What is TPE Rubber?

TPE stands for thermoplastic elastomer material. The industry also refers to it as thermoplastic rubber. It has several similar characteristics to thermoplastics. Hence, it is widely used for a variety of applications.

Moreover, TPE becomes free-flowing when heated. Contrarily, the material regains its original shape upon cooling down.

Additionally, TPE is easily recyclable and reusable. Hence, production waste never really goes to waste. Additionally, TPE makes extruding and injection molding relatively easy, thanks to its soft nature.

Also, TPE has some pretty typical applications around our everyday use of appliances. These include automotive components, home appliances, wires, cables, etc.

Emerging TPE Applications in 2025

- Electric Vehicles (EVs): Used in sealing systems, soft-touch interiors, and lightweight wire coatings to enhance efficiency and reduce vehicle weight.

- Medical Devices: Demand for phthalate-free TPEs is increasing for tubing, masks, and flexible components that meet FDA and ISO 10993 standards.

- 3D Printing: TPE filaments now allow for flexible prototyping and small-batch production of grips, gaskets, and wearables.

- Smart Wearables: Used in straps and flexible housings for smartwatches due to its elasticity and skin-safe formulation.

What are the Different Types of TPE?

Yes, thermoplastic elastomer material products have several different types of TPE compounds.

Have you ever come across terms such as TPUs or TPV? Both stand for (Thermoplastic PolyUrethane) and (Thermo-Plastic Vulcanizates). People often confuse both these terms with TPE.

They both sound pretty similar to thermoplastic elastomers for a reason. In reality, both TPU and TPV are TPE compounds. These are the two most commonly used TPEs globally.

Moreover, there are also bio-based thermoplastic elastomers and thermoplastic rubber.

But how do we get these different types of TPE? Well, it often happens that customers want different properties of thermoplastic elastomers. When that happens, the best way to achieve this involves blending TPE with other materials.

The result leads to the conversion of raw thermoplastic elastomer into TPVs or TPUs. Sometimes, manufacturers go out of their way to produce a specific recipe that has never been produced before.

All of this allows us to attain properties suitable for client needs.

Send Your Inquiry Now!

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

TPE Rubber Properties

The thermoplastic elastomer has fundamental thermoplastic and elastomeric properties. These essential properties allow you to differentiate between TPE and regular rubber products.

For instance, the shore scale for TPE comes at 20 Shore OO to 90 Shore A. This is relatively softer than many other materials, such as silicone rubber.

Thermoplastic elastomers (TPE) are cost-effective to produce, largely due to their efficient and straightforward manufacturing process.

This significant production advantage makes TPE a preferred material for manufacturers seeking to balance quality with economy.

Another great thing about thermoplastic elastomer is the time it takes to produce. To understand this, let’s first understand how conventional rubber is molded.

All thermoset rubbers have to go through a chemical cross-linking reaction. The process is vital for molding, and the most common technique used today is vulcanization.

However, the vulcanization process can take several minutes to a few hours to complete. This depends on various factors, including the material leading to vulcanized rubber.

Nevertheless, in the case of TPE, it only takes as long as 30 seconds for the cross-linking process to complete. Hence, manufacturers find it convenient to produce the product.

TPE: Prominent Elastomeric Properties

Recyclability and Eco-Friendliness

Thermoplastic elastomers can be reprocessed and recycled, minimizing waste and scrap. Even unused TPEs often end up in landfills without environmental harm, making them eco-friendly.

Good Colorability

TPE material has excellent colorability, allowing manufacturers to easily process it and achieve any color required by customers.

Wear and Tear Resistance

TPEs perform exceptionally well against wear and tear, making them suitable for multiple industrial applications.

Pressure Resistance and Shape Recovery

Thermoplastic elastomers can withstand high pressure and flex without damage. Once the pressure is released, they quickly return to their original shape.

Chemical and Weather Resistance

TPEs resist various chemicals, including alcohols, dilute alkalis, oils, greases, and hydrocarbons. They also perform well under harsh weather conditions.

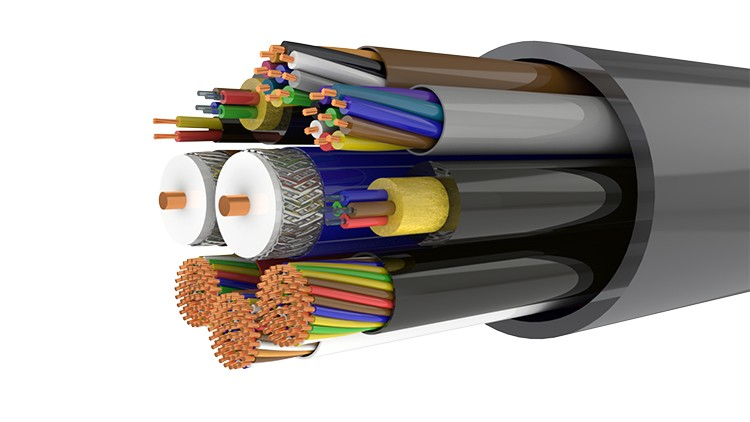

Electrical Insulation

TPEs have average electrical properties, meaning they do not conduct electricity effectively, providing natural insulation.

