What is EPDM, and What are its Properties?

EDPM is a commonly used elastomeric synthetic rubber with good thermal and weather resistance. It also has a long-lasting, high tensile strength.

EPDM seals are suitable for use in bleach, chlorine, water, and other materials. Ozone resistance and the capability to overcome deionized water make EPDM, ethylene propylene diene monomer, ideal for industrial applications.

EPDM always regains its original shape regardless of the temperature range after stretching. Its adhesive and elastic properties make this a possibility. Nonetheless, EPDM doesn’t excel in everything.

For instance, it is not suitable for chlorinated hydrocarbons, hydrocarbon solvent applications, petroleum oil, and other fluids.

Here are some of the properties of EPDM:

- Broad operational temperature range

- Ideal for a broad number of applications

- Highly tolerant to alkalis, ketones, diluted & mineral acids, and sodium hydroxide solutions

- Steam resistance

- Abrasion resistance

- Tear resistance

- Good mechanical properties

- Good compression set

- Ozone and sunlight resistance

- Ideal for cold materials and extreme temperatures

Send Your Inquiry Now!

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

What is Viton, and What are its Properties?

Viton is a durable, high-performing fluorinated hydrocarbon rubber that’s common in valve seals and o-rings. It is an ideal solution for use within environments that need chemical resistance, ozone resistance, and high-temperature resistance.

Therefore, it can work in high-temperature applications such as in the valve industry.

The challenge with Viton is that it is more costly than EPDM. Viton handles aliphatic and aromatic hydrocarbons well, in addition to strong acid materials and halogenated fluids.

Viton is among the most potent fluoroelastomers with temperature tolerances. That is why it is a good choice for demanding and tough sealing applications. Its resilience is simply on another level.

The properties of Viton include the following:

- It is friendly to the environment

- Durable

- Absorbs fluids well, hence, exceptional moisture absorption

- Potent heat resistance

- High-temperature tolerances

- Great for sterilization

- Remains elastic and flexible even when exposed to high pressure

- Chemical resistance and compatibility

- Performs well in high temperatures

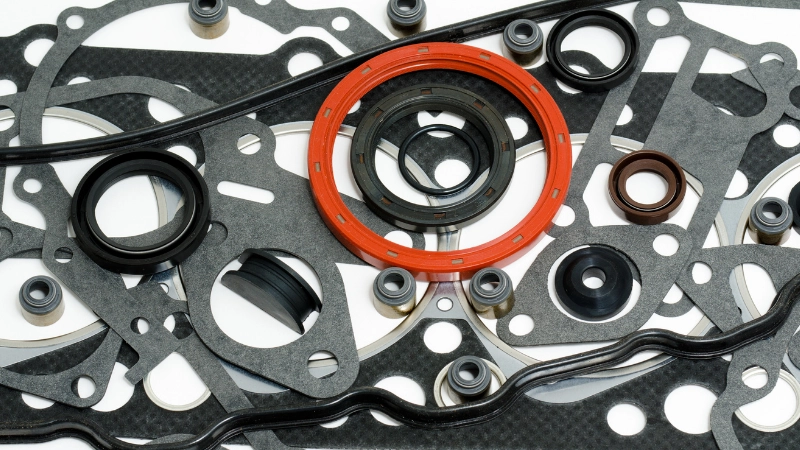

Viton vs. EPDM O-Rings & Gaskets

It is imperative to first discuss Viton and EPDM seals’ physical and mechanical properties before settling on the better option for o rings and gaskets.

- Viton is not a distinctive material in the industrial space. It is made up of a synthetic rubber fluoropolymer elastomer. The fluoropolymer family has impressive resistance to bases, acids, and solvents.

- Viton is a dense material, which makes it robust. Its high-temperature tolerance makes Viton maintain its mechanical properties and elasticity.

- It has chemical resistance, including to oils, lubricants, and fuels.

- Viton also resists corrosion, burning, mold, fungus, oxygenated automotive fuels, and aromatic hydrocarbons.

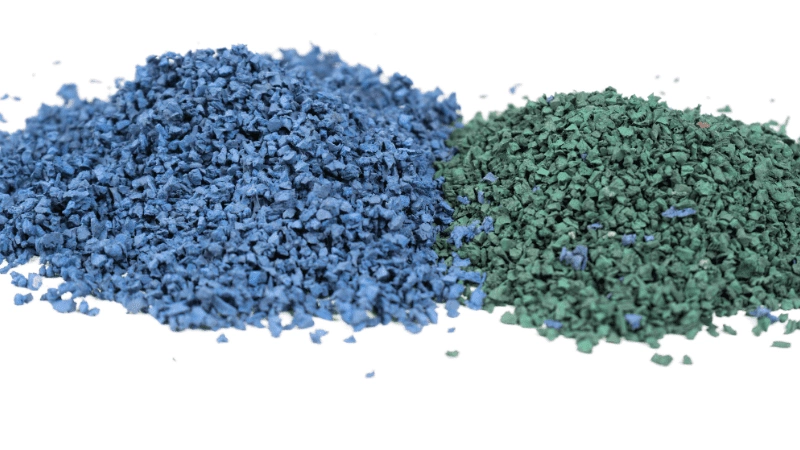

- EPDM seals are inexpensive rubbers. EPDM is an abbreviation of ethylene propylene diene monomer. It is made up of two materials, typically propylene and ethylene. Both materials are by-products of natural gas and oil.

- EPDM is a versatile synthetic rubber with a long lifespan.

