Rubber bellows seal rings may be small, but they play an essential role in protecting equipment from leaks, dust, vibration, and pressure fluctuations. Their flexibility, durability, and material options make them ideal for pumps, valves, and industrial machinery.

This guide breaks down what they are, their types, benefits, and how to choose the right one. Keep reading to make an informed decision.

What Are Rubber Bellows Seal Rings?

Rubber bellows seal rings are specialized sealing components that keep diverse systems, industrial machinery, and equipment in good working order.

These seals have a flexible, accordion-like structure known as bellows that allows them to adjust to varied situations and efficiently prevent air or liquid loss.

The fundamental function of rubber bellows seal rings is to establish a secure barrier that prevents things such as gases, fluids, or particles from escaping.

They are often employed when maintaining a tight seal is critical to preventing leaks, ensuring operational safety, enhancing performance, and optimizing industrial process efficiency.

Rubber bellows provide a robust sealing solution that meets strict automotive standards.

They reliably withstand extreme temperatures, chemicals, and corrosive substances, making them suitable for various demanding applications.

Rubber bellow seals, also known as elastomeric bellows, are unbalanced, single-acting mechanical seals that offer optimal strength and robustness. They are designed compactly and provide a sealing action that brings numerous benefits.

These seals are primarily used for water, oils, and light-duty applications. The high strength and flexibility of the bellows are critical to the reliable performance of this type of seal as it readily accommodates seal misalignment, end-float, and seal face wear.

The rubber bellow seals create positive pressure against surfaces to eliminate or control the leakage of liquids and/or gases while preventing the entrance of external contaminants such as dust and dirt.

In mechanical face seals, elastomers often provide the secondary seal and direct contact between each seal face and the adjacent surface.

One seal face is fixed and sealed statically using an O-ring or cup gasket. The other is spring-loaded and requires a semi-dynamic seal to accommodate some axial play.

These semi-dynamic applications can be critical for ensuring optimal performance by maintaining proper contact between the faces through face wear, shaft movement, etc.

For critical applications, high pressures and double mechanical seals are typically recommended. These seals also incorporate additional components such as gaskets, O-rings, or wedges made from rubber, PTFE, or flexible graphite to eliminate potential leak paths.

Maintenance of these mechanical pump seals is another crucial aspect of ensuring safety. The seal faces are held together by a force derived from compressed elastomers, metal bellows, or springs (single or multiple).

The load received by the seal faces is determined by the hydraulic system’s seal design.

The optimal selection will hinge on various characteristics of the sealing material, with key factors including viscosity, abrasiveness, density, composition, and temperature.

The secondary seal type often affects the temperature and chemical capabilities of loose parts of the seal. The materials used for the rotating and stationary faces define the sealing surface resistance to abrasion and chemicals.

The energy consumption of automotive seals on the pump, mixer, agitator, or compressor also depends on the seal face combinations. Seal faces can be balanced to further operational efficiency or allow higher-pressure sealing.

Balanced seals can be used in multiple stages or at pressures above 200 psi for higher pressures or more demanding fluid services.

Special mechanical seals can be provided for the most challenging industrial applications considering pressure, temperature, speed, or fluid.

Take the First Step:

Requst for an Inquire

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

Different Types of Rubber Bellow Seals

Rubber bellow seals come in several varieties depending on their shape, design, and use.

Following are the types of rubber bellow seals:

Single-Acting Rubber Bellow Seals: Even the most basic rubber bellow seals provide a reliable sealing solution.

They are typically utilized in applications with modest pressures and moderate temperatures, because they are only intended to seal in one direction.

Double-Acting Rubber Bellow Seals: These seals are more sophisticated than single-acting ones because they can operate in both directions. They are typically used in conditions of high pressure or high temperature.

Spiral-Wound Rubber Bellow Seals: A pipe is encircled by a rubber circle in these seals. Since they are more flexible than other rubber bellow seals, they are frequently utilized in places with sways or vibrations.

