Silicone sponge rubber possesses the properties of solid silicone rubber and is still compressible. In addition, it offers excellent sealing, insulation, and cushioning. This article explores everything you need to know about this material, including its applications, benefits, and drawbacks.

What Are Silicone Sponges?

Silicone sponge rubber is expanded rubber. This material combines the foam’s lightness and the enhanced sealing properties of silicone rubber. Silicone sponge rubber is widely used for sealing applications in medical and food processing industries.

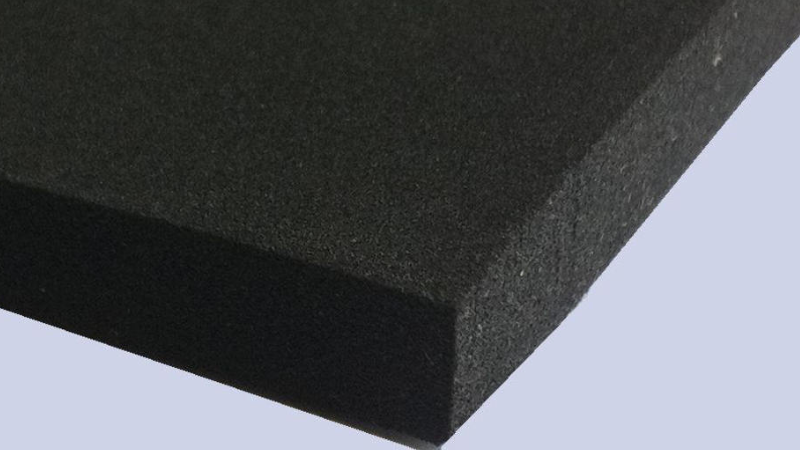

Silicone sponge rubber has a closed cell structure that prevents water intrusion into the sponge’s aggregate structure, keeping the seal’s integrity. Usually, these closed cells contribute to the material’s density. Any silicone sponge rubber with an absorption less than or equal to 5% classifies as a closed-cell sponge.

Furthermore, silicone sponge rubber is a good water seal even under low-compressive forces. The material is temperature, ozone, and UV resistant, with a low compression set. The material also satisfies the UL94 requirements.

Another property of a silicone sponge rubber is its superb vibration isolation qualities that reduce the effects of shocks on any item the sponge protects.

What Are Silicone Sponges, Gaskets & Seals Used?

As mentioned earlier, silicone sponges are used in sealing applications. Therefore, silicone sponge gaskets and seals protect equipment from external elements. In addition, since a silicone sponge has less than 5% absorption, it keeps fine particles and wind-driven rain out to preserve a piece of equipment.

Due to this material’s resilience, it is especially suitable for outdoor applications, including sealing and protecting electronics, communications, and lighting equipment. Other applications of silicone sponge rubber include;

- Heat and cold thermal insulation. Sponge silicone has high and low-temperature resistance, making it ideal for thermal shielding.

- Flame retardant applications. Closed-cell silicone sponge has flame-retardant properties, and it is a self-extinguishing rubber.

- Food processing machinery seals. Food-grade silicone sponge materials are FDA-compliant and safe for handling food. They are non-toxic and do not leach even at high and low temperatures.

- Medical devices and pharmaceutical equipment seal. Medical-grade sponge silicone seals manufacture devices like hearing aids, ear plugs, and intraocular lenses.

- Oven seals. Due to the silicone sponge’s high-temperature resistance, it is ideal for use as an oven seal. The material will not melt and maintain its properties even at extreme temperatures.

- Gasket industry. Silicone sponge is used to manufacture outdoor gaskets for moisture-tight sealing and to cushion.

How Are Silicone Sponges Made?

Silicone sponge rubber has a fine cellular construction comprising non-interconnecting cells. Gum-based polydimethylsiloxane (PMDS) is currently the most popular silicone inorganic polymer. This polymer is used to make the most of the commercially available silicone sponge rubber on the market.

