Silicone elastomers boast unique mechanical and chemical properties. Do you want to harness their full potential? Let’s explore the properties, types, and benefits of silicone elastomers. These materials are extensively used in industries ranging from healthcare to automotive. Learn about the latest elastomeric technology to optimize the use of silicone elastomers as per your needs.

What is an Elastomer?

Elastomer refers to a material with rubber-like properties. It has viscoelasticity (viscous and elastic properties) and weak intermolecular structure. An elastomer can regain its original shape after experiencing compression or stretching. With regards to chemical composition, an elastomer is a polymer that can occur naturally or produced synthetically.

Natural elastomers like rubber are obtained from trees, while synthetic elastomers like silicone are derived from petroleum byproducts. Silicone is the most extensively used elastomer due to its high chemical and environmental resistivity, and good mechanical properties. Unlike natural rubber, silicone can withstand harsh weather conditions and chemical exposure.

What is Silicone Rubber?

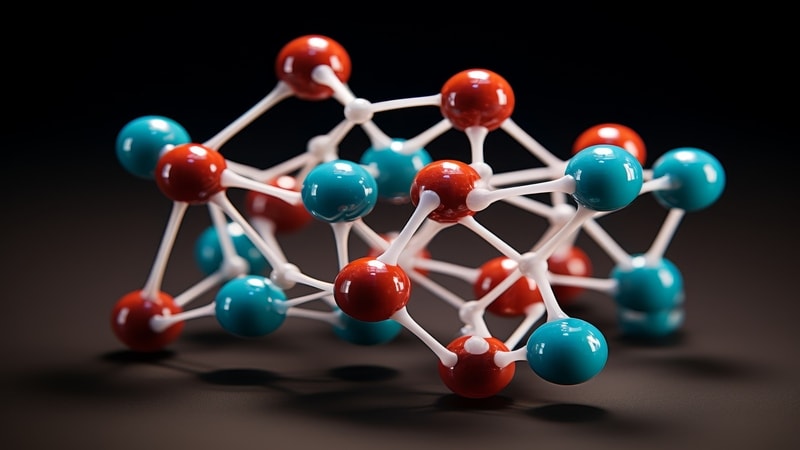

Silicone rubber is a type of elastomer that mainly consists of silicone, a synthetically produced polymer. The molecular structure of silicone rubber is made of siloxane chains composed of carbon, hydrogen, and oxygen. Various compositions of silicone rubber give it unique properties.

Silicone rubber materials exhibit temperature resistance (-55 to 300°C), durability, and non-toxicity. The material is easy to manufacture and mold; it can occur in the form of liquid, solid, sponge, etc. Silicone rubber and its types are used in various industries like medical, consumer appliances, and construction.

Is Silicone an Elastomer?

Is silicone an elastomer? Technically, yes, silicone is an elastomer, whereas “elastomers” are a broad category of materials that have elastic properties. Silicone checks all the characteristics requirements like elasticity, durability, and chemical resistance to be categorized as an elastomer. Additionally, silicone is produced synthetically through a chemical process.

The composition of silicone elastomers is rather simple. It consists of silicone and oxygen atoms formed in chains that give the inherent elasticity to silicone. The stability in silicone elastomers comes from organic compounds like methyl groups (carbon and hydrogen) that attach to silicone atoms. It gives the material its durability and chemical and environmental resistance.

During the production process, some changes are made to the chemical composition, like the addition of fillers or crosslinking agents. It aims to enhance the material’s properties or form different types of silicone, like liquid silicone rubber (LSR material). When compared, LSR materials tend to exhibit better flexibility, mouldability (due to liquid nature), and durability.

Silicone elastomers are versatile materials with specialized applications in medical devices, electronics, automobiles, and industrial machinery. Other materials, even natural rubber, can’t withstand temperature and environmental exposure, whereas silicone elastomers show remarkable performance. For instance, used in car gaskets, medical tubing, etc.

Types of Silicone Elastomers

Let’s explore various types of silicone elastomers. You can consider these materials for any of your required applications.

Liquid Silicone Rubber (LSR)

Liquid silicone rubber is an injectable elastomer that is designed for injection molding. It is a two-component liquid that combines with a catalyst (like platinum) and crosslinking agent to solidify. The LSR material is known for high thermal stability and can withstand temperature ranges from -60°C to over 200°C. It also offers good resistance to harsh chemicals and weathering.