Metal-Reinforced Rubber Bellow Seals: Due to the metal layer adhered to the rubber in these seals, they perform better when utilized in frictional or wear-prone environments.

Materials for Making Rubber Bellow Seal Rings

Rubber bellows seal rings serve a wide and diverse range of applications, from sealing joints to protecting various mechanical systems and assemblies. The material used in manufacturing these bellows is crucial for their performance.

Here are some commonly used materials for making rubber bellows seal rings:

Nitrile Rubber (NBR)

- Properties: Nitrile Rubber (NBR) has good resistance to oils, fuels, and certain chemicals. Moderate temperature resistance.

- Applications: Automotive, aerospace, and general industrial applications where oil and fuel resistance is crucial.

Ethylene Propylene Diene Monomer (EPDM)

- Properties: EPDM has excellent weather, UV, and ozone resistance. Good for high-temperature applications.

- Applications: Outdoor applications, steam systems, hot water systems.

Silicone Rubber

- Properties: Silicone rubber has high temperature resistance, flexible at low temperatures, good electrical insulating properties.

- Applications: Medical devices, aerospace, and high-temperature industrial applications.

Fluorocarbon Elastomers (FKM)

- Properties: FKM seals have exceptional resistance to chemicals, oil, and temperature.

- Applications: Chemical processing industry, high-temperature sealing applications.

Neoprene (CR)

- Properties: Neoprene bellows have good mechanical strength, flame resistance, and moderate resistance to oil and temperature.

- Applications: Marine applications, flame retardant seals, and general industrial applications.

Natural Rubber (NR)

- Properties: Natural rubber has excellent flexibility, tensile strength, and abrasion resistance.

- Applications: Not recommended for applications involving oils and fuels but good for abrasion-resistant applications.

Take the First Step:

Requst for an Inquire

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

Common Applications of Rubber Bellows Seal Rings

Let’s talk about a few common uses for the Rubber Below seal rings now that we have enough information about them. They perform a variety of functions in different equipment and systems.

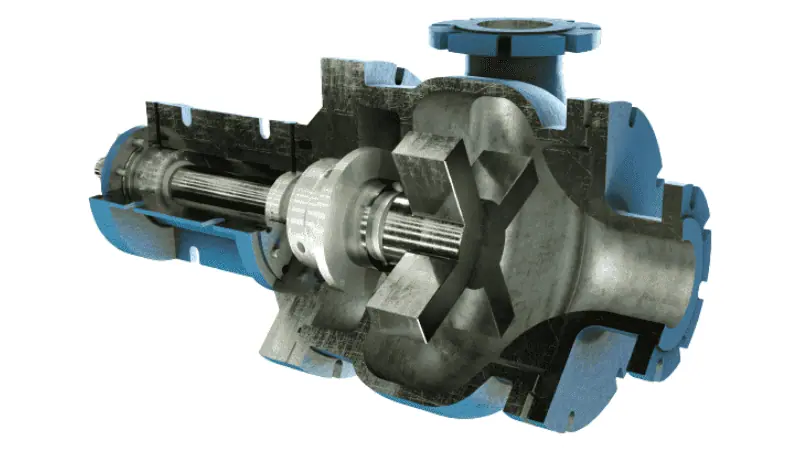

Pumps: Pumps that transfer water, sewage, or other liquids typically use rubber bellows seals. They resist corrosion from liquids and can withstand high pressure and temperature.

They are utilized in submersible, sewage, and water pumps ensuring leak-free efficient operation.

Valves: Rubber bellows seals are also frequently found in water, gas, and oil flow control valves.

They can work with many valves, including butterfly, gate, and ball valves, and provide reliable sealing.

Compensators: Rubber bellows seals are extensively used in compensators, which lessen the noise and vibration of fast-spinning machines.

They can withstand extreme temperatures and pressure while adjusting to the devices’ shifting motions. They are utilized in centrifugal and reciprocating compressors.

Medical Equipment: Rubber bellow seals, well known for their use in automotive applications, are also used in medical equipment that aids patients with health issues.

