Vulcanization is a chemical process that enhances the properties of rubber, making it more durable and elastic.

This makes vulcanized rubber indispensable in various industries, ranging from automotive to manufacturing. It provides the foundation for countless products we rely on daily.

So, let’s dive into the world of this remarkable substance and discover why it’s an essential component in so many aspects of our lives.

What is Vulcanized Rubber

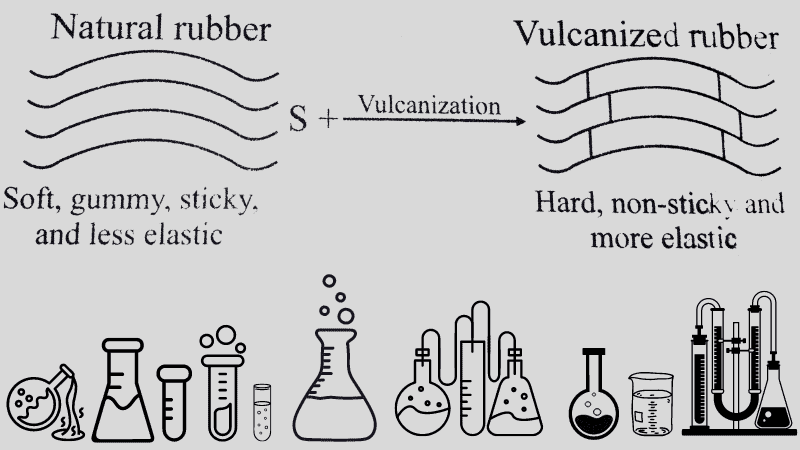

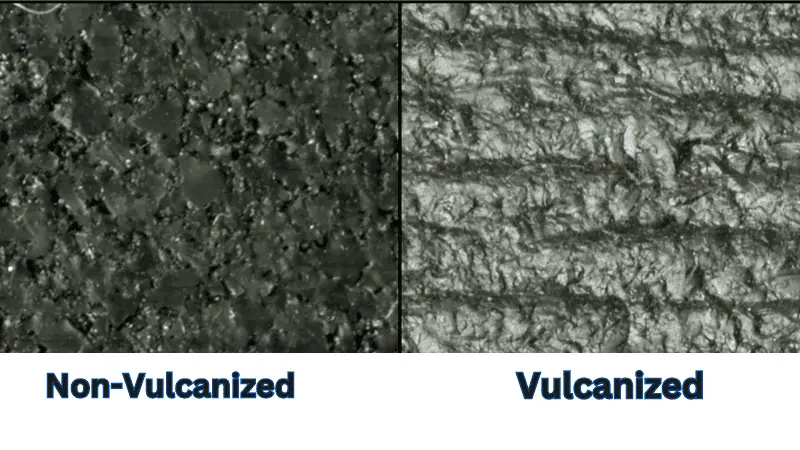

Vulcanized rubber is a type of rubber that undergoes a chemical treatment to enhance its strength and resilience. This process, known as vulcanization, modifies the molecular structure of the rubber, resulting in improved properties while retaining its natural elasticity and flexibility.

After vulcanization, a highly elastic state is obtained, in which tensile strength and recovery after deformation are high and flow is low. The temperature range in service is extended, and solubility in organic solvents is reduced.

The transformation that occurs during vulcanization is what sets vulcanized rubber apart from conventional raw rubber. By subjecting the material to heat and adding specific chemicals, such as sulfur, the rubber molecules cross-link and bond with each other.

This cross-linking and bond create a three-dimensional network within the rubber, making it more durable and resistant to wear and tear.

One example of the remarkable aspects of vulcanized rubber is its ability to maintain its original elasticity despite undergoing this chemical alteration.

Unlike other materials that become stiff or brittle when reinforced, vulcanized rubber retains its elasticity and flexibility. This characteristic makes it highly suitable for applications where both strength and pliability are required.

Vulcanization not only improves the physical and thermal properties of rubber but also enhances its resistance to chemicals and weathering.

The cross-linking of molecules prevents the components of the rubber from degrading when exposed to harsh conditions, making it a reliable choice in outdoor settings.

