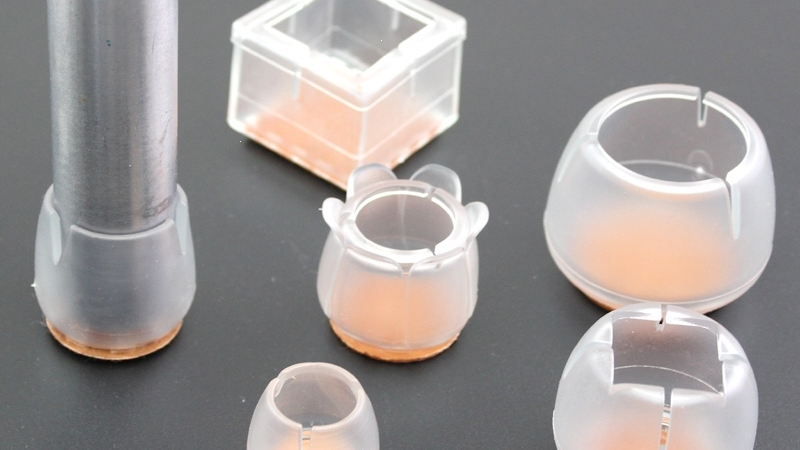

Types of Rubber Feet and Their Applications

Rubber feet come in a myriad of shapes and styles, each designed to meet specific needs and applications. Let’s dive into some of the most common types and explore where they are typically applied.

- Cylinder Bumpers

Cylinder bumpers, as their name suggests, are cylindrical in shape. They are commonly used in electronic appliances, furniture, and instruments for their simple design and versatile application.

- Recess Style

Recess-style rubber feet feature an indented, or recessed, area that provides a snug fit to the object they’re attached to. They’re often found on devices like laptops and smaller electronic gadgets, where they provide stability without adding noticeable height, weight, or bulk.

- Self-Adhesive

Self-adhesive rubber feet come with an adhesive backing, allowing them to be easily attached without any need for screws or additional fixtures. These are great for a wide range of applications including kitchen appliances, picture frames, and electronics, among others.

- Machine Screw

Machine screw-style rubber feet are designed to be screwed into the object. They provide a sturdy and durable hold and are often used in heavier machinery and appliances.

- Grommet Style

Grommet-style rubber feet, also known as recessed bumpers, have a hollow center. They can be used in various applications where there is a need to cushion or protect a protruding element.

- Stem Style

Stem-style rubber feet feature a protruding stem that can be inserted into a hole in the object. They are commonly used in furniture such as chairs and tables.

- Plug Style

Plug-style rubber feet are designed to be inserted into tubing or pipes. They are often used in chairs, tables, or other furniture with tubular legs to provide stability and floor protection.

Material Options for Rubber Feet

Rubber feet come in a range of materials to meet different application requirements. Here we will explore some of the most common material choices and their unique characteristics:

Natural Rubber

Known for its excellent flexibility and resilience, natural rubber is commonly used in applications requiring high tensile and tear strength. Its superior impact absorption makes it an excellent choice for heavy-duty rubber feet.

Silicone

Silicone rubber feet are appreciated for their excellent temperature resistance. silicone rubber bumpers are undoubtedly the most flexible material. On top of it, silicone has a variety of properties and applications. They maintain their properties even under extreme conditions, which makes them perfect for high-temperature applications.

Neoprene

Neoprene is a versatile synthetic rubber with good chemical stability and resistance to heat, oils, and many common chemicals. Its resilience and durability make it a great material for general-purpose rubber feet.

Nitrile (Buna-N)

Known for its outstanding oil and abrasion resistance, Nitrile is the material of choice for applications involving oils, fuels, and other chemical compounds.

Ethylene Propylene Diene Monomer (EPDM)

EPDM is highly resistant to aging, weathering, ozone, and UV rays. It’s often used for outdoor applications or environments subjected to harsh weather conditions.

Remember, choosing the right material for your rubber feet depends on your specific application needs. Factors to consider include the operating environment, temperature range, exposure to chemicals or oils, and the desired durability and longevity of the product.

The Manufacturing Process Behind Rubber Feet

The manufacturing process of rubber feet is a meticulous journey, involving various steps that ensure the final rubber product is robust, durable, and fit for its intended purpose. Here, we’ll delve into the key stages involved in the production of rubber feet.

