Silicone is commonly known as a non-stick material. Being non-stick, it often makes product engineers think that it does not stick to any material. This article explores the materials to which silicone sticks and the materials to which it does not stick.

Read this article to find out ways to improve the silicon adhesion and common applications where silicon adhesion matters.

Why Is Silicone Adhesion Different From Other Materials?

The unique molecular structure of silicone is the reason why it behaves differently from other materials when it comes to adhesion. Plastic and any type of rubber can easily bond with adhesives, whereas silicone has very low surface energy, which makes it resistant to sticking.

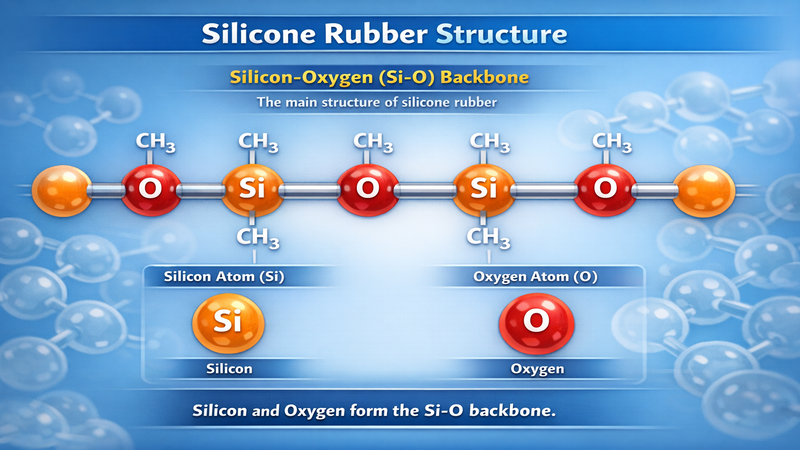

What Is Silicone Rubber Made Of?

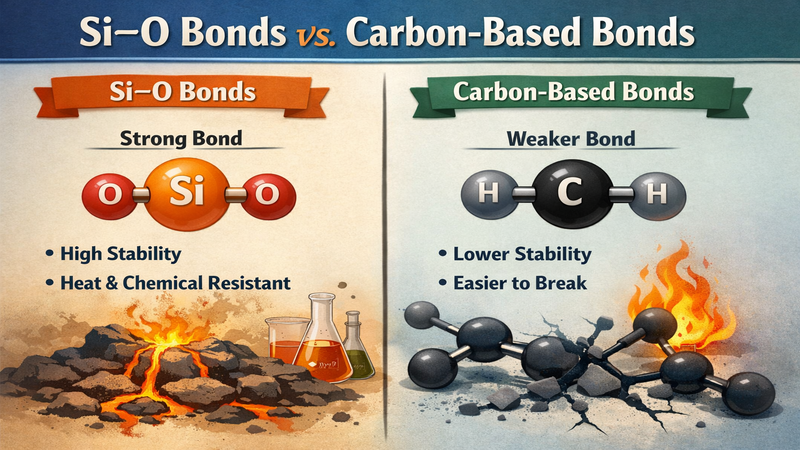

Silicone rubber is made from silicon, oxygen, carbon, and hydrogen. The main structure of the silicone rubber is built around a silicon-oxygen (Si-O) backbone. This bond is much stronger and stable than the carbon-based bond that is found in many types of plastics.

This chemical formulation gives the silicone products their flexibility and long-term stability. The bond also allows the material to remain elastic when exposed to a range of temperatures, resist UV radiation, withstand moisture, chemicals, and oxidation without breaking down.

It is crucial to note that silicone is neither a rubber nor a plastic; thus, it behaves differently from both. Its low surface energy makes it reluctant to stick. Additionally, its Si-O bond prevents adhesives from forming a strong chemical bond.

These differences help explain why silicone is nonstick, durable, and hard to bond compared to standard plastics and rubber. Note that the silicone is a polymer made of alternating silicon (Si) and oxygen (O) atoms in the backbone.

Surface Energy and Why It Matters

Surface energy refers to how easily a liquid, i.e., adhesive, can spread over the surface of a material or can be wetted. Materials with high surface energy allow adhesives to flow and spread, forming strong bonds. However, materials with low surface energy do not form a strong bond.

Silicone has a very low surface energy, which is why bonding to it is difficult. Adhesives cannot properly wet the silicon surface, so they fail to create the contact needed for mechanical or chemical adhesion. As a result, bonds are often weak and peel off easily when special treatments or primers are not used.

When compared with other materials like metal and wood, silicone has a relatively low surface energy. Metals like steel and aluminium have high surface energy and bond easily with adhesives.

Wood, because of its porous surface and high surface energy, also bonds well. Plastics have medium surface energy, but silicone is one of the most challenging materials to bond due to its non-stick surface.

