In this post, we’ll explain what silicone rubber grades are, why they matter, and how they affect the performance of various products. Let’s dive in and learn more about this fascinating subject!

Silicone Rubber Grades

Have you ever thought about the different types of silicone rubber? It’s like ice cream. There are many flavors, and each one has its unique taste. Like, silicone rubbers come in different grades, each with its own properties.

Different Silicone Rubber Grades Available in the Market

It’s time to explore the world of silicone rubber grades. Here are some of the variants you might come across:

- Food Grade: Used in kitchen tools like spatulas and cake molds.

- Medical Grade: Seen in healthcare products like catheters and medical tubes.

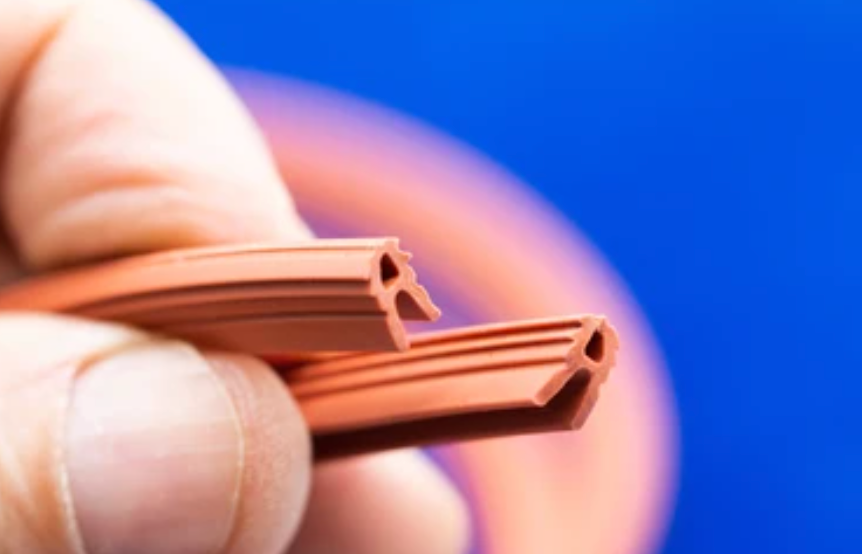

- Industrial Grade: Found in machine parts and seals.

- Flame Retardant Grade: Used in areas where fire safety is crucial.

- High Strength Grade: Ideal for demanding applications where strength matters.

Classification Based on Properties

Let’s dig a bit deeper and look at silicone rubber grades based on their properties:

General Purpose Silicone Rubbers

This is the all-rounder of the silicone world. It’s like your favorite pair of jeans that goes well with everything. This versatile silicone grade can be used in various applications, from automotive parts to kitchen utensils.

Weather Resistant Silicone Rubbers

Imagine a superhero that can withstand harsh weather conditions. That’s what weather-resistant silicone rubbers are. It stands firm against rain, snow, and UV rays, making it perfect for outdoor applications like seals and gaskets.

Heat Stabilised Silicone Rubbers

This grade of silicone rubber is a firefighter. It’s designed to handle heat without losing its shape or properties. It’s often used in ovens, microwaves, and other high-temperature environments.

High-Temperature Silicone Rubbers

Think of this grade as a heat warrior. It’s specially designed to perform well in extreme heat, often used in automotive and industrial applications where temperatures can get really high.

Remember, choosing the suitable silicone rubber grade is like choosing the right tool for a job. It can make your project easier and more successful. So, consider the grades next time you work with silicone rubbers, and choose wisely!

Types of Silicone Rubbers

Like we have different shoes for different occasions, silicone rubber also comes in various types, each suited for specific applications. Let’s look at the three main types:

Solid Silicone Rubber

Solid silicone rubber is like the sturdy hiking boots of the silicone world. It’s tough, durable, and reliable, often used in applications where strength is needed. This type of solid silicone rubber is ideal for things like seals, gaskets, and kitchen utensils. It also has a high molecular weight.

