This article aims to provide an in-depth look at what FKM seals are, their chemical composition, and their applicability across various sectors.

What are FKM Seals?

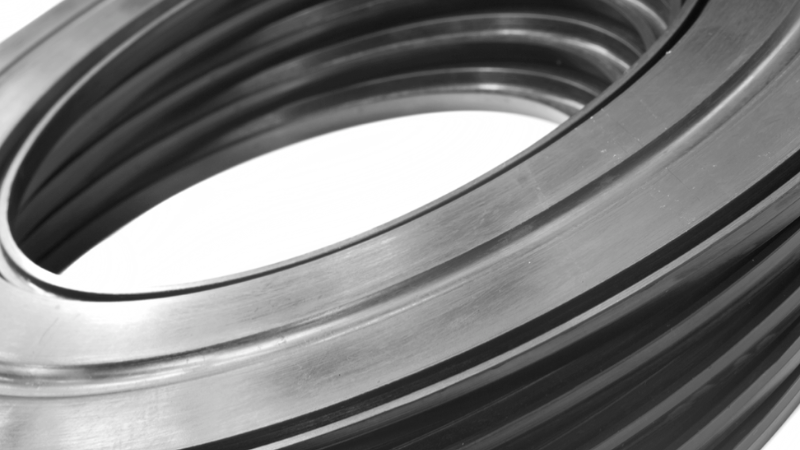

FKM falls under the category of synthetic rubber designed for high-performance applications. Distinguished by their improved chemical resistance, FKM seals are indispensable components in sealing systems that require steadfast durability against high temperatures, mineral oils, and harsh chemicals. The robustness of FKM seals can largely be attributed to their fluorine content, making them a go-to solution for challenging operational conditions.

FKM Seals Properties

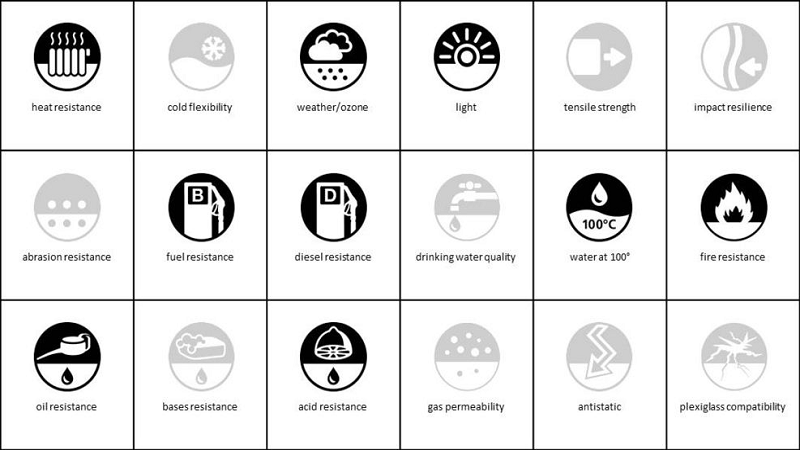

One of the critical factors contributing to the growing popularity of FKM seals is their extensive range of beneficial properties that make them suitable for challenging applications. Below are some of the notable characteristics:

- High-Temperature Resistance: FKM seals can operate efficiently in temperature extremes, often up to 200-300°C, making them ideal for applications involving high temperatures.

- Chemical Resistance: The unique chemical composition of FKM rubber provides improved chemical resistance, particularly against aliphatic and aromatic hydrocarbons, fuel oils, and other harsh chemicals.

- Low Gas Permeability: With low gas permeability, FKM seals are excellent for applications where air bubble formation or gas leakage would be problematic, ensuring a tighter seal.

- Mechanical Durability: These seals are robust against mechanical stress, showing excellent compression resistance which maintains their shape and function over extended periods.

- Heat Resistance: Their innate heat resistance makes them highly reliable in environments where temperature fluctuations are common.

- Broad Range of Application: Due to their excellent resistance and durability, FKM seals are commonly used in the pharmaceutical industries, aerospace industry, and hydraulic systems that may involve aggressive chemicals.

By understanding these properties, one can better assess the suitability of FKM seals for various applications and conditions.

FKM Seals Application

FKM seals (fluorocarbon rubber) are widely used in various industries such as automotive, aerospace, oil & gas, pharmaceuticals, and food processing. These versatile seals play a crucial role in ensuring the efficient operation of different systems and equipment. Let’s explore some of the key applications where FKM seals excel:

- Automotive: FKM seals find extensive use in engine systems, providing reliable sealing for components like valves, fuel injectors, and coolant systems. They withstand high temperatures and resist chemicals found in fuels and lubricants.

- Aerospace: In the aerospace industry, FKM seals are essential for maintaining airtight connections in hydraulic systems, fuel handling equipment, and engine compartments. Their resistance to extreme temperatures and harsh fluids makes them ideal for critical applications.

