1. What Is EPDM?

EPDM (Ethylene Propylene Diene Monomer) is a synthetic elastomer. It is known for its exceptional resistance to weathering and durability.

EPDM rubber is made by propylene, polymerizing ethylene, and a little diene monomer. This combination creates a stable, flexible, saturated backbone. It helps resist aging.

The polymer is then compounded with fillers, stabilizers, and curing agents. It is further processed into sheets, gaskets, or custom profiles.

Chemical and Physical Properties:

- EPDM is an excellent UV, ozone, and weather-resistant material. It can be ideally used outdoors.

- Extreme temperature tolerant, typically from −50°C to +150°C.

- Resist various chemicals such as acids, alkalis, and even hot water/steam.

- Low density makes it lightweight.

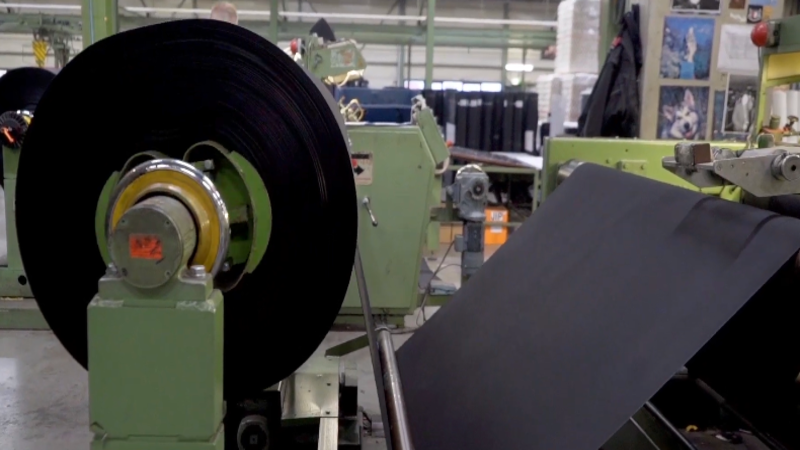

Synthetic rubbers grew fast during World War II due to the shortage of natural rubber. EPDM rubber sheets and rolls are used for roofing membranes. Extruded EPDM gaskets and seals are common in automotive and construction. Molded EPDM parts are also made for HVAC and plumbing systems.

2. What Is Natural Rubber?

Natural rubber is a latex-based elastomer. It is harvested mostly from the latex sap of rubber trees, commonly from the Hevea brasiliensis tree.

The harvesting process is done by tapping the tree bark. The latex is collected and then coagulated with acids. The coagulated sheets are rolled, dried, and smoked before being processed into usable forms.

Key properties:

- The tensile strength brings excellent load-bearing capacity.

- Due to superior elasticity and resilience it returns to shape after deformation.

- The exceptional tear resistance makes it ideal for high-impact applications.

Natural rubber cannot resist UV, ozone, and weathering. If applied in these environments, it degrades quickly. Its temperature tolerance is narrow, usually from −50°C to +70°C. Extreme temperatures can cause the material to harden or crack.

Also does not perform well in oils, fuel, and chemicals applications. Prone to swelling if mixed with certain solvents.

EPDM vs Rubber: Side-by-Side Property Comparison

| Property | EPDM Rubber | Natural Rubber |

| Tensile Strength | Good (~7–14 MPa) | Excellent (~20–25 MPa) |

| Elongation at Break | Good (~300–600%) | Excellent (~500–700%) |

| Temperature Resistance | −50°C to +150°C | −50°C to +80°C |

| Weather & UV Resistance | Excellent | Poor |

| Chemical Resistance | Excellent for acids, alkalis, hot water | Poor to moderate |

| Abrasion Resistance | Good | Excellent |

| Compression Set | Good, even in the heat | Low at room temp but worsens with heat |

| Cost | Low | Low to moderate |

| Lifecycle | Long outdoors | Long indoors, shorter outdoors |

- Tensile strength: It is the maximum force a material can withstand before breaking. A higher tensile strength means the material can handle greater stress without failing.

- Elongation at break: It is the stretching capacity of a material before it tears. Materials with high elongation are more flexible. They are less likely to crack under movement.

- Temperature resistance: It is the thermal stability of a material under prolonged heat. A wide range shows performance in both hot and cold environments.

- Weather and UV resistance: It is an indication that the material can withstand sunlight, ozone, and outdoor conditions without degrading. This factor is essential for manufacturing outdoor products.

- Chemical resistance: The material’s ability to resist damage from oils, acids, alkalis, and other chemicals. High resistance indicates reliability in harsh environments.

- Abrasion resistance: It refers to how well the material stands up to wear, friction, and repeated contact. Strong abrasion resistance extends product life in high contact applications.

- Compression set: It is the material’s ability to return to its original shape when compressed. Low compression set means better long-term sealing performance.

- Lifecycle: It shows the expected service life of the material under specified conditions. Longer lifecycles reduce replacement needs and maintenance costs.

- Cost: Cost reflects the relative affordability of the material. It helps determine budget feasibility.

4. Pros and Cons of EPDM

Pros

- Excellent UV rays and ozone resistance for outdoor use.

- Wide temperature range suitable for extreme climates.

- Resist water and steam.

- Long lifespan in outdoor environments.

- Can resist chemicals such as alkalines, polar solvents, and dilute acids.

Cons

- Poor oil and hydrocarbon resistance.

- Difficult to bond with metal, needs specific adhesives.

- Lower tear and tensile strength.

5. Pros and Cons of Natural Rubber

Pros

- Exceptional tensile and tear strength.

- High resilience and elasticity for dynamic loads.

- Good abrasion resistance for wear parts.

- Requires specific adhesives for rubber-to-metal bonding.

