Rubber finishes protect the surface of a material from improving its lifespan and function. Of all rubber finishes, silicone rubber is highly sought after industrially. And this is because of the exceptional properties of the elastomer.

Electrical insulation is a critical part of safety and hazard prevention. Many industries, including the electrical industry, use silicone rubber finishes to boost electrical insulation. As a result, components coated with silicone rubber finishes offer many benefits.

This article discusses the benefits of silicone rubber finishes for electrical insulation and the applications of the material.

What Is Silicone Rubber Finishes?

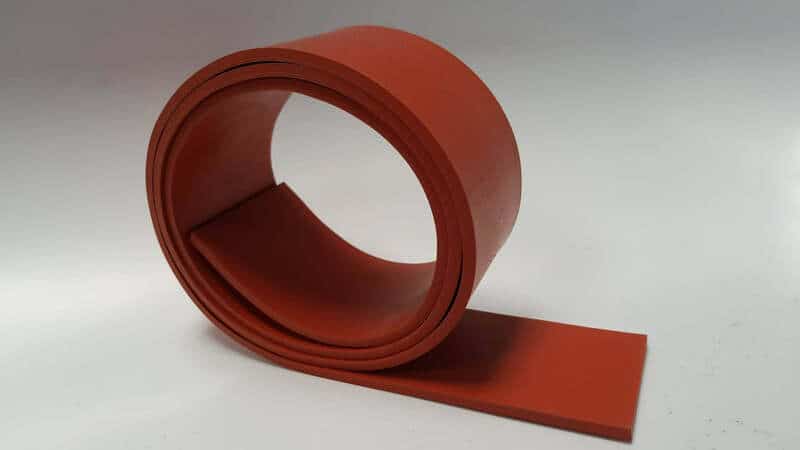

The silicone rubber finish is a coating or surface treatment that protects the surface of a substrate from external factors like moisture. Besides protection, the finish improves performance and boosts the properties of the surface. Substrate surfaces that can be coated with silicone rubber finishes include metals, ceramics, and plastics.

The properties of silicone rubber finish that make it sought after as a protective coating include chemical resistance, UV resistance, temperature resistance, and abrasion resistance. These properties make the coating suitable across several applications, including medical, consumer products, automotive, and electrical components.

Advantages of Silicone Rubber Finishes for Electrical Insulation

Chemical stability and resistance to corrosion

Chemical stability and corrosion resistance are essential to electrical insulation. A chemically-stable material will protect electrical components, prevent degradation, and increase the lifespan of electrical components.

The silicone rubber finish is chemically-stable and corrosion-resistant. The material can withstand acids, bases, oils, and solvents. Silicone rubber finishes are ideal for applications with exposure to corrosion, alcohols, esters, ketones, acids, and bases.

Physical properties and mechanical strength

Electrical insulators need physical properties like mechanical strength for safety, reliability, and ease of installation. Silicone rubber finishes have physical properties, including flexibility and tear strength. Consequently, the material can be easily installed in difficult-to-reach areas. The finish can also absorb shock and vibrations without cracking or breaking, making it ideal for electrical insulation.

Furthermore, silicone rubber finishes are reliable, maintaining the effectiveness of the electrical insulation for extended periods. The material also has resistance to abrasion and compression sets, improving durability.

Thermal stability and resistance to extreme temperatures

Silicone rubber finishes are thermally stable, withstanding low and high temperatures between -65 and 450 degrees Fahrenheit. Thermal stability is a critical characteristic of electrical insulators. This property protects electrical components from overheating and breaking down during operation. It also prevents explosions and other safety hazards.

Silicone rubber finishes operate safely under extreme conditions, making the material less likely to degrade over time. Furthermore, there is a reduced risk of electrical failures and stability even in high-temperature environments.

Low-temperature resistance and high-temperature performance

The silicone rubber finish is stable across a wide temperature range. Material may become brittle and crack at low temperatures, leading to electrical failures and safety hazards. The low-temperature resistance of the silicone rubber finish protects electrical components from cracking. Besides protection, silicone rubber finishes can provide effective electrical insulation even at temperatures as low as -65 degrees Fahrenheit.