History and Inventor of Vulcanized Rubber

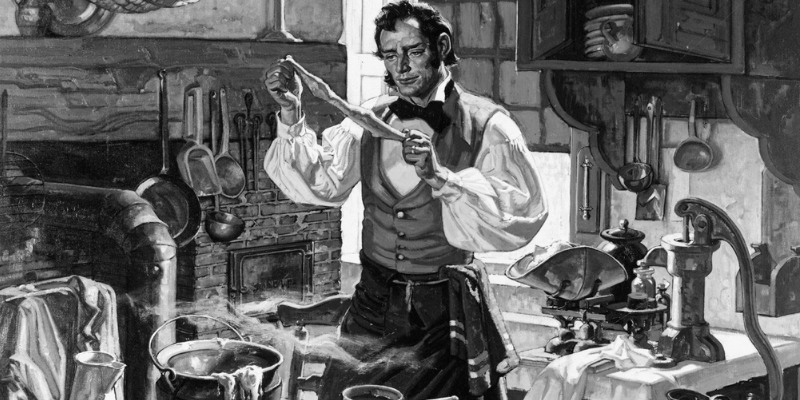

Vulcanized rubber, is a breakthrough material that revolutionized various industries. It was first invented and patented in 1839 by Charles Goodyear, who discovered the process of vulcanization by accident while trying to cure rubber by heating it.

Goodyear was conducting experiments with rubber to identify a stable and more durable alternative to natural rubber, which is prone to deterioration.

In one of his experiments, he accidentally left a mold of a sample of liquid rubber in the oven for too long, causing it to come out black and sticky.

Despite the initial undesirable appearance, he discovered during testing that the treated rubber had gained significant improvements in its physical and mechanical properties.

These improvements were largely due to the sulfur-induced cross-linking of polymer chains in the rubber, which increased its strength, durability, and resistance to heat and chemicals.

The patent for vulcanized rubber was granted to Goodyear in 1844, and the process laid the foundation for the modern rubber industry.

The discovery of vulcanized rubber by Charles Goodyear forever changed the trajectory of various industries. His accidental breakthrough unlocked new possibilities for using traditional rubber, in ways previously unimaginable.

Today, we continue to benefit from his ingenuity as vulcanized rubber remains an essential component in countless products that improve our daily lives.

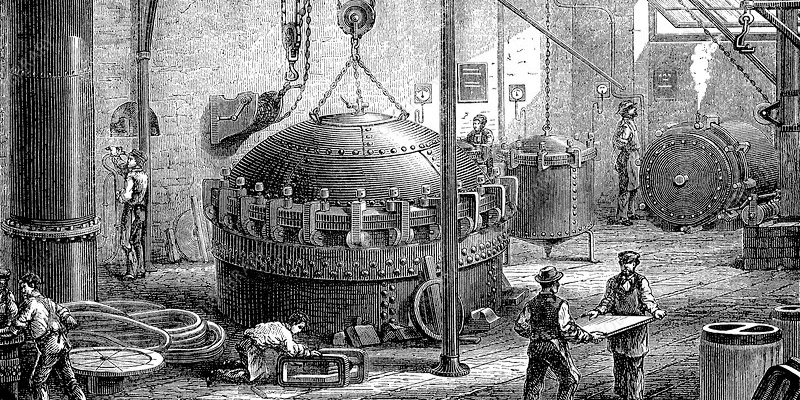

Process of Vulcanization

Vulcanized rubber is a widely used material known for its strength and durability. The process of vulcanization plays a crucial role in transforming raw rubber into this resilient substance form.

Basic Step of Vulcanization

- Preparation of rubber: Natural rubber is mixed with other materials such as fillers, plasticizers, and other chemicals to form a rubber compound.

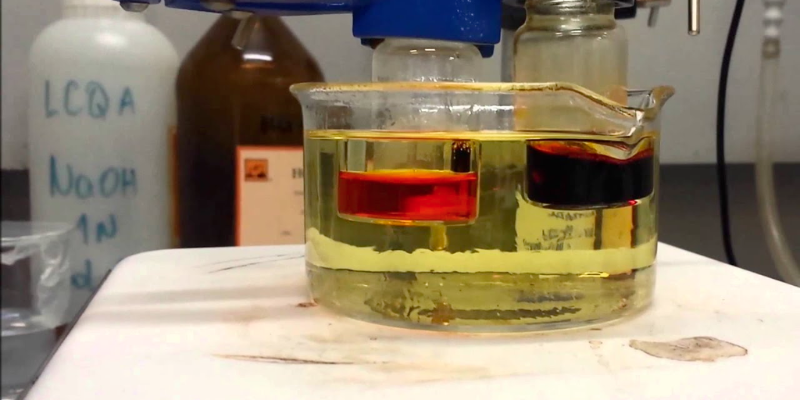

- Addition of sulfur: The rubber compound is then heated and blended with sulfur, which acts as a catalyst to initiate the cross-linking process.

