So, it’s time to understand silicone, its intricate recycling process, and some challenges manufacturers face along the way. Besides, we’re planning to conduct a comparative analysis between silicone and plastic so you can decide which product to choose. Last but not least, this article will unlock some factors that you need to look into while choosing an eco-friendly silicone supplier.

Are you ready to unwrap a comprehensive guide that will offer you an understanding of silicone’s recyclability and its implications for sustainable practices? If yes, then let’s get started.

What is Silicone?

Silicone rubber is generally referred to as silicone. It is a versatile synthetic elastomer that contains silicone and oxygen as its primary chemicals. The key element is silicone, extracted from silica (SiO). Silica is heated and distilled before combining with other chemicals like carbon, hydrogen, and methyl chloride during silicone formulation.

Traditional rubber is pretty affordable because it is sourced from nature. However, silicone is a synthetic compound. Therefore, it’s a bit more expensive than its traditional counterparts.

Uncover Common Properties of Silicone Rubber

| PHYSICAL PROPERTIES | MINIMUM & MAXIMUM VALUES |

|---|---|

| Density | 0.0400 - 3.80 g/cc |

| Water Absorption | 0.100 - 3.00% |

| Viscosity | 0.700 - 1.30e+7 cP |

| Molecular Weight | 450000 - 850000 g/mol |

| Thickness | 12.7 - 52400 microns |

| Moulding & Post Curing Shrinkage | 1% - 5% |

Here are some silicone properties that make this versatile product have countless applications in various industries, from medical to consumer goods.

- Heat Resistance: Silicone is highly resistant to cold and hot temperatures. It won’t change its shape or elasticity, or other properties, regardless of how low or high the temperature range goes. This property makes it a suitable material for applications in extreme temperature environments.

- Flexibility and Elasticity: Silicon is highly stretchable and possesses excellent elasticity properties. These properties make silicone an ideal material for crafting silicone seals and gaskets.

- Chemical Resistance: The demand for silicone is pretty high in the pharmaceutical and automotive industries. It’s because silicone products are chemical resistant, and they won’t go through wear and tear due to constant chemical exposure in these industries.

- Biocompatibility: Silicone is biocompatible. Thereby, it is safe to use for medical devices. Besides, it’s safe to use for an application that comes in contact with the human body. The best examples of safe medical products made of Silicone are medical implants and prosthetics.

- Electrical Insulation: Silicone is an exceptional electrical insulator that maintains its electrical properties regardless of the temperature range. This property makes it the most suitable material to use for the manufacturing of electrical wires, cable insulation, and electronic components.

- Non-Toxicity: Another great property of silicone is its non-toxicity. When it comes in contact with food material, it doesn’t release any harmful chemicals. Therefore, it is quite a good material to produce a kitchen to replace plastic areas and other items that come in contact with food.

- UV and Weather Resistance: Silicone is ideal for many outdoor applications because this material is highly resistant to ultraviolet radiation and harsh weather conditions.

Take the First Step:

Requst for an Inquire

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

Can Silicone Be Recycled?

Yes, silicone can be recycled but the recycling process is not as straightforward as recycling other materials like plastic and paper. You need to take silicone to a special silicone recycling plant as there is no curbside recycling pick-up program for this material.

It is good to know that the process of recycling silicone is more eco-friendly than creating new silicone. But you should never overlook the downcycling of the process. It means that silicone will degrade in quality each time you recycle it, and then there will be a point when silicone is no longer usable.

At present, there are limited silicone recycling programs. However, with the advancement of technology and awareness of silicone recycling, it’s normal to expect more efficient and accessible recycling methods.

The Process of Recycling Silicone

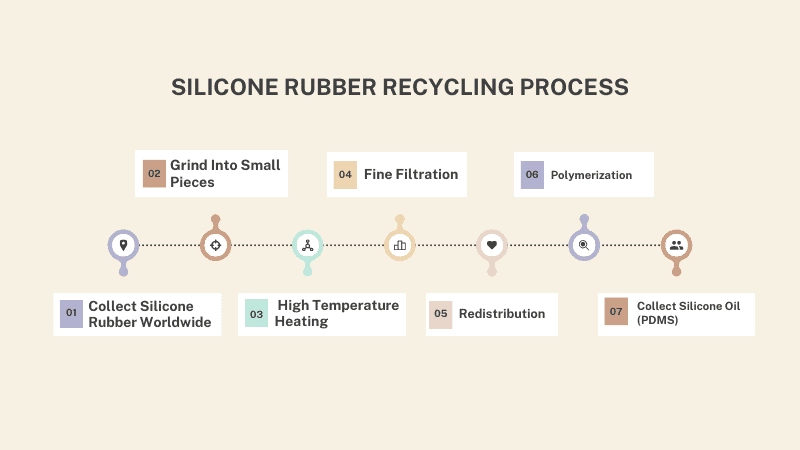

Several steps are involved in the transformation of used or waste silicone products into new and usable material. Let’s walk through a step-by-step guide to the recyclable silicone.

- Collection, Sorting, and Cleaning: In the first step of silicone recycling, silicone waste is collected from different sources. This waste needs to be sorted. Different types of materials are segregated. This sorting is a must to ensure the purity of the recycled silicone. Once sorting is completed, the cleaning process begins, and any kind of dirt, grease, impurities, or adhesive residues are removed from the silicone waste material. Silicone is ground into small pieces to ensure even heating of the material.

- High-Temperature Heating: Small pieces of silicone rubbers are heated at high temperatures inside a large chemical reactor alongside a catalyst. The purpose is to break down the chemical bonds of the silicone. The hot vapors of rubbers are cooled down in multiple stages.