EPDM vs. Viton: A Properties and Performance Comparison

Both Viton and EPDM rubber sheeting are thermoset polymer elastomeric materials. They are used in different applications across a wide range of industries. There are several differences when comparing Viton and EPDM rubber sheeting.

Nonetheless, they still share some characteristics, such as weather resistance, flexibility, and compression strength.

EPDM rubber sheeting is the perfect material for roofs. On the other hand, Viton is a preferred option for O-rings and gaskets in the automotive industry. Differences in properties make the Viton vs EPDM war intensify further.

One major way to differentiate Viton and EPDM is by their composition or origin. Unlike EPDM, Viton is a fluoropolymer elastomer. EPDM is extracted from propylene and ethylene.

This makes them have two contrasting properties. The properties are temperature tolerances and chemical resistance.

When Should You Use EPDM O-Rings or Gaskets?

Most synthetic rubbers, such as nitrile rubber, thrive in high temperatures. However, very few of them, such as EPDM, thrive in low temperatures ranging from -45 degrees Celsius to 145 degrees Celsius.

In fact, EPDM can work in about any environment and temperature range.

Its temperature tolerances make it an ideal option for insulation and sealing material in colder temperatures. Examples of applications of EPDM include:

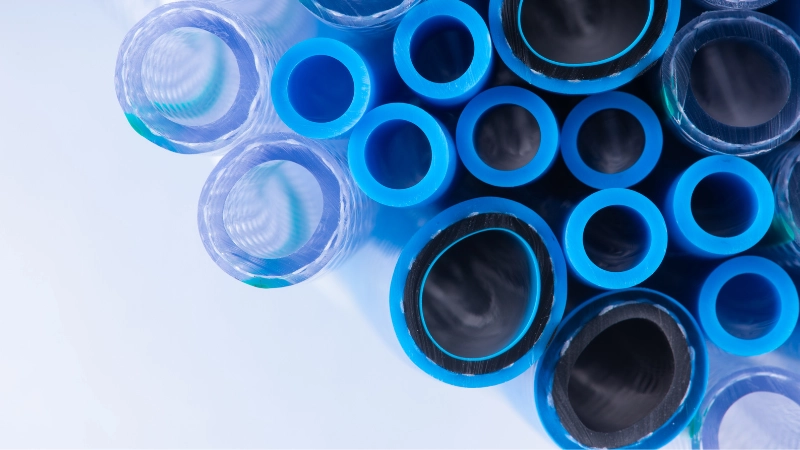

- Wire and cable connectors

- Solar panel heat collectors

- O-rings

- Freezer room seals

- Roofing

- Gaskets

- Tubing

- Electrical insulation

- Radiator and heater hoses

- Weatherstripping

- Diaphragms

- Insulators

- Window and door seals

Other impressive properties of EPDM include its moisture and chemical compatibility. It also has hot water and steam resistance.

And it can take on many diluted acids, greases, silicone oils, sodium hydroxide, detergents, and caustic potash solutions, among many other diluted acids.

EPDM, nevertheless, has poor resistance to hydrocarbons such as mineral acids, kerosene, gasoline, oils, and mineral oil-based lubricants.

Send Your Inquiry Now!

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

When Should You Use Viton O-Rings or Gaskets?

Viton offers more resistance to bases, mineral acids, and solvents as a fluoropolymer. Viton is dense and equally has mild alkali resistance.

Its properties remain intact even at higher temperatures. It remains elastic and has oil and chemical resistance. This makes it ideal for use in various places, such as brake fluids.

Viton’s effective operating temperature range is between -20 degrees Celsius and 210 degrees Celsius. This wide range makes it a favorite in applications requiring high resistance to elevated temperatures.

Some of these applications include:

- O-rings

- Valve seals

- Gaskets

- Other molded and extruded products

Viton equally has good resistance to UV, atmospheric conditions, and weather.

Its chemical resistance makes it handle corrosion, even from most mineral acids and different fluids, such as brake fluids. This makes it compatible with lubricants, fuels, and oils, such as vegetable oils and mineral oils.

EPDM vs. Viton – Which One is Better?

Viton vs. EPDM is an argument that can go on and on. However, it all comes down to what you want to do. How do you intend to use either Viton seals or EPDM? Each material has properties that can facilitate several applications.

For instance, when choosing between EPDM and Viton, there are specific factors that you should have in mind.

First off, Viton is about seven times more expensive than EPDM. If you’re looking for a more affordable option, especially for large quantities, then Viton might not be a fit for you.

Only when you’re purchasing smaller quantities will Viton be suitable. Well, unless you have the money and are ready to spend it.

But the truth is that Viton offers durability and immense quality over EPDM. Its adaptability in higher and lower temperatures and its low permeability ensure Viton resists degradation and corrosion.

In cold environments, EPDM handles well. Its steam and hot water resistance also make it a better choice in some applications. Ultimately, the material you settle on will depend on its intended application.

We’ll leave you with this guide to selecting gasket materials so that you learn more about gaskets.

Send Your Inquiry Now!

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

Conclusion

Choosing the best material to put together your o-rings or gaskets is important. An oversight can lead to errors in the application of the items. Now that you have seen the properties of Viton and EPDM, you can decide which one to use.

If you still have any doubts, we are here to help you and take you through all the necessary steps.

Contact Hongju for EPDM and Viton O-rings and Gaskets Now!

Whenever you need EPDM or Viton for your distinct applications, Hongju is always ready to help you out. Get prototypes in 3-5 days and low MOQs tailored to your needs. With 20+ years of expert craftsmanship, we deliver quality silicone solutions that accelerate your success.

Contact us now for a free project review!