In this blog post, we will explore the various uses of plastic in building construction and why it is a sustainable and efficient choice. So, let’s dive in!

Plastic in the Construction Industry

The global building and construction plastics market has seen significant growth, with its value reaching USD 130.16 billion in 2021. This shows that more and more builders, architects, and engineers are incorporating plastic materials into their projects. However, not every type of plastic is suitable for construction.

The most commonly used plastics in the building and construction industry are:

1. Polyvinyl Chloride (PVC)

Polyvinyl Chloride or PVC, stands out as the most frequently utilized plastic material within the world of building and construction. Its widespread application encompasses a variety of essential components, including pipes, cables, window profiles, as well as flooring and roofing solutions.

PVC is the top choice in construction because it makes building materials better, safer, and affordable, compared to traditional construction materials.

Furthermore, PVC is known for reducing the environmental impacts associated with the construction projects it supports.

A striking statistic from Europe highlights that approximately 70% of all manufactured PVC is channeled towards producing construction-related products such as windows, pipes, flooring, and roofing membranes. This shows the importance and reliability of PVC in building construction.

2. Polyethylene (PE)

As a construction material, Polyethylene is well known for its resilience, strength-to-weight ratio, and excellent moisture resistance. These properties make it ideal for use in pipes used in water distribution and drainage systems.

In addition to pipes, PE is also widely used as an insulation building material for electric cables and wires, which can withstand extreme temperatures.

Its ability to be easily molded into different shapes and sizes makes it a popular choice for other construction applications such as protective films, geomembranes, and plastic sheets.

3. Polycarbonate (PC)

Polycarbonate (PC) is a standout material in the construction sector, known for its incredible performance and versatility. It’s a type of thermoplastic that’s finding its way into various construction products such as windows, skylights, wall panels, and even roofing.

One of the most compelling aspects of polycarbonate is its lightweight. With a density of just 1200kg/m3—much lighter than glass, which has a density of about 2800kg/m3—polycarbonate allows for more innovative and structurally ambitious designs.

This enables easier handling and installation, even better than glass-reinforced plastic materials, and opens up new possibilities in the architectural design of buildings.

4. Polypropylene (PP)

Polypropylene is another type of plastic that’s very useful in construction, but it’s different from Polyethylene. Polypropylene can handle heat much better — it doesn’t start to melt until it reaches 320 degrees Fahrenheit. That’s a lot hotter than Polyethylene, which melts at 212 degrees Fahrenheit.

What makes Polypropylene special is how flexible it is in terms of what can be made from it. This flexibility is super handy for the construction industry which needs a lot of different things made to fit specific needs.

For example, Polypropylene shines when it comes to creating durable ropes. These ropes are tough and can handle a lot of weight without breaking. Also, this material is perfect for making carpets that are meant for both indoors and outdoors.

Other types of plastic used in construction include extruded Polystyrene, polyurethane foam, Acrylonitrile Butadiene Styrene (ABS), and Polyurethane (PU). All these plastic hardware bring unique qualities that make them useful in various applications within the building and construction industry.

Send your inquiry for prompt quotations!

6 Benefits of Using Plastic in the Construction Industry

Here are the 6 benefits of using plastic materials in building construction:

1. Durable and Lightweight

One of the top advantages of using plastic in construction is how tough and light it is. Unlike metal or wood, plastic won’t rust, rot, or corrode over time. This means buildings and parts that use plastic can last a long time without getting damaged.

Because it’s also so light, it’s easier to move and install plastic parts, which can make building projects go faster and reduce the cost of transport. When plastic is used in place of heavier materials, the overall weight of the building can be significantly reduced and improve its structural integrity.

2. Flexibility and Recyclability

Plastics stand out in the construction industry not only because they can bend and twist into almost any shape you can think of without breaking but also because they’re kind to our planet.

Once a plastic piece has done its job, instead of ending up in a landfill, it can often be recycled and these recycled plastics can be turned into something new. This makes plastics super versatile for all sorts of building needs and helps keep our environment cleaner by reducing waste.

