Vibration affects everything from machine efficiency to product longevity, making effective damping a critical part of modern engineering.

Whether you’re designing industrial equipment or automotive parts, choosing the right vibration-damping material can dramatically improve performance and reliability.

This guide explores how vibration damping works, the best materials available, and how to select the ideal solution for your application.

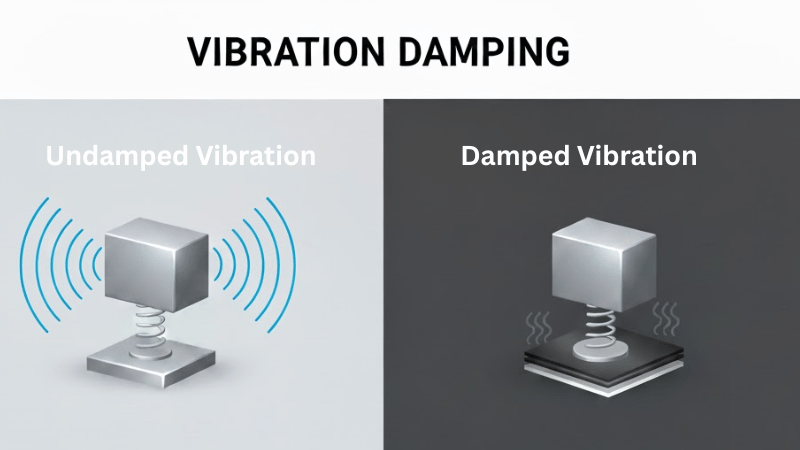

What Is Vibration Damping?

Vibration damping absorbs and dissipates vibratory energy as heat to reduce unwanted motion. It doesn’t stop vibration completely but manages it safely to improve performance, comfort, and component life.

The Main Motivation Behind Damping

Noise control, vibration isolation, and longevity of materials are the primary objectives of damping vibration equipment.

Machines or equipment with very intense vibration keep producing some irritating sounds and forces that later begin to wear out structural components. Damping materials break this cycle.

Real World Example

You may have encountered one of these vibration-dampening applications in real life, whether you noticed it or not:

- Car engine: The engine vibration is isolated from the chassis by rubber prototyping.

- Industrial machines: Anti-vibration pads prevent floors from being affected by rattles from machinery noise.

- Electronics: Silicone dampers cushion circuit boards against all the little microvibrations.

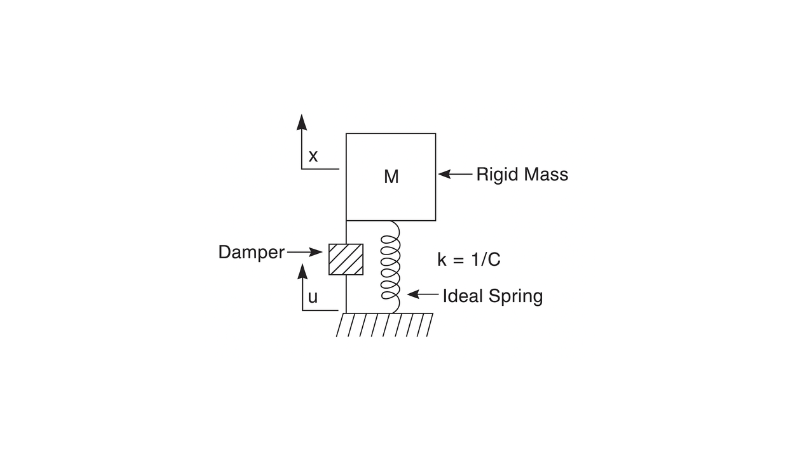

How Vibration Damping Works

It works by converting the vibrations into kinetic energy. Kinetic energy will be stored from every vibration.

That energy will also be turned into heat of lower energy through internal friction or resistance and, thus, will prevent the transmission or amplification of the vibrations.

