EMI shielding seals and gaskets are essential in safeguarding electronic devices from external interference, typically made from conductive rubber.

But, does rubber really conduct electricity? Dive into this definitive guide to learn all about conductive rubber and its various applications. Keep reading to uncover more!

What is Conductive Rubber?

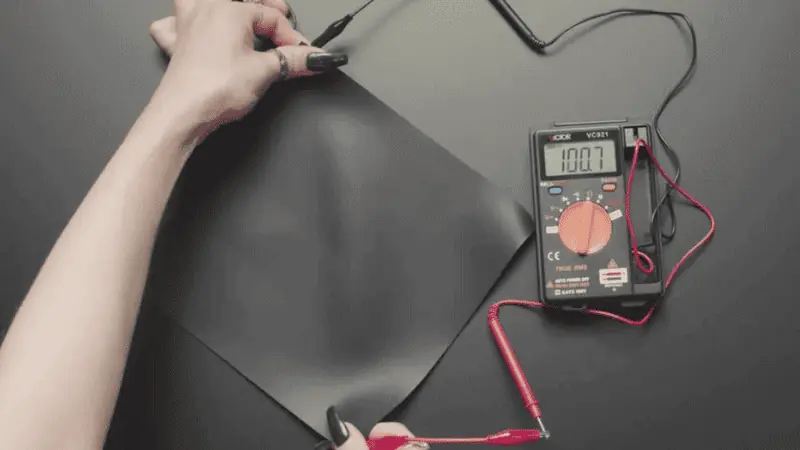

Conductive rubber is a rubber that can conduct electricity. On their own, synthetic rubber materials are insulators.

However, when treated with an electrically conductive material, these materials become electrically charged. The primary conductive material is carbon black.

Other conductive materials include silver, gold, and copper. The level of conductivity of the rubber depends on the conductive material.

Where is Conductive Rubber Used?

Conductive rubber manufactures sealing solutions that keep out electromagnetic interference (EMI). EMI emits radio waves and signals that can interfere with wireless communications. This interference also threatens critical infrastructure and non-military assets like the power grid.

But with conductive rubber, sealing solutions can provide adequate protection against interference. As a result, conductive rubber is used across several industries, especially in applications that need an environmental seal that possesses shielding effectiveness.

Other conductive rubber sectors include telecommunications, the military, computing, and electronics.

Furthermore, conductive rubber produces electrostatic discharge (ESD) protection, sensors, and static dissipative flooring. This type of rubber is also widely employed in making electrical cable insulation.

The Benefits of Using Conductive Rubber

It Prevents Electricity Buildup

Conductive rubber prevents electricity buildup, protecting electrical components and preventing electric sparks and shocks.

Traditional rubber products usually offer padding to avoid fatigue on surfaces. Nevertheless, these surfaces still produce static electricity, especially when exposed to much friction.

Unfortunately, the electricity buildup can damage the electrical components of a device.

Static electricity is prevalent in the presence of electricity and the contact faces between two dissimilar materials.

Unfortunately, static electricity can lead to fire or explosions when igniting flammable mixtures. Also, it can cause an electric shock to flow through the body, causing burns, falls, or even stopping the heart.

It Limits Interference

Placing a cell phone close to powered audio equipment causes interference and a series of beeps. In high-powered devices, the interference produces radio frequency that can cause unwanted effects on other devices. For instance, a broken microwave may cause your computer to reboot.

However, an EMI shield protects your devices and keeps the signal’s integrity. Conductive rubber is used to manufacture these shields, guarding your electronics.

Send Your Inquiry Now!

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

How to Choose the Right Type of Conductive Rubber for Your Projects?

Conductive rubber is made from different rubber materials. For example, this type of rubber may be made from EDPM, Silicone rubber, nitrile, or neoprene.

Because the elastomeric base of a conductive rubber varies, its properties change, and it is suitable for specific applications.

Therefore, before choosing a conductive rubber for your projects, consider the operating conditions of your application.

- Temperature

Consider the temperature of your application before choosing a suitable conductive rubber. Unfortunately, not all rubber materials can withstand heat.

However, the silicone elastomer is the most heat-resistant conductive rubber. In addition, it has high thermal stability, retaining its properties at high temperatures.

Furthermore, if the application’s operating conditions require low temperatures, consider the elastomeric component of your conductive rubber. Conductive silicone, fluorosilicone, and EPDM retain their properties at low temperatures.

- Hydraulic fluids

Hydraulic fluids attack the elastomeric component of conductive rubber. Therefore if your application uses hydraulic fluids, you need a conductive rubber that can withstand the effects of hydraulic fluids. Conductive nitrile rubber is the best for this type of application.

- Hydrocarbon fuels

Standard hydrocarbon fuels include diesel, gasoline, natural gas, kerosene, and propane. If your application uses any hydrocarbon fuel, conductive fluorosilicone offers good resistance to energy. Conductive EPDM is also excellent for these applications.

Send Your Inquiry Now!

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

- Ozone and weather

Ozone and the weather wear out elastomers. Only a few are resistant enough. Conductive rubber with weather resistance includes silicone, fluorosilicone, and EPDM.

- Dilute acids

Use conductive rubber that suits the process if your application uses dilute acids. Dilute acids attack rubber, leading to its degradation and deterioration. Conductive EPDM has good resistance to dilute acids.