- Oil & Gas: FKM seals play a vital role in oil refineries and drilling operations by providing leak-free sealing solutions for pumps, valves, compressors, and pipelines. They exhibit excellent resistance to aggressive chemicals and hydrocarbons.

- Pharmaceuticals: The pharmaceutical industry relies on FKM seals to maintain hygienic conditions during the manufacturing process. These seals ensure proper containment of fluids while resisting sterilization methods such as steam or chemical disinfection.

- Food Processing: Similarly to the pharmaceutical sector, FKM seals contribute to maintaining sanitary conditions in food processing equipment. They offer excellent resistance against food acids, oils, fats, and cleaning agents while preventing contamination risks.

The Pros and Cons of FKM Seals

When considering high-performance sealing solutions, it’s essential to weigh the pros and cons to determine if FKM seals are the right fit for your application. Here’s a breakdown:

Pros

- Excellent Chemical Resistance: FKM seals are virtually impervious to many harsh chemicals, including aliphatic and aromatic hydrocarbons.

- High-Temperature Durability: Capable of withstanding temperature extremes, these seals are ideal for applications that see frequent temperature fluctuations.

- Mechanical Resilience: Their mechanical stress resistance and compression resistance are high, making them a durable choice for various industrial applications.

- Low Gas Permeability: Offers excellent sealing capabilities by reducing air bubble formation and gas leakage, crucial in pneumatic and hydraulic systems.

- Wide Range of Applications: Due to their robust nature, FKM seals find utility in a diverse range of industries, from the aerospace industry to the pharmaceutical industry.

Cons

- Cost: FKM seals can be more expensive than other types of seals, which could be a determining factor for some applications.

- Not Compatible With All Chemicals: Despite their improved chemical resistance, they are not suitable for contact with ketones, amines, and certain types of acids.

- Potential for Seal Failure: In suboptimal conditions or if incorrectly installed, there could be seal failure, although this is generally rare when following proper installation and maintenance guidelines.

- Limited Flexibility at Low Temperatures: While they perform well at high temperatures, their flexibility can be compromised at extremely low temperatures.

By understanding both the advantages and drawbacks of FKM seals, you can make a more informed decision based on your specific needs and operating conditions.

When Should You Use an FKM Seal?

FKM seals are the go-to choice for applications that involve aggressive chemicals, high temperatures, and demanding operating conditions. These seals offer exceptional performance and reliability in challenging environments.

Suitable for sealing systems exposed to fuels, oils, acids, and other corrosive substances, FKM seals provide robust protection against chemical degradation. They excel in industries where resistance to harsh substances is paramount.

FKM seals are a top contender. Their durability ensures they can withstand prolonged exposure to extreme conditions without compromising functionality.

Whether you’re dealing with corrosive chemicals or operating in high-temperature environments, FKM seals prove their worth time and again. They offer peace of mind knowing that your sealing system is well-equipped to handle even the most demanding circumstances.

How to Choose the Right FKM Seal for Your Needs

There are a few key factors that you should consider. By taking these into account, you can ensure that you choose a grade of FKM seal that is suitable for your needs.

- Operating Temperature Range: The first thing to consider is the temperature range in which the seal will be operating. Different grades of FKM have varying temperature capabilities, so it’s important to choose one that can withstand the temperatures your application requires.

- Fluid Compatibility: Another crucial factor is fluid compatibility. FKM seals are designed to resist various chemicals and fluids, but not all grades offer the same level of resistance. Make sure to assess whether the seal will be exposed to any specific chemicals or fuels and select an appropriate grade accordingly.

- Pressure Requirements: Consider the pressure requirements of your application as well. Some FKM seals may not be able to handle high-pressure environments, so it’s essential to choose a grade that can withstand the pressure levels involved.

To ensure you make an informed decision when choosing an FKM seal, it’s advisable to consult with experts or refer to material compatibility charts. These resources can provide valuable guidance and help you determine which grade of FKM seal is best suited for your specific needs.

Conclusion

FKM seals stand out as a versatile and reliable option, offering excellent resistance to high temperatures, chemicals, and mechanical stress. While they may come at a higher initial cost compared to other materials, their durability and extended seal life often make them a cost-effective solution in the long run. Understanding your specific needs and operating conditions will guide you in making an informed decision.

Get Top-Of-The-Line FKM Seals From Hongju

Are you in the market for seals that offer unbeatable performance, even in high-temperature and aggressive chemical environments? Get top-of-the-line FKM seals from Hongju Silicone.

Our seals are crafted with precision, ensuring exceptional durability and an extended lifespan for your machinery. Connect with our sealing experts today for a consultation tailored to your specific industry needs.