Elastomeric is a highly elastic, temperature and chemical-resistant rubber. In industrial applications, the durability and reliable performance of sealing play a vital role.

Thus, selecting the right material for sealing is essential in all industries. This article explains why elastomers are the best choice for durable rubber seals. It also discusses the elastomeric rubber types and their properties.

Understanding Use Of Elastomeric Rubber In Sealing Applications

Elastomeric material is composed of elastic polymers. These polymers have high elasticity and resilience properties. The key characteristic of this rubber is its high flexibility. This means that the material can recover to its original shape when stretched.

These rubbers also have high sealing efficiency. This enables them to work even under continuous pressure. All these properties make elastomers the best rubber for sealing

How Does Elastomeric Rubber Work in Seals?

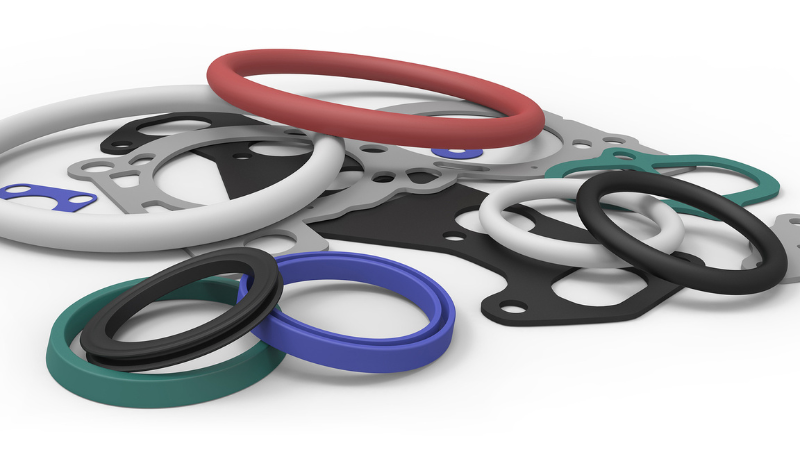

When used in sealing, elastomeric rubber compresses and acts as a strong wall. Thus, avoid leakage or movement of fluids, gases, and other particles. The elastic property of this synthetic rubber allows it to stretch without breaking. Thus, it is beneficial for gaskets, o-rings, and other rubber products.

This rubber can also tolerate extreme temperatures and harsh chemicals. Thus, works in all industrial settings.

Key 5 Performance Metrics for Elastomeric Rubber Seal

Some key performance metrics to evaluate elastomeric rubber include:

Compression Set Resistance:

Industrial sealing application require compressive strength for better performance. Procurement managers need to ensure that the material they are using has good compression resistance.

Chemical Resistance:

In industrial settings, sealing applications are often subject to harsh chemicals. Therefore, businesses need to choose materials that are oil, fuel, and solvent resistant. As elastomeric rubber is chemically resistant, it is a great choice for industries.

Temperature Tolerance:

The ability of rubber to withstand extreme temperatures is another metric to consider. Elastomeric rubber works well in all temperature ranges.

UV and Aging Resistance:

Seals used in outdoor applications must be UV and aging resistant. Elastomeric rubber is formed to resist UV and ozone rays.

Common Types of Elastomeric Rubber Used in Seals

Some of the most common types of elastomeric rubber used for seals are:

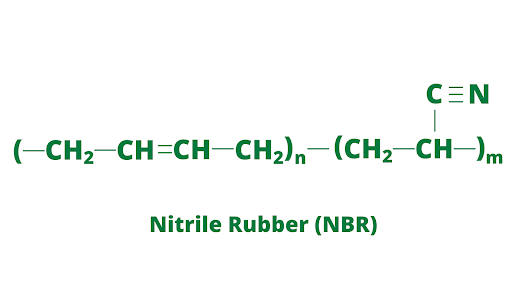

1. Nitrile Butadiene Rubber (NBR):

Nitrile butadiene Rubber is best known for its superior oil and fuel resistance. NBR is commonly used in the automotive and aerospace industries for making gaskets and seals.

The advantages of NBR are that they are oil and fuel-resistant. Also, NBR has excellent abrasion resistance.

There are some limitations to this type of natural rubber as well. The common ones include not being UV and weather resistant.

2. Ethylene Propylene Diene Monomer (EPDM):

EPDM offers high weather and water resistance. This is why it is best to use it for roofing that is exposed to water. Similarly, EPDM is used in HVAC, construction, and outdoor sealing.

The UV and weather resistance make EPDM best for all sealing applications. It is crucial to note that this rubber type is not oil or fluid-resistant.

3. Fluorocarbon Rubber (FKM/Viton):

Fluorocarbon Rubber is known for its high temperature and chemical resistance. This rubber is used in industries like oil, gas, and chemical processing.

This is because this type of rubber can withstand temperatures up to 250°Celsius. Owing to these properties, fluorocarbon rubber is the most expensive.

4. Silicone Rubber:

Silicone is a common type of elastomer. This type is commonly used in medical and food processing applications.

Silicone rubber complies with FDA guidelines and exhibits efficient thermal stability. However, this rubber type has low resilience properties.