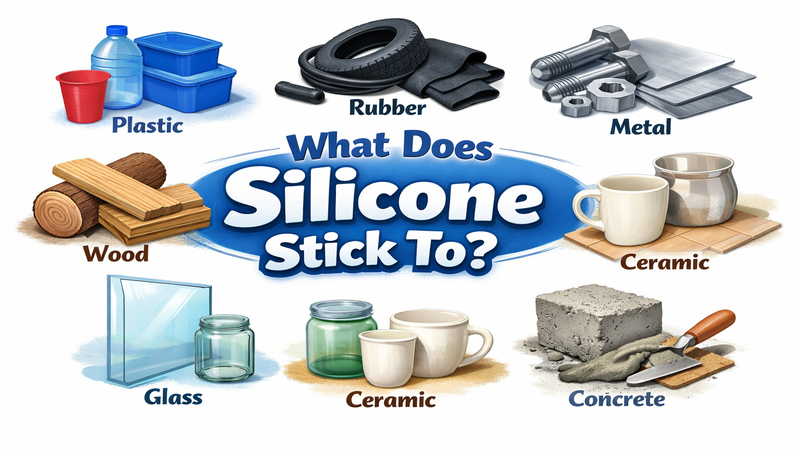

What Sticks To Silicone?

Despite having a low surface area, silicone does adhere to some materials. These materials include:

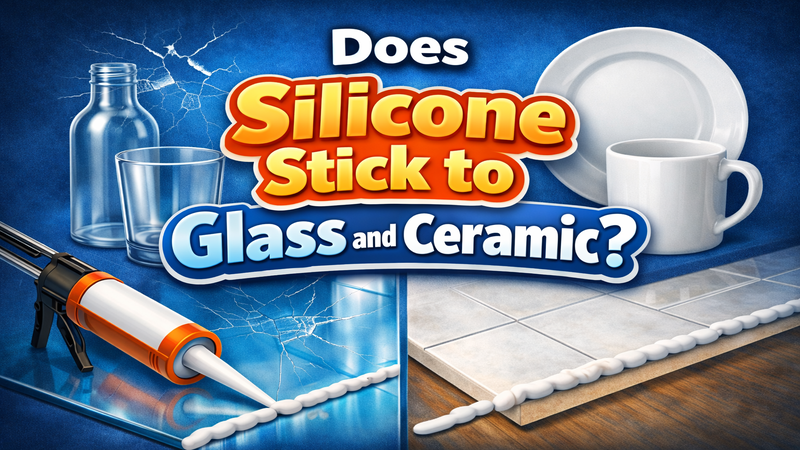

Does Silicone Stick to Glass and Ceramic?

Yes, silicone does adhere to glass and ceramic. These materials have high surface energy, thus allowing silicone to wet and cure easily.

Some common examples of silicone sealing to glass and ceramics are in aquariums, fish tanks, window glazing, weather sealing, bathrooms, and kitchens (titles, sinks, tubs)

Does Silicone Stick to Metal?

Yes, silicone sticks with metal. If the surface is prepared properly, silicone adheres really well to metals like aluminium, steel, and stainless steel.

To ensure good bonding, ensure that the surface is clean, dry, and oil-free. Primers enhance the long-term adhesion and should be used in industrial applications. Additionally, it is crucial to note that light abrasion improves grip.

The typical applications of silicone adhesion to metal include HVAC systems, automotive sealing, and industrial gaskets and tubes.

Does Silicone Stick to Wood?

To answer the question of does silicone stick to wood, we can say that yes, silicone sticks to wood. However, the bond strength depends on the wood’s surface condition.

The raw and porous wood has better mechanical grip. Whereas painted, varnished, and sealed wood has a weak adhesion.

The common uses of silicone and wood adhesion are in construction gap sealing, window frames and trim, and weatherproofing joints.

What Does Silicone Not Stick To?

Silicone does not stick to some materials, including rubber and plastic. The detailed explanation of these materials is provided below:

Does Silicone Stick to Plastic?

There is no fixed yes or no answer to the question regarding does silicone sticks to plastic. There are different types of plastics, and silicone’s adhesion varies by plastic type.

Silicone shows better adhesion to ABS, PVC, and polycarbonate with primer. However, silicone shows poor adhesion to Polypropylene (PP) and Polyethene (PE).

This is because PP and PE have very low surface area, thus preventing silicone from wetting or bonding without special treatment or applying special primers.

Does Silicone Stick to Rubber?

Silicone does not stick to rubber really well without special surface treatment. Common rubbers like natural rubber, EPDM, nitrile (NBR), and neoprene have surface chemistries that are not compatible with silicone adhesives.

A strong and durable bond requires clean surfaces, proper curing conditions, and silicone-specific adhesives. Without these steps, the silicone-to-silicone bond will lack long-term strength.

A table covering what sticks to silicone and what does not is given below:

| Material | Bonding with Silicone |

|---|---|

| Silicone Rubber | Bonds well with primer |

| Metal (Al, Steel, SS) | Good adhesion |

| Glass / Ceramic | Excellent adhesion |

| Wood (raw/porous) | Moderate adhesion |

| Plastic (ABS, PVC) | Variable |

| Rubber (non-silicone) | Poor adhesion |

| Low-Energy Plastics (PP, PE) | Very poor adhesion |

Why Is Silicone Often Called “Non-Stick”?

