Keep reading if you’re wondering what’s the best way to use these self-adhesive rubber feet. This blog will give you basic information about it – from your options and the different applications.

What are Self-Adhesive Rubber Feet?

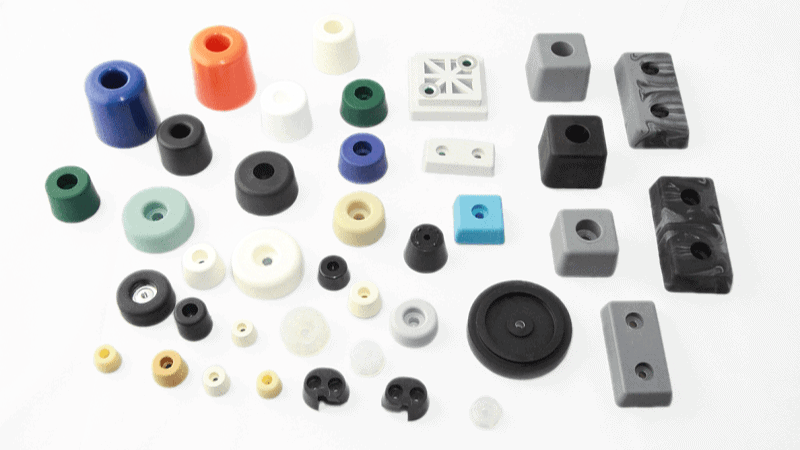

Self-adhesive rubber feet are stick-on rubber pads in different shapes and sizes. Some people also call them bumpers because you can use them as non-slip protectors for various furniture, equipment, and devices.

Well-made self-adhesive rubber feet are sticky enough to attach to multiple surfaces like wood, glass, plastic, and even metal.

These are typically made of rubber because they can keep things from slipping. On the other side is the adhesive pad you can use to stick on any surface.

Most self-adhesive rubber feet have various qualities.

For one, these are abrasion-resistant. That means you can use it without fearing it’ll leave marks on surfaces.

Depending on the specific rubber material, these can also have qualities like resistance to UV rays, dishwashing soap, and even noise and vibration. It can also have heat dissipation and sound-dampening rates.

Apart from getting these rubber feet in black or other solid colors, you can also have them in transparent material. Ensure you inquire with the manufacturer to ensure that it won’t turn yellow over time.

These versatile sticky products can also come in various shapes. The most common are squares, circles, cylinders, and hemispheres. These can either be flat or hollow. But you can have them in any shape that you want.

Selecting the appropriate shape for your rubber feet is crucial when it comes to determining their intended use. Flat rubber feet can support heavier loads, whereas hemispheric shapes are best suited for sound-dampening or energy absorption purposes.

Different Self-Adhesive Rubber Feet Applications

There are many self-adhesive rubber feet applications. You can use it for both home and workplace requirements.

At home…

You can use these rubber feet on anything that needs protection from scrapes or scratches. For example, you can use it to protect your floor from getting grazed by the metal legs of tables and chairs.

You can also use it at the bottom of the cabinet legs to keep it from slipping. The rubber feet can hold the cabinet’s weight from putting grooves on the floor.

These self-adhesive rubber feet are also perfect for items you don’t want to skid while using them. These include cutting boards, trays, bowls, etc. The rubber material provides enough resistance to keep these items from moving.

Some people use these rubber feet on equipment that vibrates. These include speakers and even washing machines. The rubber feet keep the vibrations from scuffing the floor.

These rubber feet are also helpful for hanging frames because they can keep the edges from damaging the walls.

In the office…

When you use it in the office, these rubber feet can help keep electronic devices and equipment from heating. You can put it underneath so the elevation can create space for the air to flow.

The self-adhesive rubber feet are ideal for work equipment like laptops or keyboards. The typing motion won’t make the devices move or slip.

You can also use these self-adhesive rubber feet for display purposes. Using POP displays to showcase what your business offers, use rubber feet to keep them from slipping. It can protect various glass display pieces – especially in an area with high foot traffic during the day.

Among the industries where you can see prominent self-adhesive rubber feet are automotive, retail, woodworking, and other manufacturing industries.

How to Apply Self-Adhesive Rubber Feet Properly

Rubber feet can be a useful addition to many products as they protect surfaces from scratches or damage. Applying self-adhesive rubber feet may seem like a straightforward process, but there are some important steps to follow to ensure they adhere properly and provide the intended protection. Ensure you follow these simple steps to ensure the rubber feet stick on the surface for a long time.

- Start by cleaning the surface to which you want to attach the rubber feet. Use a mild cleaning liquid like alcohol to remove the dust, dirt, or debris.

- Dry the surface using a clean cloth. Make sure it doesn’t have any oil residue.

- Peel off the self-adhesive rubber feet to expose the adhesive. Try not to touch the adhesive so as not to compromise its stickiness.

- Put the rubber feet on the application surface. Press firmly on the rubber site to ensure the adhesive completely attaches to the surface.

If possible, leave the rubber feet untouched for 24 hours. This will ensure the adhesive has enough time to “cure” and stick to the surface.

Conclusion

Self-adhesive rubber feet are versatile enough for all types of purposes and surfaces. Ensure you attach it to a clean surface so the adhesive will stick.

While these come in various shapes and sizes, you can customize them to suit your requirements. Just provide the details of your order to your supplier so they can create it according to your specifications.

Looking for Rubber Feet?

Hongju Silicone Can Help You

Hongju Silicone is a rubber compression molding and injection molding company in China. Besides rubber feet, we also offer silicone rubber keypads, rubber grommets, O-rings, Gaskets and Seals, etc.

Visit our website to discover more about Hongju Silicone and our expertise in providing high-quality silicone rubber products. Whether you need custom solutions or have specific requirements, contact us; our team is here to assist you.