Understanding the nuances of this commercial silicone material can provide insights into its wide range of applications and help businesses make informed choices.

What is MVQ Silicone Rubber Material?

MVQ silicone rubber(methyl vinyl silicone rubber) is a specialized type of elastomeric material made from a blend of organic and inorganic compounds.

It’s a variant of VMQ silicone rubber but has a methyl and vinyl group in its chemical structure, making it a unique silicone compound.

This distinct structure allows MVQ silicone to offer impressive resistance to a wide range of environmental challenges like extreme temperatures, UV radiation, and various chemical exposures like mineral oils and brake fluids.

MVQ silicone rubber is a specific type of silicone rubber, distinguished by its methyl and vinyl groups.

The base of MVQ silicone rubber material typically consists of a silicone polymer, fillers, and curing agents, all of which contribute to its outstanding performance characteristics.

The primary building blocks of this material are silicon, oxygen, carbon, and hydrogen. Its distinct chemical composition lends it unique properties, making it a first-choice material for manufacturing first-class quality seals, gaskets, and a variety of other products.

Advantages and Properties of MVQ Silicone Rubber

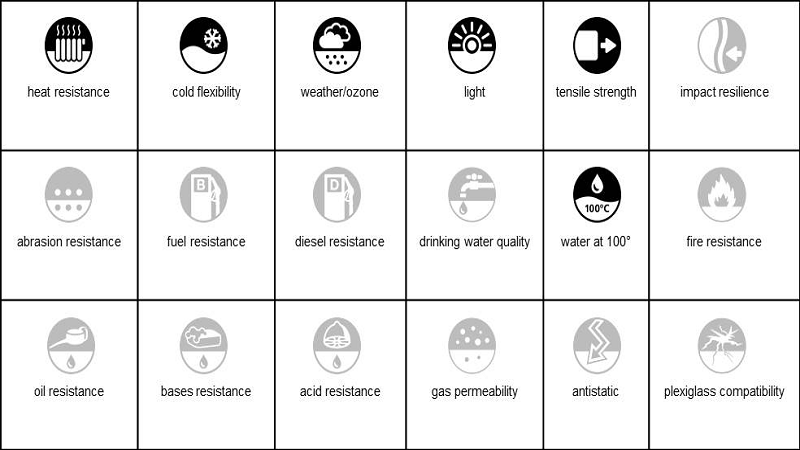

Understanding the properties and advantages of MVQ silicone rubber is crucial for its effective application across various industries.

Let’s break it down into two main categories for a comprehensive look at what makes this material so beneficial.

Properties of MVQ Silicone Rubber

- Temperature Range: One of the defining properties of MVQ silicone rubber material is its excellent thermal stability. It can withstand extreme temperatures, ranging from very cold to very hot conditions.

- Chemical Resistance: MVQ silicone exhibits strong resistance to a variety of chemicals, including mineral oils and brake fluids.

- UV Stability: The material is highly resistant to UV radiation, making it ideal for outdoor applications.

- Elastomeric Qualities: MVQ silicone rubber is a type of elastomeric material, which means it has a high degree of flexibility and resilience.

- Compatibility with Food and Medical Applications: MVQ silicone rubber is often used in the medical and food industry because of its non-toxic and hypoallergenic properties.

Advantages of MVQ Silicone Rubber

- Versatility in Applications: Due to its robust properties, MVQ silicone rubber is suitable for a wide array of applications, from food industry requirements to surgical implants.

- Longevity: The material’s resistance to UV radiation and extreme temperatures ensures a long lifespan, reducing the need for frequent replacements.

- Economic Benefits: While the initial cost may be higher than some other plastic materials, the durability and longevity of MVQ silicone material make it cost-effective in the long run.

- Ease of Manufacturing: MVQ silicone can be easily molded and extruded, making it an excellent choice for custom designs and shapes.

- Excellent Sealing Capabilities: Due to its first-class quality seals, MVQ silicone rubber is often the go-to material for sealing applications.

