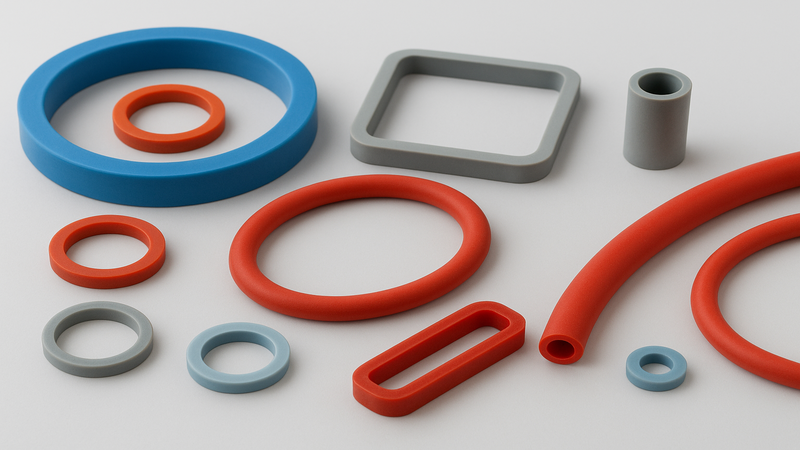

Wondering how silicone rubber gets the precise shape of seals, gaskets, and tubes? Silicone rubber extrusion transforms raw silicone into profiles, tubing, and seals.

These components withstand extreme temperatures and harsh conditions. It is the most sustainable way to make silicone parts for industrial, medical, or consumer use. Want to learn how the silicone extrusion process works? Keep reading to learn.

What Is Silicone Rubber Extrusion and Why Does It Matter

Silicone rubber extrusion is a process in which an uncured silicone compound is shaped into a precise component. An extruder, a screw feed, and a die continuously work to design a component. Common profiles include seals, tubes, cords, and gaskets.

It produces silicone components with exact dimensional tolerances. In post silicone extrusions, the profiles undergo a curing stage. This process crosslinks the polymer chains. It guarantees the desired mechanical strength, elasticity, and long-term stability.

Silicone extrusions hold great value. The extruded products withstand extreme temperatures (–60°C to +230°C). They also resist chemicals, UV exposure, and harsh weather conditions.

You can customize silicone in shape, size, and color. Its mechanical properties provide strength and flexibility. It is the sustainable and eco-friendly choice in countless applications, such as:

- Industries: Oven gaskets, sealing strips, cable insulation.

- Medical: Tubes, drains, and seals for sterile environments.

- Consumer: Appliance seals, weatherstrips, and wearable parts.

How the Silicone Rubber Extrusion Process Works

Engineers design silicone rubber extrusions with precision in every stage. Each step undergoes precise control to produce accurate profiles. Each component delivers consistent performance and meets compliance standards.

1. Raw Material Preparation

First, raw silicone is prepared for the process. An open mill adds silicone. Here it is blended with curing agents, pigments, and performance additives. This ensures uniform color and properties.

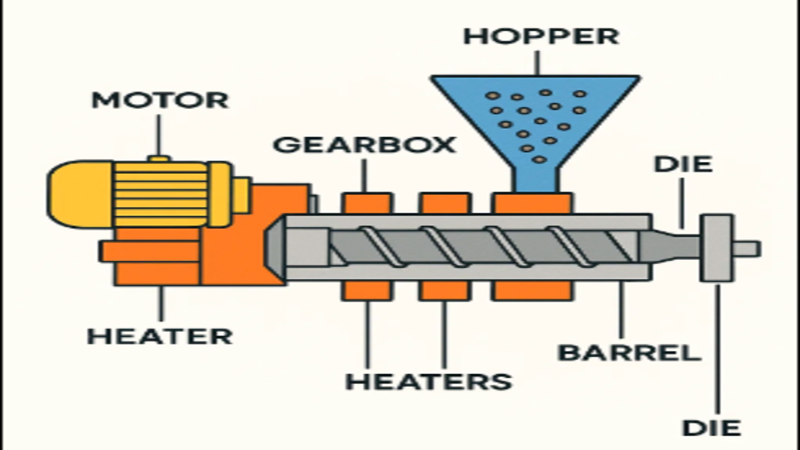

2. Extruder Mechanics

An extruder feeds the silicone compound. A rotating extruder screw pushes the material toward the die. Screw design influences mixing efficiency. The die shape determines the profile’s geometry. Multiple extruders give faster and more versatile production.

3. Curing Methods

For shaping silicone, manufacturers need to cure it to stabilize its structure. Common silicone extrusions curing methods include:

| Curing Method | Advantages | Limitations |

|---|---|---|

| Hot Air Vulcanization (HAV) | Continuous process, high speed | Consume high energy |

| Steam Curing | Even heat distribution | Needs specialized equipment |

| Salt Bath Curing | Smooth surface finish | Salt disposal management |

| Room Temperature Vulcanization (RTV) | Energy-efficient | Slower production speed |

4. Quality Control

Quality checks bring dimensional accuracy and material integrity. Technicians check extrusion speed, pressure, and temperature to maintain consistent output. Any deviations are immediately corrected. They prevent defects such as warping, surface imperfections, or variations in hardness.