Silicone is often called non-stick, as cured silicone has impressive release properties. Once fully cured, its surface energy gets too low, which prevents most materials from forming strong bonds. Instead of bonding and sticking, these materials leave no residue behind.

This behaviour makes silicone a widely used material in cookware, including spatulas, moulds, and baking mats. In manufacturing, silicone moulds allow plastic, rubber, and resin to be removed without damaging it.

In the kitchen, silicone baking mats prevent food from sticking, making them easy to clean and reusable. These same non-stick characteristics, however, make silicone a tough material to bond in adhesive applications.

How to Improve Silicone Adhesion?

Product manufacturers can improve silicone adhesion by using the following methods:

1. Preparing The Surface

The first thing that helps in improving silicone adhesion is preparing the surface. To clean the surface, you need to:

- Remove dirt, grease, oil, and moisture from the surface.

- Degrease the surface to get rid of oil and agents that are harmful to silicone adhesion.

- Lightly sand or mechanically roughen the surface area to improve the mechanical grip (Abrasion is done mostly on metal and wood)

However, sometimes only preparing the surface does not guarantee a strong bond.

2. Using Primers and Surface Treatment

The other step, product engineers mostly take to make the silicone or surface a good adhesive, is using primers or carrying out special surface treatments. Primers are mandatory when bonding silicone to low-energy surfaces like plastics, rubbers, or metals, where adhesion is weak.

Industrial primers offer higher bond strength and durability for critical applications. DIY or consumer-grade primers work best for light sealing.

Advanced treatments like plasma or chemical surface treatment increase the surface area temporarily, allowing silicone to bond easily in industrial settings.

Best Glue and Adhesives for Silicone Rubber

When working with silicone rubber products, product engineers notice that standard adhesives, i.e., Cyanoacrylate and Epoxy, often fail. This is because they do not properly wet or bond to silicone surfaces.

Silicon is flexible, whereas Cyanoacrylate and Epoxy cure into a rigid material, which causes cracks or peeling when the silicone stretches or flexes.

Note that cyanoacrylates are a family of fast-acting adhesives derived from cyanoacrylic esters. The general chemical structure is CH₂=C(CN)-COOR.

Some of the best silicone sealants for silicone rubber include:

1. RTV (Room-Temperature-Vulcanisation) Silicone Sealant

This glue cures at room temperature without any special equipment. It maintains flexibility, matching silicone’s elasticity. Also, RTV bonds well to silicone, glass, metals, and ceramics.

2. Special Acrylics / PSA (Pressure-Sensitive Adhesives)

This silicone sealant is flexible and easy to apply. It is perfect for temporary or semi-permanent bonds. PSA works best on clean and high-energy surfaces.

3. Heat-Vulcanised Silicone Sealant

These glues require heat to cure. It is ideal for permanent silicone-to-silicone bonds, and it is perfect for industrial applications.

Common Applications Where Silicone Adhesion Matters

Some of the common applications where silicone adhesion is important include:

- In automotive seals, to prevent leaks and protect the engine from heat, oil, and vibration.

- In electronics and waterproofing, to provide flexible, moisture-resistant protection for circuits.

- In medical and food-grade applications, to ensure safe, non-toxic silicone for implants, tubings, and bakeware.

- In DIY and household sealing for windows, bathrooms, and kitchens.

Conclusion

To sum up, we can say that silicone adhesion depends on surface energy, rather than strength. As mentioned earlier, silicone sticks well to materials with high surface energy, like glass, ceramic, and metals. Similarly, silicone sticks poorly to low-energy plastics and rubbers unless they are treated.

By selecting the right adhesive and applying the appropriate adhesion techniques, product engineers can form stable silicone bonds with other materials.

Hongju Silicone: Your Trusted Silicone Rubber Manufacturer

At Hongju, our experienced staff provide top-notch and high-quality silicone rubber products to our customers. Our rapid prototyping, low MOQ requirements, and more than 2 decades of experience in design and production make us your trusted partner.

Contact us today to receive a customised quote tailored to your specific requirements.

FAQs

Q1: Why is silicone’s adhesion vital in kitchen and bathroom safety?

Its waterproof, flexible seal effectively bonds to tiles, glass, and sinks, preventing leaks and mold growth where moisture is constant.

Q2: How does silicone ensure durability in outdoor or industrial applications?

It adheres strongly to metals, glass, and masonry while withstanding extreme temperatures and weather, creating reliable seals for construction and automotive use.

Q3: How does silicone adhesion contribute to medical device reliability?

Its biocompatible, secure bonding to plastics and glass ensures leak-proof seals in sterile environments, critical for surgical tools and diagnostic equipment where failure is not an option.

Q4: Why is silicone preferred for custom repairs and DIY projects?

It adheres to diverse materials like wood, fabric, and certain plastics with long-lasting flexibility, offering an accessible solution for household fixes and creative applications.