Since there are many types and uses of rubber grommets, you must get to know them thoroughly to choose the right one to use. This article will give you basic information about rubber grommets and how they usually work.

What is a Rubber Grommet?

A rubber grommet is a cover for sharp edges. It intends to protect whatever passes through its position from cuts or friction damages. It goes by several names, like eyelets, edging, and bushing (or insulating bushing). It’s a highly versatile product that many industries use, including construction, production, manufacturing, etc.

What are Rubber Grommets Made of?

There are several types of rubber materials for grommets.

- Natural rubber. This has excellent tensile strength. It’s also very resistant to any strains or tears. It also has solid electrical insulation, making it ideal for wires, cables, or anything with electrical systems.

- Fluorocarbon Rubber (FKM or Viton). This type of rubber is very stable and can withstand extremely high temperatures. It is also ideal for environments that are strongly alkaline or acidic.

- Neoprene Rubber. This is an excellent material resistant to flame, heat, ozone corrosion, and weather elements. So this is the perfect material if the rubber grommet will be outdoors or in fire-risk environments.

- Nitrile Rubber (Buna-N). This is oil-resistant, so it’s ideal for automotive or mechanical purposes. Anything that has exposure to oil should use this type of rubber grommet. This material has semiconductor and antistatic properties as well. If this is your choice of rubber, check the mechanical industry standard. It has to have a shelf life of 4 to 5 years.

- Silicone Rubber. This is a versatile type of rubber that can offer different color options. It’s a preference among manufacturers because it’s a friendlier material. That means it’s odorless and safe even when it comes into contact with the skin or food. That’s why silicone grommets are typical for food processing, other kitchen devices, and medical equipment.

What are the Benefits of Using Rubber Grommets?

Rubber grommets possess many qualities that make them more beneficial than those made of metal, nylon, or PVC (Polyvinyl Chloride). These are easier and quicker to apply. Instead of screwing them into place, you can push them into position. There’s no need for any nut locks on the other side. The rubber is flexible enough to squeeze into place.

Another quality of rubber grommets is they are weather-resistant. This makes it great for electrical wires and machinery for outdoor use. Or at least those that need protection from any leaks.

Rubber is also heat resistant. That means rubber grommets are ideal for machines that have the potential to overheat or if it uses high electricity. This makes it a safer option for warehouse and manufacturing sites.

Because of all these qualities, rubber grommets naturally make the product more durable. There’s no need to replace the grommet, and it won’t speed up the wear and tear of the product. Rubber grommets also ensure that anything that passes through its position, whether wires, cords, ropes, or cables, won’t be cut. The friction will not cause any damage.

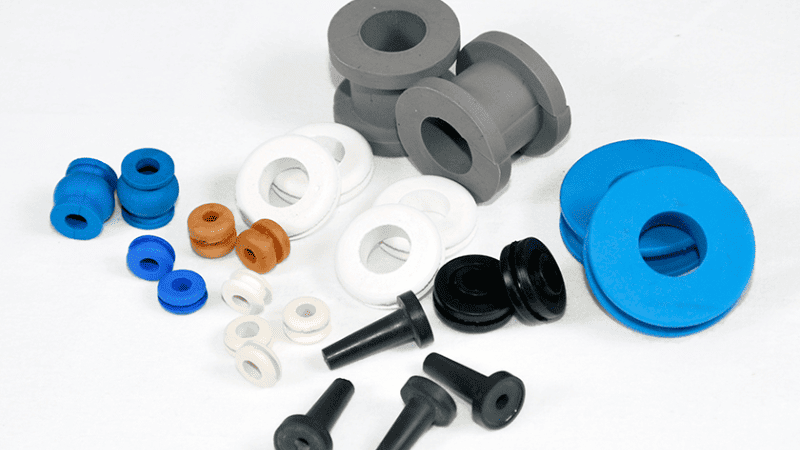

Different Rubber Grommet Shapes

Rubber grommets come in different shapes and sizes. Common shapes include square, oblong, round, rectangular, oval, and even D-shaped. To know what shape is ideal, you have to define the application of the rubber grommet.

Usually, it’s the design that dictates the specific use of the grommet.

For instance, ring-shaped grommets are ideal for wires, pipes, and cables to help avoid tears and friction damage. The rubber grommets with flared tops can protect against water or dust particles. The strip (rectangular) rubber grommets can give any device a more appealing appearance.

You must choose the right design because the shape of the rubber grommet will determine how effective it will be. If there is a need to absorb vibrations, there’s a perfect shape. If it’s for insulation purposes or protection, there’s an ideal shape for it.

Of course, you don’t have to be stuck with a specific shape. You can have a new design if you know what that rubber grommet is for. Rubber is flexible enough, so it can fit the mold that you need.

How do Rubber Grommets Works?

