Manufacturers know that using good materials is important. The right materials make things fit well and last a long time in different places. From manufacturing plants to automotive workshops, these resilient objects play a crucial role in maintaining safety standards.

So next time you need a rubber grommet for an application, remember the key players: industry-grade materials, precise specifications, and reliable manufacturers who know how to get the job done right.

What are Rubber Grommets?

A rubber grommet is a flexible ring made of rubber or silicone that goes into a hole in metal or plastic. Let’s break down this definition and its usage to gain a better understanding.

Understanding Rubber Grommets

A rubber grommet is a type of ring, usually made from a flexible material like rubber or silicone, that is designed to be inserted into a hole in a piece of metal, plastic, or other hard material. Round rubber grommets or oval rubber grommets are the most common shapes. The primary purpose of a grommet is to shield, route, or insulate objects passing through the hole, protecting them from sharp edges.

This buffering action preserves the integrity of wires or other materials passing through, extending their lifespan and maintaining their functionality. “Rubber grommets” also refer to those made of synthetic rubbers. The most well-known ones include neoprene rubber grommets, nitrile rubber grommets, and silicone rubber grommets.

Wide Application of Rubber Grommets

Given their protective role, rubber grommets are extensively utilized across numerous industries. For instance, they’re commonly found in settings where wires or other sensitive objects must traverse harsh or rough surfaces. You can see them in action in electrical systems, automobile wiring assemblies, and even within our homes and offices, where they’re employed in furniture to prevent wear and tear on cables.

Although there are various types of rubber grommets available in the market, each type differs in its properties and, consequently, its suitability for specific applications. For example, Rubber cable grommets are made waterproof and dustproof to protect sensitive components and can be found in every significant industry, from the office workplace to factories. Oval rubber grommets, also called oblong rubber grommets, they’re used in automotive, and electrical enclosures – generally, for any panel in any industry.

Inquire About Our Silicone and Plastic Products!

Different types of rubber grommets

Rubber grommets come in a variety of types, each designed to meet specific needs and applications. Here we’ll discuss six of the most common types:

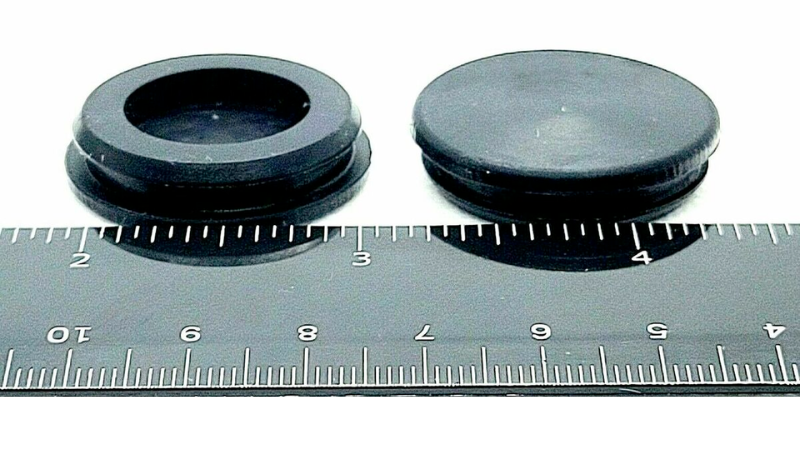

Closed Rubber Grommet

Closed Rubber Grommets are typically used in applications where a hole is not required. Closed grommets serve to seal holes to prevent dust, moisture, or other unwanted elements from entering a specific area, providing excellent sealing capabilities in electronic appliances and other equipment.

Standard Rubber Grommet

The most common type is the Standard Rubber Grommet. They are used to protect cables or wires from sharp corners and other rough and sharp edges. With a hole in the center, they are perfect for applications that require wire and cable management.

Custom Rubber Grommet

Custom Rubber Grommets are designed to cater to unique applications that cannot be covered by standard sizes or shapes. Customers can customize rubber grommets of different rubber materials according to the needs of their products. They are tailored to meet specific dimensional and material requirements, offering flexibility and precise fit for specialized needs.

Diaphragm Rubber Grommet

Diaphragm Rubber Grommets, also known as blind rubber grommets or sealing grommets, feature a thin center membrane. This type of rubber cable grommet contains a thin, central film, which can be pierced to allow different-sized wires to pass through into an enclosure or through a panel. They are used to create a seal and protect components from dust, moisture, and other environmental factors. The membrane can be pierced to allow passage of a wire or a tube, but when not pierced, it offers a closed seal.