PMDS is ideal for industrial purposes due to its non-flammable and inert properties.

When making silicone sponge rubber, a silicone elastomer is a heat cured. This elastomer expands to create a closed-cell sponge structure. In addition, the expansion results in compressible air pockets. These air pockets are similar to the action of yeast on bread.

Silicone sponge rubber has the performance advantages and properties of solid silicone but in a softer and more malleable form.

Types of Silicone Sponges Rubber

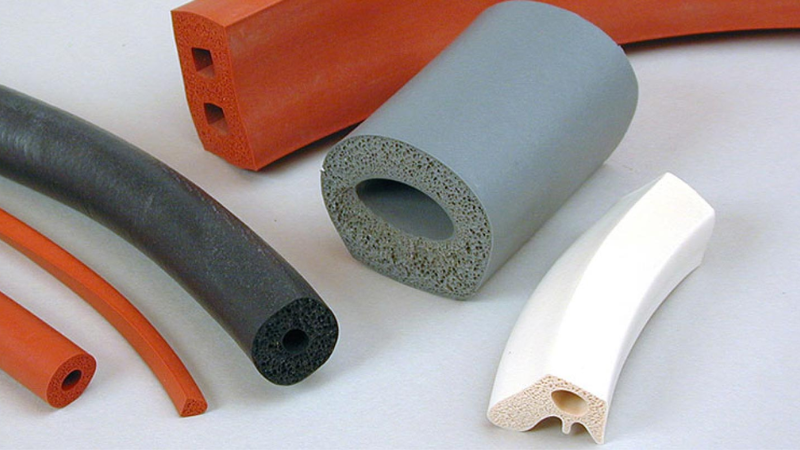

Sponge rubber is ideal for sealing solutions across several industries. They protect equipment by preventing water, air, oil, or dust ingress. Sponge rubber is not made from only silicone. Other sponge rubber materials include neoprene and EPDM, and other elastomers.

EPDM Sponge Rubber

EPDM sponge rubber is another popular sealing material ideal for automotive and outdoor applications. This is due to its excellent UV and ozone resistance. Furthermore, the EPDM sponge has an extraordinary temperature range between -40 and 302 degrees Fahrenheit.

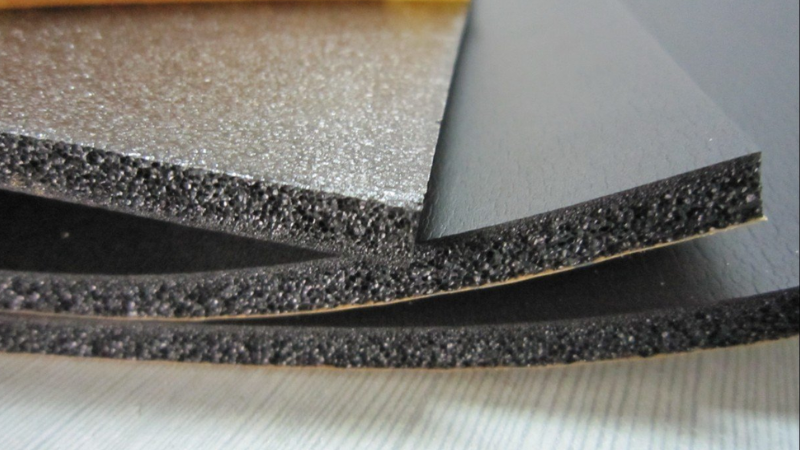

The material also has excellent weathering and abrasion resistance. EPDM sponge rubber is usually manufactured in blocks converted into sheets of varying thicknesses.

Neoprene Sponge Rubber

Neoprene sponge rubber has high abrasion resistance. This material is also chemically inert and can withstand temperatures between -40 to 230 degrees Fahrenheit. In addition, neoprene sponge has good oil and UV resistance and is suitable for industrial and outdoor applications.

Like EPDM, neoprene sponge is first made as blocks during its manufacture. Afterward, it is split into sheets of varying thicknesses.