5. Neoprene Rubber:

Neoprene Rubber is commonly used for general-purpose sealing. This type of elastomeric rubber is used in marine, HVAC, and industrial machinery. This natural rubber has good chemical resistance, but it is not heat resistant.

Why is Elastomeric Rubber the Best Choice for Durable Seals?

Elastomeric Rubber is the best choice for industrial seal materials. The following are some reasons justifying this statement:

Superior Flexibility & Elasticity:

Elastomeric rubber offers excellent flexibility and elasticity. Also, elastomeric rubber maintains a leak-proof seal under continuous pressure.

High Resistance to Chemicals:

Elastomers are designed to resist oil, fuels, solvents, acids, and alkalis. This high chemical resistance makes elastomeric rubber the best choice for durable seals.

Cost Savings:

Elastomer rubbers have a long lifespan. This rubber is sturdy and does not require much maintenance. As a result, they have a low maintenance cost.

Similarly, the seals made of elastomers don’t require many replacements. This is the reason behind their low replacement cost.

Elastomeric Rubber vs. Other Sealing Materials: A Detailed Comparison

Below is a comparison between synthetic elastomer rubber and other sealing materials:

| Material | Strengths | Weaknesses |

|---|---|---|

| Elastomeric Material Rubber | Not flexible and have a higher cost. | It can degrade in UV rays if not formulated using additives. |

| Metal Seals | Extreme durability and pressure resistance. | Not flexible and have a higher cost. |

| Plastic Seals | Lightweight and corrosion-resistant. | No elasticity and is prone to breakage. |

| Cork & Fiber Seals | Chemical resistant and eco-friendly. | Offers less durability. |

Common Seal Failure Problems & How Elastomeric Rubber Solve Them

The common seal failures and ways by which elastomeric compounds solve them include:

Leakage & Seal Deterioration:

Choosing the wrong seal material type can result in leakage and deterioration. Elastomers’ natural rubber solves this problem by offering elasticity and tight seals.

Environmental & Chemical Degradation

Another failure of seals is that they degrade when exposed to UV, ozone, and chemicals. Elastomeric polymers are formed using an additive. This additive ensures that the seals resist environmental and chemical degradation.

How to Select the Right Elastomeric Rubber for Your Industry?

You can choose the right type of natural rubber for your industry by following the tips below:

- Temperature range – Ensure that the rubber can bear the temperature of your industry.

- Chemical exposure – Determine if the products, i.e., gaskets or o-rings, will be exposed to chemicals or not. If yes, make sure to choose rubber that is chemical resistant.

- Compression set & elasticity – Select the rubber type that can withstand pressure.

- Regulatory compliance (FDA, RoHS, ISO) – Choose the rubber that meets FDA, RoHS, and ISO standards

Custom vs. Standard Elastomeric Rubber Seals: Which One to Choose?

Businesses often choose off-the-shelf seals when they don’t have many requirements, for example, silicone rubber keypads are a common off-the-shelf product.

Custom formulations are required when the sealing applications have specific requirements. The specific requirements include certain sizes and dimensions.

Both options are reliable, and engineers should choose the one that suits their needs.

How to Choose a Reliable Supplier or Manufacturer?

The supplier determines the quality, reliability, and durability of the rubber material. Thus, choosing a reliable supplier is essential. When selecting a supplier, whether for swimming caps or rubber sheets, consider the following points:

Reputation and Expertise:

A supplier with a proven track record must be given importance. Similarly, the supplier must have experience working with different industries.

Customization Capability:

While choosing a supplier, you need to ensure that they can customise products as per your needs. Ensuring this will benefit you in case you have any specific requirements.

Delivery by Time:

Research and choose the supplier who can meet the deadlines. Suppliers who offer high lead times should not be preferred.

Maintain Quality Standards:

It is important to choose a supplier who follows quality standards. This will ensure that the supplier will deliver high-quality rubber products.

How to Get the Best Price for Bulk Elastomeric Rubber?

The cost-saving strategies for securing the best price for bulk orders include:

Pricing:

While buying in bulk, understand the difference between wholesale and retail pricing. This will enable you to negotiate a competitive price.

Also, inform the supplier of your willingness to work in the long run to secure more discounts.

Payment Terms:

While buying in bulk, make sure to decide on the payment terms with the supplier. Doing this will help you to avoid financial stress in the future.

MOQ Requirement:

Some suppliers have minimum order requirements. You need to find ways to avoid minimum order charges without ordering in excess.

Conclusion

The elastomer properties make elastomeric natural rubber ideal for sealing applications. With its high flexibility, this rubber is perfect for all industries.

Identify your industrial needs and choose the right type of elastomeric rubber today. Be sure to select a reliable supplier to maximize the benefits of this natural rubber.

Trusted Rubber Products Manufacturer For Your Business

Are you looking to transform your sealing applications? If yes, then Hongju Silicone is here to help. With decades of experience, we specialize in manufacturing high-quality rubber products.

No matter what your requirements are, our expert team is ready to meet them. Contact us now to get customized solutions for your business.