Are you impressed by the exceptional longevity and biocompatibility of silicone products? These unique properties in silicone are due to its composition.

Let’s explore how silicone is made to optimize its applicability. There are some special benefits of silicone that will leave you stunned.

Buckle up for an expert-guided journey into the world of silicone!

Properties and Characteristics of Silicone

Silicone polymer is a man-made compound synthesized in the laboratory using silicon, oxygen, carbon, and hydrogen. It is also called polysiloxane because of its composition consisting of siloxane, and a combination of silicon and oxygen atoms.

At the molecular structural level, silicone polymer has chains of oxygen and silicon atoms.

People often confuse silicone with silicon due to their similar spelling. What is silicone? Silicone polymer is a synthetic material while silicon is derived from silica which is commonly known as sand.

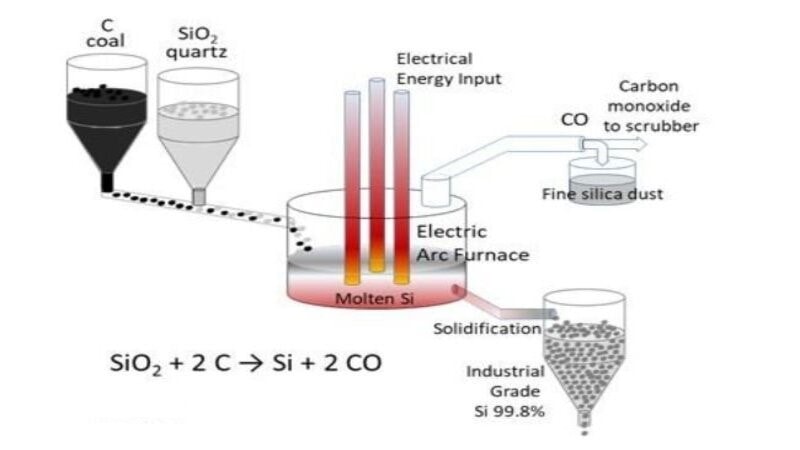

When silica is heated at extreme temperatures with carbon it converts to silicon, a fine brittle metalloid. Further, silicon is processed to extract silicone.

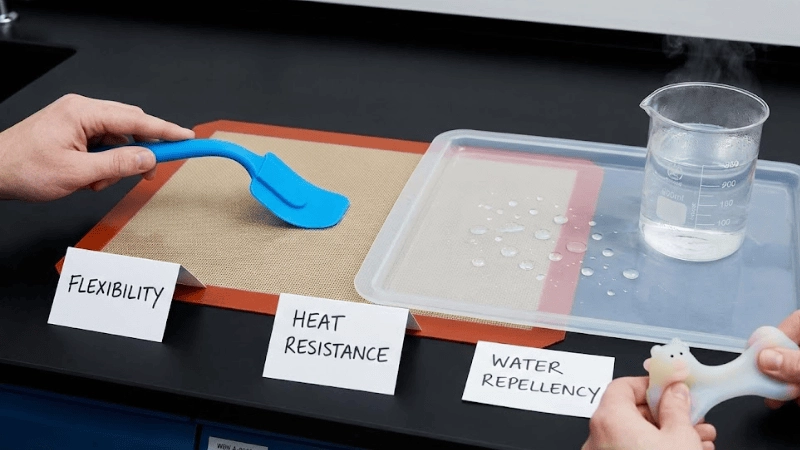

Silicone is highly related to rubber. It has excellent elasticity, flexibility, and compression set. You can easily mold and shape silicone to form different products by compression molding or injection molding.

It is also preferred for its high temperature and chemical resistance, the material is suitable for various demanding applications. Additionally, silicone is biocompatible and doesn’t react with living organisms.

Changes to silicone composition can allow you to turn it into liquids, gels, rubbers, and resins. You can also modify the chemical and physical properties of silicone as per your needs.