Low Specific Gravity

With low specific gravity, TPE allows more material coverage per pound, enabling manufacturers to produce more using less raw material.

What is TPE Rubber Used for?

Now, coming to the applications of Thermoplastic elastomers rubber. We have compiled a comprehensive table for you to go through:

| Industry | Applications | Feature |

| Electronics | Wires, cables, condenser sheaths, components for mobile phones, sockets & plugs, etc. | Excellent moldability and electrical properties |

| Industrial | Drums, shock absorbers, mounts for anti-vibration, roof membranes, suspension bushes, seals, inlet pipes, etc. | Excellent chemical resistance and high flexibility |

| Footwear | Masks, ski boots, soles for shoes, flippers, snorkels, handles for ski poles, etc. | Reasonable wear and tear resistance |

| Consumer Goods | Appliance magnetic seals, protection covers for electronics, push button panels, covers for mobile phones, remote control covers, etc. | Good moldability and flexibility |

| Health Care and Medical | Breathing tubes, valves, seals, bags, ventilation masks, syringe seals, etc. | Lightweight, chemical resistance, and flexibility |

| Automotive | Weather seals, bumpers, pressure pipes, drive belts, grommets for pipes, trims (exterior and interior), dust boots for shocks, air ducts, mats, instrument panels, glass encapsulation, etc. | Abrasion resistance and flexibility |

Send Your Inquiry Now!

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

TPE Rubber Benefits and Advantages

Thermoplastic elastomer comes with a variety of benefits and advantages. Let’s take a look at the list below:

Plastic-like Processability with Rubber-like Flexibility

TPE combines the easy processability of plastics with the flexibility and look of rubber, making it ideal for diverse applications across multiple industries.

High Consistency

TPE offers outstanding consistency, requiring little to no compounding or curing agents while maintaining uniform quality across all batches.

Excellent Colorability

TPE materials are highly colorable, allowing easy customization in various shades and finishes to meet specific design needs.

High Elasticity

With excellent elasticity, TPE provides superior elongation and a wide range of compression sets and durometers for versatile applications.

Ideal for Mass Production

TPE supports efficient manufacturing, easily processed through extrusion and injection molding with minimal waste thanks to its recyclability.

Environmentally Friendly

Due to its recyclability, TPE promotes sustainability and consumes less energy during production, reducing its environmental impact.

Cost-Effective Material

This material is known for its affordability, offering a budget-friendly alternative to latex, PVC, and silicone without compromising performance.

Excellent Thermal Stability

TPE demonstrates strong heat resistance, performing reliably under high temperatures and changing environmental conditions.

TPE Rubber Drawbacks and Disadvantages

TPE is undoubtedly one of the best rubber materials out there. However, all rubber materials, including TPE, have one or some drawbacks. For TPE, these include:

- TPE might require you to dry the raw material before the whole process occurs.

- TPE has a soft nature. However, this soft elastomer is further enhanced under higher temperature conditions.

- TPE does not provide the suitable characteristics to produce low-hardness products.

FAQs

Is TPE a safe material?

Yes, TPE is a safe material. TPE is also categorized as a safe material for kids. Thus, you have nothing to worry about, even if your kids get their hands on any TPE products.

Is TPE better than Latex?

The answer to this depends on the application in question. If the application requires more plastic-like properties, then TPE is the better option.

However, Latex will perform better in applications where its properties are required. As a result, it all comes down to the requirements. However, typically, TPE has more applications than latex.

TPE vs. PVC, which is better?

Both PVC and TPE have very similar properties. For instance, they both have high strength and great flexibility. Hence, you can use them for a variety of applications.

However, one area where TPR exceeds PVC is oil resistance and grease resistance. This also extends to diluted alkalis and acids.

Is TPE FDA-compliant?

TPE can be used for FDA applications. However, you would have to request the manufacturer for the specific type of TPE that the FDA approves.

It’s not an issue if the manufacturer knows what they are doing. FDA has approved specific grades of TPE, which you can also look for online.

Send Your Inquiry Now!

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

Conclusion

To conclude, TPE is a highly diverse material with many applications. On top of that, the flexibility and chemical resistance make it a popular material in a wide range of industries.

Hence, manufacturers find it a pleasure to produce this product because of the easy process and the minimum amount of time required.

Hongju: Your Reliable Silicone Manufacturing Partner!

Hongju is at your service with the best-in-class rubber products. Hongju Silicone turns your designs into reality within days. With flexible order quantities and two decades of production experience, we help global brands innovate efficiently.

Contact us today for a custom quote!