When we compare the two, Viton is more temperature resistant but lacks the chemical resistance of Teflon (PTFE). On the other hand, Teflon is better in terms of non-adhesive properties but is less thermal resistant. In addition, Viton has better sealing capability than Teflon due to the rigidity of the plastic on Teflon.

There are several other differences between Viton & Teflon (PTFE) O-rings. In this article, we will discuss the characteristics of both Viton & Teflon (PTFE) O-rings. After exploring these options, you’ll be empowered to make a confident choice between the two.

What are O-rings?

O-rings are round. These are mechanical seals available on the market to help seal different passages. These rings help protect from leakage. You might have seen it numerous times in daily life but might have been unable to identify it.

O-rings are made of different materials and come in different sizes. Some of their properties are similar, while some differ. O-rings are usually temperature, chemical, and electricity-resistant. The caliber of their excellent resistance depends on the material used for O-ring manufacture and silicone O-rings.

Here, we have compared two of the most widely available O-ring materials, Viton and Teflon (PTFE). Knowing the differences and their properties will help you make an informed decision.

Characteristics of Viton O-rings

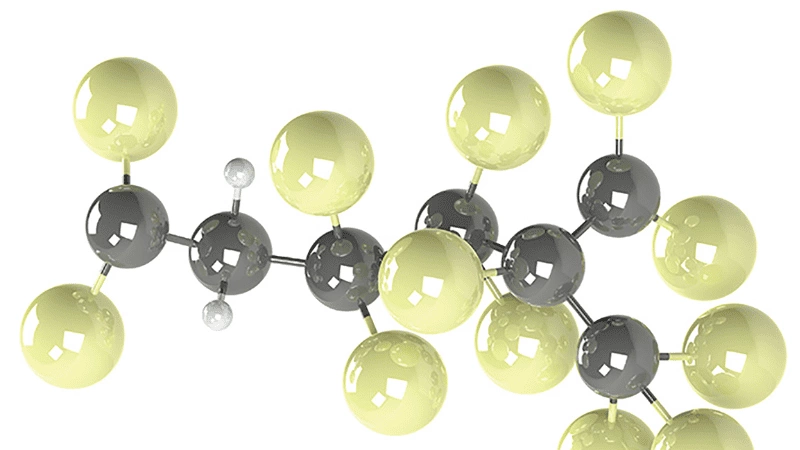

Viton O-rings are made up of synthetic rubber and fluoropolymer elastomer. Due to their durability, Viton O-rings are the top choice of many people worldwide. These O-rings can easily survive challenging conditions. Due to its numerous features, it is widely used as a sealing material for moving objects.

Different grades of Viton O-rings are available on the market depending on the type of usage. Viton has good mechanical properties and is known for its durability, flexibility, and resistance to tearing. Due to its brilliant composition, it is used in many applications. Using these rings as seals reduces maintenance, as there is minor wear and tear due to their durability.

Viton O-rings are more expensive than other nitrile o rings. Using Viton seals will generally result in less downtime for the appliances than other materials. Viton O-rings are resistant to fuels, oils, and many other chemicals.

The Viton seals exert less pressure on the stem than their Teflon counterparts while still providing a good seal. Both require the top of the guide to be machined so that the seal is secured to the guide and doesn’t move up and down with the valve stem.

This is the “positive” sealing nature of this particular type of seal. With the Viton seal exerting less pressure on the stem, the tendency for the seal to come loose from the guide and act like an umbrella seal is much less than the Teflon style.

These rings are available in several different grades depending upon the nature of use. Viton A grade is the most widely used as its fluorine content is 66%. Some other commonly used qualities include grades B and F.

Many other grades are available on the market. You can choose the one that best fits your needs by discussing it with a Viton O-rings professional. Some of the characteristics of Viton O-rings are mentioned below. Let’s discover together!

Inquire About Our Silicone and Plastic Products!

Chemical Resistance

Viton O-rings are highly resistant to chemicals. They are compatible with and work with so many chemicals that it is easier to list those they are not compatible with. Petrochemicals, biodiesel, oils, oxygen-plasma, high-vacuum, and silicon greases and oils are just a few of the chemicals they are resistant to.