They must adhere to high standards and be safe and hygienic. They are utilized in heart-lung, dialysis, and other medical equipment.

Take the First Step:

Requst for an Inquire

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

Benefits of Using Rubber Bellows Seal Rings

In various industries, rubber bellows seal rings provide several advantages:

Sealing Reliability: Rubber bellows seal rings offer reliable sealing performance, preventing leakage of fluids and gases. Their flexible design allows them to create an effective sealing, even when the shaft is not aligned.

Vibration and Noise Reduction: These seals also can decrease machine noise and vibrations, which makes demanding environments more stable and peaceful. In industrial operating conditions, this is exceptionally crucial.

Thermal Compensation: By adapting to harsh environments (temperature expansion and contraction), these seals also lower the stress on the components of the equipment.

Therefore, they are ideal for applications in demanding conditions.

Contamination Prevention: Excellent resistance is one of these seals’ key benefits. Their capacity to restrict the flow of dust, coolant, chips, and other dangerous items into machinery, preventing potential damage.

The equipment may live longer and perform better as a result.

Considerations When Choosing Rubber Bellows Seal Rings

To achieve the high performance and longevity of the seals, several crucial elements must be taken into consideration while choosing rubber bellows seal rings.

1. Compatibility with Fluids

As some chemicals or substances may damage various elastomers, you must first determine whether the rubber material is compatible with the specific fluids in your application.

Manufacturers or industry professionals of rubber products often provide material compatibility charts and guidelines that include this information.

2. Temperature and Pressure

The operating conditions, pressure, and temperature should also be taken into account. The rubber bellows you choose should be able to endure the harsh conditions of your application environment.

Some rubber sealing solutions are better suited to withstand high temperatures or pressure environments.

3. Material Selection

Choose the rubber material that best fits your industrial settings by considering its distinct features and performance characteristics. Some options to consider include nitrile, silicone, and Viton.

4. Flexibility and Misalignment

The rubber bellow seal can adjust to vibrations, end-float, and seal misalignment. This adaptability is essential for reliable performance across a range of applications. It can seal off liquids, oils, and simple jobs.

5. Seal Design

Another thing to consider is the rubber bellow seal’s design, which can have a single or dual seal. You should select a design that meets the needs of your application.

Single seals may be needed for some applications, while double seals may be required for others for effective sealing.

Take the First Step:

Requst for an Inquire

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

Conclusion

Read this overview if you are in a hurry, have limited time, and want to know about Rubber Bellows Seals. Rubber bellows seal rings are essential for sealing solutions.

They use a flexible elastomeric design that avoids oil leaks and adapts to the movement of equipment. Pay attention to material compatibility, temperature, and pressure when choosing Rubber Bellows Seal Rings.

Unlock Your Business’s Potential with Hongju!

Unlock your business’s potential with Hongju! Whether you’re looking to streamline operations, top customer expectations or leverage advanced technology, Hongju is your go-to solution.

Get prototypes in 3-5 days and low MOQs tailored to your needs. With 20+ years of expert craftsmanship, we help you innovate faster and grow smarter.

FAQs

Q1: What are the key advantages of rubber bellows seal rings?

They offer superior flexibility, excellent vibration damping, and reliable sealing in dynamic applications. Their design compensates for axial and angular misalignment, ensuring long-term leak prevention.

Q2: Which rubber material is best for chemical resistance?

FFKM (Perfluoroelastomer) provides exceptional resistance to aggressive chemicals and high temperatures. For less extreme conditions, FKM (Viton) offers strong chemical compatibility at a more accessible cost.

Q3: How do I select the right bellow design for my application?

Convoluted bellows suit large movements, while toroidal handles higher pressures. Hongju Silicone’s engineers can recommend the optimal design based on your specific pressure, movement, and space constraints.

Q4: Can you customize seals for extreme temperatures?

Yes. Hongju Silicone specializes in compounding silicone for cold environments (-60°C) and FKM for heat resistance up to 230°C, ensuring performance stability across operating conditions.