Here, in this blog post, we will briefly explain what is butyl rubber, the chemistry behind it, its manufacturing, properties, applications, and its limitations. This is going to be an interesting read so without any delay let’s get started.

What is Butyl Rubber?

Butyl rubber is formed by mixing a small portion of isoprene with the copolymer of isobutylene. It is commonly known as “butyl rubber” or sometimes referred to as “butyle”.

This rubber is a broadly used substance in many industries because of its amazing weathering properties, which allow better air retention on different surfaces. That makes it essential for playground balls, inflated windows, door seals, and seamless waterproofing.

Additionally, because of its resistance to a range of chemicals, it has uses in industrial and chemical processing applications for gaskets and hoses. Also, products can last longer in challenging outside conditions because of their resistance to weathering.

Along with its primary uses, butyl rubber’s damping qualities make it appropriate for vibration-dampening parts like motor mounts and suspension bushings. Its sterility and similarity with a wide range of substances make it a treasured element for pharmaceutical packaging and vial stoppers usage.

Chemistry of Butyl Rubber

Butyl rubber is a type of rubber known for its excellently designed and seamless chemical structure. Overall, this rubber is created by carefully synchronizing the co-polymerization of two monomers:

- Isobutylene: A four-carbon unit with a double bond and two methyl groups (CH3). It is the common monomer for synthetic rubbers.

- Isoprene: A five-carbon molecule with a crucial double bond is the secondary component necessary for the vulcanization process. Moreover, this rubber only contains 2% isoprene, which guarantees adequate vulcanization while maintaining the rubber’s intended properties.

Butyl rubber’s low degree of unsaturation enables gas molecules to pass through the polymer, rendering it waterproofing properties. Efficient packing of the primary isobutylene units further inhibits gas diffusion, enhancing the material’s durability to weathering and chemical deterioration.

Therefore, the creative combination of monomers and their resulting polymer structure is the key to its success.

Take the First Step:

Requst for an Inquire

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

Manufacturing and Processing of Butyl Rubber

Manufacturing this distinctive rubber involves a careful and controlled process involving chemical reactions. The complete process consists of the following steps:

1. Preparation of the Building Material

The first step in the manufacturing of butyl is the preparation of the building material. The two elements mentioned above are the major ingredients of the polymer. These products are generally obtained from petroleum refining processes.

2. Cationic Copolymerization (The Cold Hold)

The 2nd step involves cationic copolymerization. The reaction occurs in a temperature-controlled environment with extreme temperatures dropping to around -100°C.

A specific catalyst, a Friedel-Crafts Lewis acid, plays a pivotal role in this step. It guides the precise arrangement of the monomers as they link together to form long polymer chains.

3. Separation and Purification

The third step is separating and purifying the substance, where the embryonic rubber separates from the solvent used in the reaction. This process includes various techniques like distillation or precipitation.

After that, it leaves a fine and suspended particle slurry. Hot water dissolves and removes any residual solvent and unreacted monomers. It ensures the purity of the product with compatible properties.

4. Halogenation

The 4th step is an adaptation, in which manufacturers can tailor the properties of rubber for various applications.

This tailoring includes reacting the purified rubber with elemental bromine or chlorine and adding the halogen atoms to the polymer structure step-by-step. It increases the durability of the rubber to the chemical and heat.

5. Final Transformation

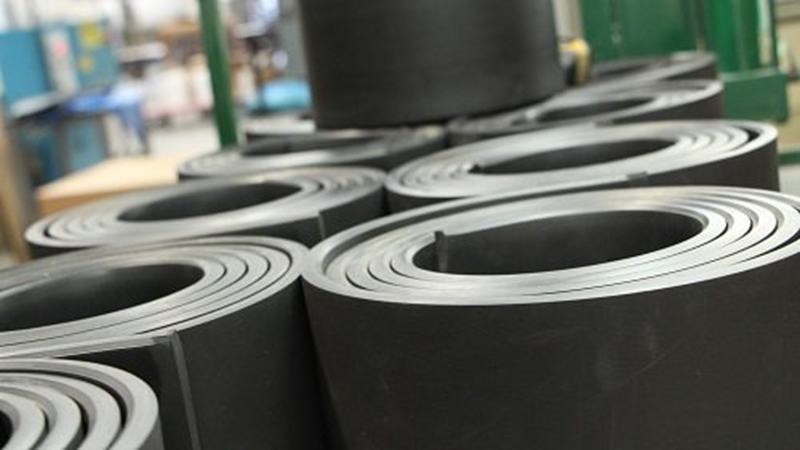

Finally, antioxidants are embodied into the mix, which shields later against degradation caused by environmental factors like heat, light, and ozone exposure. The rubber emerges in a form ready for further processing, such as sheets for gaskets, bales for tire inner liners, or crumb rubber for molded products.