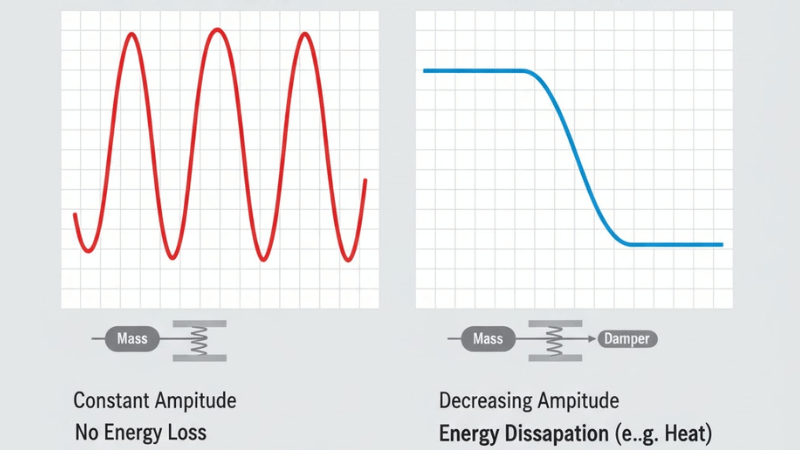

What is Dissipation Of Energy

The dissipation of energy indicates that every vibrating system in motion will find the opposition from the damping material to resist that motion easily.

That small fraction of internal friction from resistance is converted to form heat, which you probably won’t even feel, but enough to calm a good portion of vibrations.

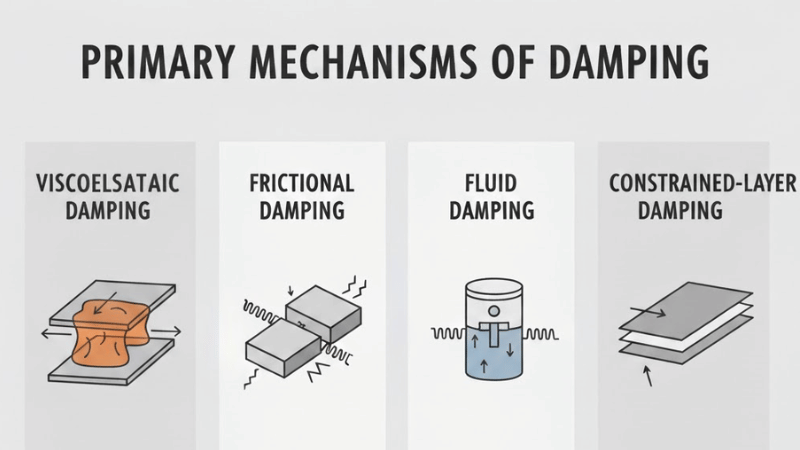

Primary Mechanisms of Damping

Different materials achieve that effect differently. These are the key ones:

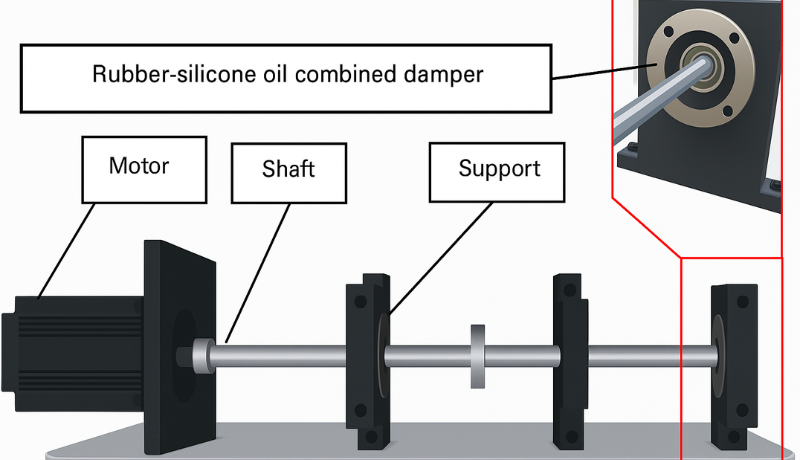

- Viscoelastic: Materials such as rubber or silicone rely on the intrinsic molecular friction of the material to absorb and dissipate the vibration energy.

- Friction: This occurs due to the relative motion between two solid surfaces without any external forces.

- Fluidic: Usually involves flows in hydraulic or viscous liquids that restrain movement through internal resistance, as in shock absorbers.