Neoprene/EPDM Sponge

The Neoprene-EPDM sponge rubber is a blend of the two elastomers. This sponge rubber combines the properties of EPDM and neoprene to create a highly versatile product.

In addition, this rubber material has the oil resistance of neoprene as well as other properties of EPDM. Therefore, it is ideal for outdoor applications and has exceptional thermal stability.

Silicone Sponge Rubber

Silicone sponge rubber is ideal for applications that require an easily deformed material. Like other sponge rubber, silicone sponge has a closed-cell structure that prevents liquid and gas ingress.

It also has excellent insulation properties. In addition, silicone offers the highest thermal stability of all types of sponge rubber with a temperature range of -65 to 450 degrees Fahrenheit. However, unlike neoprene and EPDM, silicone sponges have poor abrasion resistance.

This type of sponge rubber is also ideal for outdoor applications due to its excellent UV and ozone resistance. Silicone sponge rubber is also supplied in sheets of varying densities. Each sheet has a standard size and is suitable for specific applications.

Solid Silicone Rubber vs. Silicone Foam vs. Silicone Sponge Material

Solid silicone rubber, silicone foam, and silicone sponge material are all variants of silicone elastomer. The primary difference between them is their cell structure. Solid silicone material has no visible cell structure, and although it offers the best sealing capabilities, it is difficult to compress.

Silicone foam has an open cell structure of silicone elastomer, while silicone sponge has a closed cell structure. Another difference is their temperature. Silicone sponge rubber can withstand temperatures up to 500 degrees Fahrenheit, while silicone foam material can withstand heat up to 400 degrees Fahrenheit.

Nevertheless, both materials are soft and require much less compression force than solid silicone.

The Benefits of Using a Silicone Sponge Rubber

Silicone sponge rubber offers numerous benefits. This rubber reduces vibrations and prevents high-volume noises from passing through it. Other benefits of silicone sponge rubber include the following;

- Excellent UV and ozone resistance. UV light and ozone attack elastomers, making them lose their elastic properties. However, silicone sponge rubber can withstand the harsh outdoor effects and maintain its properties.

- Design flexibility. Due to its closed-cell structure, this rubber is flexible and ideal for manufacturing small parts.

- Silicone sponge rubber offers excellent shock absorption. Due to its high elasticity, this rubber material absorbs shocks and retains its shape.

- The rubber provides excellent sealing capabilities, making it ideal for manufacturing gaskets and O-rings

- The sponge rubber has a low water absorption of less than 1%, making it ideal for protecting equipment from water intrusion.

Some Common Complaints about Silicone Sponges and How to Solve Them?

Common complaints about silicone sponges are usually about their tear strength and cost.

Tear strength

Silicone sponge rubber has poor tear strength. Tear strength is the resistance of a rubber material to forces ripping the material till it fails. Silicone sponge rubber cannot resist abrasion and will fail when exposed to damage. Adding fillers like silica can improve the tear strength of this material.

Cost

Because silicone sponge rubber offers exceptional performance compared to other sponge rubber, it comes at a premium cost. Although you cannot solve the cost complaint, it is essential to note that the long-term use of this rubber is cost-effective.

Conclusion

Silicone sponge rubber is not the same as solid silicone rubber. Although they possess the same properties, they have different structures. Silicone sponge rubber has low water absorption and is UV and ozone resistant. The material also has a wide temperature range.

Although this rubber provides numerous benefits for applications, it also has downsides. Fortunately, you can work around these downsides and save costs in the long run.

Get Customized Silicone Products at Hongju!

Solid silicone is excellent but not ideal for applications requiring low compression forces. As a rubber products supplier, you can include silicone sponge rubber in your catalog and drive sales.

Fortunately, Hongju is a rubber products manufacturer that produces rubber products to suit your needs. We can work with your team to create prototypes that suit your requirements.

Also, we guarantee only high-quality products because of our over 2 decades of experience in the rubber manufacturing industry. Contact us today!