The industrial sectors including gas, oil, and transport heavily utilize HNBR. That’s because of its incredible heat resistance and fluid resistance, be it coolant, engine oil, fuel, etc– even those with hydrogen sulfide, alkaline corrosion inhibitors, salt solutions, and amines.

Because of its physical strength and broad temperature range, the HNBR market is projected to grow at 7.7% CAGR and reach $34.7 billion by 2033.

Chemical Composition of HNBR

HNBR is a stable and saturated polymer structure with advanced chemical composition and production.

- Origin

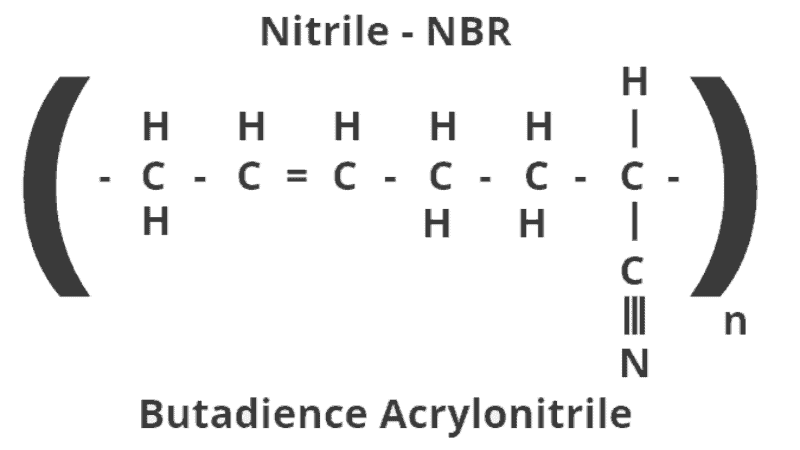

Nitrile Rubber (NBR): It’s derived from the synthetic rubber Nitrile Rubber or NBR. It’s a versatile material for high-temperature resistance, tensile strength, and excellent resistance to fuel, oil, and other chemicals.

It’s also an elastic and flexible material which makes it perfect for a broad range of applications including seals and hoses.

Its chemical resistance improves through the hydrogenation process. The process involves selective hydrogenation of NBR to remove the double bonds make the polymer more oxygen-resistant and increase high-temperature performance accordingly.

Compounding techniques are used to create HNBR. If you want low-temperature performance, low ACN grades are applied, and for high-temperature performance, highly saturated HNBR grades are used with white fillers.

- Key Chemical Properties

HNBR is a great synthetic elastomer with excellent chemical properties perfect for industrial applications.

Its thermal stability, oxidative aging resistance, and good resistance to many environmental factors make it a superior material for automotive components including gaskets, seals, and other applications.

- Acids– HNBR’s resistance is good for diluted acid, maintaining its overall structural integrity. For concentrated acids, its performance is also fair to good depending on the duration of the exposure.

- Aldehydes– Depending on the type of aldehyde, its resistance can be fair to good.

- Alkalies– For diluted or mild alkaline, HNBR exhibits good resistance, but for concentrated ones, resistance may be affected which leads to softening, degradation, and swelling over time.

- Amines: Amines are common in industrial applications, and HNBR demonstrates good resistance to this organic compound.

- Animal and Vegetable Oils– HNBR also exhibits good to excellent resistance to animal and vegetable oils, making it perfect for the food processing industry.

- Esters– Conduct compatibility testing when using HNBR for applications that involve esters. In general, Alkyl Phosphate has poor compatibility with HNBR although Aryl Phosphate may have fair compatibility with the elastomer.

- Fuel– For Aliphatic Hydrocarbon, the performance is excellent. For Aromatic Hydrocarbon, it’s fair to good. And for Extended (Oxygenated) Fuel, the resistance is good to excellent.

- LP Gases & Fuel Oils– HNBR is perfect for automotive, oil, and gas industries as it has excellent compatibility with LP gases and fuel oils. Its general oil resistance is good to excellent including mineral oils and silicone oil.

Hongju Awaits Your Quote Request!