Apart from high flexibility and tensile strength, LSR material also has unique characteristics like biocompatibility. The material doesn’t react with natural organisms, making it ideal for use in medical and food-grade applications. It is used in medical tubing, food packaging, and toys. The LSR material is transparent and can be changed to any color with pigments.

Solid Silicone Rubber

Solid silicone rubber is also known as high-consistency rubber (HCR). It is the most commonly used elastomer that is formed by high-temperature vulcanization of silicone. The hardness and solid structure are gained from the addition of fillers. Solid silicone can be cured with platinum catalysts, condensation, peroxide, or oxime.

Solid silicone rubber materials show high mechanical strength, tear resistance, and good electrical insulation properties. It is used in various industries like aerospace, defense, automotive, fine chemicals, construction, electrical and electronics, food processing, and mechanical engineering.

Understanding Elastomeric Technology

Elastomeric technology is the set of processes and equipment involved in the production of elastomers. The elastomeric technology has advanced over time with the advent of liquid elastomers used in injection molding. Commonly used elastomeric technology involves die-cutting, transfer molding, rubber molding, and compression molding.

Each of these technologies has different applications. For instance, liquid injection molding machines contribute to medical advancements like the production of catheters, pacemaker components, and prosthetics from biocompatible LSR material. Similarly, die-cutting is instrumental in automotive innovations like gaskets, seals, and cable insulations.

The latest elastomeric technology enables efficient use of elastomers like liquid silicone rubber materials, solid silicone rubber, etc. It has enhanced design flexibility to make complex components with high precision. No doubt, elastomers have extensive use; they’re everywhere, from your car windshield to the phone you’re using.

Properties of Silicone Rubber

Silicone rubber is a marvel of chemical sciences. It has excellent properties that allow use in a variety of applications. Let’s explore:

Mechanical Performance

Silicone rubber shows excellent mechanical properties, it has excellent flexibility and tear resistance. The material also exhibits good tensile strength for specific applications, but it’s not very exceptional. The mechanical performance is reinforced with high-temperature resistance of -100 to 300°C. Silicone rubber is ideal for applications where shape retention is crucial.

Chemical Resistance

Silicone rubber is highly chemical resistant due to its chemical composition. The material doesn’t react to harsh chemicals, living organisms, and the environment. The material is also biocompatible and used in medical applications. These distinct characteristics also make it suitable for rough environments and outdoor use.

Flexibility

Silicone rubber mimics the properties of natural rubber and offers exceptional flexibility. The material doesn’t deform and regain its original shape. It has an excellent compression set than comparable materials. Silicone rubber properties like flexibility, hardness, and tensile strength can also be enhanced with changes to its formulation.

Applications of Silicone Rubber

Silicone rubber benefits make it highly usable for different applications. The material has revolutionized the industry. Let’s discover applications of silicone rubber in key industries.

Industrial Applications

Silicone rubber is used in different components of industrial machinery. It is used to produce seals, joints, conveyor belts, etc. The material has vast industrial applications due to high temperatures, chemical resistance, and flexibility. It can function properly in demanding conditions, especially outdoor applications, without losing its key properties.

Medical Applications

Silicone rubber is biocompatible and chemically inert. It can easily be formed in different shapes due to its flexible structure. The material has extensive use in the medical industry. It is considered one of the safest synthetic materials by regulatory bodies like the FDA. Silicone rubber is used in medical devices, including implants, surgical instruments, and medical tubing.

Consumer Applications

Silicone rubber benefits are not limited to industrial or medical applications; it’s also used in consumer goods. The material is non-toxic, hypoallergenic, and food-safe which allows application in products like kitchen utensils, housewares, and baby products. Most of the footwear soles are also made from silicone rubber due to its excellent flexibility.

Advantages of Silicone Elastomers Over Other Materials

Silicone elastomers outshine other materials in terms of properties and applicability. Let’s discover the advantages of silicone elastomers:

Durability

Silicone rubber is a highly durable material with exceptional longevity. The material is resistant to harsh chemicals and weathering. It is also heat resistant and can withstand -100 to 300°C temperatures without losing its properties. You can use silicone rubber in extreme conditions.