- Heating and pressure: The sulfur-treated rubber compound is then heated and pressurized for several hours to complete the vulcanization process.

- Shaping and cooling: The vulcanized rubber is then cooled and shaped into the desired product, such as tires, tubing, or other industrial parts.

Additional Additives

During vulcanization, additional additives can be incorporated to improve specific properties of the rubber.

For instance, additives may be included to enhance heat resistance or flexibility depending on the intended application of the final product. These additives work in synergy with sulfur or curing agents to achieve desired characteristics.

To illustrate further, let’s consider some examples of additives used during vulcanization:

- Accelerators: These compounds speed up the curing process by reducing the time needed for cross-linking.

- Anti-aging agents: These additives increase the longevity of vulcanized rubber by preventing degradation caused by environmental factors like UV radiation.

- Plasticizers: These substances improve flexibility and reduce stiffness in final products.

- Fillers: Materials such as carbon black are commonly added to enhance mechanical properties like hardness and abrasion resistance.

Properties and Applications of Vulcanised Rubber

Vulcanized rubber, also known as natural rubber, has a number of benefits and applications due to its superior properties compared to other types of rubber.

Properties of Vulcanised Rubber

Here are some of the properties:

- Durability: Vulcanized rubber is much more durable than other rubber materials, making it ideal for use in applications that require long-term durability, such as tires, industrial parts, and footwear.

- Resistance to heat and chemicals: Vulcanized rubber is highly resistant to heat and a wide range of chemicals, making it ideal for use in high-temperature applications such as in industrial settings and also in chemical-resistant applications.

- Waterproof: Vulcanized rubber is extremely waterproof, making it ideal for use in applications where water exposure is a concern, such as in rain boots.

- Flexibility: Vulcanized rubber has excellent flexibility and elasticity, which makes it ideal for use in applications that require movement, such as footwear and medical devices.

Applications of Vulcanised Rubber

Vulcanized rubber is a versatile material that exhibits physical properties with several unique properties, making it highly desirable for various applications.

Here are some examples of applications where vulcanized rubber is used:

- Tires: Vulcanized rubber is the primary material used in the manufacturing of tires, as it provides superior durability and traction on the road.

- Industrial parts: Vulcanized rubber is widely used in the manufacturing of industrial parts, such as seals, tubing, and gaskets, as it provides superior protection against heat, chemicals, and abrasion.

- Footwear: Vulcanized rubber is used in the manufacturing of a wide range of footwear products, such as rain boots, sneakers, and work boots, as it provides excellent durability, flexibility, and waterproofing.

- Medical devices: Vulcanized rubber is widely used in the manufacturing of medical devices, such as catheters, stents, and surgical gloves, as it provides superior chemical and biological resistance.

Vulcanized Rubber vs. Unvulcanized Rubber

Vulcanized rubber and unvulcanized rubber are two distinct types of rubber with unique properties and applications. Here are some of the key differences:

Manufacturing Process

- Vulcanized rubber is made by treating natural rubber with sulfur, which increases its stability and durability.

- Unvulcanized rubber is natural rubber that has not been treated with sulfur.

Physical Properties

- Vulcanized rubber is resistant to heat, abrasion, and chemicals, making it suitable for use in a wide range of industrial and consumer applications such as tires and industrial parts.

- Unvulcanized rubber is more flexible and elastic than vulcanized rubber, making it suitable for use in applications where flexibility and elasticity are more important than durability, such as in latex gloves and shoes.

Applications

- Vulcanized rubber is widely used in the manufacture of tires, industrial parts, and a wide range of consumer products, providing excellent durability, flexibility, and resistance to abrasion.

- Unvulcanized rubber is mainly used in applications where flexibility and elasticity are more important than durability, such as in silicone caulk and vinyl gloves.

Price

- Vulcanized rubber is generally more expensive than unvulcanized rubber due to the additional processing and production costs involved in the vulcanization process.

- Unvulcanized rubber is generally less expensive than vulcanized rubber due to the absence of the vulcanization process.

Different Types of Vulcanized Rubber

Natural rubber can be improved by vulcanization with sulfur or other curing agents. However, it’s not just natural rubber that can undergo this transformative process.