Liquid Silicone Rubber (LSR)

Liquid silicone rubber (LSR) is a bit like a pair of running shoes – flexible, adaptable, and easy to work with. This type of silicone can be injected into molds, making it perfect for detailed designs and complex shapes. It’s often used for medical silicone products, baby products, and kitchenware. Learn more about liquid silicone rubber here.

Room Temperature Vulcanized (RTV) Silicone Rubber

RTV silicone rubber is like a pair of cozy house slippers – easy to use and comfortable. This silicone type cures or sets at room temperature, making it perfect for DIY projects and small-scale applications. It’s commonly used for craft projects, small molds, and sealants.

Comparison

| Type | Properties | Characteristics |

| Solid Silicone Rubber | High-strength, durable, heat-resistant | Ideal for seals, gaskets, and kitchen utensils |

| Liquid Silicone Rubber (LSR) | Flexible, adaptable, detailed | Perfect for medical products, baby products, and kitchenware |

| Room Temperature Vulcanized (RTV) Silicone Rubber | Easy to use, cures at room temperature | Commonly used for craft projects, small molds, and sealants |

Remember, just like you wouldn’t wear high heels to go hiking, choosing the right type of silicone rubber for your specific project or application is important.

Properties of Silicone Rubber

Like a superhero has certain powers, silicone rubber has some amazing mechanical and physical properties. These make it a powerful tool for lots of applications. Let’s talk about them!

Physical Properties of Silicone Rubber

1. Heat Resistance and Wide Temperature Range

Silicone rubber has the superpower of being heat resistant. It’s like a sun-loving lizard that can enjoy both the hot desert sun and the cool night. It can work in temperatures as high as 200°C and as low as -60°C. This makes it perfect for hot stuff like oven mitts and cool stuff like freezer seals.

2. Excellent Electrical Insulation Properties

Imagine if you could stand in a lightning storm and not get zapped. That’s like what silicone rubber can do. It’s an excellent electrical insulator, which means it stops electricity from passing through. This is why it’s often used in wires and cables. Part of the credit goes to its relatively long polymer chains.

3. Chemical Stability and Resistance

Silicone rubber is like a superhero that’s immune to toxic gases. It’s stable and resists many chemicals, including oils and acids. This makes it perfect for use in harsh environments, like factories or garages.

Mechanical Properties of Silicone Rubber

1. Elasticity and Flexibility

Silicone rubber is super stretchy and flexible, like a gymnast. It can bend and twist without breaking. This is great for things that need to be flexible, like hoses and flexible molds, thanks to its incredible mechanical properties.

2. Tensile Strength and Tear Resistance

But silicone rubber isn’t just flexible. It’s also strong. It has high tensile strength, so it can resist being pulled apart. It’s also tear-resistant and doesn’t easily rip or get holes. This is why it’s used for tough jobs, like car parts and heavy-duty seals.

3. Compression Set and Resilience

Finally, silicone rubber can bounce back. It has a low compression set, which means if you squish it, it’ll return to its original shape when you let go. This makes it great for things like seals and gaskets, which must keep their shape to work properly.

All these physical and mechanical properties make silicone rubber a real superhero of materials. So next time you see a silicone product, you’ll know just how amazing it is!

Grades And Material Properties

Just like a chef uses different ingredients to change the taste of a dish, different grades of silicone rubber change its properties. Let’s take a closer look at how this works.

How Different Grades Affect Material Properties

Different grades of silicone rubber are like different flavors of ice cream. Each one has something unique about it. These grades can change how the silicone rubber behaves. For example, some grades can make it more heat-resistant, while others can make it stronger.

Key Material Properties Influenced By Silicone Rubber Grades

Let’s see how different grades can affect key properties of silicone rubber:

1. Heat Resistance And Thermal Stability

Some grades of silicone rubber are like a camel in the desert – they can handle the heat! These grades are used in things like oven mitts and hot engine parts.

2. Chemical Resistance And Compatibility

Other grades of silicone rubber are like a superhero with a shield – they can resist chemicals! These grades are used where they might contact oils or acids, like in factories.

