Whether it’s in automotive gaskets, industrial seals, or footwear, the prowess of oil-resistant rubbers like nitrile rubber showcases not only superior oil resistance but a range of other beneficial mechanical and chemical properties.

This article delves into the intricacies of these highly resistant rubbers, their unique chemical structure, and the multitude of applications they serve.

What is Oil-Resistant Rubber?

Oil-resistant rubber, also known as elastomer, is a specialized type of rubber that possesses the ability to withstand the harmful effects of oil.

It is formulated using specific additives and compounds that provide exceptional resistance against oil-based substances. This unique composition allows oil-resistant rubber to maintain its integrity even when exposed to oils and petroleum-based fluids.

Key features and characteristics of oil-resistant rubber include:

- Superior Oil Resistance: As its name suggests, the primary trait of this rubber is its exceptional resistance to oils, including mineral oils, vegetable oils, and even certain petrochemicals.

- Good Mechanical Properties: Beyond just oil resistance, these rubbers also display good mechanical properties, meaning they can maintain their structural integrity under stress and strain.

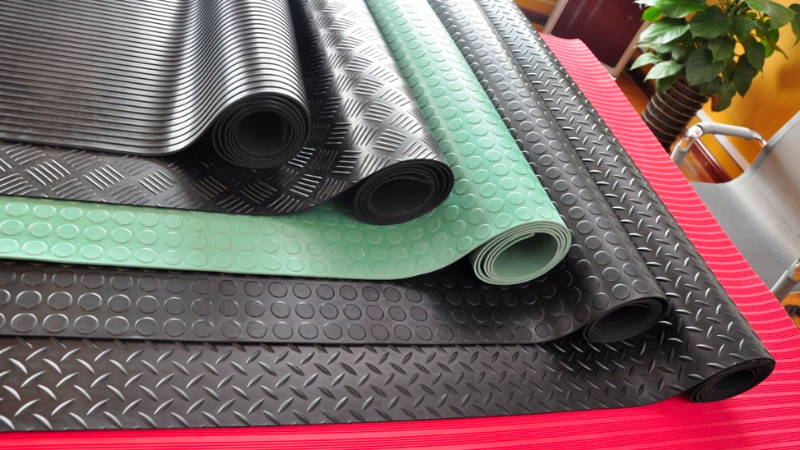

- Abrasion Resistance: Oil-resistant rubbers, especially nitrile rubber, possess commendable abrasion resistance, making them suitable for applications where wear and tear are common.

- Chemical Resistance: The chemical structure of these rubbers endows them with resistance against a variety of chemicals, not just oils. This broadens their applicability in various industries, including chemical processing.

- High Temperature and Ageing Resistance: These rubbers can endure high temperatures without losing their essential properties. Additionally, they demonstrate commendable ageing resistance, meaning they won’t degrade easily over time.

- Tensile Strength: The strength of these rubbers, particularly their tensile strength, enables them to be used in applications that require them to withstand pulling forces.

Importance of Oil-Resistant Rubber in Various Industries

Oil-resistant rubber plays a crucial role in multiple industries, providing essential benefits and ensuring reliable performance. Let’s explore the significance of oil-resistant rubber in different sectors:

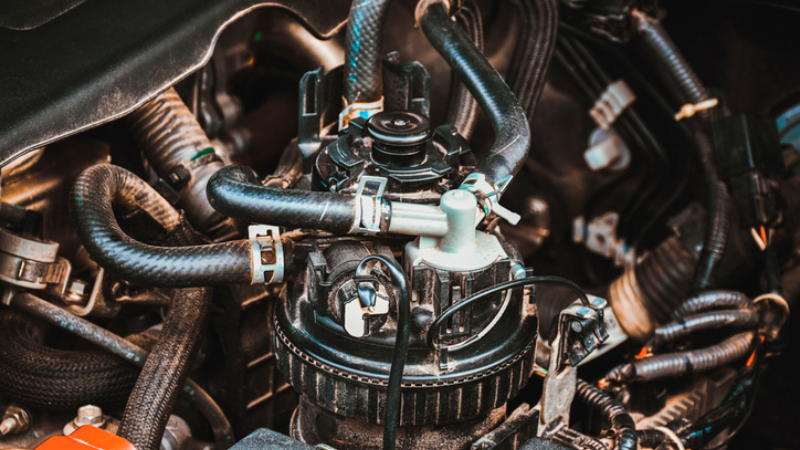

- Automotive applications heavily rely on oil-resistant rubber to guarantee optimal performance within engine compartments. This versatile material is widely used for gaskets, seals, and hoses, effectively preventing oil leaks and maintaining the integrity of automotive systems.

- In the manufacturing sector, oil-resistant rubber is vital for various components that come into contact with oils during production processes. Conveyor belts, O-rings, and other equipment require this specialized rubber to withstand exposure to oils and maintain operational efficiency.

- The aerospace industry also depends on oil-resistant rubber due to its ability to withstand aviation fuels. Aircraft fuel systems, hydraulic seals, and engine parts extensively utilize this resilient material for enhanced safety and longevity.

By using oil-resistant rubber in these areas, industries can ensure durability, minimize downtime caused by leaks or failures, and enhance overall productivity.

Drawbacks of Using Oil-Resistant Rubbers

Here’s a deeper dive into the challenges or drawbacks one might encounter when opting for oil-resistant rubbers:

- Some oil-resistant rubbers may not provide adequate resistance to certain chemicals or solvents apart from oils.

- Certain grades of oil-resistant rubbers can be more expensive compared to standard rubbers due to their specialized formulations.

- Prolonged exposure to extreme temperatures or aggressive chemicals can gradually deteriorate the properties of some oil-resistant rubbers.