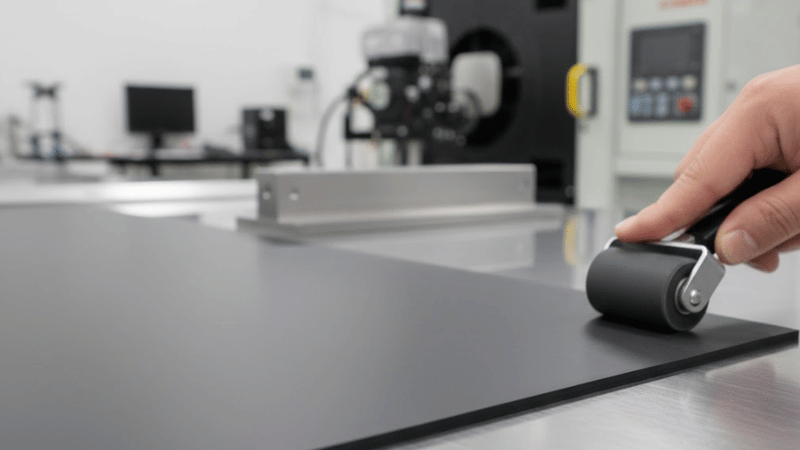

- Constraining layer damping: Combines multiple bonded layers that flex and absorb energy caused by vibrations at their interfaces.

Every mechanism targets specific vibration ranges and conditions, but they all work by turning the unwanted movement into harmless heat.

Ideal Characteristics of Vibration Damping Materials

Here are some ideal characteristics of vibration-damping materials:

1. Durometer (Hardness)

Durometer measures the hardness of materials. Softer (lower durometer) materials are more flexible and better at vibration absorption, especially at lower frequencies, while harder materials work on the high end but might transmit more vibration.

2. Mass and Elasticity

These contribute to a material’s base frequency or natural frequency as well as the damping rate. Denser and more elastic materials can hold energy fast and dissipate it without cracking or deforming.

3. Temperature and Chemical Resistance

Most applications in vibration damping are in tough environments; thus, high-temperature extremes, whether hot or cold, and motor oils, chemicals, and UV light resistance are key improvements in performance in accordance with these conditions.

4. Adhesion to Metal or Substrate

Good adhesion will always ensure that there is constant contact between the damping material and the surface it protects. Without it, energy transfer increases, and control over vibration diminishes.

5. Size and Weight

The larger or heavier system produces more vibration energy; hence, much more is required of the internal damping capacity and structural integrity of those materials.

Summary Table Of Key-Characters

| Characteristic | Why It Matters | Typical Range |

| Durometer (Shore A) | Determines flexibility | 30–70A |

| Density | Influences energy absorption | 1.1–1.5 g/cm³ |

| Temperature Resistance | Maintains damping performance | -40°C to 120°C |

| Adhesion to Substrate | Ensures stability and longevity | High bonding strength |

| Size and Weight | Affects energy capacity and damping rate | Application dependent |

Best Vibration Damping Materials

Let’s move on to some types that are commonly known for their use and best application.

1. EPDM Rubber

EPDM (ethylene propylene diene monomer) is one of the best materials for vibration damping in every respect, especially outdoors or wherever temperatures change.

It withstands environmental conditions and exposure and will not degrade upon ozone and UV light exposure. Thus, automotive and HVAC systems applications are considered.

2. Natural Rubber

If we compare EPDM with Natural rubber, it has the best elasticity and shock-absorbing characteristics to eliminate mechanical vibrations. Its main application is in low heat and dry conditions.

General applications are engine mounts or shock pads where flexibility and rebound are most essential.

3. Neoprene Rubber

Neoprene balances flexibility against chemical resistance, as it withstands contact with lubricants, coolant fluids, and moderate heat.

Thus, it is popular in industrial machinery and electronic enclosures. It also shows resistance to ozone and aging, giving it a longer service life.