Versatility

Silicone rubber has unique properties that make it a versatile material for a variety of applications. It’s almost everywhere; from the car you drive to space, shuttles have various silicone rubber components.

Safety

Silicone rubber is chemically and biologically non-reactive material. It is graded safe for use in the food and medical industry by various regulatory authorities. The material is non-toxic, hypoallergenic, and inert.

Cost-Effectiveness

Silicone rubber is presumed expensive, but the material’s durability and longevity cover its costs. When compared to similar materials, silicone rubber performs better in rough conditions and lasts longer.

Specialty Silicone Materials

Silicone is chemically modified with the addition of crosslinking compounds and fillers to enhance its properties for specific applications. The modification can improve both chemical and mechanical properties. Let’s discover one of the prominent specialty silicone materials:

Cellular Silicone Materials

Cellular silicone material is used in the manufacturing of specialized foam for mattresses. The curing process is modified to produce silicone foam and sponge. The liquid silicone is expanded in a vacuum mold by entrapping air during the curing process. Chemical foaming is also employed to produce cellular silicone by mixing blowing agents with liquid silicone.

Testing and Certification

Silicone is tested to determine its suitability for different applications. Esteemed bodies like the American Society for Testing Materials (ASTM) have standardized tests to check the chemical and mechanical properties of silicone. You can take the service of a registered testing lab and obtain certification to use silicone for your specific application.

Material Testing

Common material tests of silicone include ASTM D412 (Tensile Properties), ASTM D2240 (Durometer Hardness), ASTM D2240 (Durometer Hardness), ASTM D471 (Resistance to Liquids), etc. All these tests are conducted to check the mechanical and chemical properties of silicone.

After conducting these tests, the material is rated safe for use in different applications. For instance, if the material passes the ASTM C920 (Sealant and Adhesion) test, it can be used for industrial and construction applications. Similarly, ASTM F2038 governs use for medical applications.

How to Choose Between Silicone and Other Elastomers

Let’s compare silicone rubber with other elastomers to evaluate their properties. You can select the right material for any intended application conveniently.

| Properties | Silicone | Nitrile Rubber | Natural Rubber |

|---|---|---|---|

| Temperature Resistance | High-temperature resistance within the range of -60°C to 250°C and flame retardant | Heat resistant and can withstand -40°C to 120°C | Low-temperature resistance within the range of 40°C to 80°C |

| Chemical Exposure | Highly resistant to harsh chemicals and solvents like petroleum and other chemicals | Sufficient resistance to various chemicals but reactive to acids and bases | Low chemical resistance and easily soluble in harsh chemicals and oils |

| Environmental Resistance | Excellent resistance to UV, ozone, and weathering | Can’t withstand rough weather conditions and develop cracks over time | Unable to offer resistance against UV rays, ozone, and weathering |

| Flexibility and Durability | Highly flexible and durable material | Good flexibility but not very durable in low-temperature conditions | Excellent flexibility and tensile strength but suitable for specific applications |

Frequently Asked Questions (FAQs)

Q.Is silicone better than other elastomers?

Silicone outshines all other elastomers in terms of durability and longevity. However, the suitability varies with the application; you can compare different materials to decide which is better.

Q.What industries benefit the most from LSR materials?

The liquid silicone rubber benefits allow its application in healthcare, automotive, and consumer goods industries. The liquid silicone rubber properties make it a beneficial material.

Q.Are silicone elastomers eco-friendly?

Silicone elastomers are recyclable and reused in the manufacturing process to produce usable products. These elastomers can be melted in an incinerator or re-extruded.

Conclusion

Do you want to make the best use of silicone elastomers? Evaluate different properties of silicone elastomers and compare their performance. Don’t forget to review our checklist to choose the best silicone elastomer. If you know the intended application, selecting the right elastomer is easy peasy.

Where to find the top-quality elastomeric material? Hongju is offering the best quality silicone custom-built for different applications. Explore more to find the perfect match!

Hongju Silicone: Top Manufacturer of Silicone Elastomers

Looking for a reputable manufacturer of elastomers? Hongju has been catering to the silicone needs of diverse industries for the last two decades. It employs advanced technology to manufacture top-quality silicone products. Get in touch with one of our representatives to explore material options and get the desired silicone product ready!