By understanding these properties and advantages, one can better appreciate why MVQ silicone rubber is such a valuable material in various industries.

Take the First Step:

Requst for an Inquire

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

Technical Data Sheet for MVQ Silicone Rubber

When selecting a material for specific industrial or commercial applications, having a thorough understanding of its technical specifications is imperative. Below is a general technical data sheet that outlines the key characteristics of MVQ silicone rubber.

| Property | Specification |

|---|---|

| Temperature Range | -60°C to 225°C |

| Tensile Strength | 7-12 MPa |

| Elongation | 300-720% |

| Hardness | 30-80 Shore A |

| Specific Gravity | 1.1-1.3 |

| Resistance to Oils | Excellent (Mineral and Brake Fluids) |

| UV Resistance | High |

| Food Safety Compliance | FDA, LFGB |

| Medical Grade Compliance | USP Class VI |

Note: The specifications may vary depending on the manufacturer and specific MVQ silicone compound used.

This data sheet provides an overview of MVQ silicone rubber’s properties and should serve as a useful guide for determining its suitability for various applications.

How to Process and Fabricate MVQ Silicone Rubber Material?

Understanding the processing and fabrication methods for MVQ silicone rubber material is essential for achieving the desired performance and functionality. Here are some common techniques and best practices.

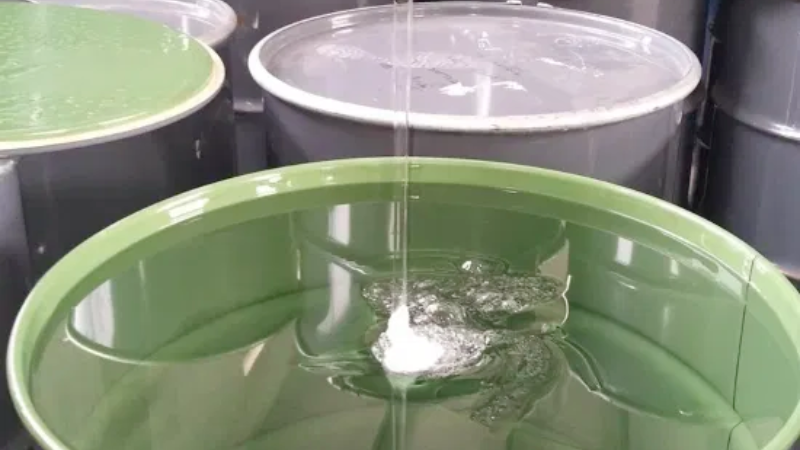

Material Preparation

Start by thoroughly understanding the technical data sheet that comes with your MVQ silicone rubber.

This will provide insights into its specific characteristics, such as temperature range, resistance to extreme temperatures, and compatibility with mineral oils and brake fluids.

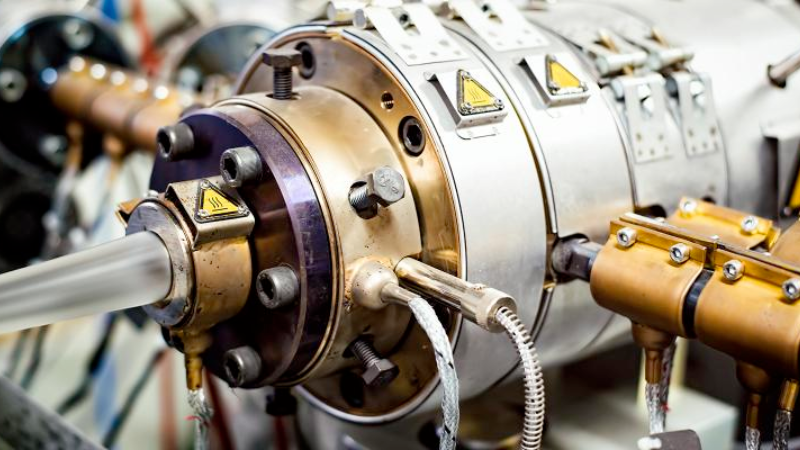

Compression molding is a popular method for forming MVQ silicone rubber into various shapes. The material is heated and then compressed into a mold. This method is often employed for making first-class quality seals and other custom parts.

