O-rings and X-rings may look similar, but they serve different purposes across a variety of applications. From industrial sealing systems to motorcycle chains, each type has its own strengths.

This article breaks down the key differences between O-rings and X-rings, explores material options, and shows you how to choose the right seal or chain based on your specific needs.

What is an O-ring?

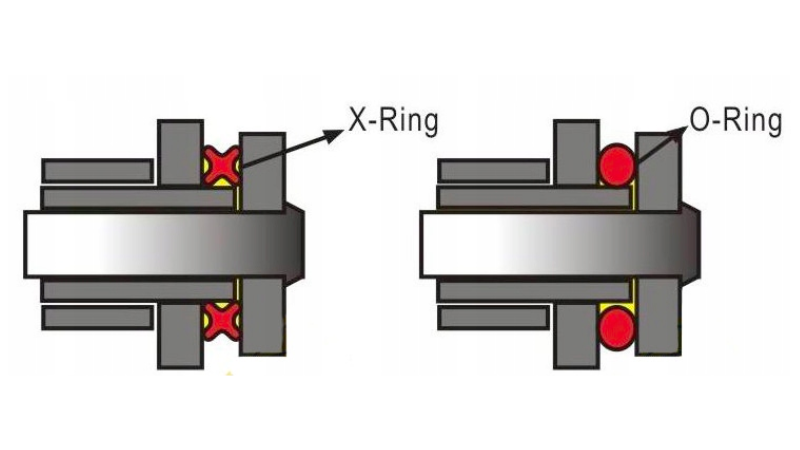

An O-ring is a loop of elastomer with a round cross-section, primarily used to seal two connecting parts in both static and dynamic applications. They are commonly used to prevent leaks between sealing surfaces and are often found in a variety of industrial applications, including motorcycle chains known as o-ring chains.

O-rings offer a simple yet effective way to make seals and prevent metal-on-metal contact between components, thus minimizing wear and extending seal life. Because of their versatility, O-rings are available in various materials like silicone, nitrile, and fluorocarbon, each offering unique benefits such as heat resistance.

What is an X-ring?

An X-ring has an X-shaped cross-section rather than a round one like the O-ring. This unique design allows it to offer more sealing interfaces, making it especially useful in dynamic applications where movement and pressure changes are frequent.

X-rings are often used in high-pressure environments and offer extended service life compared to traditional O-rings. They are particularly useful in applications requiring a tight seal, such as x-ring chains in motorcycle chains.

Much like standard O-rings, X-rings come in a variety of materials designed for specific applications, with properties such as heat resistance and enhanced seal life.

Send Your Inquiry Now!

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

Material Variations: A Closer Look at X-Ring and O-Ring Options

Different materials offer distinct advantages and limitations, and choosing the right one can dramatically impact the seal life and overall performance of the inner components of the ring. Below, we break down some popular materials for both O-rings and X-rings.

Material Options for O-Rings

- Nitrile Rubber: This is a standard material for O-rings and is highly resistant to oil and other petroleum products. It’s an excellent choice for automotive applications and o-ring chains in motorcycles.

- Silicone: Known for its excellent heat resistance, silicone O-rings are ideal for applications where high temperatures are a concern, such as in aerospace or kitchen appliances.

- Fluorocarbon: For harsh environments that require chemical resistance, fluorocarbon O-rings are a solid choice. They are also commonly found in aerospace applications.

Material Options for X-Rings

- Hydrogenated Nitrile Butadiene Rubber (HNBR): This material offers exceptional mechanical properties and is resistant to wear, making it suitable for high-pressure pumps and x-ring chains in motorcycle chains.

- Ethylene Propylene Diene Monomer (EPDM): This material is ideal for outdoor applications due to its resistance to UV light and weather conditions. It is often used in roofing and water drainage systems.

- Polyurethane: Known for its durability and extended service life, polyurethane is frequently used in dynamic systems such as pneumatic cylinders and heavy machinery.

Understanding the material composition is crucial when selecting an O-ring or X-ring for a specific application. The right material can ensure optimal performance, durability, and seal life.

Send Your Inquiry Now!

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

Which One is Better: O-rings or X-rings?

The answer to the question of “Which is better—O-rings or X-rings?” isn’t straightforward. Both have their unique advantages and disadvantages, and the “better” option depends on your specific needs, application, and operating conditions. Here’s a quick rundown:

1. For Cost-Effectiveness: O-rings

If initial cost is a significant factor for you, then O-rings are generally more cost-effective. They are less expensive to manufacture and, thus, to purchase. However, keep in mind that they may require more frequent replacement, particularly in high-stress or dynamic applications.

2. For Longevity: X-rings

If you’re looking for a solution that offers an extended service life, X-rings, especially those made of Hydrogenated Nitrile Butadiene Rubber (HNBR), are a strong candidate. Their unique design minimizes friction and wear, extending their lifespan.

3. For Versatility: O-rings

O-rings come in shapes and a broader range of materials and are suitable for various applications, from aerospace to kitchen appliances. Whether you need heat resistance or chemical resistance, there’s likely an O-ring material that fits the bill.

4. For High-Pressure and Dynamic Applications: X-rings

The more sealing surfaces of an X-ring make it better suited for high-pressure environments or systems with a lot of movement, such as motorcycle chains with X-ring chains.