Due to their vast resistance, they are widely used and one of the most versatile O-rings. Viton O-rings are not compatible with ketones. They are crude with some chemicals, so it is best that you check beforehand to save yourself and others from any mishap.

They can also withstand harsh weather conditions, mold, ozone, and fungus. These resistance properties make it easier to maintain them.

Temperature Range

Viton offers greater temperature resistance but falls short of Teflon’s (PTFE) chemical resistance. As mentioned earlier, there are different grades of Viton O-rings. The temperature limit range that all the stages of Viton O-rings can survive is from -26°C to +205°/230°C Celsius.

In Fahrenheit, the content is from -15°F to +400°/440°F. It can work reasonably quickly in high-temperature conditions. Moreover, unlike extremely high-temperature resistance, they are not flexible enough to sustain low temperatures.

Hence, Viton O-rings are durable and compatible with high-temperature applications and should be avoided in the lower temperature range. If the temperature content increases from the upper limit, the ring starts to melt. Conversely, if used in low-temperature performance, the O-rings do not function properly and become inflexible and stiff.

Size of Viton O-rings

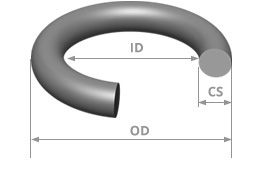

Viton O-rings come in various sizes. The three points from which to measure O-rings are inner diameter (ID), outer diameter (OD), and cross-section (CS). Each ring has a different ID, OD, and CS. Knowing where to use the O-ring beforehand helps you better understand which size to choose.

Limitations of Viton O-rings

Viton seals are not compatible with certain chemicals. Moreover, unlike extremely high-temperature resistance, they are not flexible enough to sustain low temperatures. The substances that Viton seals are not compatible with are:

- Ketones

- Amines

- Skydrol fluids

- low gas permeability

- Nitro hydrocarbons

- Hot chlorinated hydrocarbons and mineral acids

Applications of Viton O-rings

It is easily used for applications that require a low compression set and extremely high temperatures. It is compatible with aircraft, mechanical devices, automobiles, fuel-transporting cars, different values, pumps, and the chemical industry. It is also used in industries where petroleum is refined.

Because they can sustain high temperatures, Viton O-rings are also used in explosive environments.

Inquire About Our Silicone and Plastic Products!

Characteristics of Teflon (PTFE)

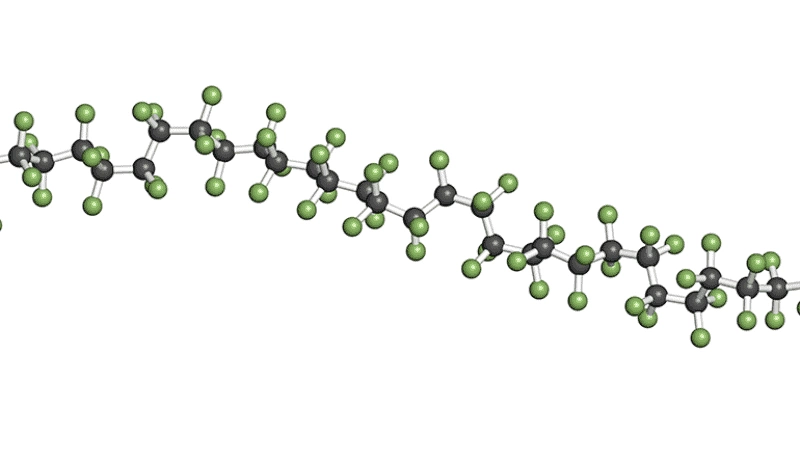

Teflon (PTFE) O-rings are made up of Polytetrafluoroethylene material. PTFE is white and is a famous and widely used material for O-rings. In some scenarios, Teflon (PTFE) O-rings are preferred over regular elastic O-rings.

Teflon seals have several advantages over elastomers. Some of them are corrosion resistance, electrical properties, a more comprehensive range of temperatures, heat resistance, oil resistance, and longer shelf life.

These rings are soft and elastic, have low friction, work well in low—and medium-pressure applications, and are ideal for many appliances. Moreover, they do not change size when moisture is absorbed.

Apart from all these features, PTFE O-rings have certain drawbacks, too. The characteristics of this ring material are discussed below so you can understand them.