Injection molding is another common technique, particularly for mass production. The MVQ silicone rubber material is heated and then injected into a mold under pressure. This method is suitable for intricate designs and offers high-speed production capabilities.

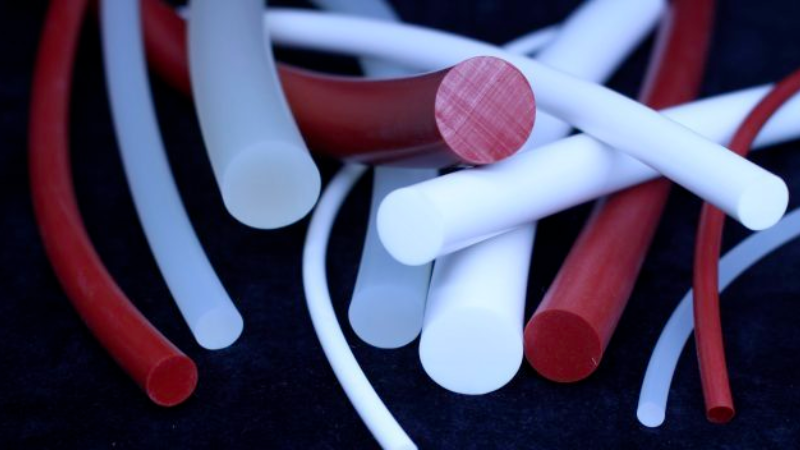

- Extrusion

For products like tubes or profiles, extrusion is often the method of choice. In this process, the MVQ material is pushed through a die, taking on its shape as it cools.

- Post-Curing

Some MVQ silicone rubber materials require post-curing, a process in which the formed material is further heated to achieve optimum mechanical properties and resistance to high temperatures and UV radiation.

- Cutting and Finishing

Once the MVQ silicone rubber is formed, it often needs to be cut, sanded, or otherwise finished to meet the final specifications. Laser cutting and waterjet cutting are two popular methods for achieving high precision.

Understanding MVQ Silicone Rubber: Formats and Applications

After getting acquainted with the technical aspects of MVQ silicone rubber, the next logical step is to explore its various formats and how these are applied across different industries.

This will provide a comprehensive understanding of why MVQ silicone rubber is the material of choice for a myriad of applications.