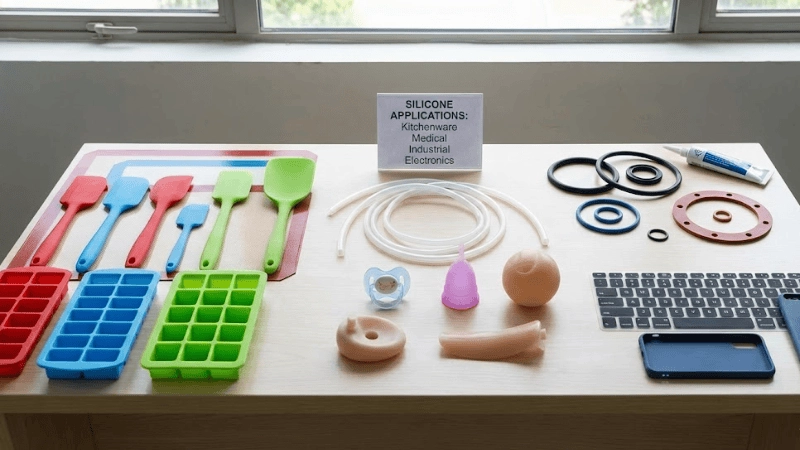

It increases the versatility of silicone making it ideal for numerous applications. The material is extensively used in the medical applications, automotive, electronic devices, and consumer goods sectors.

Types of Silicone

There are various silicone types produced to meet specific needs. Each type exhibits unique properties with suitability for different applications. Let’s explore:

Liquid Silicone Rubber (LSR)

Liquid silicone rubber exists in liquid form that can be injected into a mold to form any product. It is cured at room temperature without the need for a curing agent.

The production includes two parts, a combination of base polymer with catalyst and cross-linker with additives. LSR is extensively used in the production of medical equipment like tubings, stethoscopes, etc.

Heat Cured Rubber (HCR) Silicone

As the name suggests, heat-cured rubber silicone is cured with the application of heat. It consists of polydimethylsiloxane, a synthetic elastomer known for high flexibility and heat-resistant properties.

To allow heat curing, the HCR silicone is mixed with platinum complexes during synthesis. These additives trigger the formation of cross-links (to harden HCR silicone) when subject to heating.

Room Temperature Vulcanizing-Silicone (RTV)

Room Temperature Vulcanizing Silicone is available in single-component and dual-component structures. It is curable at room temperature with a catalyst.

The RTV has excellent durability and longevity but is only ideal for low-temperature applications. RTV is used to produce molds and eye lenses. Most sealants used in gaskets are made from RTV material.

| Silicone Type | Properties | Uses |

|---|---|---|

| Liquid Silicone Rubber (LSR) | Best known for flexibility, chemical resistance, and thermal stability | Medical devices, baby products, gaskets, and electronics |

| Heat Cured Rubber (HCR) Silicone | Exhibits good tensile strength, elasticity, and resilience | Sealing and Adhesion, Tubes, Kitchen utensils, and automotive parts |

| Room Temperature Vulcanizing-Silicone (RTV) | Good for cross-material adhesion, resistance to weathering, UV, and chemicals | Mold-making, electronics coverings, and eye lenses |

Manufacturing Process

Silicone is manufactured through a simple process with fewer steps. Let’s help you make good silicone:

Silicon Extraction

The first step to producing silicone is the extraction of silicon from silica, usually called sand. It is heated at extreme temperatures of about 1800 degrees Celsius to form a brittle metalloid. It is then ground to make silicon powder.

Siloxane Formation

The silicon powder is combined with methyl chloride through a heat-activated chemical reaction. The result is chlorosilanes primarily consisting of dimethyldichlorosilane. The chlorosilanes then undergo two processes 1. Fractional distillation and 2. Hydrolysis to form siloxane.

Silicone Formation

Siloxane is the basic compound that is used to produce silicone. In the final step, siloxane is polymerized to produce silicone, the magic material with a plethora of useful benefits.

The silicone is processed into linear polymers or cross-linked polymers to give it the desired form of liquid or solid.

Blending and Mixing

Further, silicone is added with pigments and additives and then blended with a catalyst. It benefits silicone and helps make it usable for different applications. The final processed silicone can be extruded and cured to make the required products.

Applications and Uses of Silicone

Silicone is a versatile material that is produced in different forms like liquids, gels, rubbers, and resins. There are various uses of silicone across diverse industries. Are you wondering where silicone is used? The adhesive that holds your car’s windshield is made from silicone.

The best thing about silicone is its chemical composition. It gives it excellent flexibility, heat resistance, and chemical resistance. Due to these chemical properties silicone is used in sealants, adhesives, lubricants, extrusions, and other products.

Silicone has good biocompatibility making it a toxicity-free material. Thanks to its cross-linking it reduces chemical reactivity. It is considered one of the safest synthetic polymer materials and; is therefore used in kitchenware, pet products, personal care items, etc.

Benefits of Silicone

There are numerous benefits of silicone due to its unique characteristics. It is one of the most used materials on earth. Let’s explore the different benefits of silicone:

Heat Resistance

The unique Si-O bond in silicone is exceptionally strong (bond energy of ~444 kJ/mol), which grants it superior thermal and chemical stability compared to carbon-based polymers. This is a key reason for its wide operating temperature range.