In addition, high-temperature performance is essential. Silicone rubber finishes perform well in temperatures as high as 450 degrees Fahrenheit without losing their properties or degrading. High-temperature performance in electrical insulators protects electrical components against overheating and safety hazards.

Weather resistance and UV radiation protection

Silicone rubber finishes have excellent weather and UV resistance. As a result, the material can withstand harsh conditions without losing its color, shape, or form. Weather resistance and UV radiation protection are essential in electrical insulation because they ensure that electrical components function properly when exposed.

Another reason for weather resistance and UV radiation protection is that it ensures the safety of electrical components while prolonging their lifespan. Fortunately, silicone rubber finishes protect against UV radiation and the weather, increasing the reliability and safety of an electrical system.

Versatile material suitable for demanding applications

Silicone rubber is a very versatile material with properties including chemical resistance, heat resistance, flexibility, and tear strength. Consequently, the finish can be molded into several shapes and sizes depending on the application requirements.

Furthermore, because of its properties, this protective coating can withstand harsh conditions without losing its properties. Demanding applications that use silicone rubber finishes include automotive, medical, industrial, and aerospace industries.

Electrical insulation properties and high voltage shielding

Silicone rubber finishes have electrical insulation properties that are ideal for coating electric components. The electrical insulation properties of silicone rubber finishes include high dielectric strength and low dielectric constant. Consequently, silicone rubber finishes can withstand high voltage without degrading. In addition, the material does not store electric charges.

Furthermore, because of its high voltage shielding, silicone rubber finishes preventing electrical breakdowns while ensuring the safety and reliability of the electrical system. Consequently, there is limited electromagnetic interference (EMI) and reduced risk of failure and fire hazards.

Applications of Silicone Rubber Finishes

Electrical insulation for high-voltage cables and insulators

A popular application of silicone rubber finishes is high-voltage cables and insulators. Silicone rubber finishes providing high cable insulation, preventing electrical breakdown and ensuring safe power transmission. This is due to silicone rubber’s chemical, heat resistance, and high dielectric strength.

Silicone components for consumer products and food preparation

Silicone rubber finishes are versatile and used in the consumer goods and food industries. This finish is used primarily in manufacturing bakeware, cookware, kitchen appliances, children’s toys, and personal care products. Due to its non-toxicity and chemical resistance, the silicone rubber material is safe and does not cause allergic reactions.

Silicone sponge products for prolonged exposure to extreme temperatures

Silicone sponge products are flexible and lightweight silicone materials used for sealing, insulation, and cushioning. These products are suitable for making gaskets and seals used across several industries like automotive, aerospace, and electronics.

Silicone sponge products are thermally stable, withstanding extreme temperatures up to 400 degrees Fahrenheit. In addition, due to its flexibility and softness, the material does not deform during prolonged exposure to extreme conditions.

O-rings and rubber products for various industries

Silicone o-rings are a flexible sealing solution that prevents leaks in hydraulic systems and automotive engines. This seal is UV- and chemical-resistant and can withstand high temperatures. Because of their flexibility, O-rings are used across several industries, including medical, pharmaceutical, food and beverage, and chemical processing.

Conclusion

Silicone rubber finishes are excellent electrical insulators. They are versatile and perform well at high temperatures. This material also provides high-voltage shielding, UV radiation protection, and chemical stability. Furthermore, regardless of the industry, silicone rubber finishes are an excellent solution for preventing corrosion and improving resistance and performance.

Discover the Perfect Solution for Your Business with Hongju

Silicone rubber finishes have proven to be useful across several industries, including electronics. You can contact a trusted rubber supplier or manufacturer to incorporate silicone rubber finishes in your business. Fortunately, Hongju Silicone is an expert rubber products manufacturer with experience creating tailor-made silicone products. We have quick turnaround times and deliver prototypes within five working days.

Reach out to us to start your silicone rubber finish business.