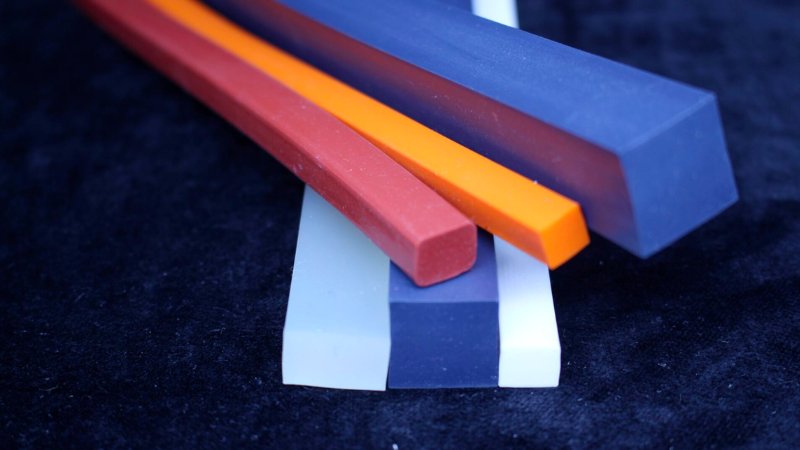

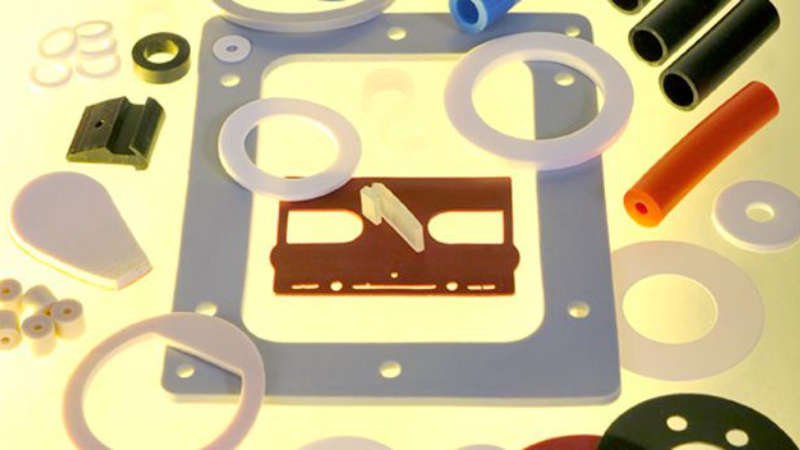

Formats of MVQ Silicone Rubber

- Sheets: Useful in sealing and gasket applications, especially where high temperatures are involved.

- Tubing: Commonly used in the medical and food industry for fluid transfer processes.

- Seals: MVQ silicone rubber makes for first-class quality seals that are used widely in the automotive and aerospace industries.

- O-rings: Due to its excellent resistance to extreme temperatures and oils, it’s widely used in mechanical assemblies.

- Custom Molded Parts: For specialized applications, custom molded parts can be fabricated using MVQ silicone compounds.

Applications of MVQ Silicone Rubber

- Automotive: Resistant to brake fluids and hot air, making it ideal for various automobile parts.

- Medical: Suitable for surgical implants and other medical equipment due to its biocompatibility.

- Food Industry: Complies with FDA standards, making it safe for food contact surfaces.

- Aerospace: Its resilience against extreme temperatures and UV radiation makes it a prime choice for aerospace applications.

- Industrial Maintenance: Utilized in elastomeric materials and other industrial maintenance applications due to its broad temperature range and resistance to mineral oils.

Understanding the formats and applications of MVQ silicone rubber can help in making an informed decision when selecting materials for specific projects or industrial processes.

Take the First Step:

Requst for an Inquire

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

Comparing MVQ Silicone Rubber with Other Types

To further understand the unique qualities and applications of MVQ silicone rubber, it’s helpful to compare it with other types of silicone rubbers. Below is a comparison table that elucidates key attributes across different silicone rubber types.

| Feature | MVQ Silicone Rubber | VMQ Silicone Rubber | Commercial Silicone Material |

|---|---|---|---|

| Temperature Range | -60°C to 225°C | -55°C to 200°C | -40°C to 180°C |

| Resistance to Oils | Moderate | Low | Moderate |

| UV Radiation Resistance | High | Moderate | Low |

| Food Industry Safe | Yes | No | Limited |

| Medical Applications | Suitable for surgical implants | Limited | No |

| Elasticity | High | Moderate | Moderate |

| Resistance to Acids and Alkalis | Moderate | Low | Low |

| Common Applications | Automotive, medical, aerospace | General purpose | Gaskets, seals |

This table aims to provide a snapshot of how MVQ silicone rubber stands against other types in various key aspects. It is clear that MVQ offers a unique set of advantages, making it a versatile choice for applications in extreme temperatures, the medical and food industry, and more.

Quality Control and Testing of MVQ Silicone Rubber Material

Quality control measures play a crucial role in ensuring the reliability of silicone rubber materials.

By subjecting these materials to rigorous testing, manufacturers can identify any potential defects or weaknesses, allowing them to deliver high-quality products that meet customer expectations.

Importance of quality control measures in ensuring product reliability

Quality control is essential in maintaining the consistent performance and durability of silicone rubber materials.

The use of substandard materials or faulty manufacturing processes can lead to product failure, which not only impacts customer satisfaction but also poses safety risks. Implementing robust quality control measures helps identify any deviations from desired specifications early on, enabling corrective actions to be taken promptly.

