The need to protect the environment is becoming prevalent for businesses and consumers. Therefore, a product must be eco-friendly with sustainable manufacturing processes. Sustainable manufacturing focuses on the eco-friendliness of a production process while optimizing costs and increasing efficiency.

Although there are several materials for making finishes and protective coatings, silicone rubber stands out. Compared to other materials, silicone rubber has a low carbon footprint, and its durability ensures minimal waste accumulation.

This article explores the differences between silicone rubber and other rubber materials. We also discuss the sustainability benefits of the material and how silicone rubber finishes are applicable across several industries.

What Is Silicone Rubber?

Silicone rubber is a synthetic elastomer with silicon, carbon, hydrogen, and oxygen base elements. The elastomer is a versatile material with excellent properties, including heat, chemical, and UV resistance, making it suitable for manufacturing.

Silicone rubber is used across several industries due to its versatility. The material can withstand extreme application conditions and easily be molded into different shapes and sizes.

Another reason why silicone rubber is suited to several industrial applications is its durability and inertness. The elastomer is durable and is not easily damaged despite undergoing deformation.

In addition, silicone rubber is inert and non-reactive and, therefore, suitable for medical and food applications. Other industries that use silicone rubber include electronics, aerospace, consumer products, and automotive.

What Are the Differences between Silicone Rubber and Other Rubber Materials?

Silicone rubber is not the only material for manufacturing finishes. However, silicone rubber stands out due to its excellent properties, including UV resistance, biocompatibility, thermal stability, and chemical resistance.

Other rubber materials for manufacturing finishes and protective coatings include ethylene propylene diene monomer (EPDM), neoprene, natural rubber, nitrile rubber, and butyl rubber.

The table below summarizes the differences between silicone rubber and other rubber materials.

| Property | Silicone rubber | Other Rubber Materials |

| Temperature resistance | Excellent high and low-temperature resistance | Limited temperature range |

| Chemical resistance | Better resistance to acids, bases, oils, and solvents | Limited chemical resistance. More susceptible to breakdown on prolonged exposure to chemicals |

| Electrical insulation | Excellent electrical insulation. Prevents electrical interference | Fair to good electrical insulation depending on rubber material |

| Durability | Excellent abrasion resistance and durability | Good to excellent abrasion resistance depending on rubber material and specific application |

| Biocompatibility | Biocompatible, non-reactive, and non-toxic | Low level of biocompatibility in other rubber materials, except for butyl rubber |

| Cost | Higher initial cost | Less expensive than silicone rubber |

Benefits of Silicone Rubber Finishes

Resistance to Extreme Temperatures

Silicone rubber finishes are resistant to extreme temperatures. This protective coating can withstand temperatures as low as -65 degrees and as high as 450 degrees Fahrenheit. Consequently, devices coated with silicone rubber finishes do not degrade or lose their properties when exposed to high temperatures.

Furthermore, this finish does not lose flexibility or become brittle in low temperatures. Therefore, it is suitable for use in cold environments.

Thermal Stability and Ability to Withstand Extreme Heat

Silicone rubber finishes are thermally stable. This protective coating withstands extreme temperatures and provides safety in high-heat applications. Silicone rubber finishes are often used in the aerospace, electronics, and automotive industry to ensure the safety and functionality of the components.

Environmental and Weather Resistance

Silicone rubber finishes can withstand harsh weather. As a result, devices coated with silicone rubber finish maintain their color and appearance even with prolonged exposure to sunlight or extreme conditions.

Consequently, because of its environmental and weather resistance, silicone rubber finishes are applicable in coating devices used for outdoor applications.

Chemical Resistance and Ability to Withstand Oils and Chemicals

Silicone rubber finishes are inert and hardly leach. They also resist chemicals, including acids, bases, and oils. Because of its chemical resistance, silicone rubber finishes are used in applications with prolonged chemical exposure. The finish does not lose its color, appearance, or properties when exposed to chemicals.

Medical-grade and Food-grade Materials

Because silicone rubber finishes are biocompatible and inert, they are used in food and medical-grade applications. Furthermore, because silicone rubber finishes can withstand high temperatures, the material can be used in medical applications and sterilized often without losing shape, color, or form.

In addition, silicone rubber finishes are odorless and tasteless. Therefore, they do not absorb the taste or odor of food. The material is also non-stick, making it easy to clean.

Unique Properties for Consumer Goods and Electronics

The unique properties of silicone rubber finish that makes it suitable for consumer goods and electronics include durability, shock absorption, insulation, and non-slip properties. Silicone rubber finishes are durable and last as long as possible, making them ideal for coating consumer goods and electronics.

In addition, the material has excellent shock absorption properties and provides electrical insulation for electronic devices. Also, because of its non-slip properties, silicone rubber finishes offer a secure and comfortable grip on consumer goods and electronics.