- Fine Filtration: The technical term for liquid removed from the heating step is dimethylcyclosiloxane (DMC). This raw liquid form has some solid impurities that are filtered through a series of filtration processes.

Take the First Step:

Requst for an Inquire

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

- Redistribution: The filtered DMC is poured into chemical reactors for further heating with a catalyst. This step removes moisture and impurities while refining the chemical structure of this liquid. The final outcome of this step is a clear, odorless, and waterlike liquid, which is a building block of silicone oil or polydimethylsiloxane (PDMS).

- Polymerization: It is the final stage of silicone recycling that builds up the silicone chain after determining the viscosities of our silicone oils.

- Silicone Oil Collection: Once the reactor cools down, finished oil is collected and goes through another round of fine filtration before its packaging and distribution.

Silicone vs. Plastic: An Environmental Comparison

Here is a table that offers you a quick comparison between the environmental impact of silicone and plastic.

| Aspect | Silicone Rubber | Plastic |

|---|---|---|

| Origin | Derived from sand, a naturally abundant material. | Primarily derived from non-renewable petrochemicals. |

| Biodegradability | Not biodegradable but generally doesn't break down into harmful micro-particles. | Many types break down into microplastics, posing a threat to aquatic life. |

| Energy Consumption | Requires significant energy due to high-temperature processing. | Typically energy-intensive, often more so than silicone rubber. |

| Durability & Lifespan | Resistant to extreme temperatures, reducing the need for frequent replacement. | Some plastics degrade when exposed to sunlight and heat, leading to quicker material failures. |

| Waste & Pollution | Less likely to contribute to microplastic pollution. | Major contributor to global microplastic pollution. |

| Toxicity & Health Impact | Usually non-toxic; doesn't leach harmful chemicals, making it safe for food and medical use. | Certain plastics leach harmful chemicals, raising health concerns. |

| Recyclability | Limited recycling options, but its durability reduces the frequency of replacement. | Varies; while some are recyclable, global recycling rates remain low. |

| Carbon Footprint | Moderate due to its origin from sand and the production process. | Often higher due to its petrochemical origin and energy-intensive production. |

If you compare silicone with plastic, you understand that silicone has a low carbon footprint and is non-toxic, in terms of being eco-friendly. It is a safe option for both humans and the environment. Although silicone has limited recycling facilities, unlike plastic, its long lifespan and durability make it the most suitable material for various industries.

The problem with many plastics is that they degrade quickly, and thereby they contribute to growing problems of microplastics in the environment. The toxicity of plastic is hard to overlook. Plastic releases harmful toxins that pose serious health risks.

Silicone as a finished product is a safe product for people’s health. Its features, like chemical resistance, low toxicity, hypoallergenic properties, and resistance to bacteria, make it a better material than plastic.

Silicone Rubber isn’t the Perfect Solution, But It is Better than Plastic

Whenever you are considering the environmental impact of materials, you know that silicone might not be a perfect choice, but it’s better than plastic when considering environmental impact. Its durability, low carbon footprint, and non-toxic nature make it a more sustainable choice.

If industries start choosing silicone over plastic for specific applications, then they can reduce their environmental impact while promoting a greener future.

Eco-Friendly Silicone Supplier Selection

When a company is committed to sustainability it always looks for eco-friendly silicone suppliers. So, here are some factors that will make the fresh silicone and supplier selection an effortless task.

- Certification: You need to pick a supplier that can show you certifications such as ISO 14001 when choosing silicone suppliers. This certification will tell you that suppliers who accept silicone are quite serious about environmental impact. And they are following the strict safety standards of the industry.

- Raw Material Sourcing: You need to check where suppliers source their raw materials supplier cares about the environment, so they will prefer using sustainable, high-quality, and ethically sourced materials. Also check, whether the supplier has a clear recycling program and waste management policy to minimize their carbon footprint or not.

- Manufacturing Process Evaluation: Another way to select a green supplier of silicone is to look into their manufacturing process. If suppliers are committed to eco-friendliness, they prioritize minimum waste generation and employ energy-efficient practices.

- Transparency: You need to pick a supplier that is transparent. A green supplier always shares information about their eco-friendly practices and sustainability efforts. They don’t mind sharing case studies, reports, and certifications.

- Product Packaging Evaluation: Every green supplier opts for minimal and recyclable packaging material to minimize waste. So, it’s another way to find a green silicone supplier.

Take the First Step:

Requst for an Inquire

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

Conclusion

Silicone is a versatile material with some amazing properties of heat resistance, UV resistance, elasticity, biocompatibility, and non-toxicity. These wonderful properties let the manufacturer harness this material for various applications. When compared with plastic, silicone seems like a winner in the eyes of those who care about the environment.

Silicone can be recycled, even though there are some limited recycling units. However, once industries start preferring eco-friendly silicone materials over toxic plastic, we will be able to have more accessible silicone recycling units. This preference is a must for promoting a greener and more sustainable future. What do you think?

Join the Movement for Sustainable Silicone Recycling with Hongju

Hongu is committed to manufacturing eco-friendly silicone products. Our products go through rigour safety and industry standards to ensure minimal waste and sustainable production. Whether you are looking for silicone keypads, gasket seals, rubber feet, silicone swim caps, or anything. We are here to encourage the adoption of eco-friendly silicone products in your daily life.

Together, we can make a significant impact on reducing waste and preserving the environment for future generations. Let’s save our environment from harmful chemicals and create safe-to-use products for every industry. Contact us for a green future!