6. Shipping and Fabrication

The processed rubber is then shipped to manufacturers securely to transform into various products, including waterproofing roofs, sealants, and vital components for countless industries. Compared to plastic material, its applications are vast for rubber roof surfaces and the construction industry.

Take the First Step:

Requst for an Inquire

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

Properties of Butyl Rubber

Butyl rubber finds applications across various fields of material science due to its remarkable weathering tendency and higher gas impermeability. In particular, it exhibits numerous beneficial aspects:

- Higher Flexibility: This excellent rubber has surprisingly high flexibility in addition to its gas retention capabilities. This attribute makes it a pivotal substance for hoses, gaskets, seals, and other products requiring specific applications.

- Ozone Resistance: Butyl holds a very good resistance to ozone. That is why it is a perfect choice for applications where ozone is a concern.

- Low Permeability Rate: This synthetic material is unique because of its lower moisture, gases, and air permeability. It makes the reliable choice for tire inner tubes, rubber roof coating, and other roofing applications requiring waterproofing properties.

- Lower Compression: Butyl rubber exhibits a low compression set. This property enhances its durability and longevity in various applications.

- Versatile Vulcanization: It offers broad versatility in vulcanization processes. So, it is adaptable for use in many chemical processes to create different compounds.

- High Tensile Strength: This synthetic rubber has great tensile strength, which also makes it a cost-effective material for various industrial projects. The best use case scenarios include durable sealing joints and sealants for various industries.

- Lower Modulus Elastomer: Butyl rubber also has the potential to regain its shape even when stretched over a long distance. This property shows its potential use for resilience and elasticity.

Applications of Butyl Rubber

There are numerous construction and automotive applications of butyl rubber, and it is widely suitable for use in different industries. Some of its key benefits and applications are listed below:

1. Industrial Usage

Butyl has various uses in the construction industry and industrial settings. It is one of the common materials used in the processing of various elements at the industrial level which commonly includes condenser packing, tank linings, and conveyor belts.

2. Medicinal Usage

Some unique features of butyl make it compatible with the formulation of artificial materials used in joint replacement. In addition, it is widely used to produce blood collection vessels and tubes.

3. Usage in Adhesives

Its excellent weather resistance makes it a valuable component in various adhesive formulations. It is a game changer for cement, flooring, roofing solutions, tapes, sealing, and valve cement.

4. Automotive Usage

The high damping and barrier features of this synthetic product make it ideal for use in the formulation of hoses, gaskets, etc. It is also a popular choice for sealants in the automotive industry. Its durable seal protects against cracks in automotive applications.

5. Tires Industry

Butyl rubber has an excellent air retention feature. This fetches its standout applications in tire manufacturing for different vehicles, including bicycles, cars, trucks, etc. It improves tire quality and increases longevity.

Take the First Step:

Requst for an Inquire

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

Limitations of Butyl Rubber

Butyl rubber possesses a few limitations that need consideration when you opt for it:

1. Poor Sheild against Fire

Although this synthetic rubber is of good use in various industries, its protection from fire is very poor. Its susceptibility to combustion makes it unsuitable for use in proximity to flammable environments and other surfaces.

2. Low Rebounding Rate

The rebounding rate of this synthetic material is notably low as compared to some other rubbers. So, it is not suitable for applications that call for a higher energy spring or bounce-back capabilities.

3. Limited Oil Tolerance

Butyl does not perform well in the presence of petroleum and oil-based products. Because these products could cause the rubber to lose its shape and, hence, make it ineffective for its intended purpose.

4. Poor Processing

The inherent tendency of this synthetic material to trap air during processing can lead to swelling or blistering. It poses challenges during the manufacturing process. So, it’s mostly avoided during many industrial applications because of these processing difficulties.

5. High Cost

While not exorbitantly priced, butyl rubber is relatively expensive. Additionally, its lower abrasion resistance necessitates frequent replacements, further contributing to its overall cost. Therefore, its high cost poses a significant concern, particularly when cost-effectiveness is paramount.

Take the First Step:

Requst for an Inquire

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

Conclusion

The remarkable gas impermeability of butyl rubber makes it perfect for versatile use. Its toughness increases the service life even when exposed to harsh outdoor situations, such as rubber roof application.

Its chemical resistance makes it appropriate for industrial gaskets and hoses and makes it a unique high-demand substance in the industrial sector.

However, butyl rubber has some limitations as well. Even with these drawbacks, butyl rubber is still a vital component in many different industries, but choosing the right material requires an awareness of these drawbacks.

So, this synthetic rubber is always the popular choice whenever you need a stretchable and weather-resistant material for your industry.

Connect with Hongju Silicone’s Experts for Insights on Butyl Rubber

Despite the versatility and excellent material composition of butyl rubber, you need to connect with expert rubber manufacturers to take maximum advantage of it. Take advantage of Hongju Silicone’s more than 20 years of product manufacturing experience.

Our experts help you choose the right butyl rubber for your application. Not sure yet? Contact us and find out how we can help your business.