Physical and Mechanical Properties

HNBR can withstand mechanical stresses since it has an exceptional balance of resilience, hardness, and flexibility. From soft seals to heavy-duty structural components, its industrial and performance-demanding applications are wide-ranging.

| Quality | State |

|---|

Comparison with Standard NBR

NBR and HNBR share a lot of similarities in terms of chemical properties, but they have distinct compositions and differences in terms of overall performance. Choose a synthetic rubber depending on the application and level of performance you’re looking to achieve.

| Feature/Property | HNBR (Hydrogenated NBR) | Standard NBR |

|---|

Hongju Awaits Your Quote Request!

Processing and Manufacturing with HNBR

Molding and extrusion are some of the main techniques used for processing HNBR and other rubber and plastic products. The method used should depend on the geometry and complexity of the project requirements.

Molding uses both pressure and heat to fill the mold cavity, also called the matrix. Molding is a great process to achieve versatility, accuracy, and efficiency. A manufacturer could use compression molding, melt molding, transfer molding, or injection molding.

The best molding method depends on the type of product to be manufactured. If you’re looking for a manufacturer for your next project, it’s best to choose one that can use various processes depending on your specifications, objectives, and budget.

Molding processes are usually used for complex designs, tight tolerances, better precision, and high-volume production.

On the other hand, extrusion is typically used for simpler designs that require consistent cross-sectional shapes or products that tend to be long and continuous including tubes, hoses, and seals.

Unlike molded components, extruded rubber products are forced through a die of the required cross-section using an extruder. These parts are made with unvulcanized rubber compounds fed into the extruder. This leaves the products in a soft and pliable state.

They are then vulcanized and hardened to be usable. Extrusion is a great method as well since it can produce various shapes as well as lightweight and flexible products. There’s also minimal waste and it’s generally an economical and efficient process.

Your chosen manufacturer will work with you to discuss the right methods and materials for your exact project in mind.

The characteristics should also match the intended use— whether you need an output with high-temperature stability, good chemical resistance, robust durability, and so on.

Applications of HNBR

HNBR compounds typically are widely employed in medical, aerospace, industrial, oil and gas, fluid power, semiconductor, and consumer electronics industries. One of the main industries that adopted HNBR is the automotive sector.

Car components, including o rings, seals, and gaskets, require stringent requirements that include oil, temperature, and abrasion resistance. HNBR has been a big contributor to the performance of the vehicles we have today.

The super compound is also instrumental in oil field exploration given how harsh downhole environments can be. From drilling devices to good construction, HNBR products have been very helpful in the oil and gas industry.

Because of the compound’s exceptional properties and great performance, various HNBR rubber products can be produced including:

- Fuel system seals & hoses

- Air-conditioning seals & hoses

- Engine seals, grommets, o rings & gaskets

- Piston seals

- Serpentine belts

- Suspension seals

- Vee packing

- Blowout preventers

- Oilfield packers & hangers

- Heat exchanger gaskets

- Rotary shaft seals

- Steel and Paper mills

Molded/Extruded HNBR parts

- Dynamic and Static Seals

- Grommets

- Gaskets

- Vibration isolation mounts

- Bumpers, tips & appliance feet

- Grommet inserters

- Extruded rubber profiles & tubing

- Rubber bellows & boots

Hydrogenated Nitrile Butadiene Rubber meets a lot of modern applications as well as engineering and industrial demands.

It’s a huge advancement in polymer science and its enhanced properties and resistance to various harsh external factors make it a superior choice in terms of quality and consistency.

Hongju Awaits Your Quote Request!

Conclusion

As factories advance and optimize their processes, HNBR will have a role to play in the future of high-performance elastomers.

With ongoing research and development, there will be more advanced HNBR variants with even better performance and even wider applications.

If you want to make use of better synthetic rubbers like HNBR elastomers to upgrade your existing products or develop new ones, make sure to work with a rubber and plastic manufacturer with years of experience in the industry.

Get Started with Hongju Silicone

Contact Hongju Silicone to discuss your product requirements, timeline, and budget. With decades of experience as an innovative silicone rubber products manufacturer in China, rest assured your project will be in good hands.

Plus, we use eco-friendly materials and processes to give your brand a more robust value proposition. Contact us today with Hongju Silicone!