Each type of vulcanized rubber exhibits a temperature range and unique qualities suitable for specific applications.

- Natural Rubber (NR): Natural rubber is the raw material used to make Vulcanized Rubber, and is obtained from rubber trees. Given the incredible benefits of natural rubber, it only makes sense to use it for various applications. This type of Vulcanized Rubber is mainly used in applications where flexibility and elasticity are more important than durability, such as in latex gloves and shoes.

- Sulphur-Cured Rubber (SCR): SCR is produced by treating natural rubber with sulfur, which makes it more resistant to heat and chemicals than NR. This type of Vulcanized Rubber is widely used in the manufacture of tires, industrial parts, and a wide range of consumer products.

- Carbon-Black Vulcanized Rubber (CB SCR): CB SCR is SCR that has been mixed with carbon black, which gives it improved resistance to abrasion and extended service life. This type of Vulcanized Rubber is widely used in the manufacture of tire cords, industrial hoses, and other applications where durability and abrasion resistance are critical. Carbon black-filled rubber compounds form the majority of rubber materials manufactured because of the reinforcing effects exerted by this class of fillers.

- Butadiene Rubber (BR): BR is a synthetic rubber that is produced by polymerizing butadiene with other monomers. This type of Vulcanized Rubber is widely used in the manufacture of tires, shoes, and other applications where high resistance to abrasion and chemicals is required.

- Silicone Rubber: Silicone Rubber is a synthetic rubber that has excellent resistance to heat, chemicals, and harsh environmental conditions. This type of Vulcanized Rubber is widely used in the manufacture of seals, gaskets, and other applications where stability and high-temperature resistance are critical.

The different types of vulcanized Rubber each have their own unique properties and are commonly used in a wide range of applications where flexibility, durability, and resistance to heat, chemicals, and abrasion are required.

Environmental Impact and Future Developments

Here are some quick points on the environmental impact of vulcanized Rubber and future developments in the industry:

Environmental impact

- The vulcanization process produces sulfur dioxide (SO2), a pollutant that contributes to acid rain and air pollution.

- Vulcanized Rubber also has high energy and water requirements during production, which can have a negative impact on the environment.

- The process of recycling Vulcanized rubber can require significant energy inputs.

- The disposal of vulcanized rubber in landfills can result in the release of toxic fumes and other chemicals into the environment.

Future developments

In response, there have been several efforts to reduce the environmental impact of Vulcanized Rubber, including the use of alternative plastic vulcanization technologies and the development of more environmentally friendly rubber products.

Here are some examples of the key developments in this area:

- Low Sulfur Vulcanization: Low-sulfur vulcanization is a process that reduces the amount of sulfur used in the vulcanization process, thereby reducing the emission of SO2. This technology is widely used in the manufacture of tires, hoses, and other products.

- Sulfur-Free Vulcanization: Sulfur-free vulcanization is a process that does not use sulfur in the vulcanization process, eliminating the emission of SO2. This technology is still in the development stage, but it is expected to contribute significantly to the reduction of air pollution.

- Natural Rubber: Natural rubber is considered to be more environmentally friendly than synthetic rubber, as it is obtained from rubber trees and does not require the use of chemical processes. However, the supply of natural rubber is subject to variability and seasonality, which can limit the availability of the material.

- Bio-based Rubber: Bio-based rubber is a rubber product produced from renewable resources such as plants, algae, or microorganisms. This technology is expected to significantly reduce the environmental impact of Vulcanized Rubber by reducing the dependence on fossil fuels and reducing the emission of greenhouse gases.

In the future, it is expected that there will be continued efforts to reduce the environmental impact of vulcanized rubber, while also improving the performance and properties of this important material.

Conclusion

In conclusion, vulcanized rubber is a versatile material that has revolutionized various industries. While it’s an essential material for many applications, its environmental impact requires careful management to minimize its potential negative impacts.

As technology advances, further developments in the field of vulcanization can be expected, leading to the creation of even more innovative uses for this remarkable material.

Buy High-Quality rubber products from Hongju

As a supplier of rubber products, it is essential to uphold your reputation by delivering the absolute best. Fortunately, Hongju Silicone is a leading manufacturer of silicone rubber products.

Contact us and we produce a wide range of synthetic rubber products. With over 23 years of experience, the company manufactures only high-quality silicone rubber products.

Take the First Step:

Requst for an Inquire

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.