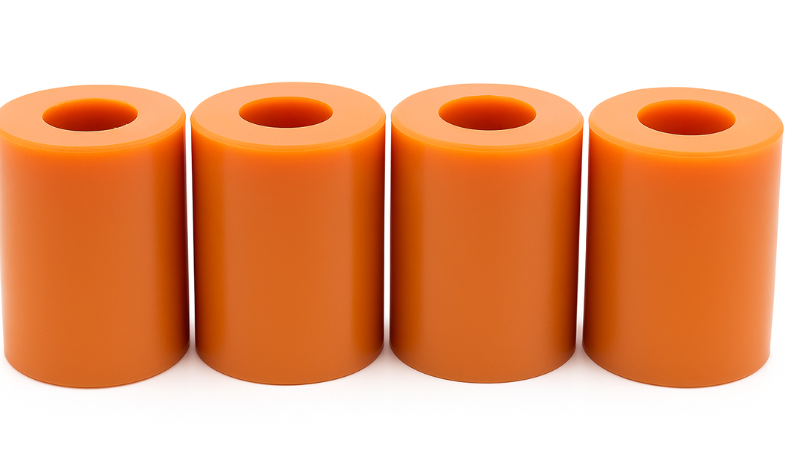

4. Polyurethane

Polyurethanes are noted for their strength, resistance to wear, and capacity to bear heavy loads. These are typically utilized in applications characterized by high-pressure stress, such as heavy machinery and vehicle suspensions.

Despite being extremely tough, it still provides a good deal of vibration absorption.

5. Silicone

Silicone has a greater application at the industrial level. Among the most temperature-stable materials, silicone retains its excellent damping characteristics in freezing and extreme heat.

Therefore is ideally suited for use in electronics, aerospace, and precision instruments.

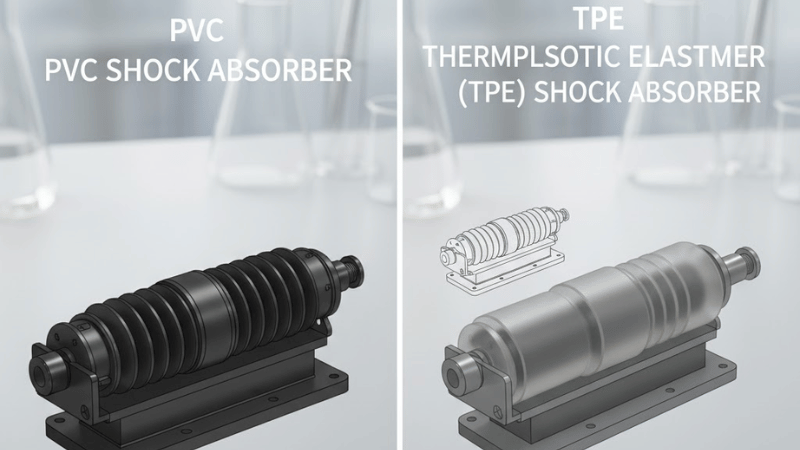

6. PVC and Thermoplastic Elastomers (TPEs)

PVC and TPEs are low-cost materials for general-purpose damping. There are so many types of plastic that can be used as dampers. They can hold their own against light intensity in instances where durability is not especially necessary.

Think of them as the inexpensive, entry-level choice for casual vibration control.

How to Choose the Right Damping Material?

In choosing a damping material, application is the factor that determines suitability.

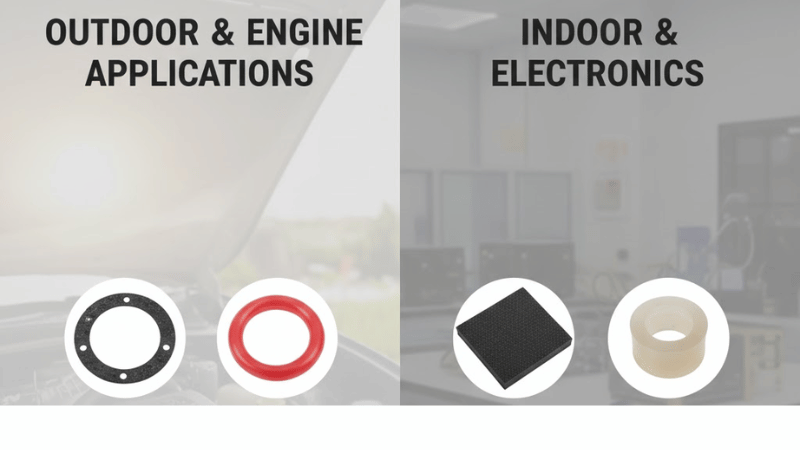

1. Consideration of the Environment

The installation, for example, is subjected to heat, moisture, oil, or UV light. In that case, EPDM or silicone would be the materials of choice for outdoor or engine applications.