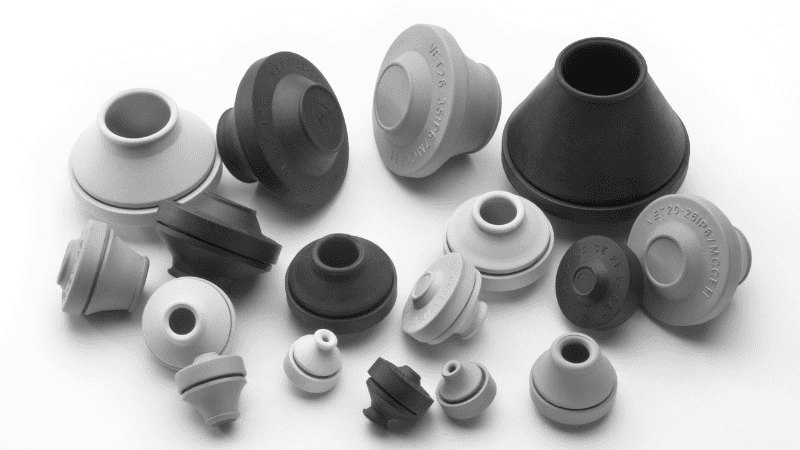

Rubber grommets are versatile products. It can work in different ways. It can be a plug, insulator, protector, etc. It’s important to note that the rubber grommet’s design is essential in ensuring it can work perfectly.

For instance, open rubber grommets protect the edges of a hole. These grommets should be flexible and smooth enough to keep friction minimal. No need to worry about friction damage when wires, cables, ropes, and other cords pass through. The metal edge of the hole will use the robber grommet as its cover. The grommet has to be thick enough to provide this protection while giving enough space in the middle for things to go through.

As a plug, the blind rubber grommet will be for sealing holes. It must be strong enough to hold back pressure from one side of the product. This can also be ideal for preventing dust from building up.

Sometimes, a small hole is put in the middle of the rubber grommet so a wire can go through it. This is a semi-blind rubber grommet. This will give it an even firmer hold.

The rectangular rubber grommet usually sits along the edge of a plate or panel. It works to make the edge smoother. Usually, this comes with adhesive on one side, so the application is more accessible.

There are rubber grommets for extreme environments. These usually use silicone material to withstand both low and high temperatures.

It’s essential to keep in mind that rubber grommets are not only versatile, but it offers a lot of design possibilities. As long as you know what you want to use it for, you can design it to meet that requirement.

Rubber Grommet Applications

By now, you have a better idea of various rubber grommet applications. Many industries benefit from the use of these rubber grommets. These include:

- Automotive engineering

- Avionics and airplane engineering

- Construction

- Electronics

- Internet and telecommunications

- Medical equipment manufacturers

- Military and defense

- Transportation

These are only a few of the industries that use rubber grommets. Each of these industries uses them for various applications. These are as follows.

As a protection

Covering sharp edges is an actual application of rubber grommets. It can cover the advantages of a hole so anything that passes through it will not have cuts or damage from friction. It can also cover the edge of a plate – specifically if it’s made of metal.

Because of this protection, wires, cables, and other parts that usually come into contact will last longer. It can keep you safe from electrical fires or shocks – especially if the grommet is for electrical boxes.

As an insulator

Rubber is heat resistant, so it’s an excellent insulator. That means this is great for machines that operate for long hours. It’s also ideal for cars, vehicles, and anything that heats up when it runs long distances.

As a seal

These rubber grommets – specifically those without holes can be an effective plug. It can withstand the pressure that comes from one side. It can protect one side from the other – like if one side has to remain dry while the other is full of liquid.

As a stabilizer

Rubber grommets are also ideal for strain relief. It can grip any wire in place. That way, it will not cause damage to the wire. Not only that, it will keep the wire from pulling out unexpectedly. A perfect example of this is the port of laptops and PCs. A rubber grommet can keep the wire secure so it doesn’t pull out.

This also means the rubber grommet can help absorb vibration too. This makes it ideal for cars and machines that usually vibrate while it’s ON.

Conclusion

Rubber grommets are integral components of products that play a vital role in ensuring their functionality and stability. Determining the appropriate design for a grommet depends on its intended application.

When considering the material options, it’s crucial to take into account the type of rubber needed, depending on the operating conditions, such as extreme temperatures. Silicone rubber is suitable for harsh environments.

Looking for Rubber grommets?

Hongju Silicone Can Help You

Hongju is an innovative rubber grommets manufacturer in China. We are dedicated to providing high-quality silicone rubber products for our customers. Our main products include custom silicone keypads, rubber O-rings, rubber feet, custom gaskets, seals, etc.

Visit our website to discover more about Hongju Silicone and our expertise in providing high-quality silicone rubber products. Whether you need custom solutions or have specific requirements, contact us; our team is here to assist you.