Silicone rubber is a versatile material widely used in food and medical applications due to its non-toxic, heat-resistant, and inert properties. Food-grade silicone meets strict safety standards for contact with food, while medical-grade silicone is approved for sub-dermal devices and medical equipment.

This guide explores the differences between the two, their manufacturing processes, and their unique applications in industries such as healthcare, food processing, and more. Whether you’re choosing silicone for kitchenware or medical devices, understanding these distinctions ensures safety and compliance.

Why Choose Silicone for Food and Medical Purposes?

Silicone is the perfect material when a product is meant for sensitive use. That’s because it has properties that make it resistant to heat, fungal, and even ultraviolet effects. This makes it tasteless, non-toxic, and odorless, too.

Because of these remarkable properties, liquid silicone rubber has a longer lifespan than other rubber types. It has excellent tensile properties and can withstand a wide range of temperatures from -100 °C to 200 °C.

Silicone rubber has high compressibility and is an excellent material for all products – including those requiring food-grade and medical-grade levels.

Since food-grade and medical-grade silicone come into contact with the human body directly and indirectly, it shouldn’t cause any irritation or harm upon contact.

Now that you know why silicone rubber is the best material, it’s time to learn more about the difference between food-grade silicone and medical-grade silicone rubber.

What is Food-grade Silicone Rubber?

Food-grade silicone rubber is a material that meets the food standard regulations of a specific country or region. It could mean the material is safe for food applications such as silicone cookware when it passes the laws.

Getting a Food-grade Approval

To determine if the silicone rubber is of food-grade quality, it’ll have to be assessed by the regulating authority. It’s important to know who sets the food regulation standards.

That way, the silicone medical grade materials will surely meet the specific regulations set by the governing body. After all, every country or region has its food standards.

The known regulators of food-grade materials include the US Food and Drug Administration (FDA), EU legislation and guidelines, and the Council of Europe Resolution on silicones.

How will the regulating authority, like the FDA, check the silicone rubber?

They will do this by fingerprinting the silicone and conducting tests and scans. They’ll check the silicone rubber materials for traces of elements harmful to the body, like formaldehyde.

To make a silicone rubber material safe for food applications, it should use a specific curing system that’s platinum-catalyzed. Not only that, but it should also go through a post-curing process to ensure the mechanical properties of the food-grade silicone will work well.

This process will also remove any volatile by-products from the silicone. This may result from the crosslinking of chemicals and any low-molecular components of the raw material.

Properties of Food-grade Silicones

A food-grade silicone rubber should use a synthetic polymer manufactured with non-toxic silica as its primary component. This makes it highly resistant to extreme environments, temperatures, and stresses.

That means the food-grade silicone material can withstand temperatures between -60°C and 230°C and won’t lose shape. It’s highly durable and resilient enough to be used multiple times.

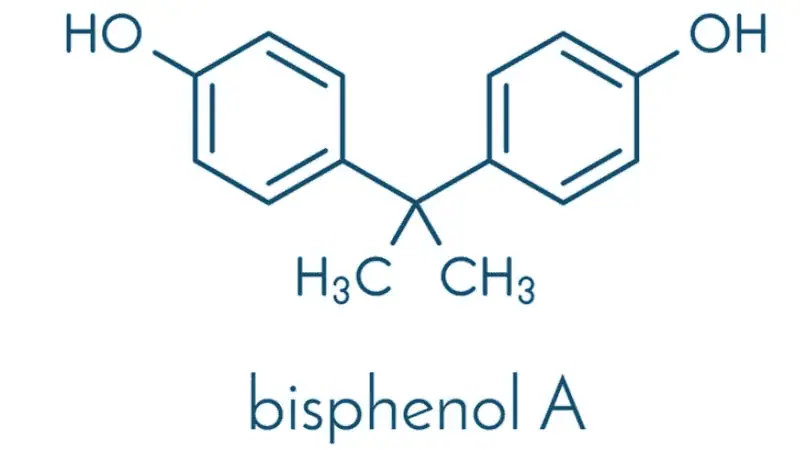

It should be odorless, non-corrosive, and non-toxic. There should be no harmful fillers like BPA or BPS. It should also have pure and inert properties that make it a safe material to come into contact with food.

A food-grade silicone material must resist liquids like oil from food and most chemicals. It has to prevent leakage so it won’t cause any contamination that can spoil food.

Anti-fungal and non-stick properties are also essential properties of food-grade silicone. It ensures no molds or fungal decay will grow and contaminate the food.

Food-grade Silicone Applications

Examples of the applications include the following:

- Ice cube trays

- Baking molds

- Kitchen knives

- Whisks

- Spoons and other kitchen utensils

- Food containers

- Gaskets for food processing machines and equipment

- Oven seals

- O-rings

- Tubing for breweries, food transfers, dairies, coffee machines, etc.

- Electric insulators

If you are looking for a manufacturer of food-grade silicone, click here!

Take the First Step:

Requst for an Inquire

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

What is Medical-grade Silicone?