Material Selection

The first step revolves around selecting the right kind of rubber. This could range from natural rubber to different types of synthetic rubbers like EPDM, SBR, and Neoprene. The choice of material depends on the application of the rubber foot, including factors like temperature resistance, hardness, and compression set.

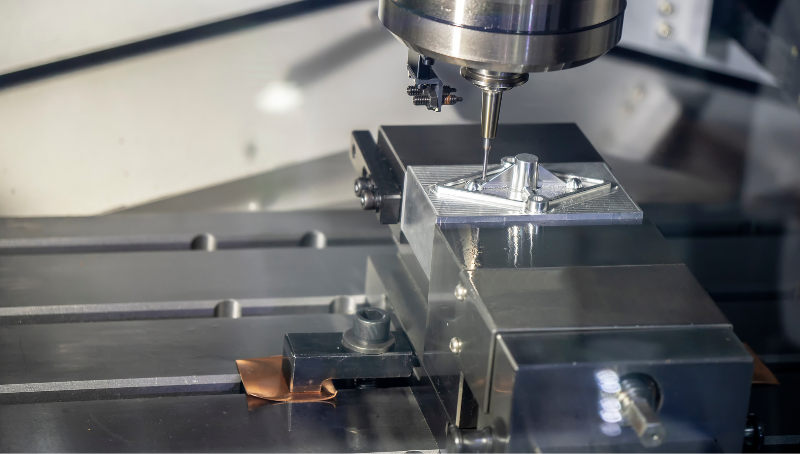

Design and Mold Creation

Once the material is chosen, the design phase begins. It involves creating the exact specifications of the rubber foot, including its shape, size, and style. After the design is finalized, a mold is created using materials like steel or aluminum. The mold matches the design’s exact dimensions and features.

Rubber Mixing

The rubber is then prepared by mixing it with various additives to enhance its properties. This could include accelerators, vulcanizing agents, and fillers. The mixed rubber is then heated to make it pliable and ready for molding.

Molding Process

The heated rubber is placed into the mold, and pressure is applied. The rubber takes the form and shape of the mold under this pressure. This can be done through different molding processes such as compression molding, injection molding, or transfer molding.

Curing and Finishing

The molded rubber is then cured, a process involving heat and time, which causes the rubber to harden and maintain its shape. After curing, the rubber feet are removed from the mold and go through a finishing process where excess material is trimmed, and the product is polished for a smooth finish.

This comprehensive process ensures that the final product, the rubber feet, is of high quality, durable, and ready for its intended use. This meticulous manufacturing journey underscores the importance of every rubber foot in providing stability, protection, and noise reduction to various appliances and equipment.

Installing and Replacing Rubber Feet Properly

Proper installation and replacement of rubber feet are critical to ensure optimal performance and longevity. This process might seem straightforward, but it requires attention to detail. Let’s break down the key steps you should follow:

Clean the Surface for Better Adhesion

One crucial step that should never be overlooked is cleaning the surface. Before attaching new rubber feet, it is essential to ensure that the area where they will be placed is free from any dirt, dust, or debris. This will help to achieve a stronger adhesion and ensure that the rubber feet stay in place for a longer period.

To clean the surface effectively, you can follow these steps:

- Begin by wiping the area with a damp cloth or sponge to remove any loose particles.

- If there are stubborn stains or sticky residue on the surface, use an appropriate adhesive remover to dissolve them.

- Gently scrub the area using a soft brush or toothbrush to ensure all dirt is removed.

- Rinse the surface thoroughly with clean water and allow it to dry completely before proceeding with attaching the new rubber feet.

By taking these cleaning steps, you create an optimal environment for proper adhesion of your rubber feet, ensuring they remain securely in place.

Use Appropriate Tools When Replacing Worn-out Rubber Feet.

When it comes time to replace worn-out rubber feet, having the right tools on hand can make the process much easier and more efficient. Depending on how your current rubber feet are attached, you may need different tools such as screwdrivers or adhesive removers.

Here are some common scenarios and their respective tool requirements:

- Screw-On Rubber Feet: If your existing rubber feet are screwed onto your furniture or equipment, you will need a compatible screwdriver (such as Phillips or flathead) to remove them.

- Adhesive Rubber Feet: For adhesive-backed rubber feet that are glued onto surfaces, an adhesive remover can help loosen and dissolve the adhesive for easy removal without damaging your furniture.