The wide temperature range that silicone can withstand is between -60°C to 200°C. Within this range, the material doesn’t deform, degrade, or lose its physical properties.

Elastic Properties

Silicone consists of siloxane that has a flexible chemical structure that gives it rubber-like properties. Silicone is a highly elastic material making it usable for applications with continuous stretching and compression.

The material has a good compression set and doesn’t deform quickly.

Biocompatibility

Silicone is a biocompatible material and doesn’t affect living organisms in any way. It is considered non-toxic, hypoallergenic, and safe to use for human beings. The material is inert and unreactive to chemical and biological compounds.

Di-electric Strength

Silicone is one of the best insulators that can withstand high voltages. Its chemical structure doesn’t allow conduction. It protects current-carrying conductors from environmental effects while maintaining proper electrical insulation.

Safety and Environmental Considerations

Silicone is a safe, toxicity-free, and biocompatible material. What is silicone made of that makes it so safe? It is obtained from silica or sand, a natural compound. The material is inherently inert and doesn’t react to living organisms or other chemicals.

Silicone is approved by various regulatory authorities like FDA in the United States for use in medical-grade equipment. It is also extensively used in cooking utensils, especially baby products like baby bibs and milk feeders, etc.

Some formations of silicone polymer are termed toxic. They’re added with harmful additives that enhance different properties of silicone like chemical and temperature resistance for use in industrial settings.

Such silicone poses health hazards in case ingested or inhaled.

Silicone is not biodegradable and has a severe environmental impact. It is one of the key contributors to plastic pollution in the ocean that has disturbed aquatic and marine life.

Every silicone product has specific disposal instructions that help prevent environmental pollution.

Industrial Applications of Silicone

There are multiple uses of silicone in different industries. Let’s explore the uses of silicone in some key industries.

Healthcare

According to a market analysis , silicone-based materials constitute over 70% of the polymer-based medical device components market, valued at over USD 10 billion in 2023, driven by their unmatched biocompatibility and sterilization resistance. It is used to produce implants, prosthetics, medical tubing, and a variety of other products.

Automotive

Silicone has extensive use in the automotive sector due to its exceptional chemical and temperature resistance.

You will find silicone in gaskets, seals, hoses, linings, insulations, etc. The material shows good durability and longevity.

Mold-making

Silicone is a robust, malleable, and highly flexible material. It is used in producing molds for different tools and equipment. These molds are used with CNC machines and other manufacturing units to produce silicone products like casings, vases, toys, etc.

Consumer Goods

If you look around, you will find multiple silicone products almost everywhere. It is used to produce kitchenware, baby products, personal care products, items like wristbands, toothbrushes, etc. Silicone is a highly safe-to-use and durable material.

Conclusion

Silicone stands as an extraordinary synthetic polymer, distinguished by its unique siloxane (Si-O) backbone which grants it exceptional thermal stability, chemical resistance, and flexibility across a wide temperature range (-60°C to 200°C).

You now understand how is silicone made and where silicone comes from. This versatile material has exceptional benefits like heat resistance, chemical resistance, and electrical insulation properties.

Next up, you can explore information and learn more about silicone rubbers. If you’re looking for high-quality silicone, Hongju Silicone is a top producer of silicone products with 20+ years of manufacturing excellence. It has advanced R&D and is best known for tailored solutions.

Hongju: Your Trusted Partner in Silicone Solutions

With over 20 years of expert craftsmanship, Hongju deliver rapid 3-5 day prototyping and flexible low MOQs tailored to your needs.

Are you looking for top-grade silicone products? Get in touch with our experts for one-on-one consultation!

FAQs

Q1. Is silicone a plastic or rubber?

Silicone is not a plastic or rubber, it has similar properties to rubber and plastic but it’s a standalone material. How silicone is made is different from plastic and rubber manufacturing.

Q2. Is silicon and silicone the same thing?

Silicon and silicone are not the same thing. They have very similar spelling but entirely different structures. Silicon is the sand that is around you while silicone is a material made from silicon that is similar to rubber.

Q3. Where does silicone come from?

Silicone doesn’t occur naturally, it is produced through the chemical synthesis of silica or sand. It is man-made and can be modified to exhibit different properties.

Q4: What is your production time?

The average production cycle for our products is 9-15 workdays, but this can vary according to the quantity of orders, the complexity of our products, and the different seasons.