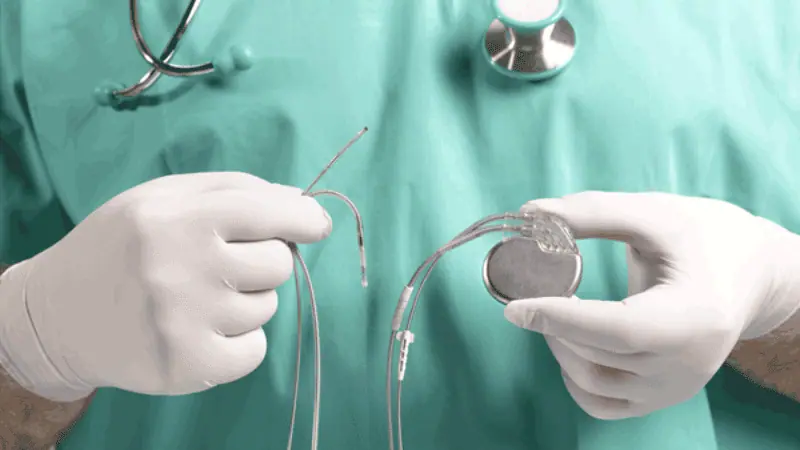

Medical-grade silicone rubber is a type of synthetic elastomer that’s non-toxic and has inert properties. This makes it safe even for sub-dermal devices under human skin. Even if silicone rubber products use fillers and vulcanizing agents during manufacturing, it does not use harmful additives to the human body.

Getting Medical-grade Approval

Medical grade gains approval from regulating bodies. In the US, it’s the Center for Devices and Radiological Health (CDRH) that checks medical-grade silicone. This agency also operates under FDA regulations. Other countries have their counterparts for these regulating authorities.

Because its use is more sensitive than food-grade silicone, medical-grade silicone has stricter standards. It should meet USP standards and also the approval of both the ISO and FDA. It can only get “medical-grade” approval if it can fulfill three critical requirements.

- Good history of successful testing of implantation on animals and humans.

- The manufacturing process should pass the standards for proper pharmaceutical manufacturing conditions.

- Adequate quality control for medical applications

Usually, medical-grade silicone uses platinum-catalyzed curing systems. It should not use peroxide-curing methods because it leaves harmful acid residues.

When approved, the regulating body puts the medical-grade silicone rubber into either of two types. One is room-temperature vulcanizing, and the other is heat-vulcanizing.

Properties of Medical-grade Silicones

A medical-grade liquid silicone should have specific properties and the highest quality. It should even be safer than food-grade silicone. The medical devices industry won’t use any other medical equipment unless it has a medical grade.

But even other professionals who want the highest standards for their silicone rubber use the ones with the medical grade. So what are the properties of medical-grade silicone?

First, it should be non-porous. This means it shouldn’t have even microscopic holes in it. That way, no fluid, bacteria, or other microorganisms will go through it. This will prevent any infections from happening.

Second, it should be naturally inert. This is a critical feature that any medical device manufacturer should have. This means it won’t react to any chemical or even when it comes into contact with human tissue. This will help avoid irritations and infection. This inertness is a silica property, which is silicone’s primary component.

Third, it should be temperature and chemical-resistant. Despite its durability, rubber materials wear down when exposed to fluids. However, there are materials like silicone that are chemically resistant to water, acids, ammonia, oxidizing chemicals, and isopropyl alcohol.

Silicone is also temperature resistant and can stay stable through extreme temperatures from -100 °C to 200 °C.

Medical-grade Silicone Applications

Here are the different applications of medical-grade silicone.

- Gels

- Condoms

- Feeding tubes

- Catheters

- Syringe pistons

- Menstrual cups

- Respiratory masks

- Silicon sheets for scar treatment

- Seals and gaskets for medical equipment

- Implants (both for long-term and short-term use)

If you are looking for a manufacturer of medical-grade silicone, click here!

Take the First Step:

Requst for an Inquire

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

Difference Between Food-grade Silicone and Medical-grade Silicone

Here are the differences between food-grade and medical-grade silicone.

| FOOD-GRADE SILICONE | MEDICAL-GRADE SILICONE |

|---|---|

| Ideal material for products that’ll come into contact with food. | Ideal material for impact devices or any pharmaceutical products for medical purposes. |

| Goes through testing to ensure that the food that comes into contact with it is safe for consumption. | It goes through testing for bio-compatibility so it can be safe for medical applications. |

| More cost-efficient to manufacture. | More expensive because it requires chemical and temperature durability. |

| Should pass the standards of FDA, BFR, and EU regulations. | Should pass the standards of the CDRH under the authority of the FDA |

| Does not require animal or human testing. | Requires adequate animal and human testing. |

Conclusion

When using food-grade or medical-grade silicone, ensure they are non-toxic, temperature-resistant, and inert. Both should undergo platinum-catalyzed curing for safety.

Note the standards differ for each, so choose the appropriate type to avoid harm.

Are You Looking for Silicone Products? Hongju Can Help You!

Hongju has been producing custom food-grade and medical-grade silicone products since 1999. As a leading custom-molded silicone rubber products manufacturer in China.

We are committed to providing superior quality products to our customers as well as considerate service. Send your inquiry now!