- Self-Stick Bumper Pads: In some cases, self-stick bumper pads can be a convenient alternative to replacing worn-out rubber feet. These pads come with adhesive backing and can be easily applied to the desired surface.

Remember to exercise caution when using tools, especially when dealing with delicate surfaces or objects. Using appropriate tools will ensure a smooth replacement process without causing any unnecessary damage.

Follow Manufacturer Instructions During Installation

To achieve optimal performance and longevity of your rubber feet, it is important to follow the manufacturer’s instructions for proper alignment and positioning during installation. Each type of rubber foot may have specific guidelines provided by the manufacturer, which should be read and followed accordingly.

Here are some general tips to keep in mind:

- Ensure that the surface is clean and dry before starting the installation.

- Check for any markings or indicators on both the rubber feet and the surface where they will be attached.

- Align each rubber foot carefully according to these markings or indicators.

- Apply even pressure while attaching the rubber feet to ensure a secure bond.

By following the manufacturer’s instructions, you can be confident that your rubber feet are installed correctly, providing stability, protection, and enhanced functionality to your furniture or equipment.

How to Choose the Right Rubber Feet for Your Needs?

Before you jump into buying rubber feet for your business, consider the following factors in choosing a rubber feet manufacturer:

Manufacturer’s Reputation

Start by evaluating the reputation of the manufacturer. Are they known for high-quality products? Do they have positive reviews and testimonials? A well-regarded manufacturer is more likely to produce reliable rubber feet that meet your needs.

Quality Control

Quality control is a vital part of the manufacturing process. Ensure that the manufacturer has rigorous quality control procedures in place to guarantee that the rubber feet meet the required specifications and standards.

Specifications and Features

Review the specifications and features of the rubber feet. This includes the type of rubber used, size, shape, load capacity, and installation method. Make sure these align with your application requirements.

Usability or Performance

Consider the performance of the rubber feet. How well do they reduce vibration, provide grip, and resist environmental factors like heat, moisture, and chemicals? The rubber feet should perform well in the conditions in which they will be used.

Product Warranty

Look for products that come with a warranty. This provides assurance to customers that the manufacturer stands behind the quality of their product. If anything goes wrong within the warranty period, you will be able to get a replacement or refund.

Budget

Lastly, consider your budget. While it’s important not to compromise on quality, you should also find rubber feet that offer the best value for money. Compare prices from different manufacturers and choose one that fits within your budget without compromising on the other factors mentioned above.

Making a well-informed decision when choosing rubber feet will ensure that you get a product that not only fits your needs but also offers longevity and performance. Keep these factors in mind to make the best choice.

Exploring the Future of Rubber Feet

As we delve into the future of rubber feet, it’s clear that technological advancements and environmental consciousness will play pivotal roles in shaping the industry. There is a noticeable shift towards the use of sustainable materials and manufacturing processes to reduce the industry’s carbon footprint. Eco-friendly rubber, produced through sustainable farming or recycled materials, is gaining significant traction. These products provide the same functionality as traditional rubber feet while minimizing environmental impact.

Moreover, we anticipate an increase in customization and precision manufacturing. Advances in 3D printing technology will allow for the production of rubber feet tailored to the specific needs of individual applications. This will improve efficiency and performance, making products more effective and durable.

Additionally, smart rubber feet integrated with sensors might become a reality. These would monitor wear and tear, alerting users when replacements are necessary, thereby preventing damage to the equipment they support.

In summary, the future of rubber feet points towards sustainability, advanced technology, and increased functionality.

Conclusion

Rubber feet are an essential component with a wide variety of applications. Their multifaceted benefits, types, and features make them an ideal choice for many industries. By considering the manufacturer’s reputation, quality control, specifications, performance, warranty, and budget, you can select the perfect rubber feet for your needs.

As we look to the future, trends such as sustainability, advanced manufacturing techniques, and smart features will continue to shape the rubber feet industry.

Get Top-Of-The-Line Rubber Feet From Hongju

Looking for top-quality rubber feet? Hongju Silicone is your trusted manufacturer. We specialize in high-performance rubber feet, tailored to suit various needs. Leveraging advanced technology, strict quality control, and years of expertise, we ensure the provision of durable, effective, and budget-friendly rubber products for your specific applications. Choose Hongju for excellence and reliability.