3. Electrical Insulation Properties

There are also grades of silicone rubber that are like a rubber boot in a storm – they can stop electricity. These grades are used in electrical wires and components.

4. Mechanical Strength And Durability

And finally, some grades of silicone rubber are like a weightlifter – they are solid and tough. These grades are used for heavy-duty applications, like car parts and construction seals.

| Grade | Heat Resistance | Chemical Resistance | Electrical Insulation | Mechanical Strength |

| Food Grade | Good | Good | Good | Good |

| Medical Grade | Excellent | Excellent | Good | Good |

| Industrial Grade | Excellent | Excellent | Excellent | Excellent |

| Flame Retardant Grade | Excellent | Good | Excellent | Excellent |

| High Strength Grade | Good | Good | Excellent | Excellent |

Remember, just like you wouldn’t use a hammer to paint a picture, choosing the right grade of silicone rubber for your specific needs is essential. Each grade has its own superpowers, so choose wisely!

Applications of Silicone Rubber

Now that we’ve got a grip on silicone rubber’s various grades and properties, it’s time to see this superhero in action. Let’s explore how silicone rubber is used in different industries.

- Automotive and Transportation

Silicone rubber is like a trusted co-driver in the world of cars and transport. It’s used in making seals, gaskets, and hoses that can handle the heat and vibration of an engine. Its heat resistance and strength make it perfect for these demanding jobs.

- Electronics and Electrical

Silicone rubber is also a key player in the electronics world. It’s like the insulation on a wire, protecting the important stuff inside. It covers wires and makes keypads because it’s a flexible insulator. Next time you’re typing on a keyboard or charging your phone, remember the role of silicone rubber!

- Medical and Healthcare

In the medical field, silicone rubber is like a helpful nurse. It makes things like tubes, seals, and medical devices. Its flexibility and the fact that it doesn’t react with the body make it safe and reliable for these critical jobs.

- Construction and Architecture

Last but not least, silicone rubber is like a strong and reliable building block in construction and architecture. It’s used for seals, gaskets, and even in weatherproofing buildings. Its durability and resistance to the weather make it perfect for these big tasks.

Manufacturing And Processing of Silicone Rubber

Silicone rubber must be made like a delicious cake that doesn’t appear out of nowhere. Let’s peek behind the scenes and learn how this versatile material is manufactured and processed.

1. Silicone Rubber Manufacturing Processes

Making silicone rubber is like making a fancy dinner. There are several steps, and each one is important. First, raw materials are combined in a special recipe. Then, they go through various processes like mixing, molding, and curing. These steps transform the raw silicone materials into the silicone rubber we know and love.

2. What Is Injection Molding and Its Relevance to Silicone Rubber

Injection molding is like using a cookie cutter to make cookies. It’s a process used to shape silicone rubber using an injection molding machine. The rubber is heated until it’s liquid, then it’s squirted into a mold, a bit like dough into a cookie cutter. When it cools and hardens, you have a silicone rubber part in the shape of the mold. This process is beneficial for making complex shapes or large quantities of parts.

3. What Is Vulcanization Process

Vulcanization is the step that gives silicone rubber its superpowers. It’s like the oven that bakes the dough into cookies. In this process, the silicone rubber is heated. This causes a chemical reaction that makes silicone rubber stronger and more resilient. After vulcanization, the silicone rubber is ready for action!

Conclusion

So there you have it! From its various grades and powerful properties to its many uses and how it’s made, silicone rubber truly is a superhero of materials. Remember, choosing the right grade and type for your needs is crucial for success. For more insights and details about the fascinating world of silicone rubber, feel free to explore other resources on our website. Thanks for joining us on this journey, and we look forward to sharing more valuable information with you!

Unleash the Power of Silicone Rubber with Hongju!

At Hongju Silicone, we’re not just experts in silicone rubber – we’re passionate about it. With our high-quality products, extensive knowledge, and commitment to customer satisfaction, we can help you make the most out of this extraordinary material. Contact us today for a consultation or explore our diverse range of silicone rubber products. Let’s shape a better future together with silicone rubber!