3. Easy to Install

Plastic components are renowned for their straightforward installation process that streamlines construction projects. This is because of the lightweight and flexible nature of plastics, allowing them to be maneuvered and fitted into place effortlessly.

Unlike traditional materials that may require specialized tools or techniques, plastic products often come ready for immediate use or with user-friendly fittings. As a result, construction projects can be completed more efficiently and with less labor.

4. Cost-Effective

In addition to being lightweight and easy to install, plastic materials are also generally cost-effective compared to traditional building materials such as wood or metal.

This cost-effectiveness is due to the lower production costs of plastics and their ability to be easily molded into different shapes without compromising on strength or durability. This makes plastic an attractive option for construction projects that have a tight budget.

5. Low Maintenance

Plastic materials require little maintenance compared to other building materials such as wood or metal.

As we mentioned earlier, plastics are resistant to rust, rot, and corrosion, which means they can withstand harsh weather conditions without deteriorating. They also don’t need any painting or staining, reducing the need for ongoing maintenance costs.

6. Energy-Efficient

Energy efficiency is what makes plastic materials a popular choice for building insulation. With their excellent moisture resistance and insulating properties, plastics can help reduce energy consumption in buildings by maintaining stable indoor temperatures.

One study discovered that the energy conserved through the application of plastic materials in buildings over a single year equates to the yearly energy requirements of approximately 4.6 million American households.

This saving stems from plastics’ inherent properties such as insulation effectiveness, durability, and lightweight, which optimize energy usage in buildings.

Send your inquiry for prompt quotations!

Applications of Plastic in the Construction Industry

Some common applications of plastic in the construction industry include:

- Plastic Pipes and Plumbing Systems: Due to their durability and resistance to corrosion, plastic pipes are extensively used in plumbing systems. They are easier to install and maintain compared to traditional metal pipes, reducing the overall cost of plumbing projects.

- Insulation Materials: With exceptional thermal insulation properties, plastics are often used as insulation materials in buildings. This helps in maintaining indoor temperatures, resulting in lower energy consumption for heating and cooling.

- Structural Components: In construction, plastics are used to create structural components such as beams, frames, and panels. Their lightweight and strength contribute to innovative building designs while ensuring structural integrity.

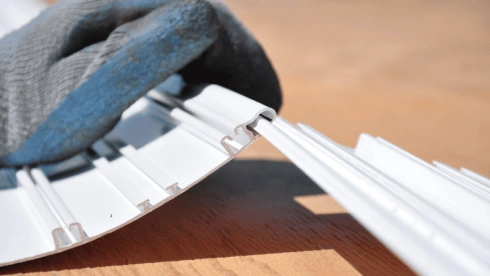

- Exterior Cladding and Roofing: Plastics offer a versatile option for exterior cladding and roofing, providing weather resistance and long-term durability. They are available in various colors and textures, enhancing the aesthetic appeal of buildings.

- Interior Finishes and Fixtures: For interior decoration, plastics are used in finishes and fixtures including wall coverings, flooring, and lighting fixtures. They offer a wide range of design possibilities and are easy to clean and maintain.

Conclusion

In conclusion, using plastic in building work is a big step forward. It brings together lasting materials, easy shapes, saving money, and being kind to our environment. Plastics help make buildings that last longer, use less energy, and can be turned into new things when no longer needed.

They make it easier for people who build things to try new ideas, from how we fit pipes to keeping our houses warm, and even how they look and feel.

So, if you are a contractor, builder, or architect looking to improve your construction projects, it might be time to consider incorporating plastic materials into your designs.

Why is Hongju the Best Plastic Manufacturer?

Choose Hongju for your next construction project and experience an unparalleled commitment to eco-friendliness and safety standards. Specializing in silicone rubber products since 1999, our range includes everything from Silicone Rubber Keypads to O-rings.

Trust in our advanced Compression Molding, Injection Molding, and Die Cutting capabilities to deliver quality and innovation in every product. Visit Hongjusilicone to learn more and get the perfect solution for your business!