Edge Rubber Grommet

Edge Rubber Grommets are designed to be placed around the edges of holes in metal, plastic, or other hard materials. They provide protection for wires or other items passing through the hole, preventing them from rubbing against potentially sharp or rough edges.

Stepped Rubber Grommet

Stepped Rubber Grommets are a variant that comes with a step or shoulder on the inside diameter. This design feature allows for the passage of items of different diameters while still offering an excellent seal.

Understanding the differences among these rubber grommets is key to selecting the right one for your application, as we’ll explore further in the following sections.

Inquire About Our Silicone and Plastic Products!

The Benefits of Using Rubber Grommets

Rubber grommets offer a range of advantages, cables, and equipment. From shielding against pointed rims to dampening vibrations, these versatile components play a crucial role in various industries. Let’s explore the benefits of using rubber grommets in more detail.

Protection against sharp edges

One of the primary functions of rubber grommets is to shield wires and cables from being cut or damaged by the rough edges of drilled holes. When passing through holes in metal or other materials, wires are prone to abrasion and potential breakage. Rubber grommets act as a protective barrier, preventing direct contact between the wire and any sharp edges.

Vibration dampening

Machinery and movement can generate substantial vibrations that may lead to premature wear and tear on equipment. Rubber grommets excel at absorbing these vibrations, acting as shock absorbers for sensitive components. By reducing the impact of vibrations, grommets help extend the lifespan of machinery while minimizing maintenance costs.

Insulation properties

Rubber possesses excellent insulating properties, making it an ideal material choice for protecting your electrical appliances and wiring from heat or moisture damage. When wires come into contact with extreme temperatures or humidity, their performance can be compromised, leading to short circuits or even fire hazards.

In addition to these key benefits, synthetic rubber grommets offer other advantages worth mentioning:

- Versatility: Rubber grommets come in various shapes and sizes to accommodate different applications.

- Easy installation: They are simple to install without requiring specialized tools or expertise.

- Cost-effective solution: Rubber grommets provide long-lasting protection at an affordable price point.

- Noise reduction: By absorbing vibrations, grommets contribute to reducing noise levels in machinery and equipment.

Rubber grommets are a small component that provides significant benefits, making them a smart choice for a myriad of applications.

Inquire About Our Silicone and Plastic Products!

Common Problems with Rubber Grommets

Despite their utility, rubber grommets are not without their potential issues. These can arise from incorrect installation, unsuitable environmental conditions, or simply choosing the wrong type of grommet for your specific needs.

Improper Fit

One of the most common problems associated with rubber grommets is an improper fit. This can occur if the grommet’s size doesn’t match the hole’s size or if the rubber grommet shapes or is not properly seated in the hole. An improperly fitted grommet can result in insufficient protection, leading to potential damage to the wire or material passing through it.

Material Degradation

Over time and under certain environmental conditions, rubber grommets may undergo material degradation. This may include hardening, softening, cracking, or discoloration of the grommet. Such degradation can compromise the grommet’s function and can be accelerated by exposure to harsh chemicals, extreme temperatures, or UV light.

Incorrect Material Selection

Choosing the wrong type of rubber grommet for your application can also lead to problems. For example, using a general-purpose grommet when a high-temperature or chemical-resistant grommet is needed can result in early failure of the grommet.

By being aware of these potential issues, you can take steps to prevent them and thus ensure that your rubber grommets perform optimally for a longer period.

Inquire About Our Silicone and Plastic Products!

The Type of Tools Used to Measure Rubber Grommets

Accurate measurement of rubber grommets is essential to ensure their proper fit and function. A variety of measurement tools can be used depending on the specific parameters you need to measure. Here are a few commonly used tools:

Calipers

Calipers, particularly digital ones, are an excellent tool for measuring the external and internal diameters of a rubber grommet. They can provide highly accurate measurements, which is crucial for ensuring that the grommet will fit correctly into its intended hole.

Micrometers

Micrometers are similar to calipers but are typically used for even more precise measurements. They can be used to measure smaller dimensions with high accuracy and are often used in quality control processes in the manufacturing industry.

Depth Gauges

To measure the thickness or depth of a rubber grommet, a depth gauge can be used. This tool can precisely measure the depth of a hole, which is helpful when you need to ascertain the grommet’s seating depth.

Durometers

While not a measuring tool in the traditional sense, a durometer can be used to measure the hardness of a rubber grommet, which can be an important parameter depending on the application. It can help in determining whether the grommet has the necessary firmness to withstand specific pressures or environments.

Each of these tools has its specific use cases, and choosing the right one depends on what aspects of the rubber grommet you need to measure. Correct measurement is a crucial step in ensuring the effective and efficient performance of your rubber grommets.

