What is an O-ring?

The O-ring is probably one of the simplest seals available for mechanical systems. Despite having a basic design, this type of gasket has various applications. But its primary purpose is to ensure no leaks when mechanisms are put together.

Because of how simple it is, the o-ring is a favorite among manufacturers. It’s inexpensive and dependable. Like its name, this has the shape of an “O” and can be helpful in static or dynamic applications. You can see it in things like pumps, cylinders, and connectors.

The material of these o-rings can either be flexible synthetic rubber or thermoplastic. It sits within the groove of a mechanical part where it’s compressed between two surfaces during assembly. The material of the o-ring molds itself to the shape of wherever it’s compressed – making the perfect seal against leaks.

How did O-rings Come about?

The history of o-rings goes back to 72-year-old Niels Christensen. He’s a machinist who got the first US patent for this gasket.

Christensen was born in the year 1865 in Tørring, Denmark. In 1891, he immigrated to the US and got a job designing streetcar air brake systems. In his quest to perfect the technique, he looked for the right sealing solution. He ended up studying rubber and shaping it into rings.

In 1936, he discovered that he could set the rubber rings in the groove of pistons and cylinders. It has proven to be an effective seal. He could work through the patent application in the next two years and was finally granted one in 1939.

The US government recognized the o-ring of Christensen during World War II. It was considered a critical item related to war. This permitted them to have it manufactured by other companies. At that time, Christensen got $75,000 as payment for the o-ring design.

Then in 1971, he won litigation that got him $100,000 more for the O-rings. This amount was then distributed to his heirs.

Different Varieties of O-rings

O-rings, as the name suggests, are circular. While this is the most popular shape, there are times when O-ring manufacturers produce other shapes like squares, X-shape, etc. – depending on what the requirement is.

An o-ring uses silicone rubber, neoprene, nitrile rubber, polyurethane, and fluorocarbon. These materials give it some flexibility – but not in the same way, rubber bands have elasticity. This flexibility allows it to take on the shape of the mechanism that it will seal. The flexibility also allows the o-ring to create a snug fit to be an effective sealant.

The choice of material will also depend on the application. Some functions need a specific hardness or heat tolerance. These require a particular type of material. It also matters if the machinery that the o-ring will be a part of is static or dynamic. These dictate other factors about the o-ring, like the quality, application temperature, chemical compatibility, sealing pressure, movement, action, etc.

There are different ways to manufacture o-rings, like compression, injection, or transfer molding. When designing these o-rings, the primary consideration is the groove shape into which the o-ring will settle. This groove is usually in one of the surfaces put together. It determines the size, color, and even thickness of the ring.

Why are O-rings so Important?

O-rings are essential because they can provide an effective sealant without costing too much. It blocks the path of any liquid or gas to prevent it from escaping. This is possible thanks to the fantastic properties of o-rings. Compressed between two surfaces, it squeezes the o-ring and eliminates any clearance and chance of leakage.

Without a proper sealant, some machinery will be unable to function well. For instance, paintball guns use o-rings. It keeps the air sealed in to create a powerful shot.

Sometimes, o-rings can spell the difference between life and death. Think of a diesel or gas engine. If the o-ring fails to provide the proper seal, it can cause the gas to leak out. One spark can lead to an explosion. This can compromise the lives of the people around it.

Another example is scuba gear. Divers ensure that the o-ring at the neck of the air tank is secure. If it fails, the diver could be getting seawater instead of oxygen.

These are only a few of the reasons why o-rings are essential. But beyond that, o-rings must be made of suitable materials for effective sealants. Using the wrong one might compromise its ability to seal anything.

For instance, if you want to use the o-ring in a high-temperature environment, make sure you know the tolerance of the material. For example, nitrile is best for temperatures between -50C and 120C. Polyacrylate is best for temperatures between -25C and 175C. Fluorocarbon can withstand higher temperature ranges, anywhere between -25C and 205C. Make sure you understand the tolerance of the material to use the correct o-ring.

What is the Difference Between a Washer and an O-ring?

There’s a lot of confusion between a washer and an O-ring. It’s essential to understand the difference to use the correct option accordingly.

While an o-ring can come in other shapes, it’s generally round. It also uses compressible material. These include rubber, silicone, neoprene, etc. This compressible feature allows the o-ring to be effective as a sealant. When you put the o-ring in a groove, and two surfaces are put together, it compresses the o-ring. This allows the o-ring to fill the gaps in the track.