Sustainability Benefits of Silicone Rubber Finishes

Durability and Resistance to Wear and Tear

Silicone rubber finishes are sustainable and have a lower carbon footprint than other materials. In addition, because this finish is durable and resistant to wear and tear, there is a lower risk of damage. Therefore, silicone rubber finishes are more sustainable and eco-friendly without needing constant replacements.

Ability to Be Recycled and Reused

Silicone rubber finishes can be recycled and reused. Because of its durability and excellent properties, silicone rubber finishes can be reused to limit waste production. In addition, although expensive, silicone rubber finishes can be recycled into new products.

Reduction in Waste and Energy Consumption

Silicone rubber finishes are durable and do not need frequent maintenance or repair. Hence, there is a reduction in waste and energy consumption. The material is also reusable to reduce waste accumulation.

In addition, using silicone rubber finishes can improve the lifespan and efficiency of industrial components, reducing leaks and preventing energy losses.

Potential for Carbon Reduction in Manufacturing Processes

The manufacturing process for silicone rubber finishes is relatively more energy-efficient. Therefore, compared to other protective coatings, there is a potential for reducing carbon emissions.

Furthermore, because of the high-temperature stability of silicone rubber, the manufacturing process needs less energy-intensive techniques. Consequently, injection molding and compression molding are often used to manufacture silicone rubber finishes, reducing carbon footprint.

Silicone Rubber Finishes in Various Industries

Automotive Industry and Protective Coatings

Silicone rubber finishes are used as protective coatings in the automotive industry. The finish is applied to automotive components, protecting them from abrasion, corrosion, and damage. In addition, silicone rubber finishes are used for sealing solutions and to dampen vibration in automotive components.

The Medical Industry and Medical Grade Materials

The silicone rubber finish is used in the medical industry due to its chemical resistance and biocompatibility. The finishes are often used for medical devices and surgical equipment that come in contact with body tissue. These devices include catheters, prosthetics, and implants. The protective coating is also used for creating dental materials like denture liners.

Consumer Goods and Complex Parts

Silicone rubber is flexible and moldable into several shapes and sizes. Silicone rubber finishes can be molded regardless of the part’s complexity and the design’s intricacy. Silicone rubber finishes are used in the consumer goods industry to produce toys, sporting goods, and household appliances.

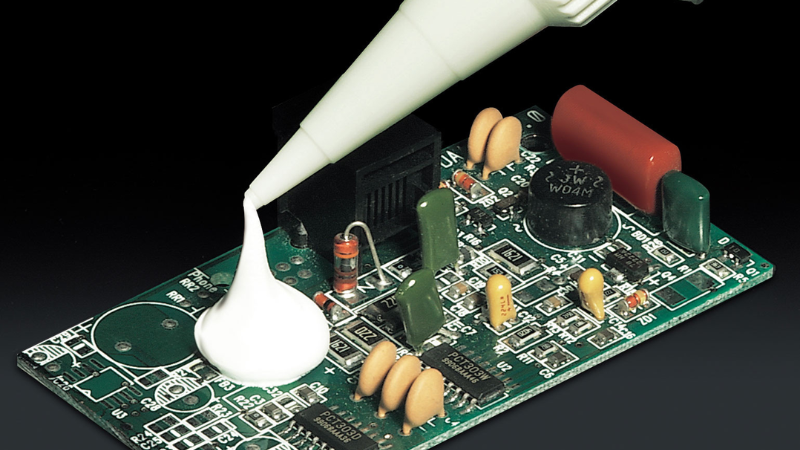

Electronics and Temperature Resistance

Silicone rubber finishes have excellent temperature resistance. As a result, the finish has several applications in the electronics industry, including protecting electronic components from damage and electrical interference.

Additionally, this finish is used for keypads and buttons for a better tactile response. The silicone rubber finish is also used as a protective cover for electronic devices, including smartphones and laptops.

Gaskets and Seals for Various Products

Gaskets and seals create a barrier between two surfaces to prevent leakages. This sealing solution is not limited to one industry. Gaskets and seals are used for various products across several industries, including automotive, medical, aerospace, and consumer goods. Additionally, silicone rubber finishes are used for gaskets and seals, improving their sealing abilities.

Conclusion

Although there are several rubber materials for manufacturing finishes, silicone rubber stands out. This elastomer is more sustainable and has excellent properties, making it a better choice than other rubber materials.

Silicone rubber finishes are biocompatible and have UV resistance, chemical resistance, and excellent thermal stability. Although the finish cost is relatively high, it is more cost-effective in the long run due to its durability. Furthermore, the material is applicable across several industries and is a more eco-friendly option.

Discover the Perfect Solution for Your Business with Hongju

Silicone rubber finishes are versatile and more sustainable. Hongju is a reputable silicone products manufacturer with over two decades of experience. You can work with the team to create the best formulations for your silicone rubber finishes. Because of our focus on sustainability, our team creates prototypes and ensures they meet your specifications before producing en masse.