Cons

- It has poor UV and ozone resistance. Needs protective coatings in outdoor environments.

- Limited heat and chemical resistance.

- Short service life in outdoor applications

Typical Applications Compared

Rubber materials are chosen based on their performance in real-world conditions. EPDM, a synthetic material, and natural rubber each shine in different sectors.

| Application Area | EPDM Rubber | Natural Rubber |

| Roofing & Construction | Roofing membranes, weather seals | Indoor flooring, skirting in equipment |

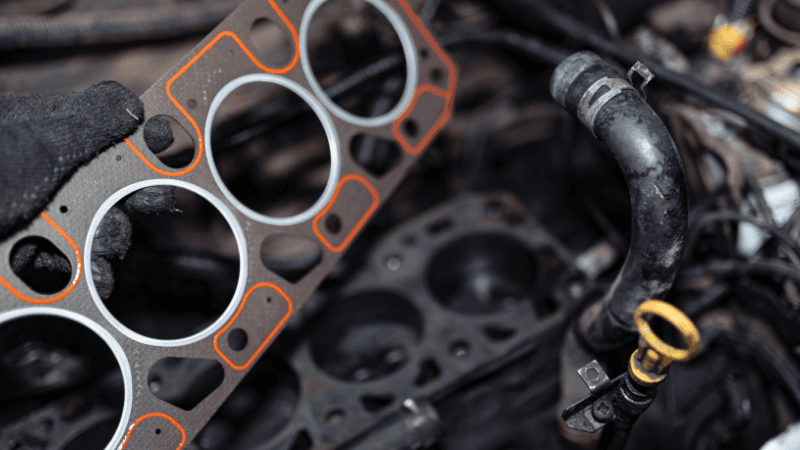

| Automotive | Door, window, and trunk seals | Shock absorbers, anti-vibration mounts |

| HVAC & Plumbing | Gaskets, hot water hoses | Low-pressure hoses, basic seals, vibration pads |

| Industrial & Mining | Playground flooring, pond liners | Conveyor belts, abrasion liners |

| Durability Focus | UV, ozone, and water resistance outdoors | High tensile strength and abrasion resistance indoors |

EPDM resists weather and UV radiation very well. When comparing EPDM rubber vs neoprene, EPDM is generally better for outdoor use due to its weather resistance. Mostly used garden hoses for long-term durability.

EPDM hoses used in water pumps work well due to their heat and water resistance. It is also used in industrial settings, vehicle hood seals, roofing, waterproofing, and HVAC systems.

Its excellent electrical insulation makes it useful for cables. When comparing EPDM and NBR rubber, NBR is oil-resistant, while EPDM performs better against weathering and heat.

Natural rubber, with its high tensile strength and elasticity, is better suited for heavy-load applications. It is commonly used in seals, hoses, and gaskets. Its resistance to abrasion makes it ideal for shock absorbers, vibration mounts, and similar components.

How to Choose Between EPDM and Natural Rubber

The selection of the right material depends on its usage. You need to consider environmental factors and application requirements. Both elastomers have specific material properties and strengths.

Consider the Environment

Start with the operating environment. For outdoor exposure, EPDM is the clear winner because it resists UV, ozone, and weather. Natural rubber performs better in indoor settings where abrasion and mechanical wear dominate.

Check Temperature Requirements

The temperature range is critical. EPDM maintains flexibility and strength above 80 °C. It can handle up to 150 °C. Natural rubber works well in moderate ranges but loses properties at high heat. Use NR if the system runs below 80 °C and other conditions are favorable.

Evaluate Exposure to Chemicals

Chemical contact also decides the material selection. EPDM resists acids, alkalis, detergents, and even hot water or steam. Natural rubber does not handle these well.

If the application involves oils, fuels, or grease, neither EPDM nor NR is ideal. Other rubber types like NBR (nitrile rubber) should be considered instead.

EPDM maintains balanced mechanical properties, including flexibility and toughness. But natural rubber shows poor mechanical properties when exposed to sunlight.

Assess Mechanical Stress

Mechanical load and stress cycles also matter. Natural rubber has superior tear strength and fatigue resistance. So it is suitable for dynamic parts like mounts or shock absorbers. EPDM is durable and better for static seals and insulation.

Factor in the Budget

Cost is always a deciding factor. Natural rubber is generally more expensive. Various factors such as limited availability, natural harvesting, and labor intensive production process influence its cost.

EPDM is a synthetic rubber. It is easily produced at scale. That’s why it is usually more affordable and widely available. For projects with tight budgets or large material requirements, EPDM provides a better cost advantage.

EPDM vs. Natural Rubber: Which One Is Better?

Each rubber material has its own strengths. One performs better in a specific application, and the other does not. So, there is no one-size-fits-all answer. Choose EPDM for outdoor, high-temperature, and chemical-resistant needs.

Select NR if you are manufacturing for indoor and abrasion-heavy applications.

The better option depends entirely on your operating conditions. By matching material to service conditions, you extend performance life, reduce failures, and optimize costs.

Conclusion

Both EPDM and natural rubber have unique strengths. Not one can be called a universal winner. The decision should always be based on environment, stress factors, and cost.

If durability in harsh weather is key, EPDM is the right investment. If performance under heavy loads is the priority, natural rubber stands out. By carefully matching material properties to your application, you can achieve longer service life and reduced maintenance.

Choose the Right Rubber from Hongju for Your Project Today!

Hongju Silicone offers fast, flexible, and high-quality silicone rubber manufacturing to power your business growth. Get rapid prototyping in just 3–5 days, low MOQ for cost efficiency, and benefit from 20+ years of expert craftsmanship.

Contact Hongju today for tailor-made silicone solutions that deliver precision, performance, and speed!

Request your quote now!