5. For Easy Maintenance: O-rings

O-rings are generally easier and quicker to replace, making them a good choice for applications where rapid servicing is required.

6. Weigh Your Options

In summary, choosing between an O-ring and an X-ring depends on your specific application requirements, the operational environment, and cost considerations.

While O-rings are a solid, versatile option for many applications, X-rings may offer advantages in specific conditions, such as high-pressure and dynamic systems.

Send Your Inquiry Now!

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

Exploring Applications: Where to Use X-Rings and O-Rings

Both O-rings and X-rings have versatile applications across a wide range of industries. Let’s delve deeper into where each type of ring is most effectively utilized.

O-Rings: A Staple in Various Sectors

- Automotive Applications: O-rings are commonly found in fuel injectors, oil filters, and air conditioning systems. Their heat resistance and sealing efficiency make them perfect for variable temperature conditions.

- Motorcycle Chains: Known as o-ring chains, these are typically utilized by casual or everyday riders. Their design helps keep the chain lubricated, thereby minimizing metal-on-metal contact and extending seal life.

- Aerospace: In hydraulic actuators and fuel systems, O-rings need to withstand extreme conditions, including very high or low temperatures and intense pressures.

X-Rings: Ideal for High-Pressure and Specialized Uses

- High-Pressure Pumps: X-rings are often employed in high-pressure water and hydraulic pumps. Their x-shaped cross-section offers more sealing surfaces, making them suitable for these demanding applications.

- Medical Devices: X-rings are gaining traction in medical devices such as oxygen concentrators and ventilators due to their long-lasting properties and extended service life.

Send Your Inquiry Now!

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

Applications in Motorcycle Chain: Standard MX vs. O-Ring vs. X-Ring Chains

When it comes to motorcycle chains, you have a variety of options to consider, each with its unique set of advantages and drawbacks.

In this section, we’ll delve into Standard MX chains, O-ring chains, and X-ring chains, exploring what sets them apart and how O-rings and X-rings come into play.

What is A Standard MX Chain?

Standard MX Chains are typically used in off-road conditions and are often favored for their rugged durability. These chains consist of inner and outer plates and are designed to handle rough terrains and high-stress conditions.

Unlike O-ring chains, MX chains lack an internal lubrication system, relying instead on external lubricants to reduce metal-on-metal contact and friction.

These chains are often the choice for those who prioritize a simple, robust design over long-term maintenance considerations.

What is an O-ring Chain?

O-ring chains feature rubber O-rings situated between the inner and outer plates of each link. These O-rings function as a sealing mechanism, trapping lubricants within the chain links.

As a result, O-ring chains offer an extended service life, greater durability, and reduced maintenance compared to standard MX chains. They are particularly well-suited for environments where seal life and longevity are top concerns.

What is an X-ring Chain?

X-ring chains take the concept of O-ring chains a step further by incorporating X-rings, which have an X-shaped cross-section. These X-rings offer more sealing surfaces, trapping lubricants more effectively and reducing friction even further.

Because of these attributes, X-ring chains typically offer the longest service life and are ideal for high-performance, high-pressure applications. The x-ring holds the lubricants better, leading to lower maintenance needs and a longer-lasting chain.

When selecting a motorcycle chain, it’s crucial to consider the kind of riding you’ll be doing. For off-road and high-speed applications, MX chains could be beneficial due to their lightweight nature.

O-ring chains offer a balanced approach, suitable for general-purpose riding. For long-distance touring or when longevity and minimal maintenance are primary concerns, X-ring chains are the best choice.

Send Your Inquiry Now!

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

Factors to Consider when Choosing X-Rings or O-Rings

Selecting the right sealing solution depends on various factors that encompass material properties, application demands, and cost considerations. Here are some factors you should weigh in your decision:

Application Environment

- Temperature Tolerance: For high-temperature environments, materials like silicone or fluorocarbon are recommended for O-rings.

- Pressure: X-rings are generally more suited for high-pressure dynamic applications due to their larger sealing surfaces.

Longevity and Maintenance

- Replacement Frequency: If you’re looking for a long-lasting option with less frequent replacements, X-rings, especially those made from Hydrogenated Nitrile Butadiene Rubber (HNBR), might be more suitable.

- Ease of Maintenance: O-rings are generally easier to replace but may require more frequent chain lubricated maintenance, particularly in o-ring chains.

Cost Implications

- Initial Cost vs. Long-Term Value: While O-rings are generally cheaper, X-rings offer an extended service life and may provide better long-term value.

- Material Costs: Different materials come at various price points. Balance your budget against the material advantages you need for your specific application.

Send Your Inquiry Now!

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

Conclusion

Choosing between X-rings and O-rings is not a one-size-fits-all decision. Each has its merits and drawbacks, depending on your specific application and requirements.

O-rings are reliable and cost-effective, while X-rings offer superior sealing and longer service life. Armed with the insights from this article, you’re now better prepared to make an informed choice for your needs.

Looking for X-rings or O-rings? Hongju Silicone Can Help You!

Whether you’re searching for advanced sealing solutions or a durable motorcycle chain, look no further than Hongju Silicone.

We offer a wide range of high-quality X-rings and O-rings designed to meet various industrial and personal needs. Contact us today to find the perfect fit for your project and give us a chance to improve your business!