But neoprene or polyurethane would be more suited for indoor use in electronics.

2. Determine the Vibration Frequency Range

Soft materials that accept large motions are best for low-frequency vibrations (engine movements), whereas dense, stiff materials are better for high-frequency vibrations (small motors or fans).

3. Durometer and Resilience Should Coordinate

The durometer should be in coherence with the weight and oscillation rates of the system; medium hardness will suit heavy equipment, while soft silicone rubbers will be apt for lightweight systems.

4. Consistent Performance Across All Temperatures

Observe for consistent behavior across ranges. Silicone and high-grade polyurethane are temperature-stable to keep the performance from drifting downwards at extremes.

Common Industrial Applications

Everywhere in modern engineering, from cars to computers, vibration damping is really rampant. Some industries exemplified are:

- Cars: For absorbing motion and reducing road noise, rubber and polyurethane are extensively relied on for engine mounts, suspension bushings, and cabin noise control systems.

- Electronics: Silicone or neoprene mounts protect delicate components such as hard disks and speakers from microvibrations, which might potentially lead to errors or damage.

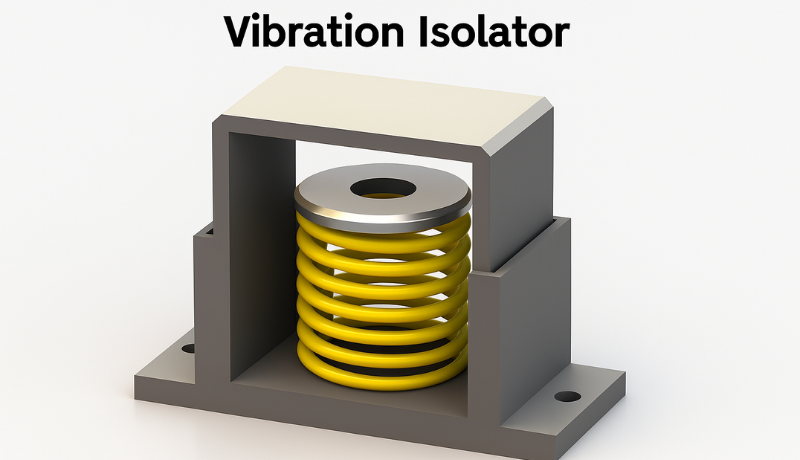

- Machinery: Vibration isolators protect compressors, pumps, and generators from deleterious wear and tear, reduce operational noise, and prolong their life.

- Construction: Dampening pads are installed in HVAC systems and structural supports of buildings to prevent vibrations from travelling through walls and floors, ultimately providing a quieter and more stable working environment.

Conclusion

Vibration damping is the silent hero behind smoothly running and long-lasting equipment. These damping materials transform unwanted motions into harmless heat energy, thus saving equipment from wear and noise.

So, if you are into construction or in the running of any type of system that screams, hums, or shakes, paying some attention here would go a long way.

Bring Your Vibration-Damping Ideas to Life with HongjuSilicone

From first concept to CNC-machined prototype in just 3–5 business days, Hongju Silicone gives you the speed and flexibility you need for low-volume, custom orders.

Backed by 20+ years of silicone design and production experience, every part is engineered for reliable vibration and noise damping in your application.

Contact Hongju Silicone today and get an instant quote on your custom vibration-damping solution.

FAQs

Q1: What’s the best material for vibration damping?

That depends on your application, but EPDM, polyurethane, and silicone would be your best bets for most industrial and automotive applications.

Q2: Is vibration damping and isolation the same?

Damping removes energy from vibrating systems in the form of heat, whereas isolation inhibits the transfer of vibrations from one structure to another.

Q3: Does silicone rubber work in reducing vibration and noise?

Yes, silicone rubbers are great for damping vibration and noise here, especially across a broad temperature range.

Q4: How long does a vibration damper last?

A vibration damper typically lasts anywhere from 5 to 10 years, depending on the material quality, operating conditions, and frequency of use.