Chemical Resistance

Teflon (PTFE) O-rings are one of the most corrosion-resistant materials on the market. The PTFE seal’s resistance makes the rings last longer and sustains their chemical compatibility.

It is compatible with almost all the chemicals used in industrial applications. Where all rubber compounds fail, you can utilize PTFE material efficiently. It is compatible with different materials, including oils, acids, bases, and other chemicals.

Furthermore, Teflon (PTFE) O-rings are more resistant and durable, which results in longer shelf life. In the long run, most of the O-rings wear and tear up. Teflon seals’s resistance makes it easier for the rings to last longer and sustains their chemical compatibility. It also provides abrasion resistance.

Temperature Range

Teflon (PTFE) O-rings are highly resistant to high and low temperatures. In high temperatures, where all other materials fail, Teflon seals work the best. Higher temperatures can result in rubber O-rings melting or losing their resistance, while in lower temperature ranges, rubber O-rings become hard and lose their elasticity.

Teflon (PTFE) O-rings work best in these scenarios because of the polytetrafluoroethylene material. Due to its actual temperature range, you can use it in extreme temperatures. Teflon (PTFE) O-rings are used in combustion processes and appliances and processes in colder environments.

Several gasket manufacturers now offer a material made of PTFE and fine stainless steel particles. The gasket is inflexible, but has the same temperature resistance as PTFE and resists cold flow.

The temperature range for Teflon seal material in Celsius is from -200°C to 250°C, whereas in Fahrenheit, it is from -328°F to 482°F.

Inquire About Our Silicone and Plastic Products!

Size of Teflon (PTFE) O-ring

Like Viton O-rings, Teflon (PTFE) O-rings come in various sizes. You can determine the size of an O-ring by measuring its inner diameter (ID), outer diameter (OD), and cross-section (CS). If all available sizes are unsuitable for your application, custom O-rings can also be made per your measurements and specifications.

Limitations of Teflon (PTFE) O-ring

With all the advantages of Teflon (PTFE) O-rings, there are several limitations too. Teflon seals are complex as compared to nitrile O-rings. Moreover, the leakage rate is also higher in these. Teflon seals require special finishing after installation to control and lower the leakage rate.

These seals cannot be installed multiple times or reused. It becomes dispensable after a single use, unlike rubber seals. Also, Teflon is slightly less thermally resistant but offers much more non-adhesive properties.

PTFE material is also a premium product. Again, a cheaper alternative might be preferable if your application involves anything less than the most extreme temperatures, pressures, and aggressive chemicals.

Due to all these factors, PTFE is only preferred in the extreme temperature range and when higher chemical resistance is required. Otherwise, rubber compound O-rings are usually preferred over Teflon seals.

Applications of Teflon (PTFE) O-ring

Teflon (PTFE) O-rings are used in several industries, including, but not limited to, the food and beverage industry, mechanical engineering, automotive, electronics and semiconductors, aerospace, and oil and gas.

Furthermore, PTFE seals are used in several pumps, transmissions, gearboxes, and rotary or screw-type air compressors. Due to their higher friction, temperature, and chemical resistance, they can easily be used in harsh environments where wear and tear is more likely.

These rings are also water resistant and do not lose their durability quickly. Due to their extended shelf life, appliances can run longer without getting serviced or changing their rings. This does not affect their flexibility or durability at all. Thanks to all the qualities of O-rings, it is the top choice where there is a chance that all rubber compounds will fail.

Inquire About Our Silicone and Plastic Products!

Conclusion

When selecting between Viton and PTFE for industrial applications, it often depends on the specific requirements of the application and the conditions to which the materials will be subjected. Knowing the environment where the O-rings will be used is essential.

Understanding the environment and circumstances where the O-ring will be used will help you decide which O-ring material is the best choice. What works best in one circumstance might not work in the other. Hence, it is best to know about Encapsulated O-rings and their usage conditions.

Are You Looking for the Perfect O-rings? Hongju Can Help You

Are you looking for high-quality O-rings? Hongju offers a range of options to meet your specific needs. We can provide the perfect solution if you require durability, chemical resistance, or specialized materials. Trust Hongju for reliable, industry-compliant O-rings!