Oil-resistant rubbers are commonly used in various industries for their ability to withstand exposure to oils. However, it is important to note that these synthetic rubbers also may have limitations and drawbacks that should be considered. Here are some key points to keep in mind:

- Limited resistance: While oil-resistant rubbers excel in resisting oils, they may not offer the same level of protection against other chemicals or solvents. It is crucial to assess the specific requirements of your application and ensure that the chosen rubber can withstand all relevant substances.

- Higher costs: Specialized formulations used in certain grades of oil-resistant rubbers can lead to higher costs compared to standard rubber options. This cost difference should be taken into account when considering the overall budget for a project.

- Deterioration over time: Prolonged exposure to extreme temperatures or aggressive chemicals can cause gradual deterioration in the properties of some oil-resistant rubbers. This can result in reduced effectiveness and a shorter lifespan, necessitating regular inspections and potential replacement if necessary.

Best Materials for Oil Resistance

There are several options available. Let’s take a look at the best materials for oil resistance:

- Nitrile Rubber (NBR): Often at the forefront when discussing oil-resistant materials, nitrile rubber, a copolymer of acrylonitrile and butadiene, offers excellent resistance to oils, fuels, and certain chemicals. Nitrile rubber is mostly used where high oil resistance is required, as in automotive seals, gaskets, or other items subject to contact with hot oils.

- Silicone Rubber: Silicone rubber not only offers good oil resistance but also exhibits high thermal stability. It can withstand extreme temperatures without losing its integrity. Silicone rubber shows excellent compatibility with many oils and lubricants commonly used in industrial settings.

- Ethylene Propylene Diene Monomer (EPDM): EPDM is a versatile material that provides superior resistance against weathering elements like sunlight, ozone, and heat. While it may not have the same level of oil resistance as nitrile or silicone rubber, it still offers moderate protection against various types of oils. EPDM is often used in outdoor applications where exposure to both weathering elements and occasional oil contact is expected.

- Polyacrylate Rubber (ACM): Known for its superior resistance to high-temperature oils and UV light, ACM is often employed in automotive transmissions and engine seals.

When selecting a material for its oil-resistant capabilities, it’s paramount to consider the specific type of oil or petroleum product, the temperature range, and any other environmental factors.

Factors to Consider When Choosing Oil-Resistant Rubbers

Selecting the right oil-resistant rubber for a specific application can be pivotal in ensuring longevity, performance, and safety. Here are some crucial factors to consider when making a selection:

Temperature Range

- Ensure the oil-resistant rubber can withstand extreme temperatures in your application.

- Look for rubbers with a wide temperature range to handle both hot and cold conditions.

Chemical Compatibility

- Consider the specific oils or fluids that will come into contact with the rubber.

- Choose a rubber that is compatible with these oils to prevent degradation or failure.

- Check compatibility charts or consult with experts if unsure.

Mechanical Requirements

Evaluate necessary physical properties for optimal performance.

- Hardness: Determine the desired hardness level based on application requirements.

- Tensile Strength: Select a rubber with sufficient tensile strength to resist tearing or breaking under stress.

- Elongation: Assess the elongation capability of the rubber to ensure flexibility and resistance to deformation.

Considering these factors will help you select an oil-resistant rubber that meets your requirements and ensures optimal performance in demanding environments without compromising quality or safety standards.

Ensuring Compatibility: Avoiding Incompatible Materials for Oil Resistance

Ensuring compatibility is a fundamental aspect when selecting materials for applications in oil-rich environments.

A mismatch could lead to premature wear, component failure, and even safety concerns. Here’s how to avoid incompatible materials when prioritizing oil resistance:

1. Understand the Specific Oil Type

As mentioned earlier, oils can vary significantly. A material that resists one type of oil might degrade quickly when exposed to another. For instance, rubber seals with natural rubber offer limited oil and fuel resistance and can deteriorate when exposed to petroleum-based oils.

2. Check Material Data Sheets

Manufacturers often provide data sheets that detail a material’s resistance to various chemicals, including different oils. These sheets can offer a quick reference for compatibility checks.

3. Beware of Blended Materials

Some rubbers are produced from blends of various polymers. While blending can enhance certain properties, it might also introduce vulnerabilities.

A blend might have one component that’s highly oil-resistant and another that’s not, leading to unpredictable behavior in oil-rich environments.

4. Environmental Factors

Other environmental factors, such as ozone resistance, UV exposure, or temperature fluctuations, can impact a material’s performance in oil. For instance, a material might resist oil at a low temperature but fail at high temperatures.

5. Consider Past Experiences and Case Studies

Sometimes, the best teacher is experience. If a particular material has failed in an oil environment previously, it’s a clear indicator of its incompatibility. On the other hand, materials that have successfully been used in similar applications can serve as reliable choices.

6. Consult with Experts

Reach out to specialists or materials scientists who have experience in the field. Their insights can be invaluable in guiding material choices. They might also be aware of the latest materials or formulations that offer enhanced oil resistance.

By taking the time to ensure material compatibility with oils, you can prevent potential failures, enhance the lifespan of components, and ensure the safety and efficiency of operations. Proper material selection is a small investment that can offer significant long-term returns.

Conclusion

Oil-resistant rubbers have proven to be indispensable in a myriad of industries, offering tailored solutions to challenges posed by oil-rich environments. From the robust nitrile rubber with its superior oil resistance to the dynamic properties of other rubber materials, it’s evident that selecting the right rubber is crucial.

Dive Deep with Hongju’s Oil-Resistant Rubber Solutions!

Embrace the future of high-performance applications with Hongju. Our advanced oil-resistant rubber solutions are tailored to meet the stringent demands of modern industries.

With unparalleled expertise, cutting-edge technology, and a commitment to excellence, contact us now, and Hongju ensures you get the best in quality and performance.