Key Factors for High-Quality Extruded Silicone Products

Getting high-quality silicone extrusions relies on careful control of several factors during production.

Die Precision and Design

A well-crafted die brings dimensional stability. It gives a consistent product shape. Minor imperfections in the die can lead to variations in size, profile, or surface finish. Manufacturers rely on custom silicone extrusions. This helps them to meet specific performance and industry requirements.

Selecting the Right Silicone Grade

An appropriate silicone grade is critical to meet performance and regulatory requirements.

- Industrial Grade: It is heat-resistant and cost-efficient. Ideal for oven gaskets, cable insulation, and sealing strips.

- Food Grade: FDA-compliant and safe for contact with consumables. It is suitable for food processing seals, beverage hoses, and dispenser gaskets.

- Medical Grade: It is an excellent vibration-dampening material. It is biocompatible and sterilizable. Designed mainly catheters, drainage lines, and surgical seals

Process Control

Maintenance of the temperature, extrusion speed, and curing time is essential. It prevents defects in silicone extrusions. Real-time adjustments bring consistent quality across large production runs.

Testing and Validation

Every batch should go through mechanical and chemical testing. Check tensile strength, flame resistance, and chemical resistance. This confirms that silicone extrusions comply with customer and industry standards.

Common Defects and Solutions

| Defect | Root Cause | Solution |

|---|---|---|

| Surface roughness | Inconsistent curing | Stabilize temperature control |

| Dimensional drift | Worn die or uneven speed | Replace die, adjust feed rate |

| Air bubbles | Poor material mixing | Improve the compounding process |

Applications of Silicone Rubber Extrusion

Extruded silicone products are extensively used in multiple industries. Silicone extrusions support different fields:

Industrial & Electrical

Manufacturers value silicone rubber extrusions for their excellent heat resistance and electrical insulation. In industrial applications, it is used in high-temperature seals for furnaces. In the electrical sector, manufacturers apply silicone extrusions in cable sheathing and wire insulation. It protects conductors in harsh operating conditions.

Medical

Silicone extrusions are valued for their biocompatibility and flexibility. Medical-grade silicone is used to produce catheters, drainage tubes, and sterile seals.

Food & Beverage

Silicone extrusion is especially important for producing food-grade hoses. Dairy processors and beverage dispensers use them. In commercial ovens, silicone seals deliver long-lasting performance under high heat.

Consumer & Harsh Environments

Silicone extrusions are a durable choice for automotive window and door seals. It maintains flexibility in extreme temperatures. In aerospace, manufacturers use extruded silicone for weather protection components. It safeguards sensitive systems against UV exposure, ozone, and severe weather conditions.

Advantages of Silicone Rubber Extrusion

Silicone rubber extrusion has many benefits. That’s why it has become the most popular choice in various industries:

- High efficiency: It provides continuous production with minimal waste.

- Flexibility: It is suitable for different manufacturing requirements due to multiple curing methods.

- Custom aesthetics: Manufacturers get full control over color, transparency, and profile designs.

- Durability: It is excellently resistant to extreme temperatures. Bear harsh chemicals and UV rays.

Challenges and How to Overcome Them

| Challenge | Solution |

|---|---|

| Material compatibility | Work with a supplier experienced in compound formulation |

| Tight tolerances | Invest in precision dies and real-time monitoring |

| Production consistency | Use automated quality control systems |

| Regulatory compliance | Partner with manufacturers certified with the FDA, ISO, and UL standards |

Future Trends in Silicone Rubber Extrusion

Companies are focusing on sustainability and new manufacturing technologies in silicone extrusion. The Industry 4.0 principles emphasize improved efficiency, predictive tools, and data-driven decision-making. The future of silicone extrusion will be focused on:

- Sustainability: Development of recyclable silicone and low-energy curing technologies.

- Composite & Multilayer Extrusion: Combining silicone with other polymers to enhance the mechanical performance.

- Smart Manufacturing: IoT-enabled systems for real-time monitoring and automated defect detection.

Conclusion

Silicone rubber extrusion is a highly versatile and valuable manufacturing process. It delivers consistent and durable components. Commonly used in industries such as aerospace, automotive, electronics, and medical.

The demand for sustainable and specialized parts is growing. So, adopt advanced extrusion techniques to stay competitive and meet future market needs.

Get Your Custom Silicone Extrusion Solutions Today

At Hongju Silicone, we specialize in custom silicone rubber extrusions. Our expert team delivers components that meet strict regulatory standards. You can choose from an extensive range of profiles, colors, and silicone grades. All components are designed to match your unique application.

Contact us now for a technical datasheet or to talk about your custom silicone extrusions.