By adhering to stringent quality standards throughout the production process, manufacturers can ensure that their MVQ silicone rubber material meets the required performance criteria.

Common tests performed on MVQ silicone rubber material

To assess the quality and suitability of MVQ silicone rubber material for various applications, several tests are commonly conducted:

- Tensile strength test: This test determines how much force a sample can withstand before breaking or deforming. It helps evaluate the material’s ability to endure stretching or pulling forces.

- Compression set test: This test measures how well the material recovers after being compressed under specific conditions. It provides insights into its resilience and long-term deformation characteristics.

- Hardness test: The hardness of MVQ silicone rubber is measured using durometer scales such as Shore A or Shore D. This test evaluates its resistance to indentation and determines its overall stiffness.

- Thermal stability test: This test examines how well the material retains its properties under different temperature conditions. It helps assess its ability to withstand extreme heat or cold without significant degradation.

Standards and certifications related to the quality assurance process

Several standards and certifications are relevant to ensuring the quality of MVQ silicone rubber material. These include:

- ISO Certifications: ISO 9001 and ISO 13485 are commonly required for quality management systems, especially in the production of medical and food-grade MVQ silicone rubber. These certifications ensure that the product meets international quality standards.

- ASTM Standards: Various ASTM standards, such as ASTM D2000 for elastomeric material, may apply. These standards specify the mechanical and chemical properties that the MVQ silicone rubber must possess.

- FDA Regulations: For MVQ silicone materials destined for food contact or medical applications, compliance with FDA regulations is mandatory. This includes migration tests to ensure no harmful substances transfer to food or medical devices.

How to Choose The Right Type of MVQ Silicone Rubber Material for Your Needs?

Selecting the correct MVQ silicone rubber material for your specific application can be a daunting task, given the variety of options available. However, with a little guidance and an understanding of the key parameters, you can make an informed decision that will meet your needs.

Consider Your Industry

Different industries have unique requirements for silicone rubber material. For example, the medical and food industry may require FDA-approved, high-purity forms of MVQ, while industrial applications may need materials with high resistance to extreme temperatures or chemicals like mineral oils and brake fluids.

Evaluate the Environmental Conditions

Consider the operating conditions where the material will be used. This includes factors like temperature range, exposure to UV radiation, and contact with vegetable oils, hot air, or chemicals.

Examine Mechanical Properties

Look for technical data sheets that outline the mechanical properties such as tensile strength, elongation, and hardness. This information is critical for understanding how well the MVQ silicone rubber will perform in your specific application.

Certifications and Standards

Ensure that the MVQ silicone rubber you choose meets the required standards and certifications for your industry. Whether it’s ISO, FDA, or ASTM standards, compliance is usually a non-negotiable factor.

Compatibility with Other Materials

Check how well the MVQ silicone rubber interacts with plastic materials or elastomeric materials you may already be using. Some silicone compounds are better suited for specific material pairings than others.

Ask for Samples

Before making a bulk order, request samples for testing to ensure that the MVQ silicone rubber meets your expectations in real-world conditions.

Consult Experts

When in doubt, consult with material scientists or engineers familiar with MVQ silicone rubber materials. Their expertise can guide you to the right material choice for your application.

By considering these factors and consulting experts, you can confidently select the MVQ silicone rubber material that is ideal for your specific needs.

Conclusion

In summary, MVQ silicone rubber material offers a broad range of benefits, from exceptional temperature resistance to versatility in applications like the food industry and medical implants.

By understanding its properties and following best practices in processing and fabrication, one can maximize its potential for high-quality outcomes.

Collaborate with Hongju for Customized MVQ Silicone Rubber Solutions

Ready to explore the advantages of MVQ silicone rubber for your project? Don’t miss out on leveraging this versatile material for your specific needs. Contact Hongju today to discuss how we can help you make the best material choices for your applications. Your success starts here!

Take the First Step:

Requst for an Inquire

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.