In this article, we will delve into the unique properties of silicone rubber compounds that make them an ideal choice for cookware and kitchen utensils, medical applications, and more.

We will also explore why silicone rubber is considered safe at high temperatures and doesn’t leach unknown chemicals, unlike some other materials.

What is Non-Leaching?

Non-leaching refers to materials that do not release harmful substances into their surroundings. It ensures the safety and purity of products and environments. Leaching can occur through contact, heat, or chemical reactions.

Why is non-leaching so important? Materials that leach chemicals into food, water, or other substances can not only degrade the quality of the product but also pose serious health risks.

For example, some plastic containers can leach harmful substances like BPA into food or drink, especially when exposed to high temperatures, such as during the microwaving process.

Here are a few key points to consider when it comes to non-leaching:

- Safety: Non-leaching materials provide peace of mind by minimizing the risk of contamination. They help maintain the integrity of products and ensure they meet regulatory standards.

- Purity: By using non-leaching materials, companies can ensure the purity of their products. This is particularly important in sectors where cleanliness and hygiene are paramount, such as pharmaceuticals or cleanroom environments.

What is Silicone Rubber?

Silicone rubber is a versatile, durable material primarily made from silicone resins and raw material fillers. Unlike natural rubber latex or plastic polymers, silicone rubber is often certified as food-grade safe and offers unparalleled, uniform heat-resistant temperature resistance.

The unique structure of silicone rubber compounds lends the material its exceptional properties.

The molecular bonds in silicone rubber are highly stable, giving it a range of advantages over other materials, such as resistance to extreme temperatures, both high and low.

This stability ensures that silicone rubber is less likely to break down over time or under harsh conditions, making it an ideal choice for various demanding applications.

The material is also chemically inert, meaning it does not react easily with other substances. This inertness makes silicone rubber especially useful in settings where chemical stability is paramount, like medical implants or high-stress industrial environments.

Key Features for Non-Leaching Applications

Silicone rubber is an ideal choice for non-leaching uses due to its exceptional properties and characteristics. Let’s explore the key features that make silicone rubber stand out in this regard:

- Low Extractable Levels: Silicone rubber exhibits low extractable levels, minimizing leachables when it comes into contact with other substances. This ensures that there is minimal transfer of unwanted chemicals or compounds.

- Excellent Chemical Resistance: With outstanding chemical resistance against acids, bases, solvents, and other reactive substances, silicone rubber remains unaffected even in harsh environments. This makes it suitable for a wide range of applications where exposure to chemicals is inevitable.

- Inert Nature: The material’s inert nature prevents unwanted interactions with surrounding elements or products. It maintains its integrity without causing any adverse effects on the environment or the items it comes into contact with.

- High Thermal Stability: Silicone rubber possesses high thermal stability, enabling it to withstand extreme temperatures without degradation. Whether exposed to intense heat or freezing cold, silicone rubber retains its structural integrity and functionality.

Take the First Step:

Requst for an Inquire

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

These key features make silicone rubber an excellent choice for non-leaching applications such as accessibility features, food-grade products, and those requiring high tear strength.

Its ability to resist chemical reactions, maintain stability under extreme temperatures, and minimize leachables sets it apart as a reliable material option.

Silicone Rubber vs. Other Materials

Below is a table that compares silicone rubber with other non-leaching materials like Glass, Stainless Steel, Polyethylene, and PTFE (Teflon) based on some common characteristics:

| Property/Characteristic | Silicone Rubber | Glass | Stainless Steel | Polyethylene | PTFE (Teflon) |

|---|---|---|---|---|---|

| Chemical Resistance | High | High | High | Moderate | High |

| Temperature Resistance | High (up to 600°F) | High (up to 2200°F) | High (variable depending on grade) | Low (up to ~120°F) | High (up to 600°F) |

| Electrical Insulation | Excellent | Excellent | Poor | Good | Good |

| Flexibility | High | None | Low | Moderate | Low |

| Cost | Moderate | Low to Moderate | Moderate to High | Low | High |

| Biocompatibility | High | High | High | Moderate | Moderate |

| Durability | Moderate to High | Moderate (breakable) | High | High | High |

| Ease of Cleaning | Moderate | High | High | High | High |

| FDA Approved for Food Contact | Usually | Yes | Yes | Yes | Usually |

| Common Uses | Cookware, medical implants, seals | Cookware, lab equipment, windows | Cookware, cutlery, medical instruments | Bottles, containers, pipes | Non-stick cookware, electrical insulation |

Applications of Silicone Rubber for Non-Leaching Uses

Silicone rubber is a versatile material that offers numerous benefits in various industries. Its non-leaching properties make it an excellent choice for applications where biocompatibility and non-toxicity are crucial. Here are some key areas where silicone rubber finds extensive use:

Medical Applications

- Silicone rubber is widely used in medical devices due to its biocompatibility, making it safe for direct contact with the human body.

- It does not leach harmful substances, ensuring patient safety during surgical procedures or long-term implantation.