- IRM 901 oil

The IRM 901 certification is the standard test method for evaluating the ability of elastomeric compounds to withstand the effects of liquids. Conductive fluorosilicone passes the standard and is safe for use.

The Manufacturing Process of Conductive Rubber

Adding conductive carbon or fillers to an elastomer gives it conductive properties. The electrical conductivity level of the filler impacts the rubber’s level of conductivity. The most conductive rubber material is a silicone-filled elastomer.

The most common rubber manufacturing processes include extrusion, calendaring, latex dipping, and molding.

The difference between rubber manufacturing and conductive rubber is that carbon or conductive material is added to the elastomer before the raw material settles.

Besides increasing the conductive properties of rubber, reinforcing your elastomer with a conductive material improves its mechanical properties.

As mentioned earlier, conductive rubber has an elastomeric-based and filler conductive material. The properties of the elastomer translate to the eventual conductive rubber product.

For instance, conductive fluorosilicone can resist fuels and chemicals. The rubber also has a shore A hardness of 50, 60, and 80 durometers.

Consequently, it is ideal for applications that need more resilient materials. Less rigid rubber materials like natural rubber are less resilient than fluorosilicone. Nevertheless, they are applicable in processes that require soft sealing solutions.

Applications of Conductive Rubber in Various Industries

Conductive rubber is used across several sectors, including medical, telecommunications, and the military. This material is often used as a component of high-quality electronic products. One such product is the silicone rubber keypad and EMI o-rings.

- Silicone rubber keypad

A silicone rubber keypad is a soft rubber webbing that improves the functionality of a keypad. Usually, the webbing is upright, but when a button is pressed, it deforms, establishing contact between a conductive-coated pill and an underlying printed circuit board (PCB). This contact completes the circuit.

Some silicone rubber keypads feature backlighting. Therefore, it reduces erroneous commands in low-light conditions, achieving higher input accuracy. Furthermore, silicone rubber keypads are aesthetic and more visible when laser-etched with backlights.

Using a high-powered laser, the laser-etching process selectively removes some paint off a silicone rubber keypad’s laser. Removing the pain allows the backlight to illuminate the silicone rubber keypad.

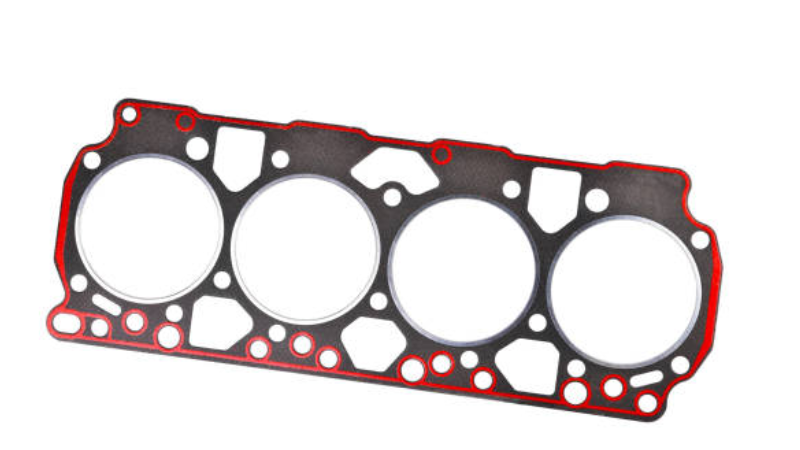

- EMI O-rings

EMI O-rings are made from electrically conductive rubber, providing shielding against electromagnetic interference(EMI). This sealing solution protects electronic systems and components from disturbances.

EMI O-rings ensure electrical conductivity between mating surfaces and require compression for proper functioning. Nevertheless, this material should be able to withstand compression sets and bounce back once the force is removed.

Conductive silicone is a sturdy material with excellent compression set and thermal resistance. Therefore, EMI o-rings made from this material are durable and keep out electromagnetic interference.

Send Your Inquiry Now!

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

The Future of Conductive Rubber

Covid-19 disrupted the demand and supply chain for raw materials and end products. Therefore, the demand for conductive rubber is reduced.

However, because this type of rubber is essential in shielding electronic devices from electromagnetic radiation, the need for the material has contributed to its massive growth.

Although conductive rubber is made from different elastomers, conductive silicone is the most popular and in demand due to its superior properties.

Conductive silicone products are durable and possess exceptional thermal stability, electrical conductivity, and compression. It is also resistant to external factors like ozone and the weather.

The future for conductive rubber is bright, especially conductive silicone and conductive EPDM. Smartphones, laptops, and other consumer electronics adopt conductive rubber. Therefore, the extensive adoption of this material in electronic products has surged its demand.

In addition, the growing demand for these devices is expected to drive segment growth for electrically conductive rubber.

Conclusion

Conductive rubber is more than just rubber. It is a rubber that conducts electricity. This rubber type is used in sealing solutions that prevent external interference and static electricity buildup.

Nevertheless, because conductive rubber is made from different elastomers, it is essential to consider the operating conditions of your application before choosing a suitable one.

Hongju – Your Custom Rubber Products Manufacturer!

The conductive rubber market has steadily grown over the years. And with its estimated growth, incorporating it into your business gives you an edge.

Hongju can manufacture conductive rubber products to meet your requirements. Contact us now and also collaborate with your team to provide tailor-made solutions, from gaskets to o-rings.