Inquire About Our Silicone and Plastic Products!

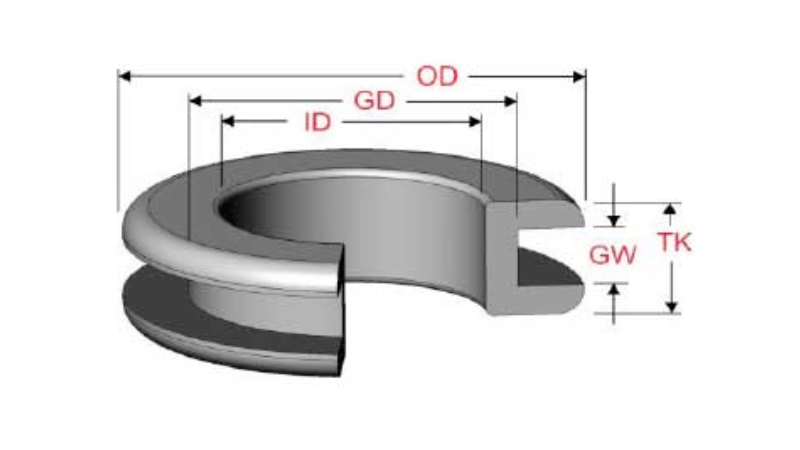

The Methods of Measuring Rubber Grommets

When it comes to measuring rubber grommets, there are two main methods that are commonly used:

Inner Diameter Measurement

One of the essential measurements you need to consider is the inner diameter. This measurement determines the size of the hole where the grommet will be inserted. To accurately measure the inner diameter, follow these steps:

- Use a caliper or ruler: Start by using a caliper or ruler with millimeter markings to measure across the inside edges of the hole.

- Take multiple measurements: To ensure accuracy, take several measurements at different points along the circumference of the hole.

- Record the smallest measurement: The smallest measurement indicates the true inner diameter and should be used when selecting a rubber grommet.

Outer Diameter Measurement

Another crucial measurement to consider when dealing with rubber grommets is their outer diameter. This measurement refers to the overall width of the grommet, including any flanges or protrusions that may be present. To measure the outer diameter effectively, follow these simple steps:

- Use a caliper or ruler: Similar to measuring inner diameter, use a caliper or ruler with millimeter markings.

- Measure across the widest points: Place your measuring tool across the widest points of the grommet’s outer edge.

- Include any flanges or protrusions: Make sure to include any flanges or protrusions in your measurement if they are part of your specific application.

Thickness Measurement

Assessing how thick or thin a rubber grommet needs to be is crucial for ensuring proper fit and function within your application. Here’s how you can accurately measure its thickness:

- Lay flat on a surface: Start by laying your rubber grommet flat on a stable surface.

- Use a caliper or ruler: Employing a caliper or ruler with millimeter markings, measure from one surface of the grommet to the other.

- Take multiple measurements: As with the inner diameter, take multiple measurements at different points along the grommet’s thickness.

By following these methods of measuring rubber grommets, you can confidently select the right size and fit for your specific needs. Remember to record all measurements accurately and consider any additional features such as flanges or protrusions when determining the outer diameter. Taking precise measurements ensures that your rubber grommets will function optimally in their intended applications.

A Few Tips on Choosing the Right Rubber Grommet for Your Needs

When selecting the silicone rubber grommet suitable for your requirements, it’s vital to contemplate various size attributes like diameter and thickness, the specific properties of the rubber used, and the industry where the grommet will be employed.

Utilize the panel method to gauge the grommet accurately. This approach ensures you secure the most fitting match for your endeavor.

One must not overlook the criticality of the base material. The substance used to craft the grommet should be contingent entirely upon the rubber’s unique attributes and purpose.

The material should exhibit heat resistance, providing a safeguard for cables against detrimental chemicals and sharp objects. Ideal choices would encompass materials like TPE, TPV, synthetic rubbers, and natural rubbers.

Inquire About Our Silicone and Plastic Products!

Conclusion

In conclusion, understanding the various types, uses, and potential problems with rubber grommets is key to making the right selection for your specific needs.

By taking into consideration factors such as your application’s environment, the grommet’s size, the type of material, and industry standards, you can ensure optimal performance and longevity.

Buy High-Quality Rubber Grommets from Hongju

At Hongju Silicone, we are committed to providing our customers with high-quality rubber grommets. With over 23 years of experience in the rubber and plastic industry, we are proud to offer a comprehensive selection of grommets in a variety of sizes, shapes, materials, and colors to suit your specific application.