- Medical-grade silicone rubber is commonly employed in products like catheters, prosthetics, and pacemaker leads.

Food Processing Equipment

- In the food industry, silicone rubber plays a vital role in preventing contamination and maintaining product integrity.

- It is used to create seals, gaskets, and tubing that come into contact with food or beverages.

- Silicone’s non-leaching nature ensures that no harmful substances migrate into the food during processing or storage.

Pharmaceutical Manufacturing

- Silicone rubber gaskets and seals are utilized extensively in pharmaceutical manufacturing facilities.

- These components help maintain a sterile environment by preventing the entry of contaminants into critical equipment and systems.

- The non-leaching properties of silicone ensure that no unwanted substances compromise the quality of pharmaceutical products.

Electronics, Automotive, and Aerospace Industries

- Silicone rubber’s reliability and resistance to leaching make it highly desirable in these industries.

- It is used as a protective coating for electronic components to prevent moisture ingress and enhance durability.

- In automotive applications, silicone rubber seals help maintain air tightness while resisting chemical degradation from fuels or fluids.

- Aerospace engineers rely on silicone-based materials for their ability to withstand extreme temperatures without leaching harmful substances.

Silicone rubber’s unique characteristics make it an ideal choice across diverse sectors. From medical devices to food processing equipment, its non-leaching properties ensure safety and product integrity.

In electronics, automotive, and aerospace industries, silicone rubber provides reliability and resistance to leaching, making it a valuable material for various applications.

Take the First Step:

Requst for an Inquire

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

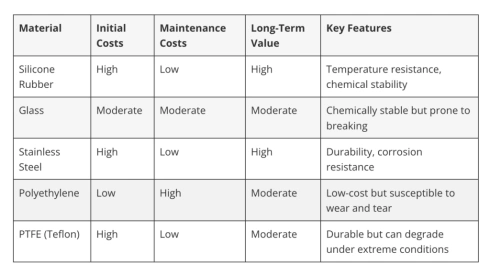

Cost Analysis of Non-Leaching Materials

Choosing the right material for non-leaching applications involves carefully examining both initial and ongoing costs.

This analysis aims to provide a detailed comparison of silicone rubber against other commonly used materials: Glass, Stainless Steel, Polyethylene, and PTFE (Teflon).

After reviewing the table, it becomes apparent that silicone rubber stands out in several key aspects when compared to materials like plastic polymer.

While it may have higher initial costs, its low maintenance expenses and long-term value more than compensate for the investment. Its superior temperature resistance and chemical stability make it an ideal choice for a wide range of non-leaching applications.

Choosing silicone rubber not only ensures safety and performance but also proves to be a cost-effective option in the long run. Therefore, for those who prioritize quality, durability, and long-term value, Silicone Rubber is a compelling choice.

Why Choose Silicone Rubber for Non-Leaching Uses?

Silicone rubber is an excellent choice for non-leaching applications due to its unique properties and benefits. Let’s explore why this material stands out:

Non-Reactive Nature Ensuring Purity

Silicone rubber’s non-reactive nature ensures the purity of products and environments. It does not interact with other substances, preventing any unwanted leaching or contamination. This makes it highly desirable for industries such as food processing, pharmaceuticals, and medical devices.

High Thermal Stability in Extreme Temperatures

One of silicone rubber’s remarkable qualities is its high thermal stability. It can withstand extreme temperatures without leaching harmful substances into the surroundings.

From industrial processes to kitchen appliances, silicone rubber provides a reliable solution that maintains safety even under intense heat or cold conditions.

Chemical Resistance for Versatile Applications

With its exceptional chemical resistance, silicone rubber can safely handle various reactive substances without compromising safety. This versatility makes it suitable for a wide range of applications across different industries.

Whether it’s sealing gaskets in automotive engines or tubing used in laboratories, silicone rubber reliably prevents leaching while maintaining performance.

Versatility and Durability for Long-Lasting Use

Silicone rubber’s versatility and durability make it an ideal choice for long-lasting non-leaching applications. Its flexibility allows it to adapt to different shapes and forms, ensuring a secure fit in diverse settings.

Moreover, silicone rubber exhibits excellent resistance to wear and tear, making it capable of enduring harsh conditions over extended periods.

Conclusion

In summary, silicone rubber offers a multitude of advantages for non-leaching applications. Its temperature resistance, food-grade safety, and chemical stability make it an unparalleled choice.

Whether it’s for silicone cookware or high-stress industrial environments, silicone rubber compounds provide reliability and longevity.

Discover the Perfect Solution for Your Business with Hongju

Don’t compromise on quality or safety for your non-leaching applications. Whether you’re a startup looking for durable and safe materials or an established enterprise aiming to optimize operations, Hongju offers tailored silicone solutions designed to streamline processes, enhance productivity, and drive growth.

Make the switch to Silicone Rubber today. Contact us now to get a free consultation and elevate your business to new heights.

Take the First Step:

Requst for an Inquire

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.