On the other hand, the washer uses a more rigid material like copper, brass, aluminum, steel, etc. It helps keep mechanical pieces together and prevents them from falling apart as the mechanical system functions. Sometimes, these washers are also made of rubber material. In a way, that allows it to serve as a sealant too.

But due to their composition, o-rings are better sealants than washers.

How do O-ring Seals Work?

To understand how o-rings work, you must know the nature of the mechanical systems that use them.

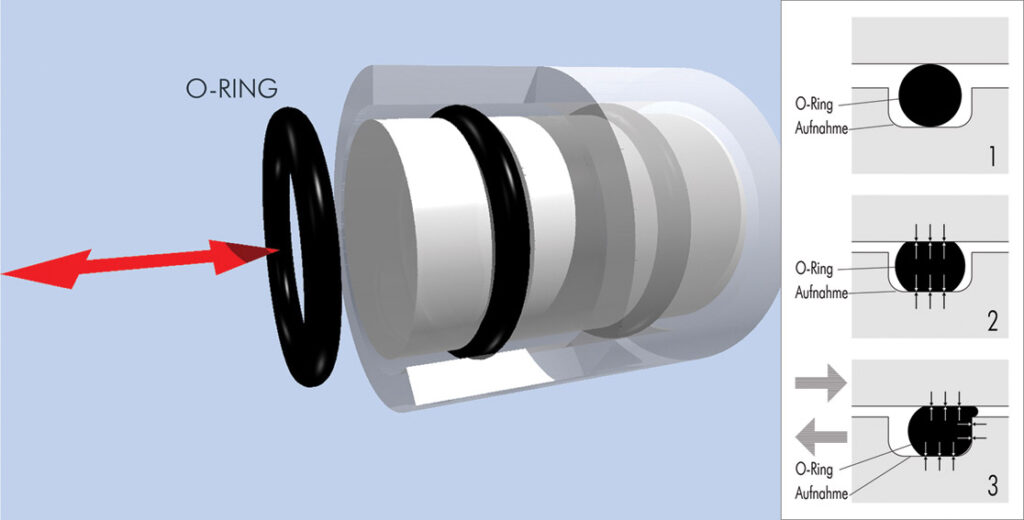

All mechanical systems are made up of parts that you assemble before functioning. How do these parts come together? At the end of every part are grooves that fit into another part of the system.

Before these parts come together, o-rings are put into the grooves. During the assembly of the components, the 2nd piece will put pressure on the o-ring in the groove of the 1st piece. The O-ring will squeeze itself further into the groove as the compression happens. This creates complete contact on all the gaps in that groove.

This creates a perfect joining of the two parts of the mechanical system.

Because the o-ring removes any gap, this provides a strong seal for the mechanical system. There will be no leaks, and the mechanical system can function correctly.

But despite this seemingly simple use, the o-ring can stop working and compromise the mechanical system’s function.

If there are leaks, the o-ring is not the correct size. Or it’s using the wrong material. You need to check this before it compromises the whole system. Make sure the o-rings have suitable hardness and pressure tolerance. There’s also a different type of o-ring ideal for static or dynamic methods.

Although o-rings will last a very long before it expires, they won’t be there forever. You need to check it now and then to ensure that it keeps leaks from happening. The leak could destroy the system, so it’s best to replace the o-ring to keep costs low.

Where are O-rings Used?

O-rings are ideal for any application that requires gas or liquid to escape. The typical applications for o-rings include the following:

- Transportation. These include passenger vehicles, trucking, and even aerospace. It’s ideal for high-performing vehicles. The o-ring can keep chemicals, fluids, and even emissions from leaking.

- Medical. O-rings can also be helpful on pumps and filtrations devices. It’s also ideal for medical field syringes and connectors. But the o-rings will require a food FDA grade.

- Electronics. O-rings for electronics require special dust protection. That means the o-rings need manufacturing in a clean environment. It has to be contaminate-free to make it ideal for electronics.

- Industrial. This also includes oil and gas use. You’ll find o-rings in gas pumps, valves, storage tanks, and dispensers. In this application, the o-ring should withstand exposure to extreme temperatures, high compression, and harmful chemicals.

- Food and Beverage. Water bottles, filtration systems, food containers, dispensers, and other food processing equipment require o-rings. These o-rings require sanitary approval before they can be used.

Learn more about O-ring applications: What Are O-Rings Used For?

Conclusion

An O-ring is a circular seal that helps to keep fluids and gases from escaping the area it’s sealing. O-rings come in all shapes and sizes, but they all have one common purpose: to create a tight seal between two objects. Contact us now if you’re looking for an o-ring that works well in your application. We can help you find the perfect o-ring for your needs and get you started on your next project.